Comprehensive Parts Diagram for Honda Generator ES6500

When it comes to ensuring reliable energy supply, a clear comprehension of each integral element is vital. The intricate relationships between these components can significantly affect overall performance and efficiency. By exploring the layout and functions of various sections, users can enhance their understanding and optimize usage.

This article will delve into the specifics of essential components found in a well-designed energy apparatus. Each part plays a crucial role, and knowing how they interact can lead to improved maintenance and troubleshooting. Gaining insight into these features is the ultimate key to achieving seamless operation.

Moreover, familiarizing oneself with these individual elements can empower users to make informed decisions regarding repairs and upgrades. Whether you are a seasoned technician or a novice, this exploration offers valuable knowledge that enhances your practical skills and understanding of energy solutions.

Understanding Honda ES6500 Generators

This section delves into the key features and components of a portable power supply system known for its reliability and efficiency. These machines are essential for providing electrical energy in various settings, from residential to commercial applications.

One of the standout aspects of this model is its robust construction and user-friendly design. Here are some important characteristics:

- Power Output: Capable of delivering substantial energy for multiple devices.

- Fuel Efficiency: Optimized to run longer on less fuel, enhancing operational cost-effectiveness.

- Noise Level: Designed to operate quietly, making it suitable for both indoor and outdoor use.

To ensure optimal performance, understanding the main components is crucial. Key elements include:

- Engine: The heart of the system, providing the necessary mechanical power.

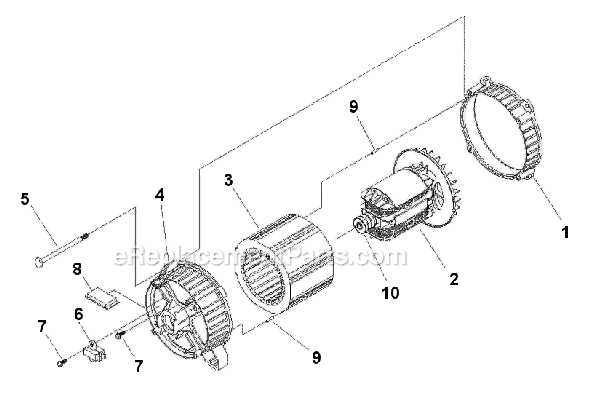

- Alternator: Converts mechanical energy into electrical energy, allowing for the generation of usable power.

- Control Panel: Features various controls and indicators for monitoring operation and adjusting settings.

- Chassis: Provides structural support and houses the internal components, ensuring durability.

Maintaining knowledge of these features and components is essential for maximizing the efficiency and longevity of the equipment.

Essential Components of ES6500

Understanding the key elements of a power-producing unit is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency, reliability, and longevity, making it imperative to be familiar with them.

Engine: The heart of the unit, responsible for converting fuel into mechanical energy.

Fuel System: This includes the tank and lines, which supply fuel to the engine, ensuring it runs smoothly.

Control Panel: The interface where users can manage power output and monitor performance metrics.

Starting Mechanism: Whether electric or recoil, this system is essential for initiating the engine.

