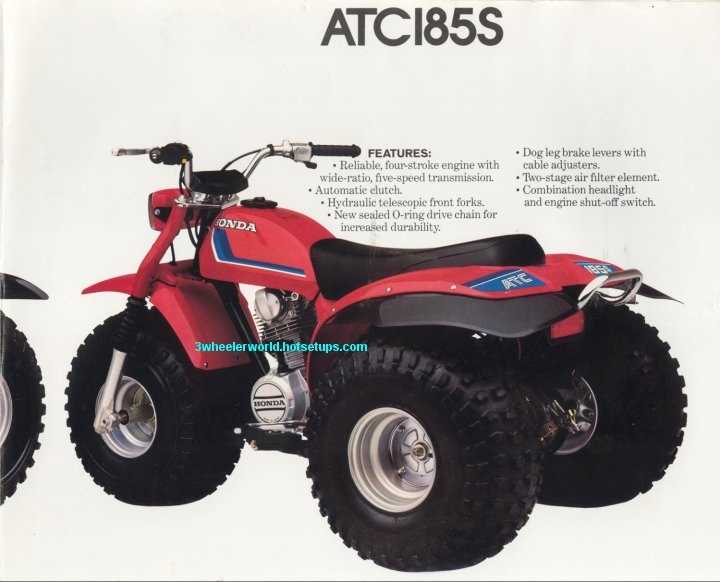

Honda 185s Parts Diagram and Component Guide

Maintaining a reliable off-road vehicle often involves understanding each component and its function. Whether it’s for repairs, upgrades, or routine check-ups, knowing the layout and arrangement of each piece can significantly simplify the process. This guide serves to help enthusiasts and owners navigate through various sections of a classic off-road model, examining everything from its engine elements to the essential driving components.

When restoring or enhancing an all-terrain vehicle from a vintage series, it’s crucial to identify the core sections and understand how each part contributes to the overall functionality. This knowledge can assist in finding the right replacements or understanding potential upgrades that suit specific needs. By diving into these details, you’ll gain a deeper appreciation of how each component works together to provide a rugged and dependable riding experience.

This article covers a range of critical elements, breaking down the vehicle’s essential areas and offering insights on the importance of each. You’ll find comprehensive information on everything from the power system to braking mechanisms, all aimed at helping you keep your classic vehicle in prime condition for all your off-road adventures.

Essential Components for the Honda 185s

Understanding the key elements of this all-terrain vehicle provides a comprehensive overview of its mechanics and functionality. These elements are essential for maintaining optimal performance, ensuring durability, and facilitating smooth operation. Below is an outline of these critical elements and their core functions.

| Component | Description | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | The core powerhouse responsible for converting fuel into energy, driving the vehicle forward, and supporting various riding conditions. | ||||||||||||||||||||

| Carburetor | Blends fuel and air in the correct ratio, essential for the vehicle’s combustion process and smooth acceleration. | ||||||||||||||||||||

| Exhaust System | Removes combustion gases, ensuring efficient engine function and minimizing harmful emissions during operation. | ||||||||||||||||||||

| Transmission | Transfers power from the engine to the wheels, allowing for speed adjustments and adapting to different terrains. | ||||||||||||||||||||

| Fuel Tank | Stores and supplies the gasoline required for the engine’s operation, built for endurance on longer rides. | ||||||||||||||||||||

| Electrical Wiring | Connects various

Understanding the Engine LayoutExploring the core configuration of this classic model reveals how its internal structure and components contribute to its robust functionality. By grasping the arrangement of key elements, enthusiasts can appreciate the simplicity and power that drive its performance. This section will delve into the main features and layout to provide a comprehensive view of the essential engine structure. Primary Components and Their RolesAt the heart of this model’s setup, you’ll find a single-cylinder engine, designed for durability and efficient power output. The cylinder, carburetor, and cooling system work in harmony to create a streamlined yet effective performance. The layout is intuitive, with each component strategically placed to maximize both space and functionality. The Significance of Component PositioningThe positioning of each component within the engine assembly isn’t just for aesthetics; it has practical benefits. Elements such as the exhaust system and fuel intake are arranged to optimize airflow and fuel efficiency. This arrangement ensures smoother operation and easier maintenance, which is crucial for those looking to keep this machine running at peak performance. Honda 185s Frame Structure and DesignThe structure of this classic off-road model’s framework is carefully crafted to provide a sturdy and resilient base for rugged terrains. Designed with durability in mind, the framework delivers enhanced stability and ensures that it can handle challenging environments with ease. This section delves into the specific elements and layout of the framework, highlighting how its composition contributes to overall performance and rider safety.

