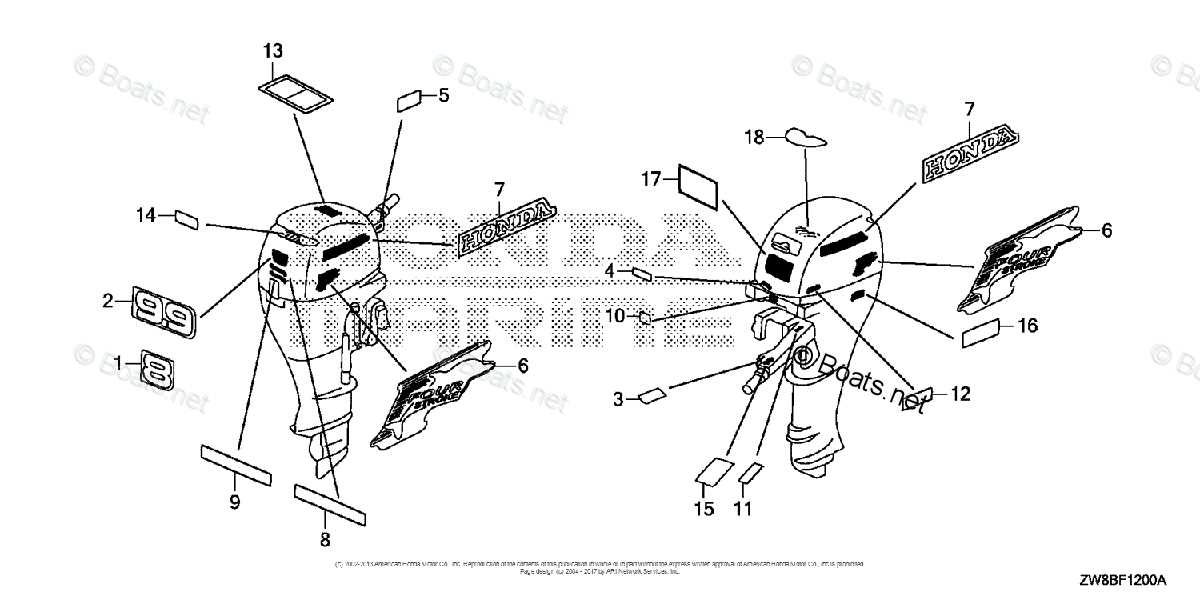

Honda 2 HP Outboard Parts Overview

Understanding the various elements of a small marine propulsion system is crucial for effective maintenance and optimal performance. This section provides a detailed overview of the different components that constitute such a system, helping users identify and comprehend their functions. By gaining insight into these vital parts, users can ensure the longevity and reliability of their watercraft.

Each element plays a significant role in the overall operation, contributing to both efficiency and safety while navigating through waterways. Whether you are a novice or an experienced user, familiarizing yourself with these components will enhance your ability to troubleshoot and carry out necessary repairs. Comprehending the functionality of each part allows for better decision-making when it comes to maintenance and upgrades.

In this guide, users will find an organized presentation of essential components, showcasing their arrangement and interrelation. This knowledge not only aids in repairs but also empowers users to make informed choices when selecting replacements or enhancements. Emphasizing the importance of regular inspection and proper care, this section aims to equip users with the understanding needed for effective marine engine management.

Key Components Explained

This section delves into the essential elements of small marine engines, offering a comprehensive understanding of their functionality and interrelation. By exploring these critical components, users can gain insight into the overall operation and maintenance of these machines.

Power Unit

The core of any marine engine is its power unit, which converts fuel into mechanical energy. This unit typically consists of a cylinder, piston, and crankshaft, all working in harmony to generate the necessary thrust for propulsion. Regular maintenance of this assembly ensures optimal performance and longevity.

Fuel System

The fuel system plays a vital role in delivering the right amount of fuel to the power unit. It includes a fuel tank, pump, and various lines that transport fuel efficiently. Proper filtration and regular checks can prevent clogging and ensure smooth operation.