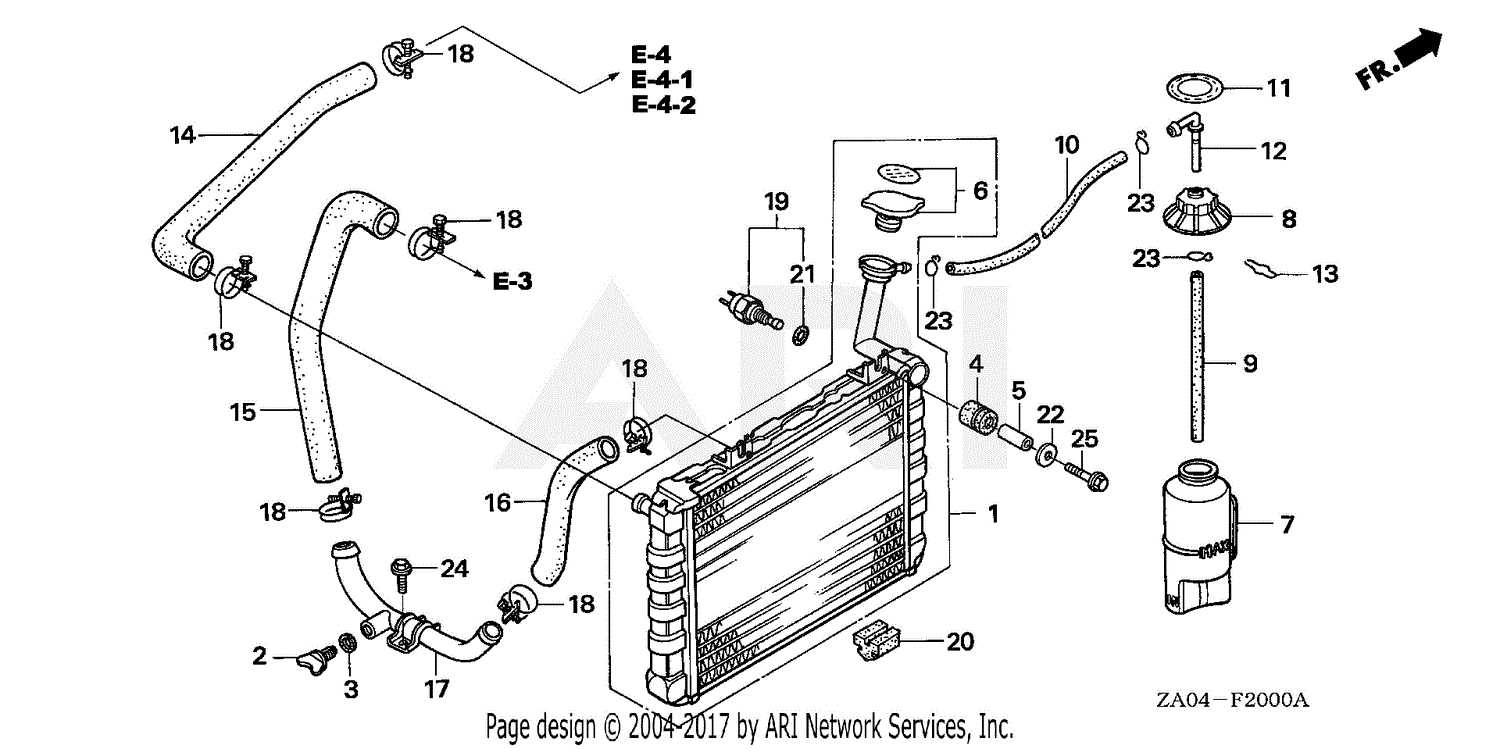

Cooling System: It prevents overheating, maintaining optimal operating temperatures during use.