Exploring the Honda 185s Fuel SystemThe fuel system of a compact utility vehicle plays a crucial role in its overall performance. Understanding the components and their functions can significantly enhance maintenance and troubleshooting efforts. This section delves into the essential elements of the fuel delivery mechanism, highlighting how they work together to ensure optimal operation. Key Components of the Fuel Delivery Mechanism

Maintaining Efficiency and PerformanceRegular maintenance of the fuel system is vital for ensuring smooth operation. Here are some essential tips:

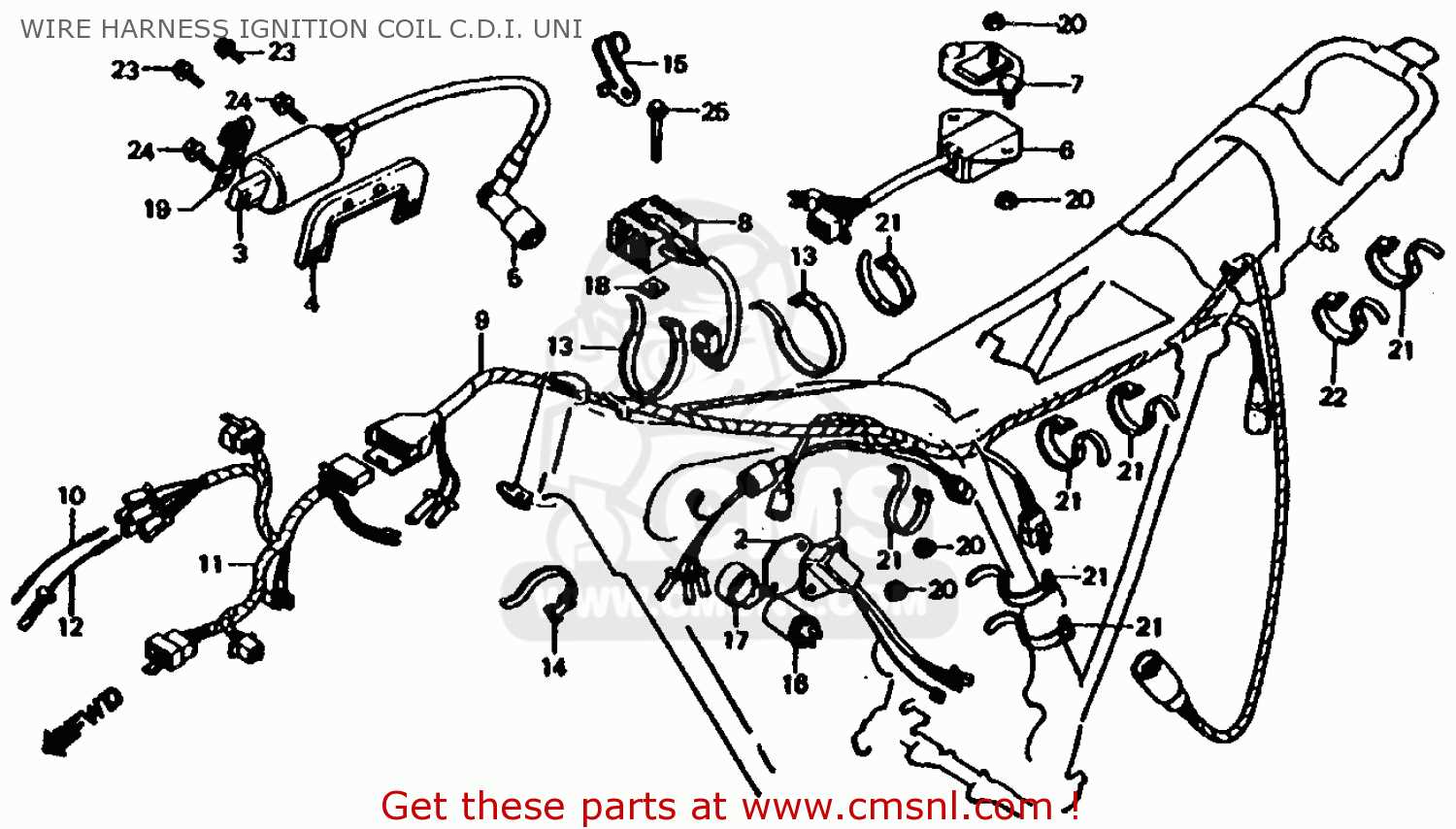

By focusing on these key components and their upkeep, users can maintain the reliability and efficiency of their vehicle’s fuel system. Electrical System Overview

The electrical framework of this all-terrain vehicle is crucial for its efficient operation and overall performance. This system encompasses various components that work in harmony to provide power and ensure the proper functioning of essential features. Understanding its structure and functionality is key to maintaining and troubleshooting any issues that may arise. Power Generation: At the core of this system is the generator, responsible for producing electricity to power the vehicle’s electrical devices. It converts mechanical energy into electrical energy, enabling a reliable power supply for ignition and lighting. Ignition System: The ignition assembly plays a vital role in ensuring the engine starts smoothly. It includes components such as the ignition coil and spark plug, which work together to ignite the fuel-air mixture in the combustion chamber, facilitating engine operation. Lighting: Adequate illumination is essential for safe navigation, particularly in low-light conditions. The lighting system consists of headlights, tail lights, and indicators, all powered by the electrical framework. These components enhance visibility and communication with other road users. Wiring Harness: The wiring harness serves as the network that connects all electrical parts. It is essential for transmitting power and signals between components, ensuring seamless communication throughout the system. Proper maintenance of the wiring is crucial to prevent shorts and failures. Battery: The storage unit provides the necessary energy for starting the engine and powering electrical devices when the engine is off. Regular checks and maintenance of the battery’s condition are vital to avoid starting issues and ensure reliability during operation. In summary, the electrical framework of this vehicle is intricate yet essential, comprising various elements that contribute to its functionality and safety. Familiarity with its components and their roles can significantly enhance maintenance efforts and operational efficiency. Guide to the Honda 185s Exhaust PartsThe exhaust system of an all-terrain vehicle is crucial for maintaining optimal performance and reducing harmful emissions. Understanding the various components that make up this system can enhance both maintenance practices and troubleshooting efforts. This section provides insights into the essential elements that contribute to a well-functioning exhaust assembly, ensuring a smoother ride and longevity for the vehicle. Key Components of the Exhaust SystemThe primary elements include the header, which collects exhaust gases from the engine; the muffler, which minimizes noise levels; and the tailpipe, responsible for directing gases away from the vehicle. Each part plays a vital role in the overall efficiency and effectiveness of the exhaust system. Maintenance TipsRegular inspections and cleaning can prevent