Complete Guide to Honda CR250 Parts Diagram

For enthusiasts and mechanics alike, comprehending the intricate assembly of a two-wheeled machine is crucial. This knowledge not only aids in effective maintenance but also enhances performance. A clear representation of the various elements and their interconnections provides a valuable resource for anyone looking to dive deeper into the mechanics of their vehicle.

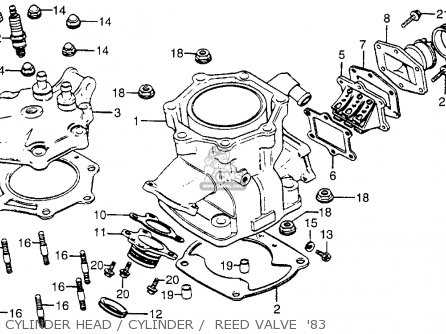

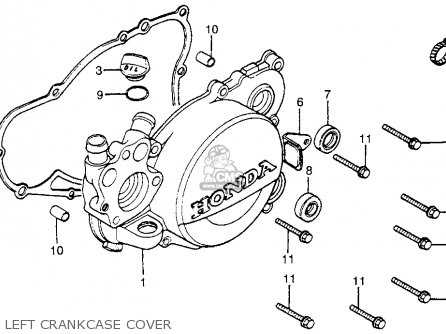

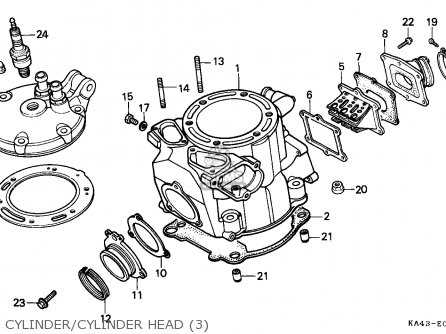

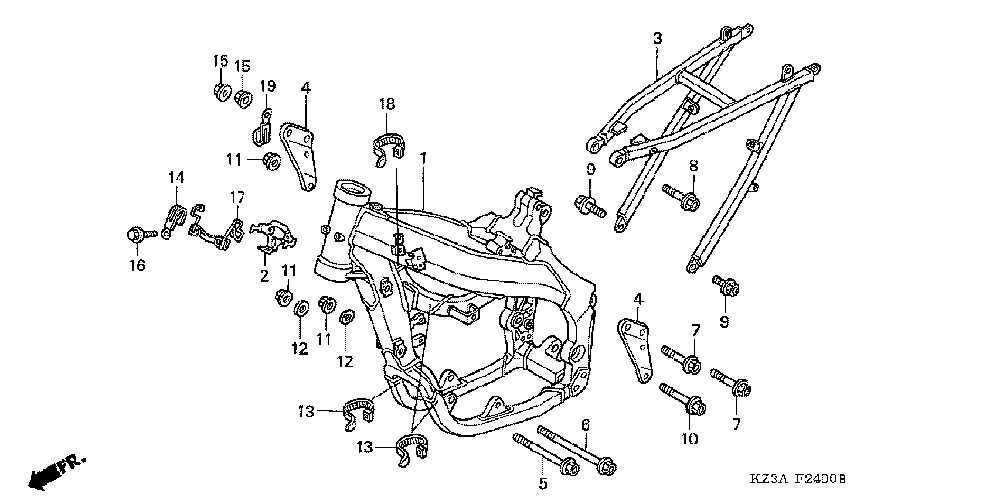

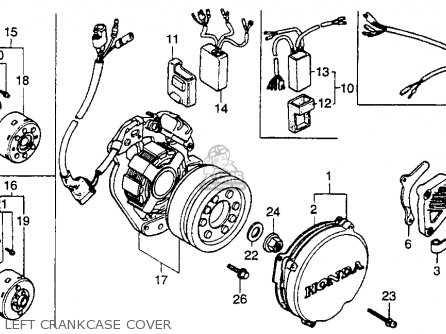

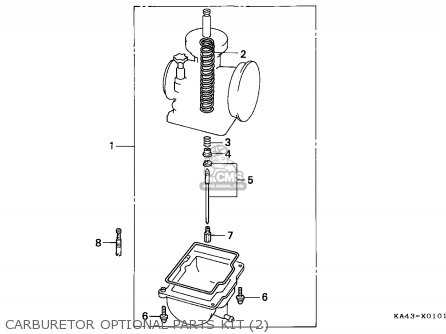

Detailed illustrations serve as a roadmap, guiding users through the complex architecture of their beloved machines. Each section of the schematic reveals the positioning and function of critical components, making it easier to identify and resolve issues. Such visuals empower users to tackle repairs and upgrades with confidence, fostering a deeper connection with their ride.