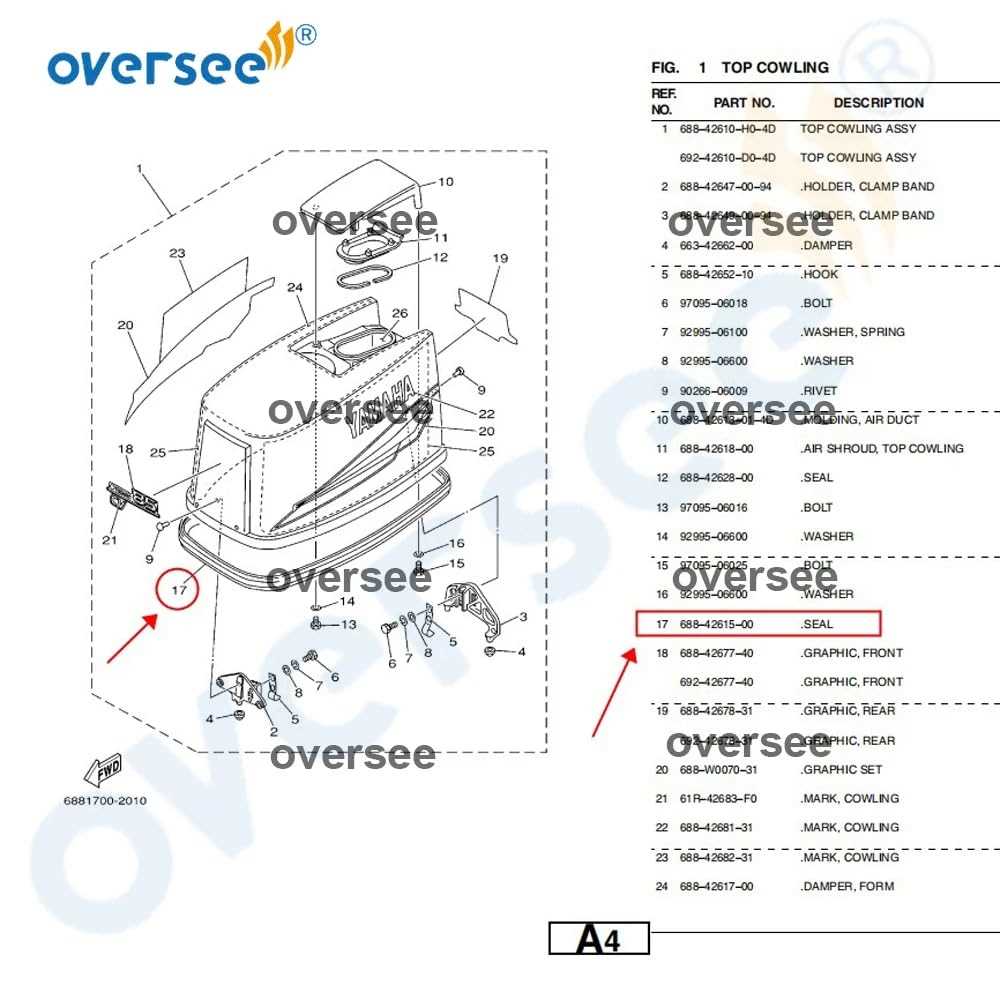

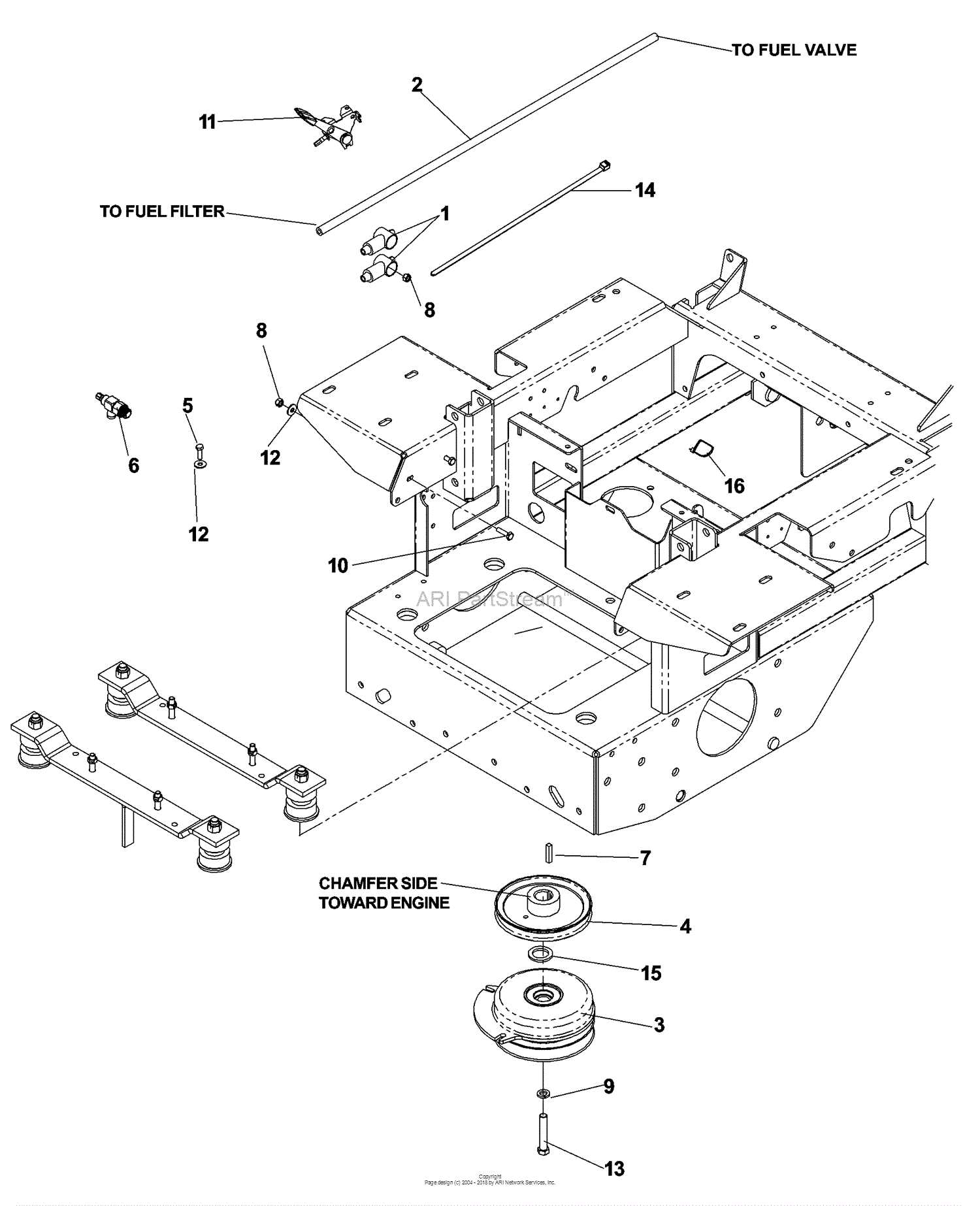

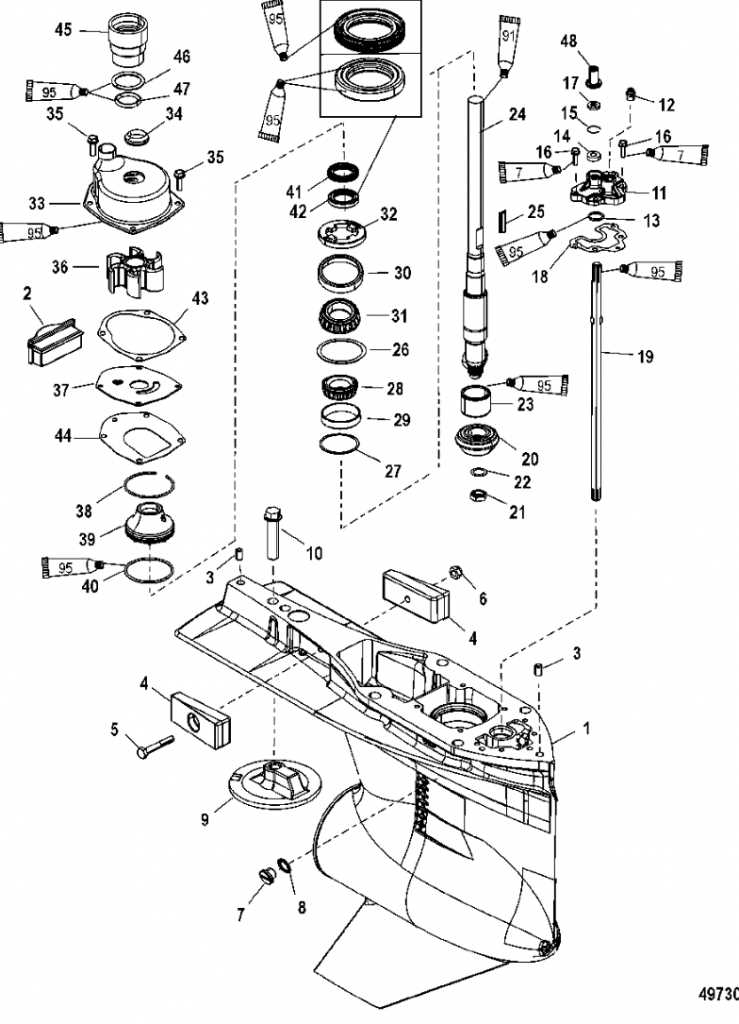

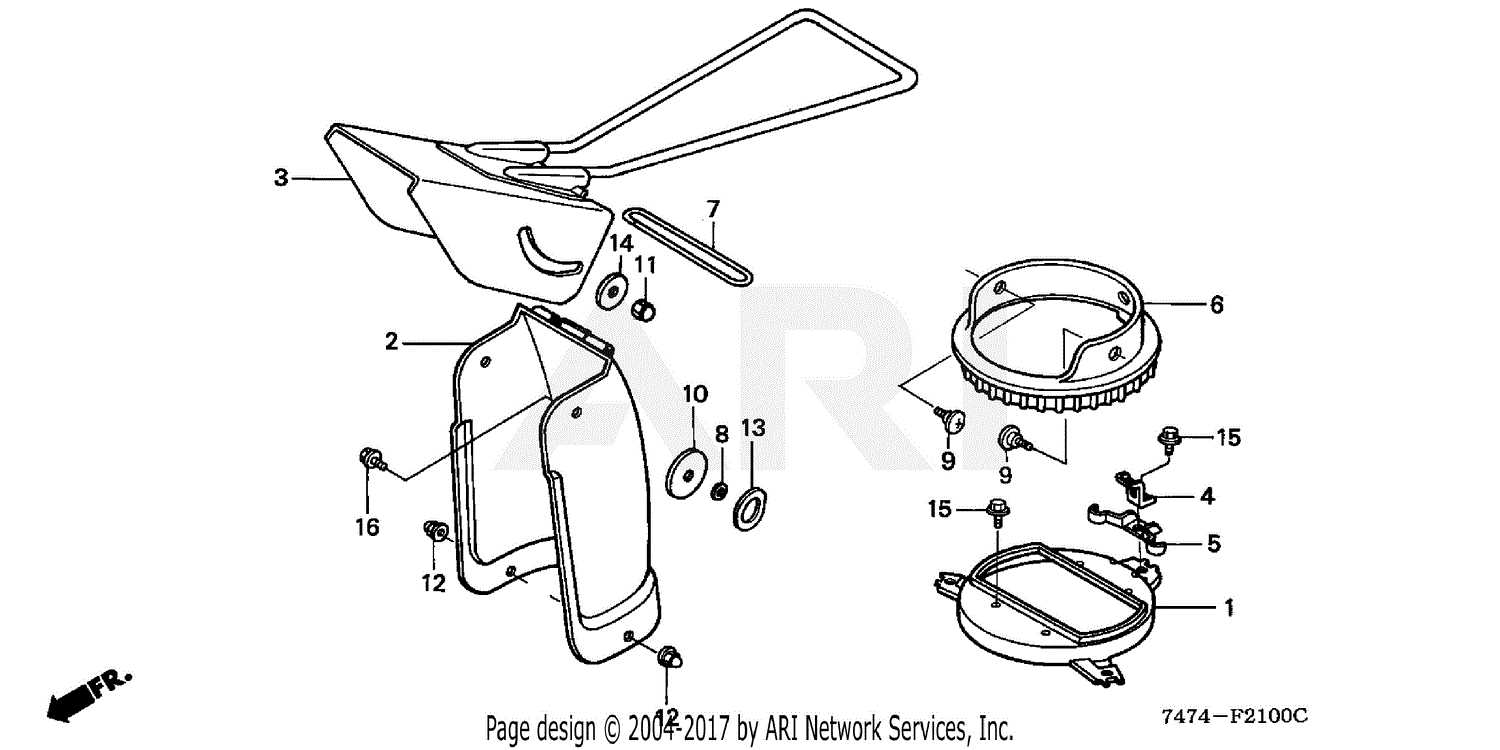

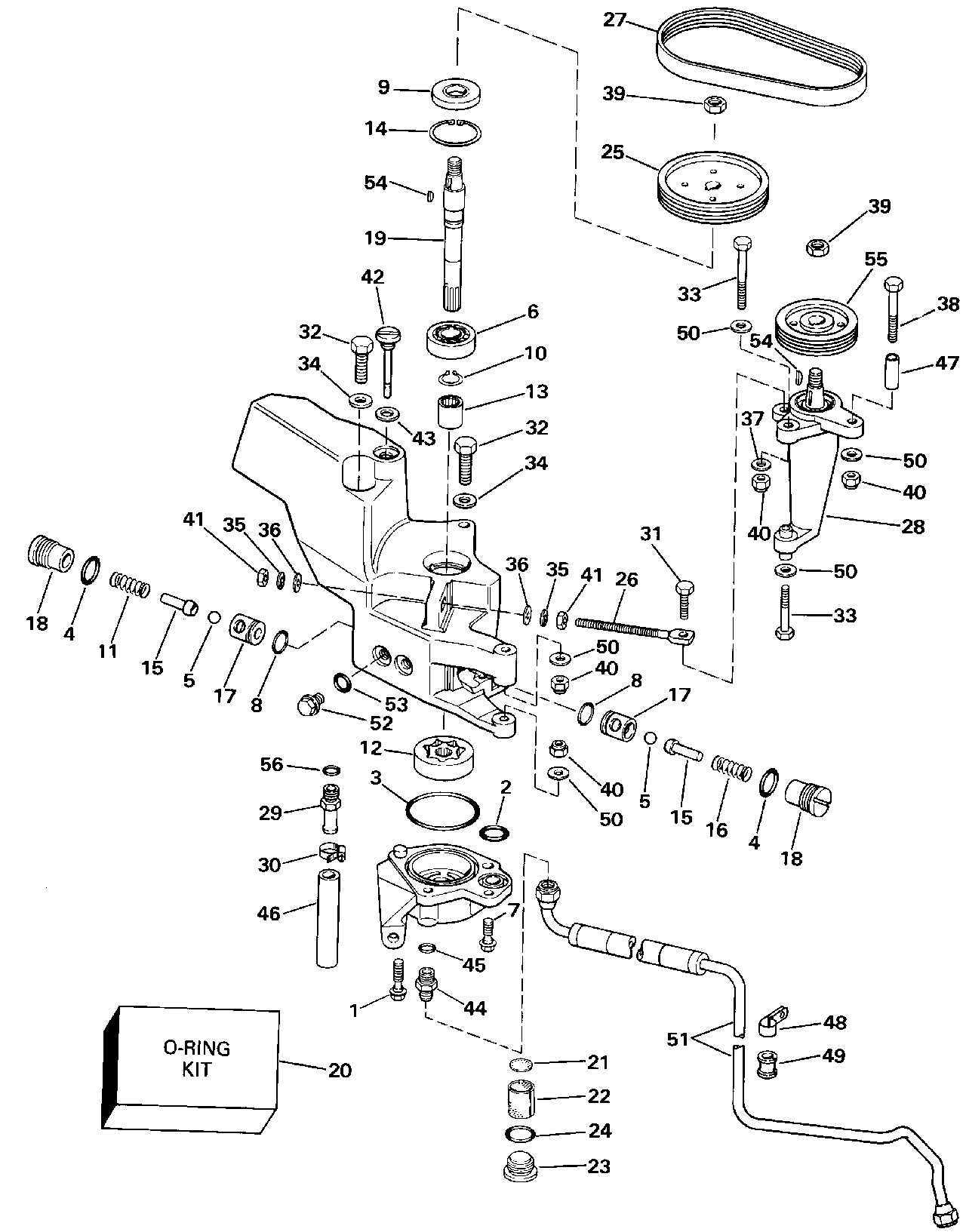

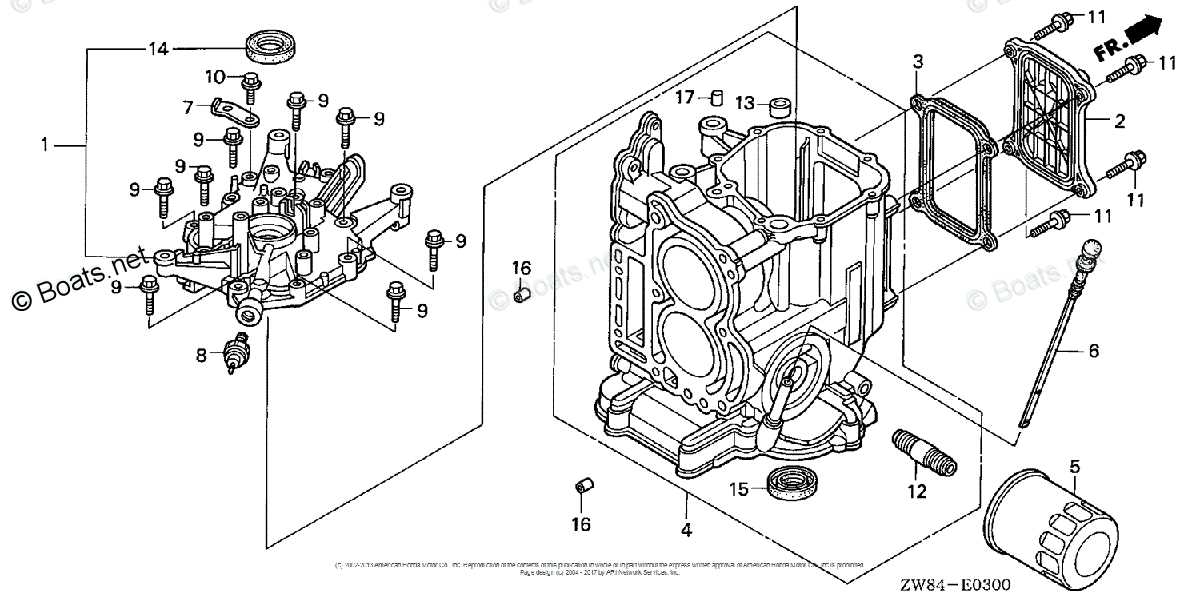

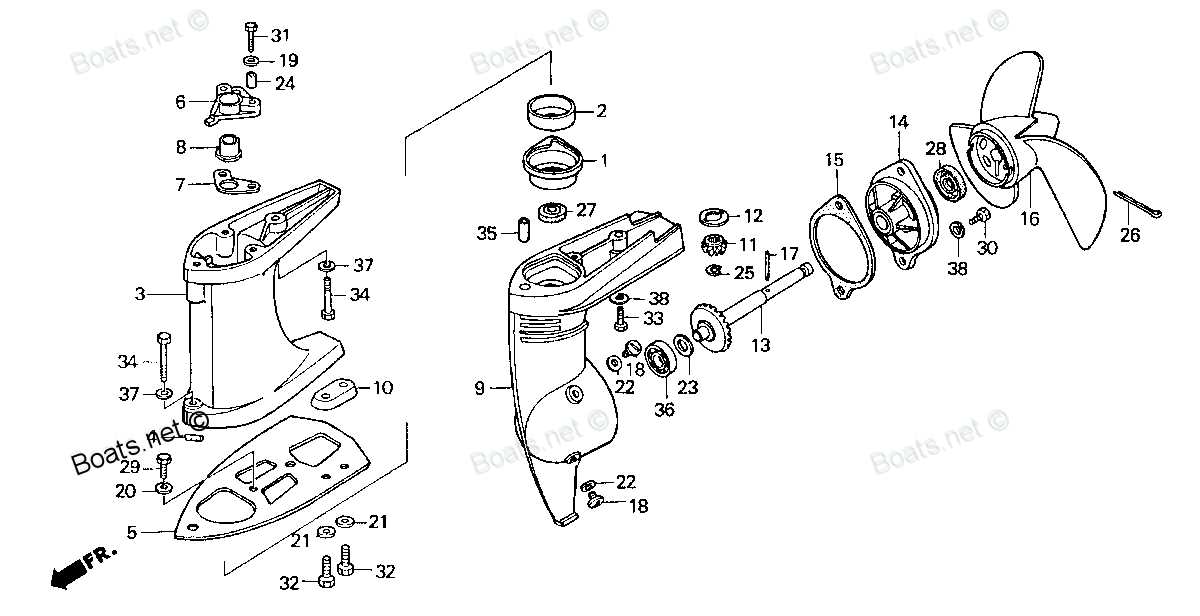

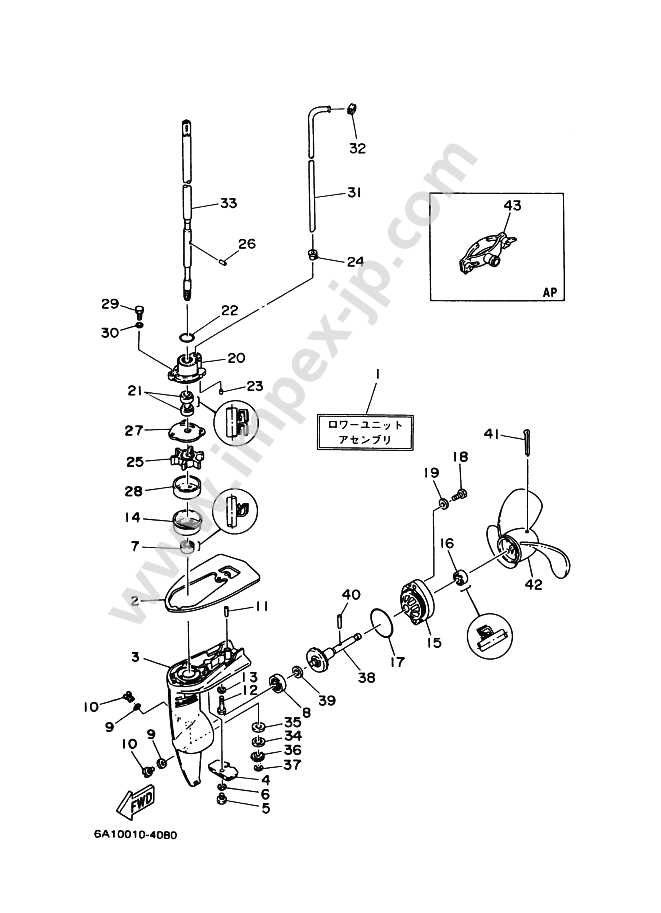

