Complete Parts Diagram for the 2000 Honda Foreman 450 ES

The intricate design of an all-terrain vehicle involves a multitude of essential elements that work harmoniously to ensure optimal performance and reliability. Understanding these components is crucial for enthusiasts and owners alike, as it allows for better maintenance and upgrades.

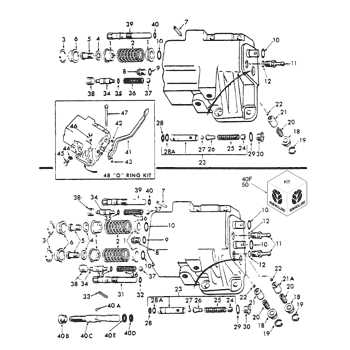

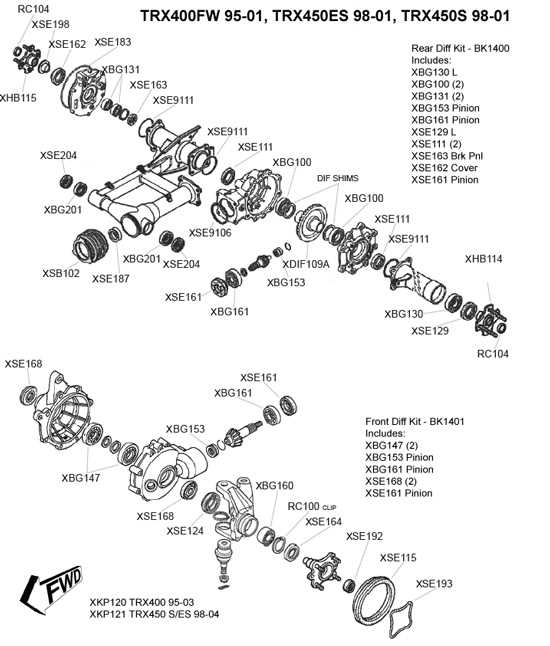

Detailed schematics serve as invaluable resources for anyone looking to repair or enhance their vehicle. They provide a visual guide that simplifies the identification and organization of each part, making the process less daunting.

By delving into these illustrations, one can uncover the ultimate insights into the mechanics of this iconic machine. From the engine to the suspension, every section contributes significantly to the overall functionality and durability.

Overview of Honda Foreman 450 ES

This section provides a comprehensive look at a popular all-terrain vehicle known for its durability and versatility. Designed for both work and recreation, it offers features that enhance performance across various terrains.

| Feature | Description |

|---|---|

| Engine | Powerful and efficient engine designed for reliability. |

| Transmission | Advanced system for smooth shifting and control. |

| Suspension | Robust suspension for improved handling and comfort. |

| Towing Capacity | Capable of handling substantial loads with ease. |

Its design incorporates various features that cater to the needs of outdoor enthusiasts and professionals alike, making it a preferred choice for many users.

Importance of Parts Diagrams

Understanding the components of machinery is essential for efficient maintenance and repair. Visual representations of these elements serve as invaluable tools, aiding users in identifying and locating specific items within complex systems. Such illustrations not only enhance clarity but also facilitate smoother disassembly and reassembly processes.

Enhanced Understanding

Detailed schematics provide a clear view of how different elements interact, enabling users to grasp the overall structure and function of the equipment. This knowledge is crucial for diagnosing issues accurately and ensuring that repairs are conducted effectively. With a visual guide, even those with limited experience can follow along and understand the intricacies of their machinery.

Streamlined Maintenance

Utilizing visual guides significantly simplifies the upkeep of equipment. When individuals can easily pinpoint the location of components, they can perform routine checks and replacements with confidence. Furthermore, having a reference can reduce the risk of errors during repairs, leading to longer-lasting performance and reliability. In essence, these visual aids are not just helpful; they are essential for maintaining the longevity of mechanical systems.

