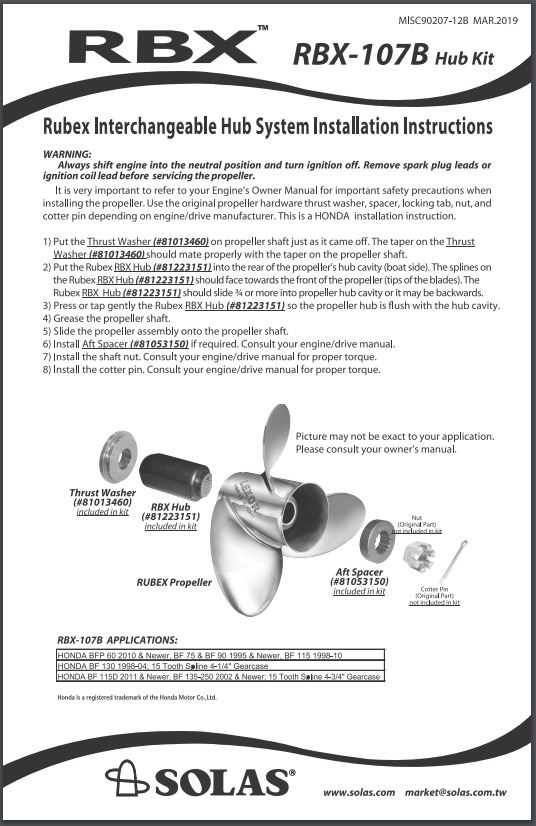

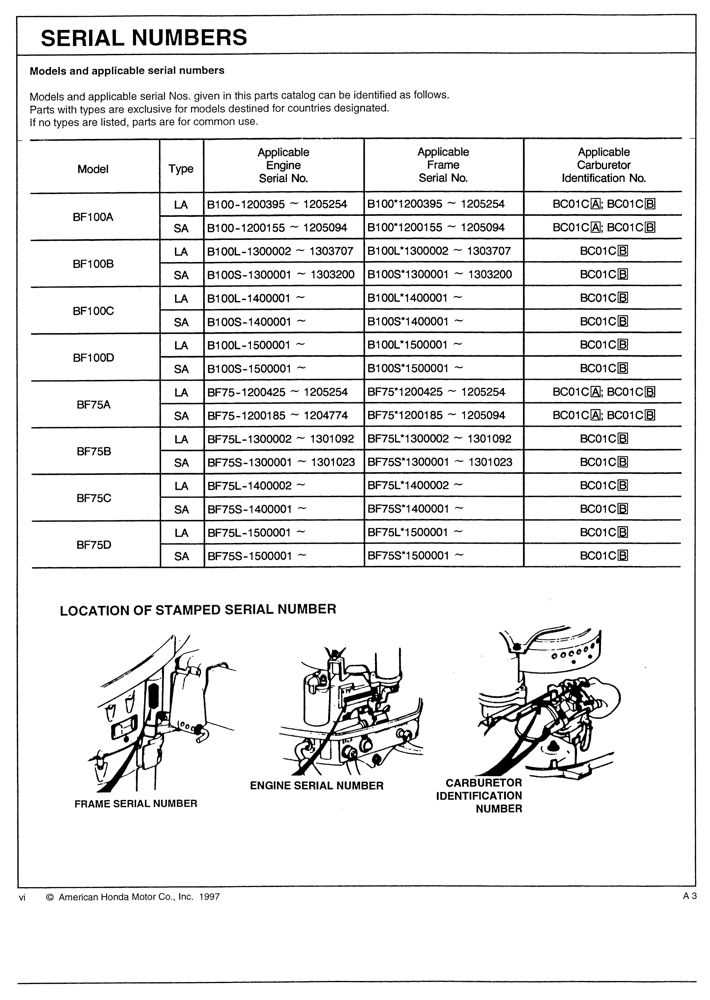

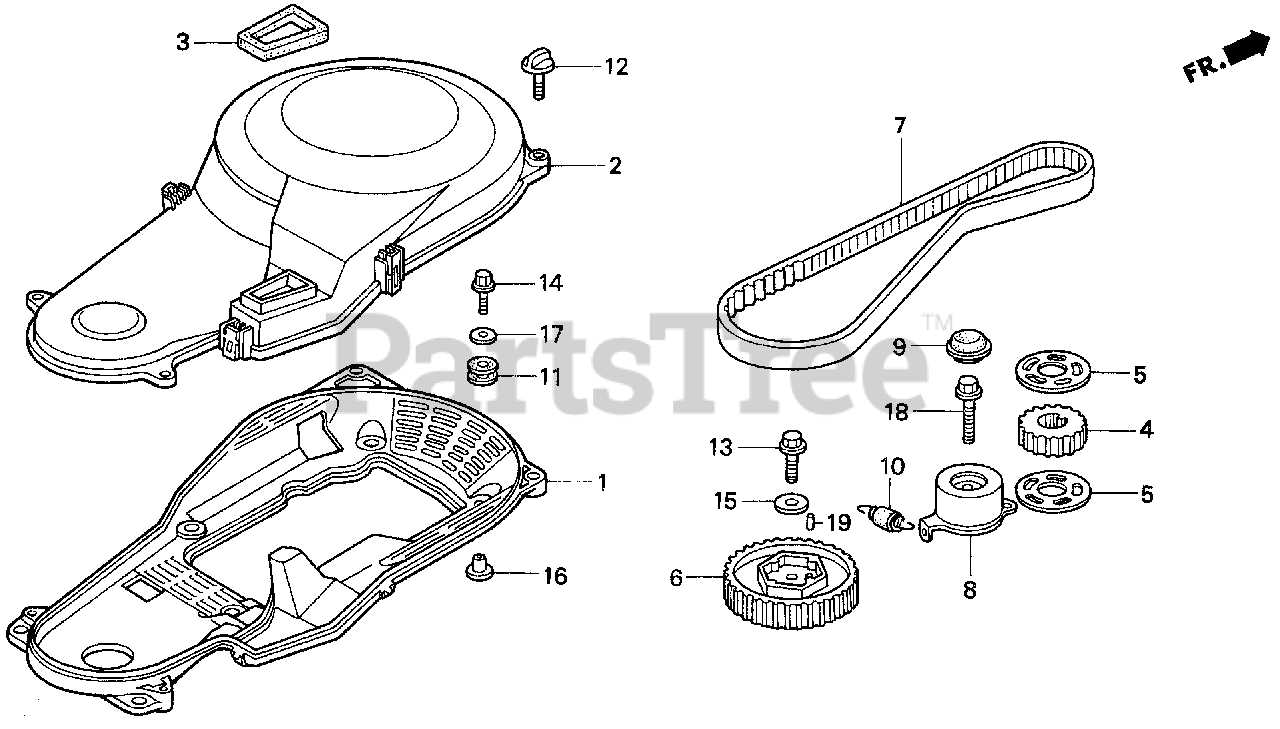

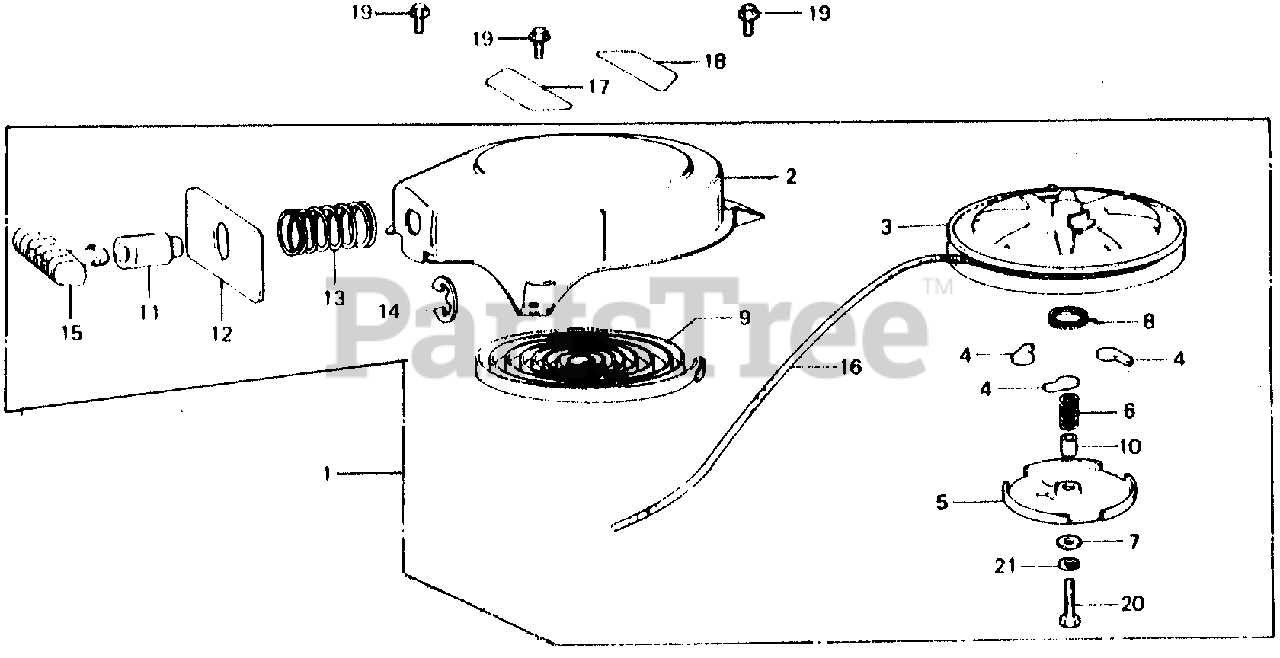

Honda BF75 Parts Overview and Diagram

When working with any mechanical system, knowing the layout of its essential elements can greatly simplify maintenance and repairs. Being familiar with how different units connect and operate together helps to identify issues and ensure efficient operation over time.

In this context, visual representations serve as a critical resource, offering a clear overview of each individual component’s place within the broader system. By understanding these relationships, users can approach tasks with greater confidence and accuracy.

Whether for routine upkeep or more complex repairs, having access to detailed layouts of the internal systems can save time and effort, ensuring that each step in the process is properly executed.

Honda BF75 Parts Diagram Overview