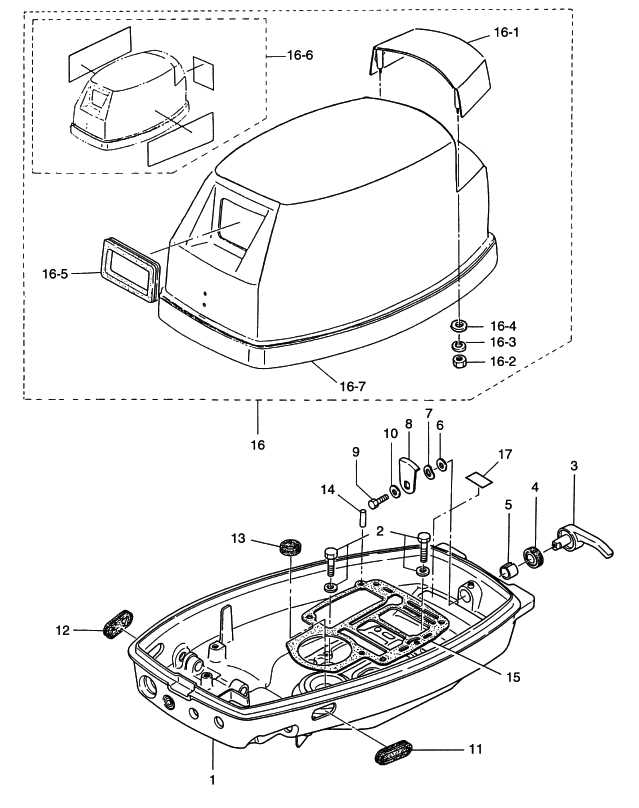

Understanding the Parts Diagram

Grasping the layout of a marine engine’s components is crucial for effective maintenance and repairs. This visual representation serves as a guide to identify and comprehend the various elements that make up the machinery.

Familiarizing oneself with this schematic allows for easier troubleshooting and enhances the understanding of how different sections interact. Each labeled element provides insight into its function, promoting efficient service and part replacement when necessary.

By mastering the relationship between components, users can ensure optimal performance and longevity of their equipment. This knowledge empowers owners to tackle repairs with confidence and maintain their vessel’s reliability in the water.

Maintenance Tips for Longevity

Ensuring the durability of your marine engine requires regular care and attention. By following some essential maintenance practices, you can significantly extend the lifespan of your equipment and enhance its performance.

- Regular Inspections: Frequently check for any signs of wear or damage. This includes examining the casing, propeller, and fuel system.

- Keep it Clean: After each use, clean the engine and remove any saltwater, dirt, or debris that may have accumulated.

- Proper Lubrication: Use high-quality lubricants on moving parts to reduce friction and prevent corrosion.