buildup and damage. Checking for leaks and ensuring that all connections are secure will help maintain the integrity of the system. Additionally, replacing worn-out components promptly is essential for optimal performance and compliance with emissions regulations. Suspension and Shock Absorbers on Honda 185sThe ability to navigate various terrains with ease relies heavily on the effectiveness of the suspension system. This crucial assembly not only provides a smooth ride but also ensures optimal handling and stability during operation. Key components play distinct roles in achieving these objectives, contributing to the overall performance of the vehicle. Shock absorbers are essential for managing the impact of uneven surfaces, reducing the bouncing effect that occurs when wheels encounter bumps. They work by absorbing and dissipating energy, preventing excessive oscillation. The design of these components significantly influences how well the vehicle can maintain traction, especially in challenging conditions. Suspension springs, another vital part of the system, support the weight of the vehicle while allowing for vertical movement. These springs compress and expand to accommodate changes in terrain, ensuring that the ride remains comfortable for the operator. The combination of shock absorbers and springs is crucial for maintaining an appropriate balance between comfort and performance. Regular inspection and maintenance of these components are necessary to ensure long-lasting functionality. Worn or damaged shock absorbers can lead to poor handling and increased tire wear, while compromised springs may affect the overall height and stability of the vehicle. By addressing issues promptly, operators can enhance the longevity and efficiency of their machinery. Honda 185s Braking Mechanism DetailsThe braking system of a utility vehicle is crucial for ensuring safety and control during operation. This mechanism comprises several components that work in tandem to slow down or stop the vehicle effectively. Understanding the intricacies of this system enhances maintenance practices and promotes longevity. At the heart of the braking system are the brake pads and rotors, which are designed to create friction when engaged. The calipers serve as the component that applies pressure to the pads against the rotors, enabling efficient deceleration. Regular inspection of these parts is essential to ensure optimal performance. Additionally, the hydraulic system plays a vital role in transferring force from the brake lever to the calipers. This mechanism relies on fluid dynamics to create the necessary pressure for braking. Any leaks or air bubbles in the system can significantly affect its efficiency, necessitating prompt repairs. Moreover, the integration of a reliable master cylinder is key to maintaining the braking pressure. This component acts as the starting point for the hydraulic system, converting mechanical force into hydraulic pressure. Ensuring its functionality is critical for the overall effectiveness of the braking mechanism. In summary, the braking system is a complex assembly that requires regular checks and maintenance. Understanding its components and their functions aids in diagnosing issues and ensuring the vehicle operates safely and efficiently. Handlebars and Controls for the Honda 185sThe steering mechanism and operational elements are crucial for ensuring a smooth and controlled riding experience. This section delves into the various components that facilitate steering and interaction with the vehicle, highlighting their functionality and importance in the overall design. Key Components of the Steering Mechanism

