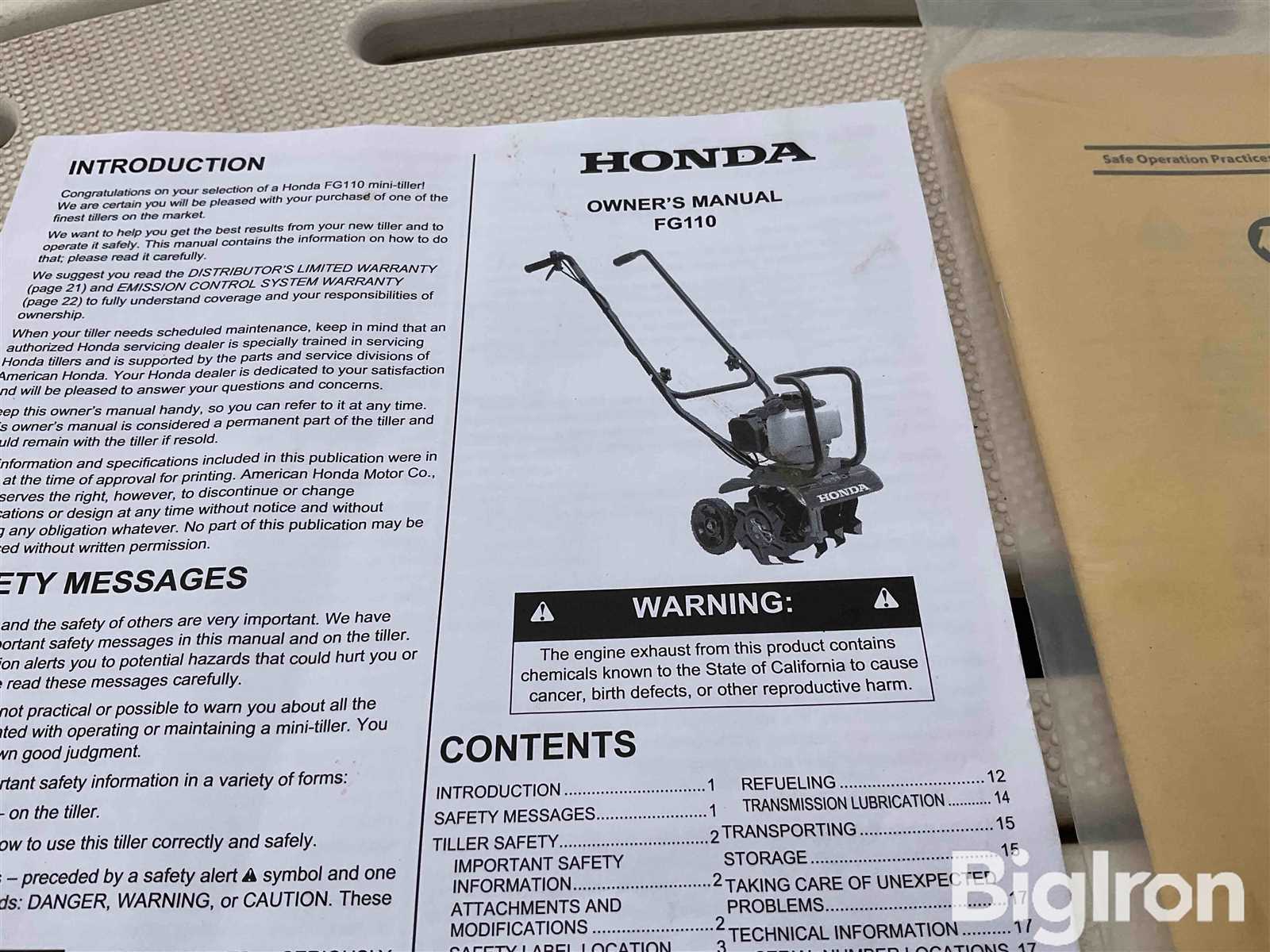

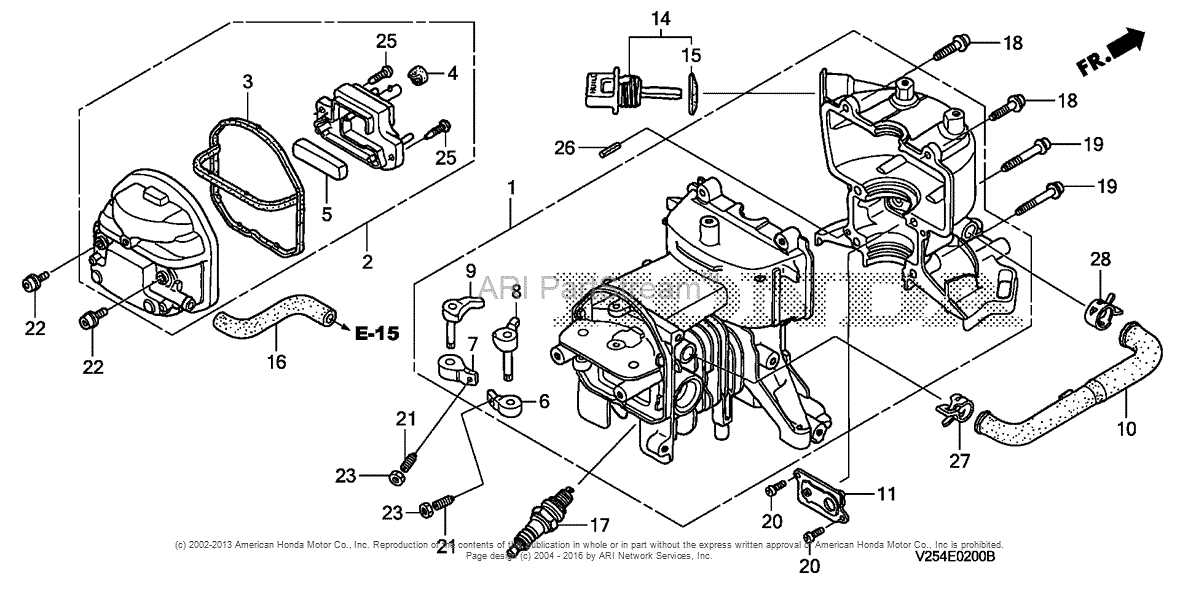

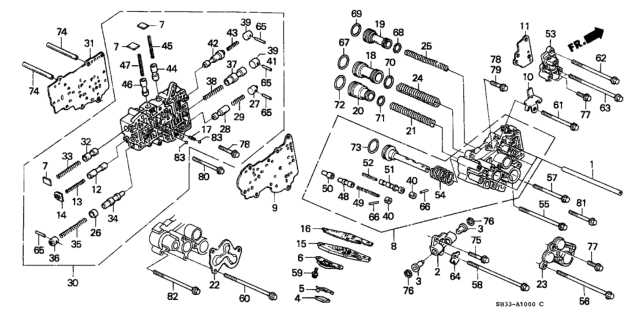

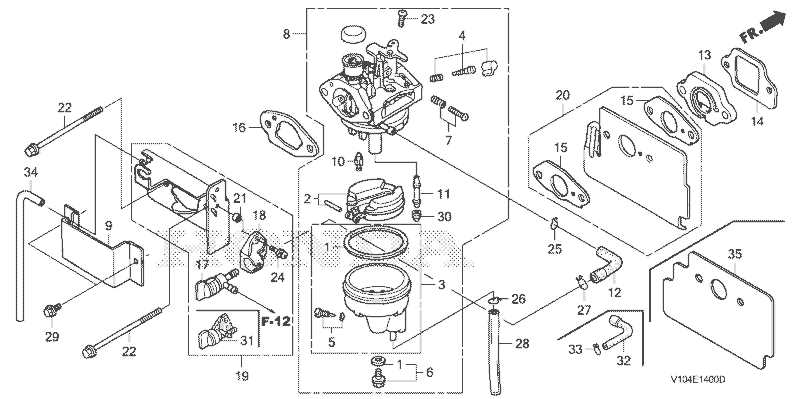

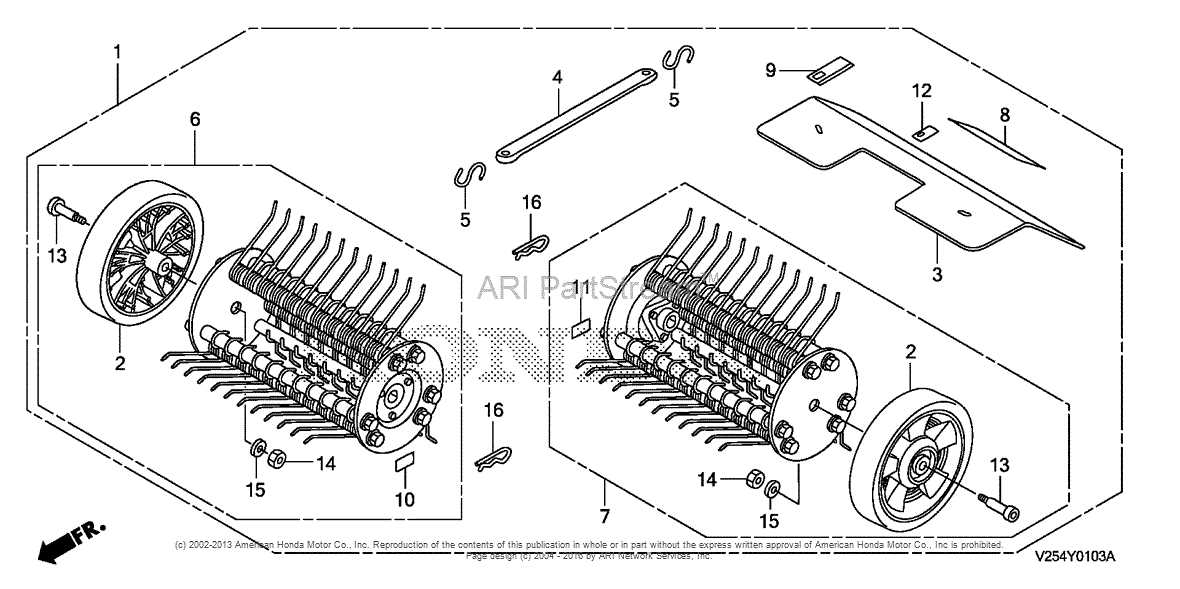

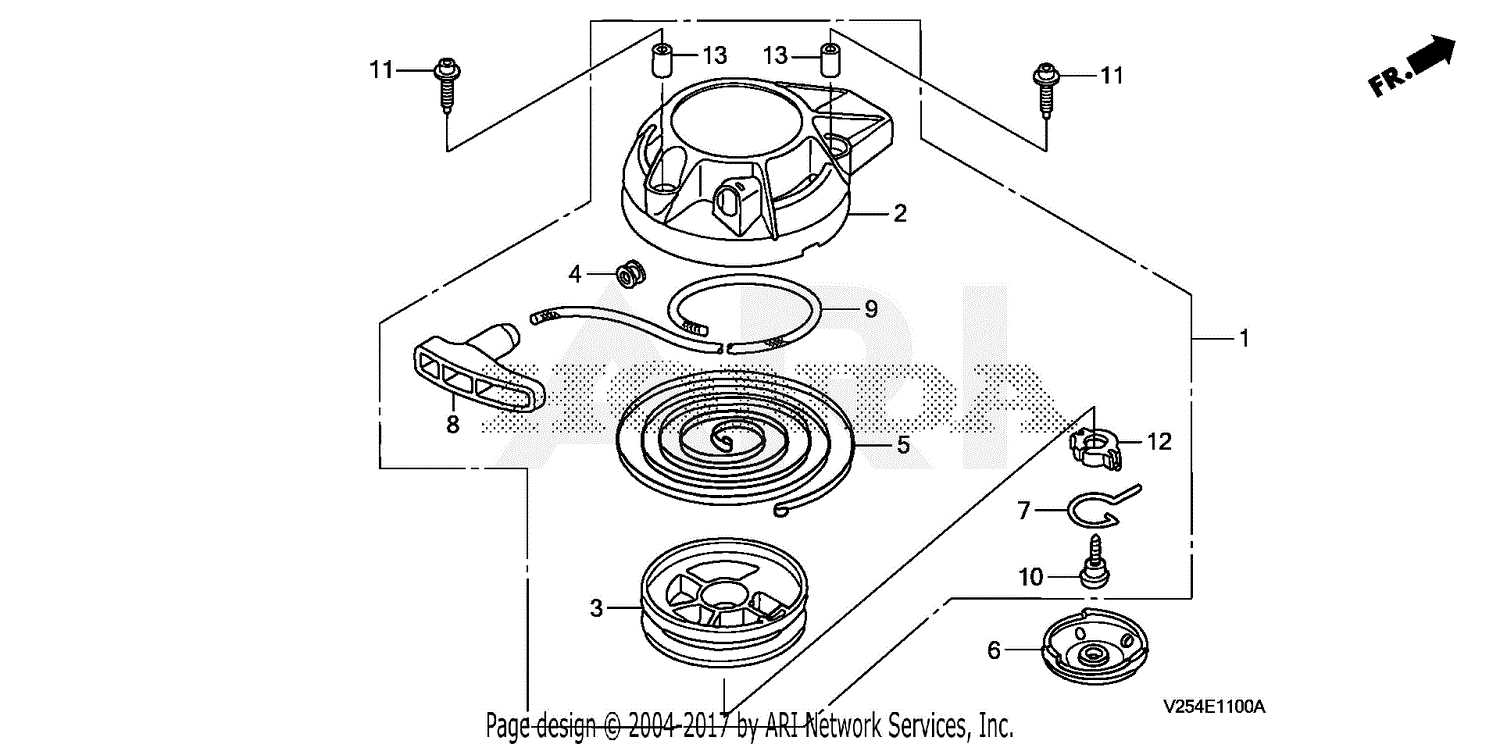

Comprehensive Honda FG110 Parts Diagram for Easy Reference

When it comes to maintaining outdoor machinery, having a clear visual reference for its components is essential. Knowing how different elements interact and fit together can significantly enhance your ability to perform repairs and ensure optimal performance. A comprehensive breakdown of these individual pieces provides insight into their functions and importance in the overall operation.

By familiarizing yourself with the various sections and parts, you empower yourself to tackle maintenance tasks more effectively. This knowledge not only aids in identifying issues but also facilitates the selection of appropriate replacements when needed. Each segment plays a critical role, and understanding their arrangement contributes to the longevity and reliability of your equipment.

Utilizing detailed illustrations and schematics allows you to navigate the complexities of assembly and disassembly with confidence. Whether you’re a seasoned technician or a passionate hobbyist, grasping the layout of these components is invaluable. With this foundation, you can ensure that your machinery runs smoothly and efficiently for years to come.

Understanding the Honda FG110

This section explores a popular model known for its efficiency and versatility in gardening tasks. Its design caters to both novice and experienced users, making it an essential tool for landscaping and soil preparation.

Key Features

The equipment is equipped with a powerful engine, ensuring robust performance. Its lightweight construction enhances maneuverability, allowing for easy handling across various terrains.

Maintenance Tips

Regular upkeep is crucial for optimal functionality. Checking the engine oil, inspecting the blades, and cleaning the air filter can significantly extend the lifespan of this tool. Investing time in maintenance guarantees peak performance and reliability.