Key Components of the Foreman 450

This section highlights essential elements that contribute to the functionality and performance of the vehicle. Understanding these components is crucial for maintenance and upgrades, ensuring longevity and efficiency.

- Engine: The powerhouse that drives the machine, providing the necessary torque and horsepower.

- Transmission: Facilitates gear shifting, optimizing performance in various terrains.

- Suspension: Enhances ride quality by absorbing shocks and providing stability.

- Braking System: Ensures safety and control, crucial for navigating challenging landscapes.

- Wheels and Tires: Impact traction and handling, tailored for different surfaces.

- Electrical System: Powers lights, ignition, and other electronic components.

Each of these elements plays a vital role in the overall operation, allowing the vehicle to excel in various conditions.

Understanding Electrical System Layout

Grasping the configuration of an electrical network is crucial for effective maintenance and troubleshooting. A well-structured layout ensures that all components function harmoniously, contributing to the overall performance of the vehicle.

Key elements to consider include:

- Power distribution: Understanding how energy flows to different parts.

- Wiring connections: Identifying the routes and types of wires used.

- Component functions: Knowing the role of each element within the system.

By familiarizing oneself with these aspects, enthusiasts and technicians can delve deeper into diagnosing issues and implementing upgrades.

- Inspect wiring for wear or damage.

- Verify connections and terminals for corrosion.

- Utilize schematics for a comprehensive overview.

Ultimately, a solid understanding of the electrical framework enhances reliability and longevity of the machine.

Transmission Parts and Functionality

The transmission system plays a crucial role in transferring power from the engine to the wheels, enabling smooth and efficient movement. Understanding the components involved and their respective functions is essential for maintaining optimal performance.

Key Components

- Gears: These are vital for altering speed and torque, ensuring the vehicle can adapt to various terrains.

- Clutch: This mechanism allows for smooth engagement and disengagement of power, facilitating gear changes.

- Shift Linkage: This component connects the gear lever to the transmission, enabling the driver to select different gears.

- Torque Converter: This device multiplies engine torque, aiding in smoother acceleration.

Functionality Overview

Each element works in harmony to deliver reliable power distribution. The gears adjust the vehicle’s speed, while the clutch ensures seamless transitions. Proper maintenance of these components is vital for longevity and performance.

Suspension System Breakdown

The suspension system plays a crucial role in enhancing ride quality and stability. It absorbs shocks from uneven terrain, ensuring a smooth experience for the rider while maintaining control over the vehicle.

Components Overview

The primary elements of a suspension system include springs, shock absorbers, and linkages. Each component works in unison to provide the ultimate balance between comfort and performance.

Functionality and Maintenance

Regular inspection and maintenance of the suspension components are essential for optimal performance. Damaged or worn parts can lead to decreased handling and increased wear on other vehicle systems. Timely replacements can significantly enhance durability and safety.

Fuel System Component Overview

The fuel system plays a crucial role in delivering the necessary energy for efficient engine operation. Understanding its components is essential for maintenance and troubleshooting, ensuring optimal performance and longevity of the machine.

Key Components

- Fuel Tank: Stores the fuel and supplies it to the system.

- Fuel Pump: Moves fuel from the tank to the engine.

- Fuel Filter: Cleans the fuel by removing impurities before it enters the engine.

- Fuel Injectors: Atomize the fuel for proper combustion.

- Carburetor: Mixture of air and fuel for engine intake in carbureted systems.

Maintenance Tips

- Regularly check fuel levels to avoid running dry.

- Inspect and replace the fuel filter as needed.

- Ensure fuel lines are free from leaks and blockages.

- Clean or replace injectors for efficient fuel delivery.

Brake Assembly and Maintenance Tips

The braking system is crucial for safety and performance, making regular upkeep essential. Understanding its components and functions can enhance longevity and efficiency. This section explores key maintenance strategies to ensure optimal operation.