Furthermore, understanding the layout contributes to a safer riding experience. When riders are familiar with how each part contributes to the overall functionality, they can make informed decisions regarding upgrades and modifications. This approach not only enhances the longevity of the vehicle but also enriches the overall riding experience.

Understanding the Honda CR250

This section delves into the intricate aspects of a renowned motocross machine, focusing on its components and functionality. By exploring the essential elements, enthusiasts can gain a deeper appreciation for its engineering and performance capabilities.

Key features of this iconic motorcycle include:

- Engine performance

- Suspension characteristics

- Weight distribution

- Handling and maneuverability

When examining the performance, it is crucial to consider:

- The power output and how it influences acceleration.

- The responsiveness of the throttle and its impact on rideability.

- The role of the exhaust system in enhancing efficiency.

Additionally, understanding the suspension setup is vital for off-road riding:

- Type of forks and their travel specifications.

- Rear shock design and adjustability features.

- How suspension affects stability and comfort on rough terrain.

Ultimately, a comprehensive grasp of these elements not only improves maintenance knowledge but also enhances the overall riding experience. Whether for competitive racing or recreational use, knowing the intricacies contributes significantly to the mastery of this exceptional two-wheeled vehicle.

Key Components of the CR250

The intricate design of a high-performance motocross machine relies on several essential elements that work harmoniously to deliver exceptional functionality. Each component plays a vital role in enhancing the overall riding experience and ensuring optimal performance on various terrains.

Engine: The heart of any motocross bike, the power unit is engineered for maximum output and efficiency. It features advanced technologies that enhance torque and horsepower, allowing for rapid acceleration and smooth operation.

Suspension: This system is crucial for absorbing shocks and maintaining stability during jumps and rough patches. A well-tuned setup ensures better control and comfort, significantly affecting the rider’s performance and confidence.

Frame: The structural foundation of the machine, the chassis provides the necessary strength and rigidity while remaining lightweight. Its design influences handling, balance, and agility, making it an essential aspect for competitive riders.

Brakes: Safety and control are paramount, and a reliable braking system is key. High-quality components offer responsive stopping power, crucial for navigating tight corners and steep descents.

Wheels and Tires: These elements are pivotal in determining traction and stability. A carefully selected combination enhances grip and maneuverability, allowing riders to tackle diverse terrains effectively.

Understanding these fundamental parts not only aids in maintenance but also empowers enthusiasts to make informed decisions regarding upgrades and modifications, ultimately enhancing the riding experience.

Importance of a Parts Diagram

A visual representation of components plays a crucial role in understanding and maintaining machinery. It provides clarity and aids in identifying each element, making the repair and assembly process much smoother.

Such a visual tool offers several advantages:

- Enhanced Understanding: It allows users to grasp the overall structure and function of various parts.

- Streamlined Repairs: With a clear reference, locating specific items becomes easier, saving time during maintenance.

- Accurate Replacements: Identifying the right components for replacement helps avoid errors and ensures proper functioning.

- Efficient Communication: It facilitates better dialogue among technicians, ensuring everyone is on the same page regarding repairs.

In summary, having a detailed visual reference is indispensable for effective maintenance and repair work, leading to better performance and longevity of the equipment.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. These visual guides simplify the identification of various elements and their relationships, making it easier to grasp the assembly’s structure and functionality. By familiarizing yourself with these illustrations, you can enhance your repair skills and ensure more efficient project completion.

Familiarizing Yourself with Symbols

Before delving into the specifics, it’s crucial to recognize the common symbols and notations used in these illustrations. Each symbol corresponds to a particular component, and knowing what each one represents can save you time and effort. Here are some typical symbols you may encounter:

- Circles: Often indicate connection points or mounting locations.

- Lines: Represent the physical connections between components.

- Shaded Areas: May denote parts that are not visible or require special attention.

Following the Numerical Sequence

Most illustrations will include a numerical sequence that guides you through the assembly process. Understanding this sequence is vital for proper reassembly. To effectively follow the numbers:

- Start from the lowest number, which usually represents the first component to be installed.