Operational Controls

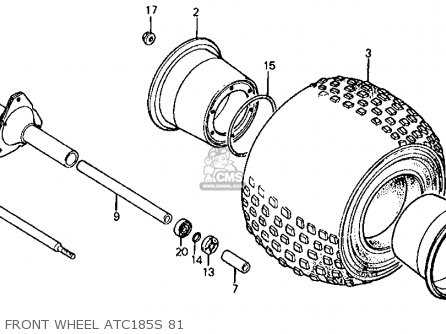

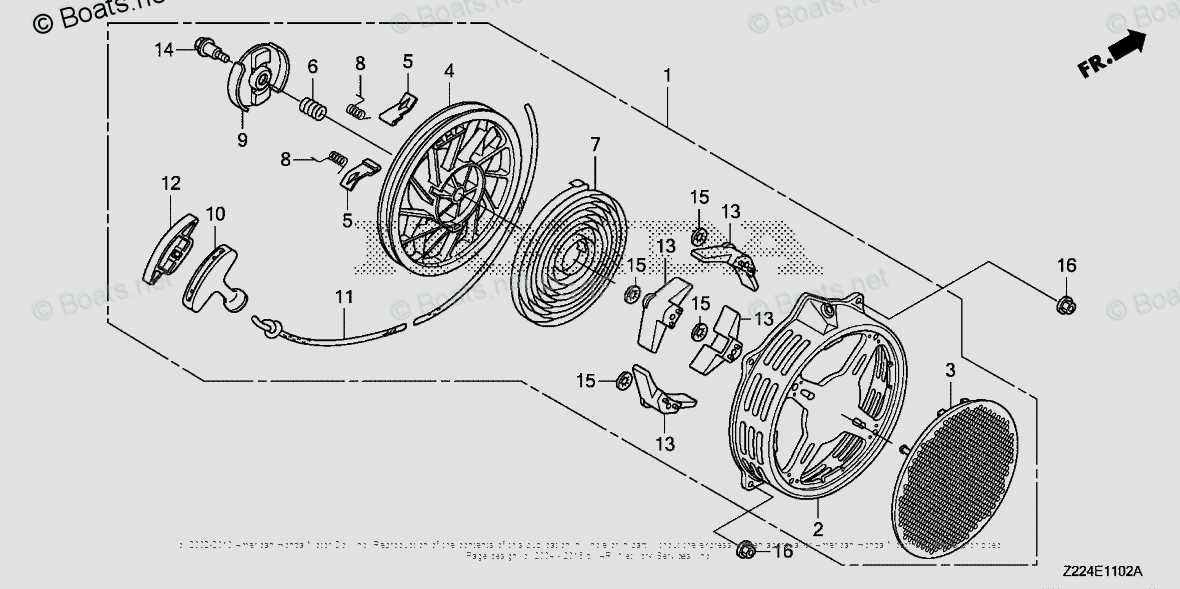

Understanding these elements is essential for effective vehicle operation and maintenance. Regular inspection and timely replacements of any worn components ensure optimal performance and safety on every journey. Overview of the Honda 185s Wheel Assembly