The visual representation of the internal components and systems is essential for understanding how each section of the equipment operates. This schematic layout allows users to identify individual elements and comprehend their relationship within the larger structure, facilitating maintenance and repair efforts.

Component Breakdown

Each segment of the machinery is displayed in a clear and structured way, offering a comprehensive look at the key units. Users can easily follow the connections between various sections, ensuring a smooth process when replacing or servicing specific elements.

Efficient Maintenance Guide

By using the detailed illustration, identifying specific elements becomes significantly easier, which minimizes the time spent on troubleshooting and helps in ensuring that the correct procedures are followed during repair work. This enhances the overall reliability and longevity of the equipment.

Understanding the Main Engine Components

To keep a marine engine running efficiently, it’s essential to have a clear understanding of its key elements. Each component plays a vital role in the overall performance, ensuring smooth operation and durability. Familiarizing yourself with these elements allows for better maintenance and troubleshooting when needed.

Cylinder Block: This is the foundation of the engine, housing critical elements that contribute to the power generation process. It’s designed to endure high pressure and heat, providing structural support.

Pistons and Crankshaft: These components convert fuel into motion. The pistons move within the cylinder block, while the crankshaft transforms their vertical motion into rotational energy, which powers the engine.

Cooling System: To prevent overheating, the cooling system ensures that the engine maintains optimal temperature during operation. This system uses water or air to dissipate heat, keeping everything within safe limits.

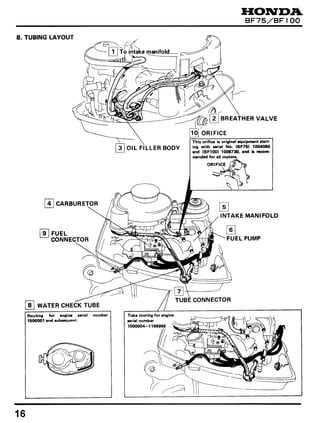

Fuel and Air Intake: For combustion to occur, the engine requires a balanced mix of fuel and air. The intake system delivers these elements into the