- Proceed in order, paying close attention to any notes regarding orientation or specific tools needed.

- Verify your work by cross-referencing each step with the corresponding illustration.

By mastering these two essential aspects, you’ll be better equipped to interpret and utilize these valuable resources in your repair endeavors.

Common CR250 Maintenance Parts

Regular upkeep is essential for optimal performance and longevity of any off-road machine. Understanding key components that require periodic inspection and replacement can greatly enhance the riding experience. Below are some frequently needed items that contribute to maintaining peak efficiency and safety.

Essential Components

- Air Filter

- Fuel Filter

- Oil Filter

- Brake Pads

- Chain and Sprockets

Fluids and Lubricants

- Engine Oil

- Transmission Fluid

- Coolant

- Brake Fluid

Ensuring that these components are in good condition is vital for a smooth and reliable ride. Regular checks and timely replacements will lead to a more enjoyable and trouble-free experience on the trails.

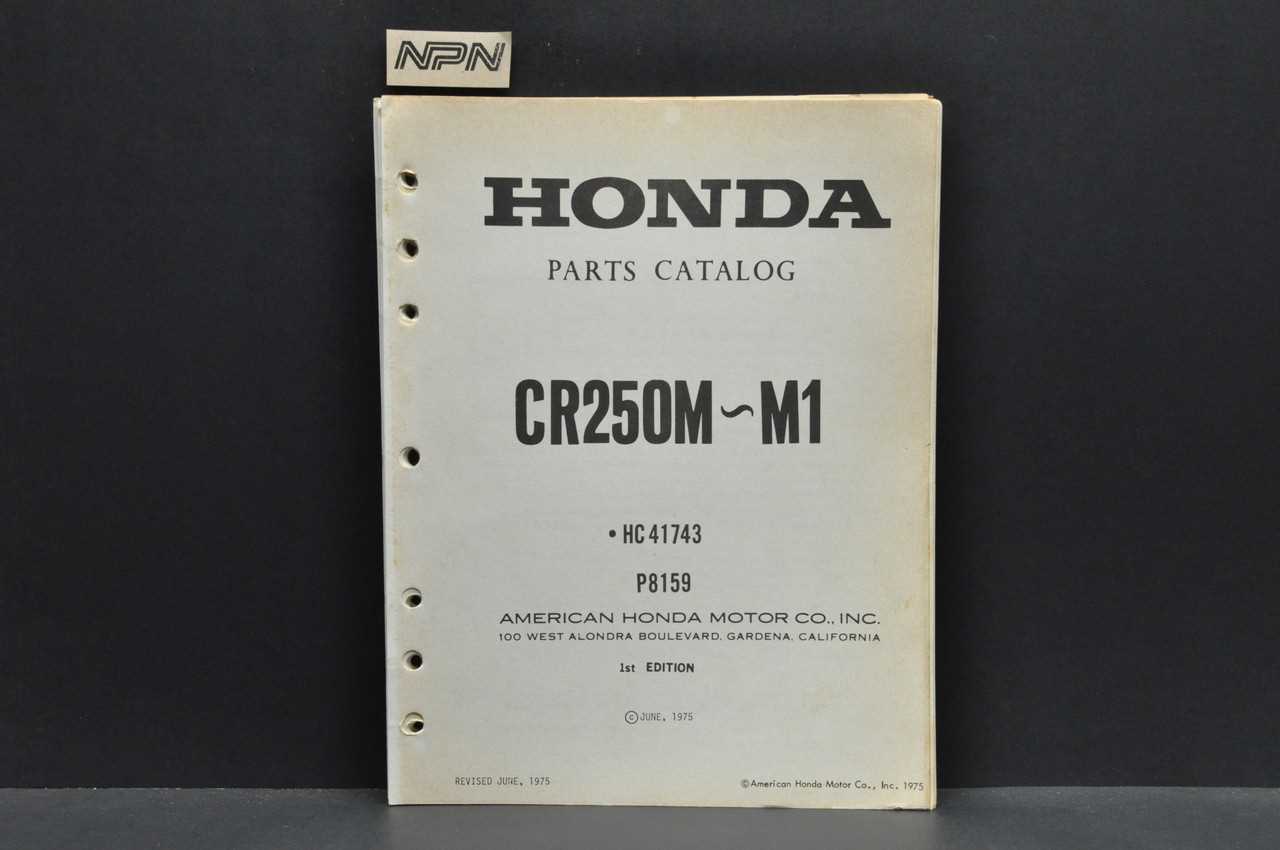

Where to Find OEM Parts

Locating genuine components for your vehicle can significantly enhance its performance and longevity. Authentic replacements ensure compatibility and reliability, making them a preferred choice for enthusiasts and everyday riders alike.