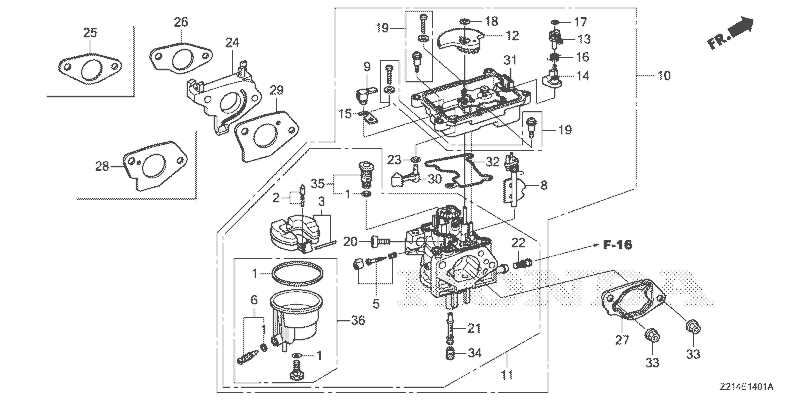

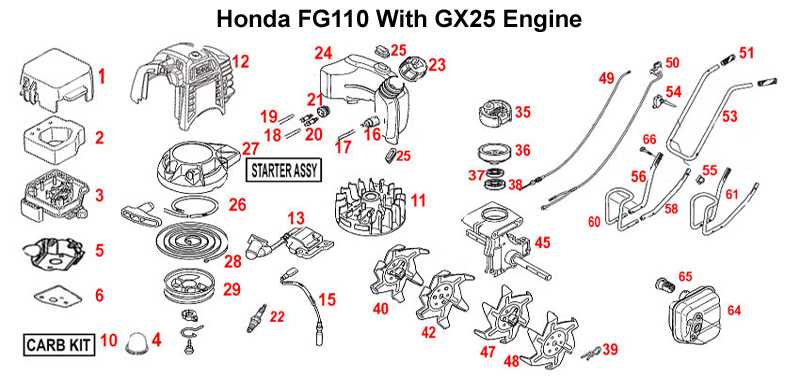

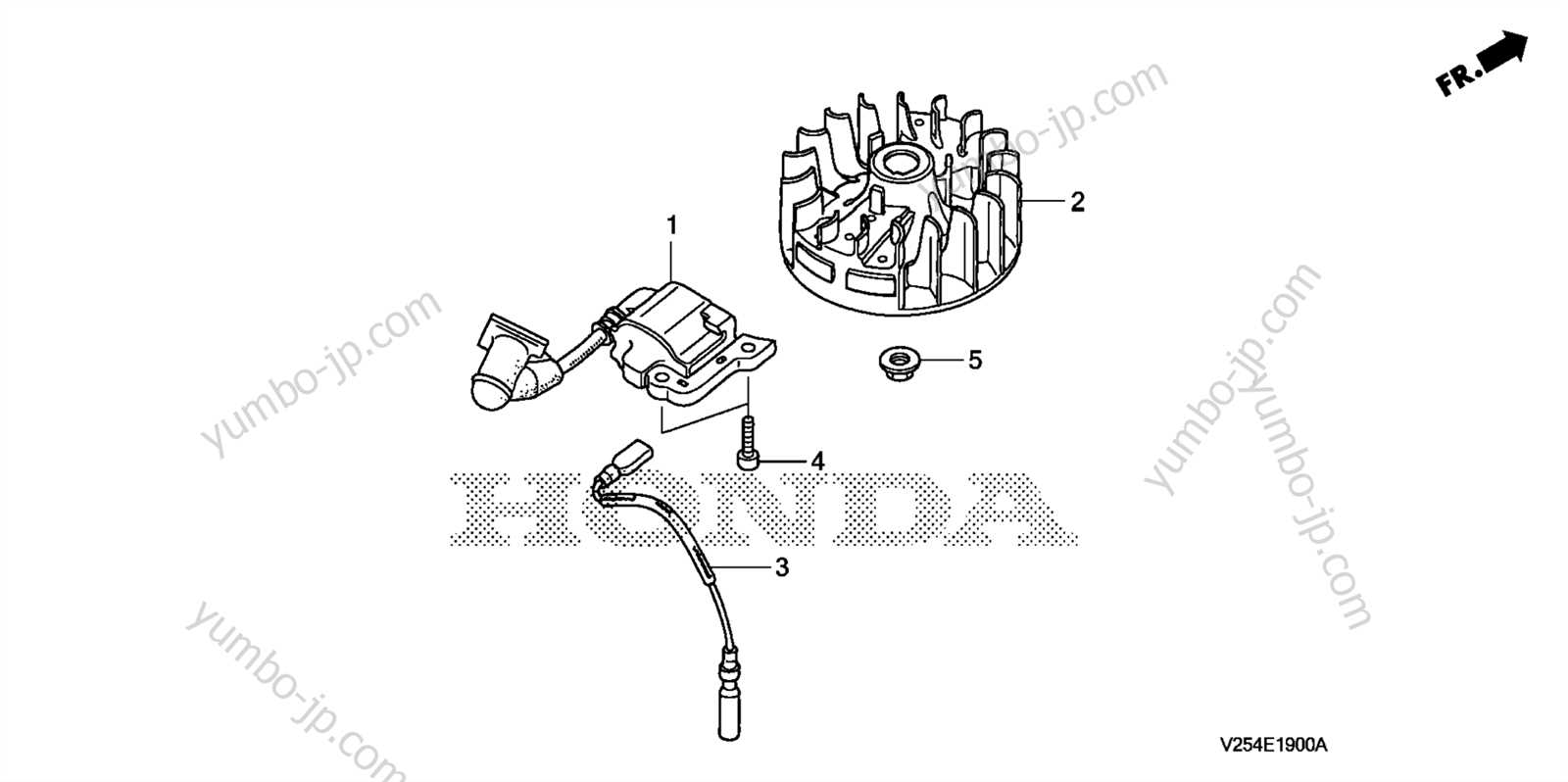

Essential Components of the FG110

The core elements of this equipment play a crucial role in its functionality and efficiency. Understanding these key parts can significantly enhance your maintenance efforts and overall performance. Each component serves a specific purpose, contributing to the machine’s reliability and ease of use.

Common Issues with Honda FG110 Parts

When working with outdoor power equipment, several challenges may arise due to wear and tear or improper maintenance. Understanding these potential problems can help users ensure optimal performance and longevity of their machinery.

Frequent Mechanical Failures

One common issue involves mechanical components that may become worn out over time. This can lead to decreased efficiency and unexpected breakdowns, necessitating timely replacements to maintain functionality.

Fuel System Complications

Another area of concern is the fuel delivery system. Clogs or leaks can result from debris accumulation or degraded materials, leading to poor engine performance. Regular inspection and cleaning are essential to prevent these complications.

How to Access the Parts Diagram

Finding the right visual representation of components can greatly enhance your understanding of machinery. This section will guide you through the process of locating these helpful illustrations, ensuring you have the resources you need for maintenance or repairs.

Steps to Locate the Visual Representation

- Visit the manufacturer’s official website.

- Navigate to the support or resources section.

- Search for the specific model using the search bar.

- Look for sections labeled “manuals” or “illustrations.”

- Download or view the available documents online.

Alternative Resources

- Check online forums dedicated to machinery enthusiasts.

- Explore third-party websites that specialize in maintenance guides.

- Visit local retailers or service centers for printed materials.

Identifying Each Part’s Function

Understanding the role of each component in a machine is crucial for effective maintenance and troubleshooting. By examining the various elements, users can gain insights into how these parts work together to enhance overall performance and efficiency. This knowledge allows for better decision-making when it comes to repairs or upgrades.

Key Components Overview

Every machine is composed of essential elements, each serving a specific purpose. From the engine that powers the unit to the handles that provide user control, recognizing these functions helps in diagnosing issues quickly and accurately.