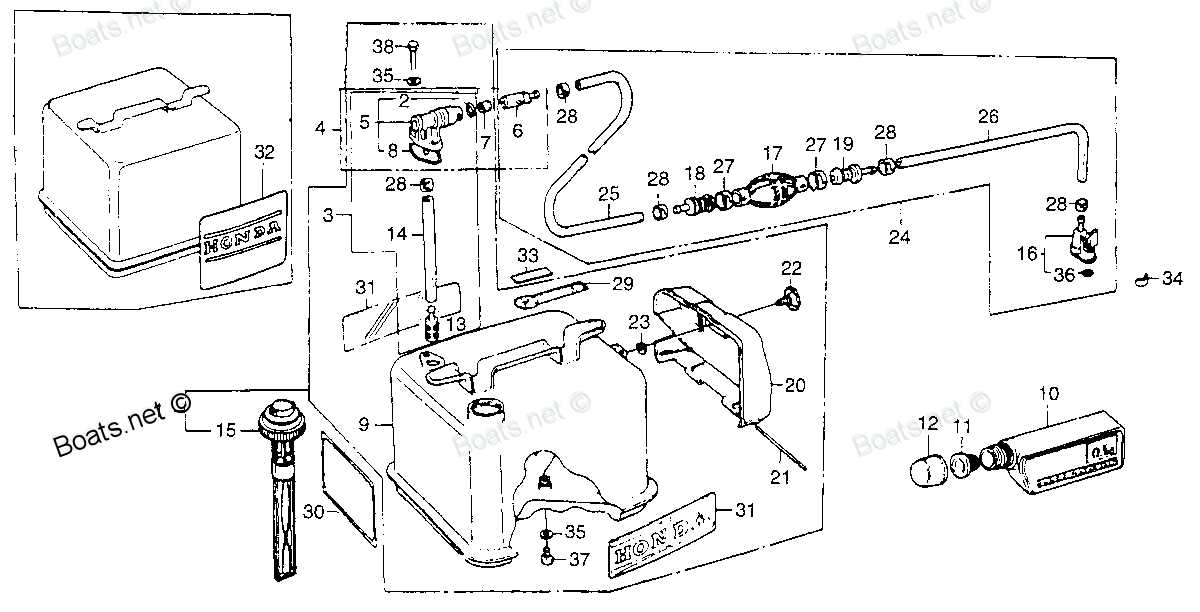

Exploring the Fuel System Layout

The fuel system is a critical component in ensuring smooth and efficient engine operation. Understanding its structure and how the different elements work together is essential for maintaining optimal performance. This section will cover the primary components of the system and their functions, offering insights into how each part contributes to fuel delivery and combustion.

Main Components

The fuel system consists of various interconnected elements designed to store, filter, and deliver fuel to the engine. These include the tank, filters, lines, and pumps. Together, they ensure the engine receives a steady and clean supply of fuel, preventing potential issues such as clogging or air intake interruptions.

Fuel Flow Path

Fuel travels through a series of channels, beginning from the storage tank and passing through several filters and pumps before reaching the engine. Each stage is crucial for removing contaminants and maintaining proper pressure, ensuring efficient combustion and engine performance.

| Component |

Cooling System Structure and PartsThe cooling system ensures that the engine operates at an optimal temperature by circulating coolant through key areas. Proper temperature regulation prevents overheating and enhances overall performance, maintaining a stable engine environment. Key components include the water pump, which drives the coolant flow, and the thermostat, responsible for adjusting the coolant circulation based on engine temperature. Additionally, passages within the engine and an external radiator facilitate heat exchange, ensuring the removal of excess heat. Effective operation of the cooling system is crucial for prolonging engine life and preventing potential malfunctions due to thermal stress. Regular checks and maintenance of this system contribute to efficient engine performance. Electrical Wiring and Key Connections

Understanding the electrical layout and vital connections is essential for maintaining functionality and ensuring that all systems operate smoothly. Properly installed wiring can help prevent common issues and ensure long-term reliability. Wiring OverviewThe wiring setup consists of several core elements that link together the main electrical components. It’s important to keep these connections secure to avoid interruptions in electrical flow. Whether you’re connecting the ignition, lighting, or control systems, attention to detail ensures a seamless power supply throughout. Main Connections

Key connections within the wiring system are the lifelines that provide power and communication between different modules. Proper attachment of these connectors is crucial to maintaining signal integrity and power distribution.

|

|---|