One of the best resources for sourcing these original items is through authorized dealers. These establishments often maintain a comprehensive inventory and can provide expert guidance on the appropriate selection for your specific model.

Online platforms also serve as valuable tools for finding authentic replacements. Websites dedicated to motorcycle accessories frequently list original components and may offer competitive pricing. It is essential, however, to verify the seller’s reputation and confirm that the items are indeed genuine.

Another excellent avenue is manufacturer catalogs. Many brands provide downloadable versions or printed brochures detailing their products, allowing you to identify and order the exact components you need.

Finally, connecting with local riding communities or forums can yield insights and recommendations for reputable sources. Members often share their experiences and may point you to trustworthy suppliers or even second-hand options that are still in great condition.

Aftermarket vs. OEM Components

The choice between aftermarket and original manufacturer components is a crucial consideration for enthusiasts and owners looking to maintain or enhance their vehicles. Each option carries its own advantages and drawbacks, influencing performance, reliability, and cost. Understanding these differences is essential for making informed decisions that align with individual needs and preferences.

OEM components are produced by the original manufacturer and are designed to meet the specific standards and specifications of the vehicle. This often ensures a precise fit and reliable performance. Using these parts can provide peace of mind, as they typically come with a warranty and are tested for quality and durability. However, this assurance often comes at a higher price point.

On the other hand, aftermarket components are created by third-party manufacturers and can offer a wider range of choices. These parts may be more affordable and can sometimes enhance performance beyond factory specifications. Nevertheless, the quality and compatibility of aftermarket options can vary significantly, leading to potential risks regarding fit and longevity. It’s crucial for buyers to research and choose reputable brands to mitigate these concerns.

Ultimately, the decision between these two types of components hinges on personal priorities–whether one values cost-effectiveness, performance enhancements, or the reliability of original parts. Careful consideration of these factors will lead to better outcomes in vehicle maintenance and upgrades.

DIY Repair Tips for CR250 Owners

Maintaining your two-wheeled companion can be both rewarding and challenging. Whether you’re tackling routine upkeep or addressing specific issues, having the right approach can make all the difference. Here are some practical suggestions to help you effectively manage repairs on your machine.

- Gather the Right Tools: Ensure you have essential tools on hand, such as wrenches, screwdrivers, and a torque wrench. A well-equipped toolbox can save you time and frustration.

- Consult the Manual: Always refer to the owner’s manual for specifications and instructions. This resource is invaluable for understanding your machine’s components and maintenance schedule.

- Start with the Basics: Before diving into complex repairs, make sure to check the basics, like fluid levels, tire pressure, and air filter condition. Often, minor adjustments can resolve bigger issues.

When it comes to specific repairs, following a methodical approach is essential.

- Identify the Problem: Clearly define the issue before starting any work. Take note of any unusual sounds or performance changes.

- Document Your Work: Keep a repair log, noting what you did and any parts replaced. This record can help track maintenance history and assist with future repairs.

- Test Thoroughly: After completing repairs, take the time to test your vehicle under various conditions. This step ensures that everything is functioning as intended.

By following these tips, you can enhance your skills and confidence in handling repairs, leading to a smoother and more enjoyable riding experience.

Identifying CR250 Wiring Diagrams

Understanding the electrical layout of a motorcycle is crucial for effective maintenance and repair. Properly identifying the wiring schematics helps enthusiasts and technicians troubleshoot issues, ensuring the bike operates smoothly and safely.

Key Components in Electrical Schematics

When examining wiring schematics, it is important to recognize the main elements involved:

- Battery: Provides the necessary power to the system.

- Ignition Coil: Converts battery voltage to a higher voltage to ignite the fuel.

- Wiring Harness: Connects all electrical components, serving as the communication backbone.

- Switches: Control various functions, such as lights and engine start.

- Relays: Act as electrical switches, managing power distribution.