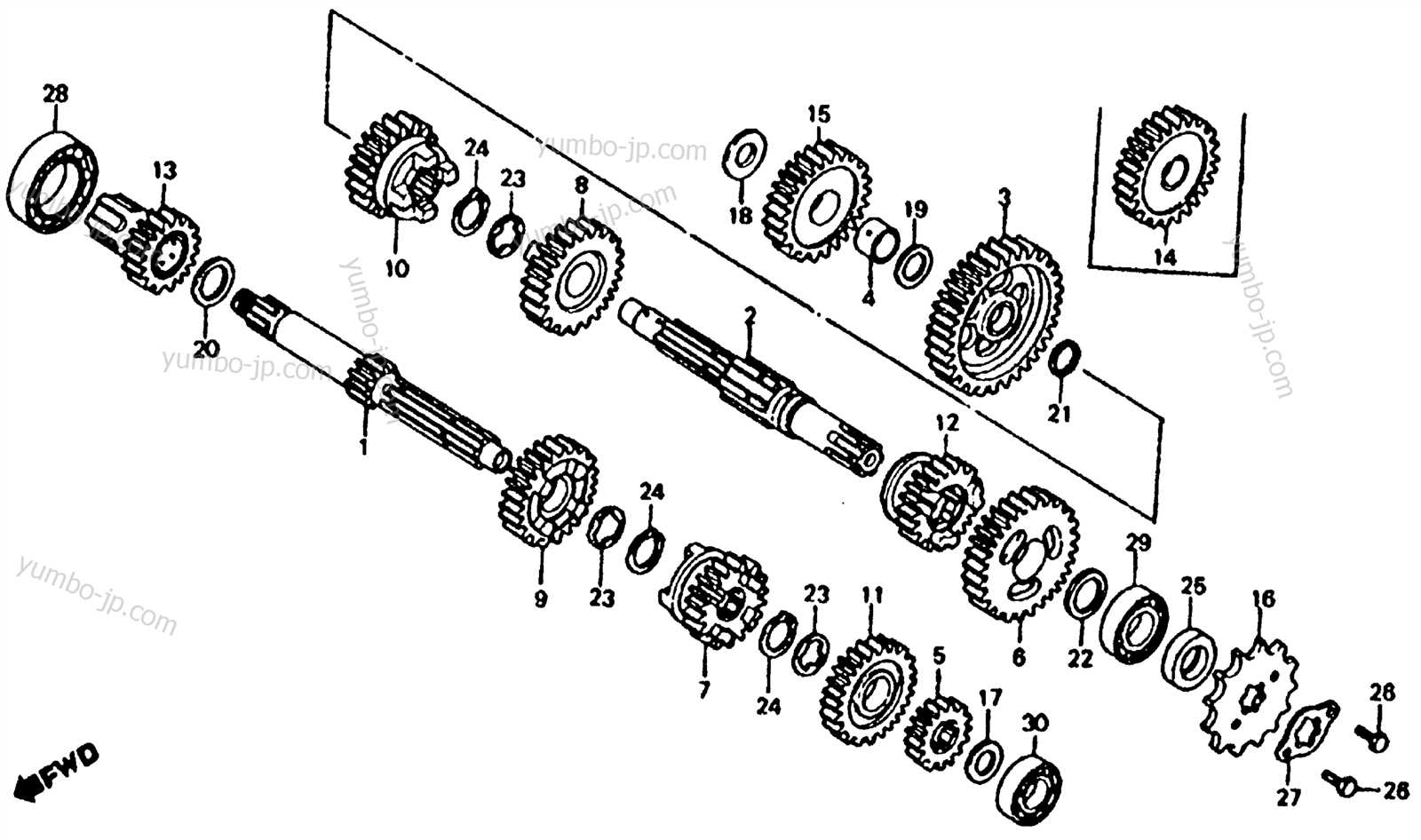

The wheel assembly is a crucial component of any three-wheeled vehicle, significantly influencing its performance and stability. This assembly is designed to support the weight of the vehicle while providing a reliable interface with the ground. Understanding its structure and function is essential for maintenance and repair, ensuring a safe and efficient ride. Components of the Wheel AssemblyThe primary elements of the wheel assembly include the rim, tire, hub, and axle. Each part plays a vital role in the overall functionality. The rim holds the tire securely in place, while the tire provides traction and absorbs shocks from uneven surfaces. The hub connects the wheel to the axle, allowing for smooth rotation. Regular inspection and maintenance of these components can prevent performance issues and enhance longevity. Importance of MaintenanceProper upkeep of the wheel assembly is essential for optimal operation. Routine checks for wear and tear, as well as ensuring correct tire pressure, contribute to better handling and fuel efficiency. Addressing any signs of damage promptly can prevent more significant problems down the line, promoting a safer driving experience. Transmission and Gear Components

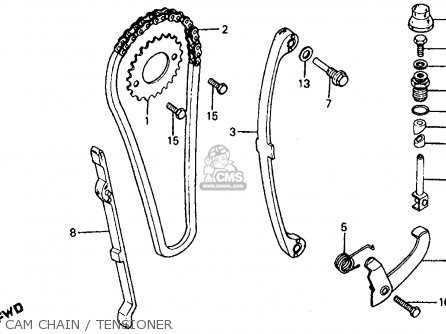

This section focuses on the essential elements that make up the transmission and gearing systems in specific off-road vehicles. Understanding the configuration and functioning of these components is crucial for effective maintenance and performance optimization. Key Transmission ElementsThe transmission system includes several vital components that work together to facilitate smooth gear shifting and power transfer. Below is a table highlighting some of the critical components and their functions:

Gear Assembly Overview