- Check Fluid Levels: Regularly inspect and top off oil and fuel levels to ensure optimal operation.

- Winterization: Prepare your engine for off-season storage by draining fluids and protecting components from moisture.

By implementing these practices, you can help ensure that your engine remains in top condition, providing reliable service for years to come.

Common Issues and Solutions

Many individuals encounter frequent challenges when operating small marine engines. Understanding these issues and their corresponding solutions can enhance the performance and longevity of the equipment.

Frequent Problems

- Engine not starting

- Unusual noises during operation

- Overheating

- Fuel leaks

Troubleshooting Steps

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Examine the cooling system for blockages.

- Ensure that all connections are secure and free of corrosion.

Addressing these common challenges with proactive maintenance can significantly improve the reliability and efficiency of your marine engine.

Replacement Parts Availability

Access to quality components is essential for maintaining the functionality of marine engines. Ensuring that suitable replacements are readily obtainable helps owners keep their equipment in optimal working condition. This section focuses on the options available for sourcing these necessary elements.

Numerous suppliers offer a variety of replacement components, catering to different models and specifications. Online retailers and local distributors frequently stock a comprehensive selection, making it easier for users to find what they need. Additionally, authorized service centers often provide original equipment manufacturer (OEM) items, ensuring compatibility and reliability.

For those seeking cost-effective solutions, aftermarket alternatives can also be considered. These options, while potentially varying in quality, can serve as a budget-friendly way to secure essential elements. However, it’s crucial to verify the specifications to ensure they meet the required standards for performance and durability.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for achieving effective results. Various tools are essential to ensure smooth operations and to facilitate the repair process, enhancing both efficiency and safety during the procedure.

Essential Hand Tools

A variety of hand tools should be part of your toolkit, including screwdrivers, wrenches, and pliers. These tools are vital for loosening and tightening fasteners, as well as for handling components with precision. Each tool serves a specific purpose, making it easier to address different aspects of the repair work.

Power Tools and Accessories

In addition to hand tools, power tools can significantly expedite repair tasks. A drill, for example, is invaluable for making holes and driving screws quickly. Furthermore, accessories like replacement blades and drill bits are important for maintaining the functionality of your power tools, ensuring that they are always ready for use.

Step-by-Step Repair Guide

This guide aims to assist you in performing maintenance and repair on a small marine propulsion unit. By following a systematic approach, you can ensure the effective functioning of your device, enhancing its performance and longevity.

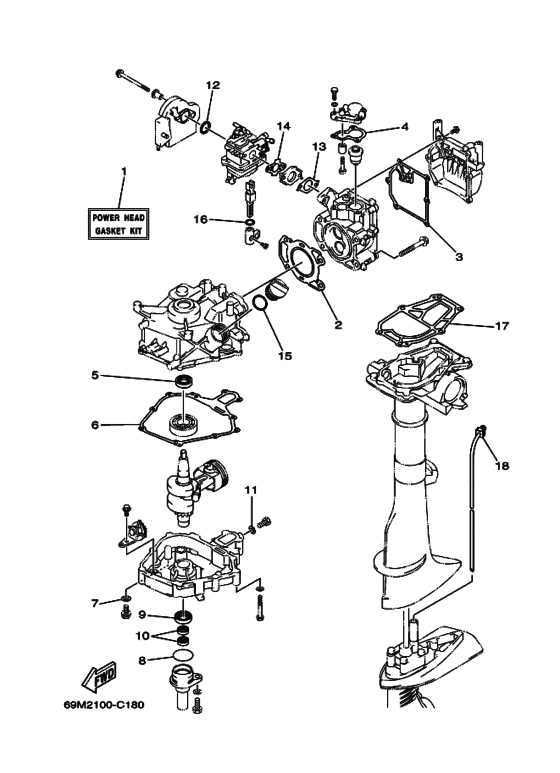

Understanding the Components

Familiarizing yourself with the various elements of the propulsion system is essential before beginning any repair work. Each component plays a vital role in the overall operation, and recognizing their functions can aid in troubleshooting issues effectively. Take the time to review each section and understand how they interact.

Repair Process Overview

Start the repair process by identifying the specific problem. Carefully examine the unit for any visible signs of wear or damage. Once the issue is pinpointed, gather the necessary tools and components for the repair. Following the steps outlined will streamline your efforts and help you achieve a successful restoration.

Safety Precautions While Working

Ensuring safety during maintenance and repair activities is essential for both personal well-being and the longevity of equipment. Adopting proper measures minimizes risks associated with operating machinery and handling tools. Prioritizing safety not only protects individuals but also enhances overall efficiency and productivity.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes gloves to shield hands from sharp objects, safety goggles to protect eyes from debris, and durable footwear to prevent injuries from heavy items. Additionally, consider using ear protection when working in noisy environments to safeguard hearing.

Workspace Organization

A well-organized workspace is fundamental for safe operations. Keep tools and materials in designated areas to avoid clutter and reduce the risk of accidents. Ensure adequate lighting to enhance visibility and minimize the chances of mishaps. Regularly inspect equipment for any signs of wear or damage, addressing issues promptly to maintain a safe working environment.