Steps to Identify Wiring Layouts

To effectively identify and understand electrical layouts, follow these steps:

- Refer to a reliable reference guide or manual specific to your model.

- Familiarize yourself with the color coding used for wires, as it indicates the function and connections.

- Trace the wiring from each component, ensuring connections are secure and intact.

- Note any anomalies or damage that may affect performance.

- Utilize a multimeter to test continuity and voltage at various points.

By mastering the identification of electrical schematics, you can enhance your skills in motorcycle maintenance, leading to a more enjoyable riding experience.

Popular Upgrades for Performance

Enhancing the capabilities of your two-wheeled machine can significantly improve your riding experience. By focusing on specific components and modifications, riders can unlock greater power, responsiveness, and overall efficiency. This section will explore some of the most sought-after improvements that enthusiasts consider for boosting performance.

Engine Modifications

Upgrading the engine can lead to substantial gains in horsepower and torque. Consider installing a high-performance exhaust system to improve airflow, or upgrade the carburetor for better fuel delivery. Additionally, performance air filters can enhance air intake, ensuring that the engine operates at its best under various conditions.

Suspension Enhancements

A well-tuned suspension is crucial for handling and stability. Upgrading fork springs or rear shocks can provide improved dampening and adjustability, allowing for a smoother ride over rough terrain. Performance linkages may also be installed to optimize geometry, resulting in better cornering and control.

Restoration Projects for Vintage Models

Reviving classic two-wheeled machines is a rewarding endeavor that combines passion with craftsmanship. These projects often require meticulous attention to detail, dedication, and a solid understanding of mechanical principles. Whether you are an experienced restorer or a newcomer, each project offers a unique set of challenges and joys.

Steps to Consider in Restoration

When embarking on a restoration journey, it is essential to follow a structured approach:

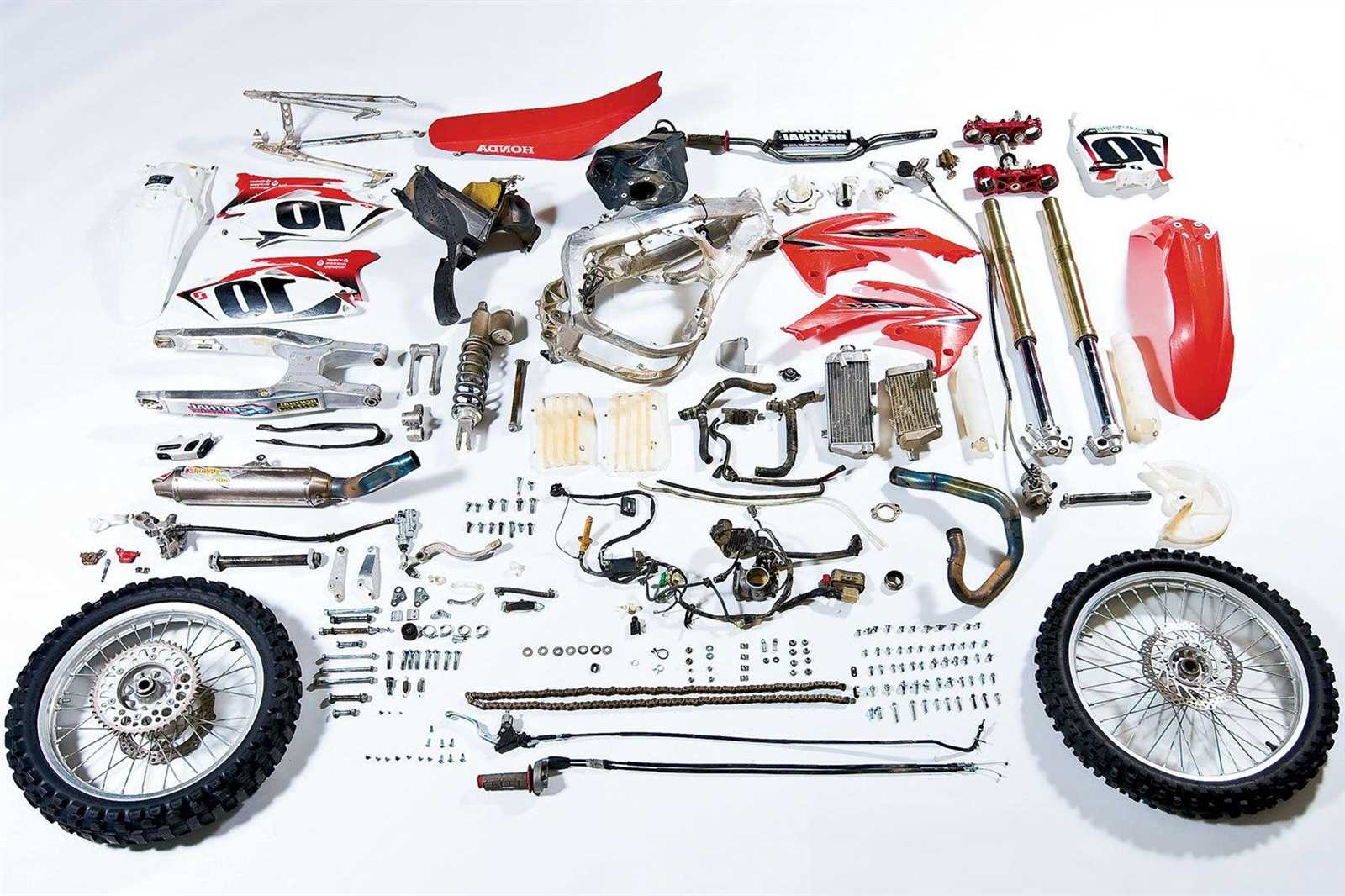

- Assessment: Evaluate the current condition of the vehicle, noting any damage or wear.

- Research: Gather information about the specific model, including historical details and common issues.

- Planning: Create a detailed plan outlining the steps, budget, and timeline for the project.

- Disassembly: Carefully take apart the machine, labeling parts for easy reassembly.

- Restoration: Clean, repair, or replace components as necessary, ensuring authenticity.

- Reassembly: Put everything back together with precision and care.

- Final Touches: Apply finishing touches, such as paint or decals, to restore its original look.

Tips for Successful Restorations

To ensure a smooth restoration process, consider these helpful tips:

- Document the entire process with photos and notes.

- Join forums or local clubs to connect with fellow enthusiasts.

- Invest in quality tools and replacement parts for better results.

- Be patient; restoration can take time and may require trial and error.

- Enjoy the journey and celebrate small victories along the way.

Restoring vintage models not only preserves their legacy but also brings a sense of achievement and fulfillment to the owner. Each project is a labor of love that celebrates the rich history of motorcycling.

Resources for CR250 Enthusiasts

For those passionate about this iconic two-wheeled machine, a wealth of resources is available to enhance your experience and knowledge. Whether you’re looking to maintain your ride or simply deepen your understanding, these tools and communities can provide invaluable support.

- Online Forums: Engage with fellow aficionados, share tips, and seek advice. Popular forums often have dedicated sections for technical discussions and troubleshooting.

- Service Manuals: Access comprehensive guides that detail maintenance procedures, specifications, and troubleshooting tips to keep your machine in peak condition.

- Parts Retailers: Numerous online and local shops specialize in aftermarket and original components, ensuring you can find what you need for repairs or upgrades.

- Video Tutorials: Platforms like YouTube host a plethora of instructional videos that can visually guide you through repairs, upgrades, and modifications.

- Social Media Groups: Join dedicated groups on platforms like Facebook or Instagram to connect with other enthusiasts, share experiences, and participate in events.

- Events and Meetups: Look for local gatherings or competitions that allow you to meet fellow riders and share knowledge in person.

Exploring these resources can greatly enhance your journey with this beloved machine, providing the knowledge and support needed for both seasoned veterans and newcomers alike.

FAQs About CR250 Parts

This section addresses common inquiries regarding components and accessories for a specific motorcycle model. Understanding these elements can enhance performance and maintenance, ensuring a smoother riding experience.

- What are the most common components that need replacement?

- Pistons

- Clutches

- Brake pads

- Where can I find reliable sources for components?

- Authorized dealerships

- Reputable online retailers

- Local motorcycle shops

- How do I know if a component is compatible?

- Check the model specifications

- Consult with experts

- Read customer reviews

- What should I consider when purchasing aftermarket items?

- Quality and durability

- Warranty options

- Performance reviews

- How often should maintenance be performed?

- Follow the manufacturer’s recommendations

- Inspect regularly after rides

- Keep a maintenance log