The gear assembly is fundamental for the proper functioning of the drivetrain. Each gear has a specific ratio that determines the vehicle’s speed and acceleration characteristics. Regular inspection and replacement of worn gears are vital to maintaining optimal performance. Seat and Comfort Features of the Honda 185s

When it comes to optimizing the riding experience, attention to seating and comfort elements is essential. The vehicle in question showcases thoughtful design choices aimed at enhancing overall usability and enjoyment. Riders can expect a blend of ergonomic features and practicality, ensuring both comfort and ease of use during extended periods of operation. The seating arrangement is crafted to provide ample support, accommodating various body types. With a carefully contoured shape, the seat minimizes fatigue, allowing for prolonged rides without discomfort. Padding is designed to absorb shock and vibrations from uneven terrains, ensuring a smoother journey even on bumpy surfaces. Additionally, the height of the seat is optimized to facilitate easy mounting and dismounting. This feature not only enhances accessibility but also contributes to a confident riding posture, promoting better control and stability. The materials used for the seat cover are durable yet comfortable, offering resistance to wear and tear while maintaining a pleasant feel. For those seeking additional convenience, there are options for adjustable components, allowing users to customize their seating position according to personal preferences. This adaptability ensures that every rider can find their ideal setup, enhancing both comfort and safety during operation. In summary, the emphasis on seating and comfort features reflects a commitment to delivering a superior riding experience, where functionality meets user-friendly design. |