Understanding Engine Performance

Engine efficiency is a critical aspect of any watercraft, influencing speed, fuel consumption, and overall handling. Comprehending how different components interact can significantly enhance the performance and longevity of the motor. A thorough grasp of these elements is essential for optimal operation.

Several factors contribute to the performance of a marine engine:

- Fuel Quality: The type of fuel used directly affects combustion efficiency and power output.

- Airflow: Proper airflow to the combustion chamber is vital for effective fuel combustion.

- Maintenance: Regular servicing and timely replacement of worn components ensure smooth operation.

- Weight Distribution: The balance of weight in the vessel can impact acceleration and maneuverability.

To maximize engine performance, consider the following practices:

- Use high-quality fuel recommended for your engine type.

- Regularly check and replace air filters to maintain proper airflow.

- Conduct routine inspections to identify and address any wear and tear.

- Adjust weight distribution to optimize handling and speed.

By understanding these fundamental aspects, operators can ensure their marine engines operate at peak performance, providing a more enjoyable experience on the water.

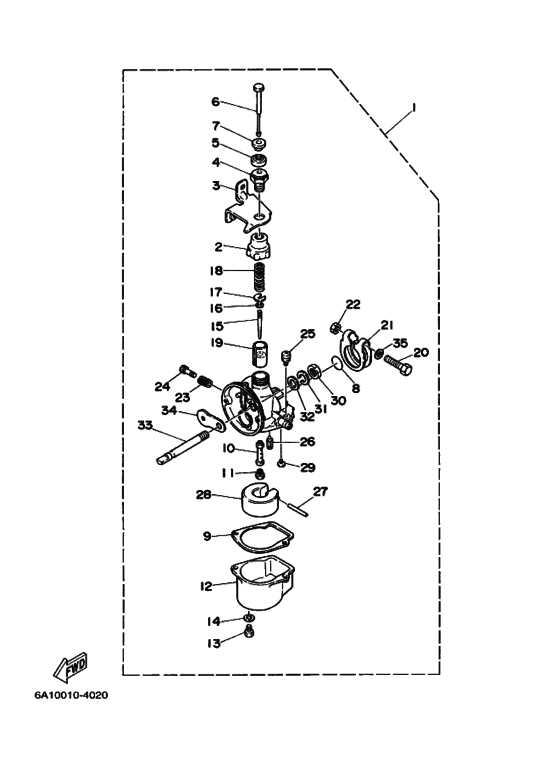

Fuel System Components Breakdown

The fuel system is a crucial element in the performance of marine engines, responsible for delivering the necessary fuel for combustion. Understanding the various components that make up this system is essential for effective maintenance and troubleshooting.

Key Components

- Fuel Tank: This is where the fuel is stored before being sent to the engine.

- Fuel Line: A conduit that transports fuel from the tank to the engine, ensuring a steady flow.

- Fuel Filter: A vital component that removes impurities from the fuel, protecting the engine from damage.

- Fuel Pump: This device is responsible for moving the fuel from the tank to the engine, maintaining adequate pressure.

- Carburetor: A mechanism that mixes air and fuel in the correct ratio for efficient combustion.

Maintenance Tips

- Regularly check and clean the fuel filter to ensure optimal performance.

- Inspect the fuel lines for any signs of wear or leaks.

- Keep the fuel tank filled to prevent condensation and contamination.

- Monitor the carburetor for proper functioning and clean it as needed.

By familiarizing yourself with these essential components and following maintenance guidelines, you can enhance the reliability and longevity of your marine engine.

Electrical System Overview

The electrical framework of a small marine engine plays a crucial role in ensuring smooth operation and reliable performance. It encompasses various components that work together to facilitate power distribution, ignition, and control functions. Understanding the key elements of this system can greatly enhance maintenance and troubleshooting efforts.

Key Components

The electrical configuration includes essential parts such as the ignition system, battery, wiring harness, and control switches. Each element serves a specific function, contributing to the overall efficiency of the marine engine.

Power Distribution Table

| Component | Function |

|---|---|

| Ignition Coil | Generates high voltage for spark creation |

| Battery | Supplies power for starting and electronic systems |

| Wiring Harness | Connects various electrical components |

| Control Switches | Regulates engine operation and electrical functions |

Frequently Asked Questions

This section aims to address common inquiries related to marine engine maintenance and components. Understanding the various elements involved can enhance the efficiency and longevity of your vessel’s performance.

| Question | Answer |

|---|---|

| What are the key components of a marine engine? | The main elements include the fuel system, cooling system, electrical components, and the drive mechanism. |

| How can I ensure my engine runs smoothly? | Regular maintenance, including oil changes, fuel system cleaning, and inspecting electrical systems, is crucial for optimal performance. |

| Where can I find replacement components? | Replacement elements can be sourced from authorized dealers, online retailers, or local marine supply stores. |

| What is the recommended maintenance schedule? | It is advisable to consult the manufacturer’s guidelines, but generally, a thorough inspection should be performed annually. |

| How do I identify the right component for my engine? | Refer to the service manual for specifications, or consult with a knowledgeable technician to ensure compatibility. |