Importance of Proper Identification

Properly identifying each element not only aids in repairs but also extends the lifespan of the equipment. Regular maintenance can be performed more effectively when users understand how each piece interacts with the others, ultimately leading to optimal functionality.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By implementing a few simple maintenance practices, you can significantly extend the lifespan of your machinery while enhancing its performance. Here are some essential tips to keep your tools in optimal condition.

Regular Cleaning

Keeping your equipment clean is fundamental to its longevity. Dirt and debris can accumulate over time, leading to mechanical issues. After each use, take the time to remove any clogs or residue. Use a soft brush or cloth to gently clean sensitive parts, ensuring that all components function smoothly.

Scheduled Inspections

Performing routine checks is crucial for identifying potential problems before they escalate. Inspect belts, hoses, and connections for wear or damage. Look for signs of rust or corrosion that may indicate deeper issues. Regular inspections can help you catch problems early, saving you time and money in repairs.

By adhering to these maintenance practices, you can ensure that your equipment remains reliable and efficient for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process when you know where to look. Various sources offer a range of options, ensuring you find the right fit for your needs.

- Official Dealerships: Authorized dealers often have a comprehensive inventory of original components, ensuring quality and compatibility.

- Online Retailers: E-commerce platforms provide convenience and a wide selection. Websites specializing in machinery components can be particularly useful.

- Local Repair Shops: Neighborhood mechanics may stock commonly needed items or can order them for you, often providing expert advice in the process.

- Salvage Yards: These places can be treasure troves for finding used items at a fraction of the cost, although quality may vary.

- Manufacturer Websites: Many companies have online catalogs where you can search for specific items and sometimes make purchases directly.

By exploring these avenues, you can efficiently find the necessary components to keep your machinery in top condition.

Upgrading Your Honda FG110

Enhancing your gardening tool can significantly improve its performance and longevity. By focusing on key upgrades, you can transform your equipment into a more efficient and reliable companion for your landscaping tasks.

- Engine Efficiency: Consider replacing the air filter and spark plug to boost power and fuel efficiency.

- Cutting Attachments: Upgrading to sharper blades or alternative attachments can enhance cutting precision and speed.

- Handle Comfort: Adding ergonomic grips can improve handling, reducing fatigue during extended use.

- Wheels and Mobility: Investing in larger or more durable wheels will facilitate smoother navigation over various terrains.

Each enhancement contributes to achieving the ultimate functionality and performance, allowing you to tackle any gardening project with ease.

DIY Repairs Using the Diagram

Engaging in self-repair projects can be a rewarding experience, allowing you to save money while gaining valuable skills. By utilizing a visual reference, you can easily identify components and understand their arrangement, simplifying the repair process. This approach not only empowers you to tackle issues with confidence but also enhances your knowledge of the machinery.

Before starting any repairs, it’s crucial to ensure you have the right tools and a clean workspace. Taking the time to prepare can significantly impact your efficiency and safety. Following a visual guide will help you understand how each element fits together, making it easier to replace or adjust parts as needed.

After identifying the problematic areas, you can carefully disassemble the necessary components. Document your progress with notes or photos to aid reassembly. This methodical approach not only keeps you organized but also prevents confusion later. Once the repairs are complete, always conduct a thorough test to ensure everything functions properly.

Comparing with Other Honda Models

When examining various models from a well-known manufacturer, it’s insightful to highlight their distinctions and similarities. This analysis helps users understand the unique features and performance capabilities across the range, facilitating informed choices tailored to individual needs.

| Model | Engine Power | Weight | Usage |

|---|---|---|---|

| Model A | 4.5 HP | 45 lbs | Residential |

| Model B | 5.0 HP | 50 lbs | Commercial |

| Model C | 4.0 HP | 40 lbs | Light-duty |

| Model D | 6.0 HP | 55 lbs | Heavy-duty |

By assessing these various models, users can identify the ideal option for their specific tasks, whether they are tackling small garden projects or larger, more demanding jobs. Each variant offers distinct attributes that cater to diverse requirements, making them valuable tools for both professionals and hobbyists alike.