Regular Inspection

Proper Cleaning

Keeping the braking components clean is vital. Dirt and debris can hinder performance, so use appropriate cleaning solutions to remove grime. Regular maintenance will enhance responsiveness and extend the lifespan of the system.

Engine Parts and Specifications

This section explores the essential components and features of the power unit in an all-terrain vehicle. Understanding these elements is crucial for maintaining optimal performance and ensuring reliability during operation.

The engine comprises several critical elements, including the cylinder head, crankshaft, and piston. Each component plays a vital role in the overall functionality, contributing to the efficiency and power output of the machine.

Specifications such as displacement, horsepower, and torque ratings are fundamental metrics that define the engine’s capabilities. These details help enthusiasts and mechanics alike assess performance and make informed decisions regarding upgrades or repairs.

Regular maintenance of these components is essential for longevity. Ensuring proper lubrication, checking for wear, and adhering to service intervals can significantly enhance the durability and reliability of the engine.

Common Replacement Parts to Consider

When maintaining a utility vehicle, certain components frequently require attention and replacement. Understanding which elements are essential for optimal performance can help ensure longevity and reliability. This section highlights key items that often need to be updated over time.

Engine Components

The engine is the heart of any vehicle, and various elements such as filters, spark plugs, and belts play critical roles. Regular checks and timely replacements of these parts can prevent larger issues and enhance overall efficiency.

Suspension and Steering

Another crucial area involves the suspension and steering systems. Components like bushings, tie rods, and shocks are subject to wear and tear. Keeping these parts in good condition is vital for maintaining control and comfort during operation.

Where to Find Diagrams Online

Finding visual references for vehicle components can be a game changer for maintenance and repairs. Various online resources provide comprehensive illustrations that assist in understanding assembly and disassembly processes. These resources can enhance your DIY projects and save you time and effort.

Official Manufacturer Websites

Many manufacturers offer detailed visual guides on their official sites. These resources often include exploded views and detailed part numbers, making it easier to identify what you need. Always check for the most accurate and up-to-date information directly from the source.

Online Forums and Communities

Engaging in specialized forums and communities can yield valuable insights. Enthusiasts frequently share diagrams and tips based on their experiences. These platforms foster collaboration and can often provide hard-to-find resources, enhancing your understanding of the vehicle.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components for repairs and replacements offers numerous advantages that enhance both performance and longevity. These components are specifically designed to fit seamlessly into the machinery, ensuring optimal functionality and reliability.

Some key benefits include:

- Quality Assurance: OEM components are manufactured to meet the highest standards, ensuring durability and performance.

- Perfect Fit: These parts are designed to match the original specifications, which minimizes the risk of installation issues.

- Manufacturer Support: Using original components often comes with the backing of the manufacturer, providing peace of mind and potential warranty coverage.

- Enhanced Resale Value: Vehicles maintained with original parts often have higher resale values, appealing to potential buyers.

- Consistent Performance: Original components contribute to the consistent operation of the equipment, reducing the likelihood of unexpected failures.

In summary, opting for original manufacturer components not only promotes efficiency and reliability but also fosters confidence in the long-term performance of the equipment.

Steps for Effective Parts Installation

Successfully installing components requires careful planning and execution. Following a systematic approach can help ensure that each element is fitted correctly and functions optimally. Here are essential steps to guide you through the process.

Preparation

- Gather all necessary tools and equipment.

- Ensure that you have the correct components for your model.

- Read the manufacturer’s guidelines and specifications thoroughly.

- Prepare a clean and organized workspace to facilitate the installation.

Installation Process

- Begin by disconnecting the battery to ensure safety.

- Remove any existing components that need replacement, taking care to keep track of all fasteners.

- Fit the new parts into their designated locations, ensuring proper alignment.

- Secure components using the appropriate fasteners, adhering to recommended torque specifications.

- Reassemble any panels or covers removed during the process.

- Reconnect the battery and perform a final check to ensure everything is secure and functional.

By following these steps diligently, you can achieve a successful installation and prolong the life of your equipment.