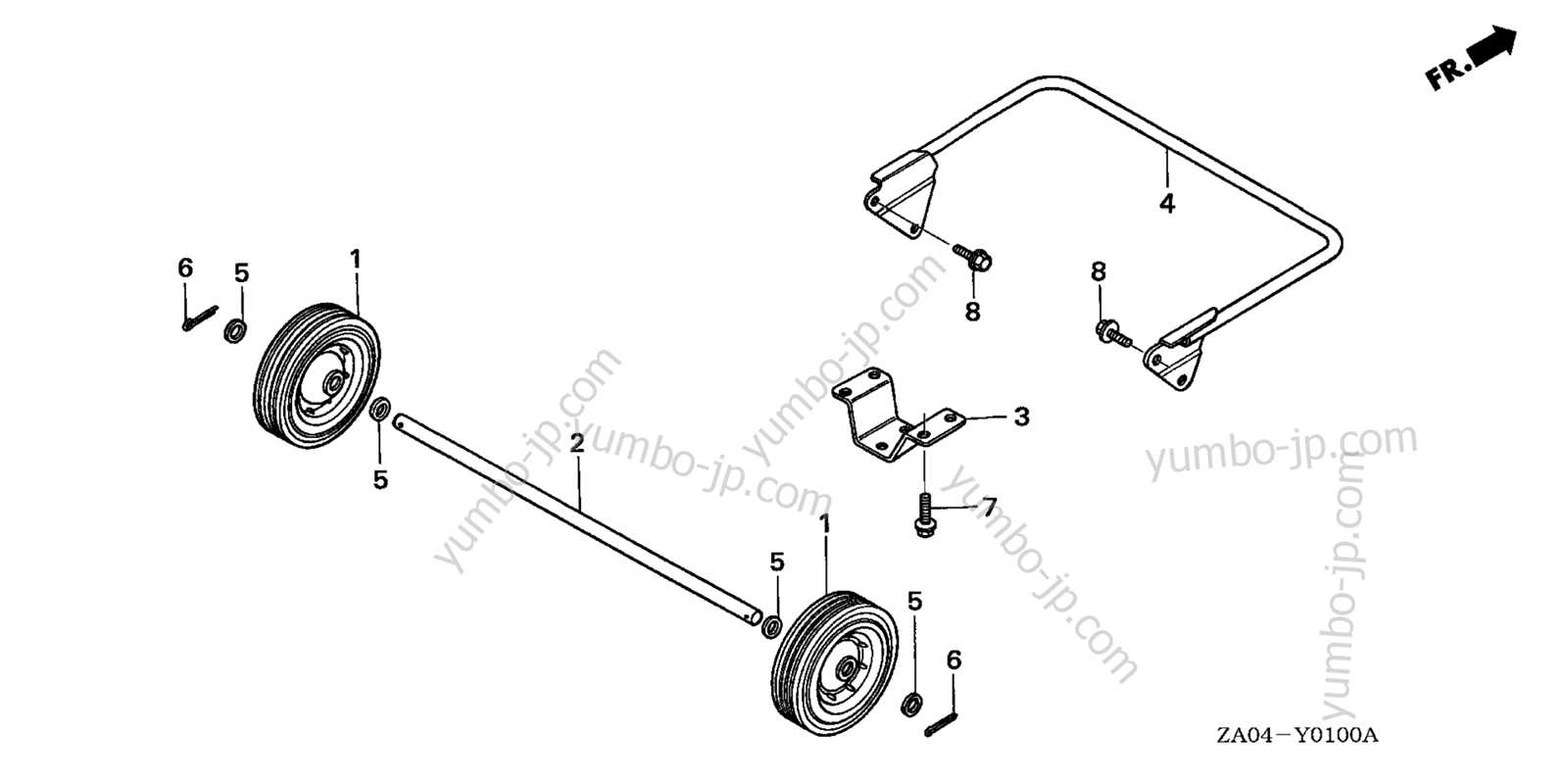

Frame: Provides structural support and stability, often designed for portability.

Exhaust System: This component directs harmful gases away from the engine, contributing to safety and efficiency.

Electrical Components: Includes wiring and fuses, ensuring safe power distribution and circuit protection.

Familiarity with these integral parts allows users to troubleshoot and maintain their equipment effectively, ultimately enhancing its performance.

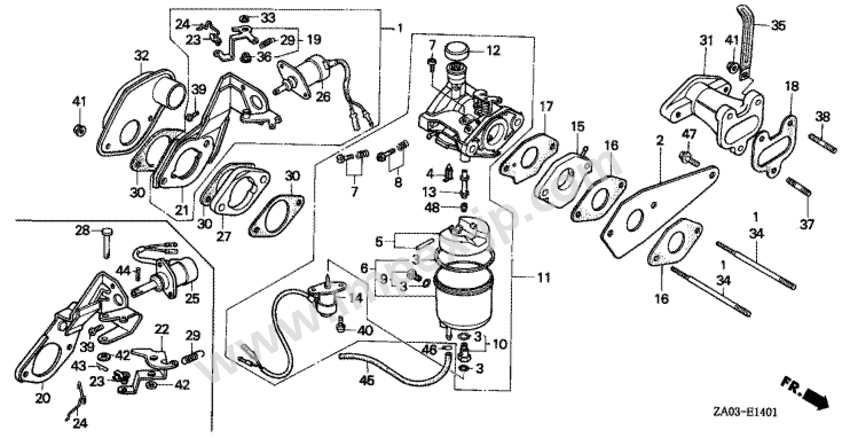

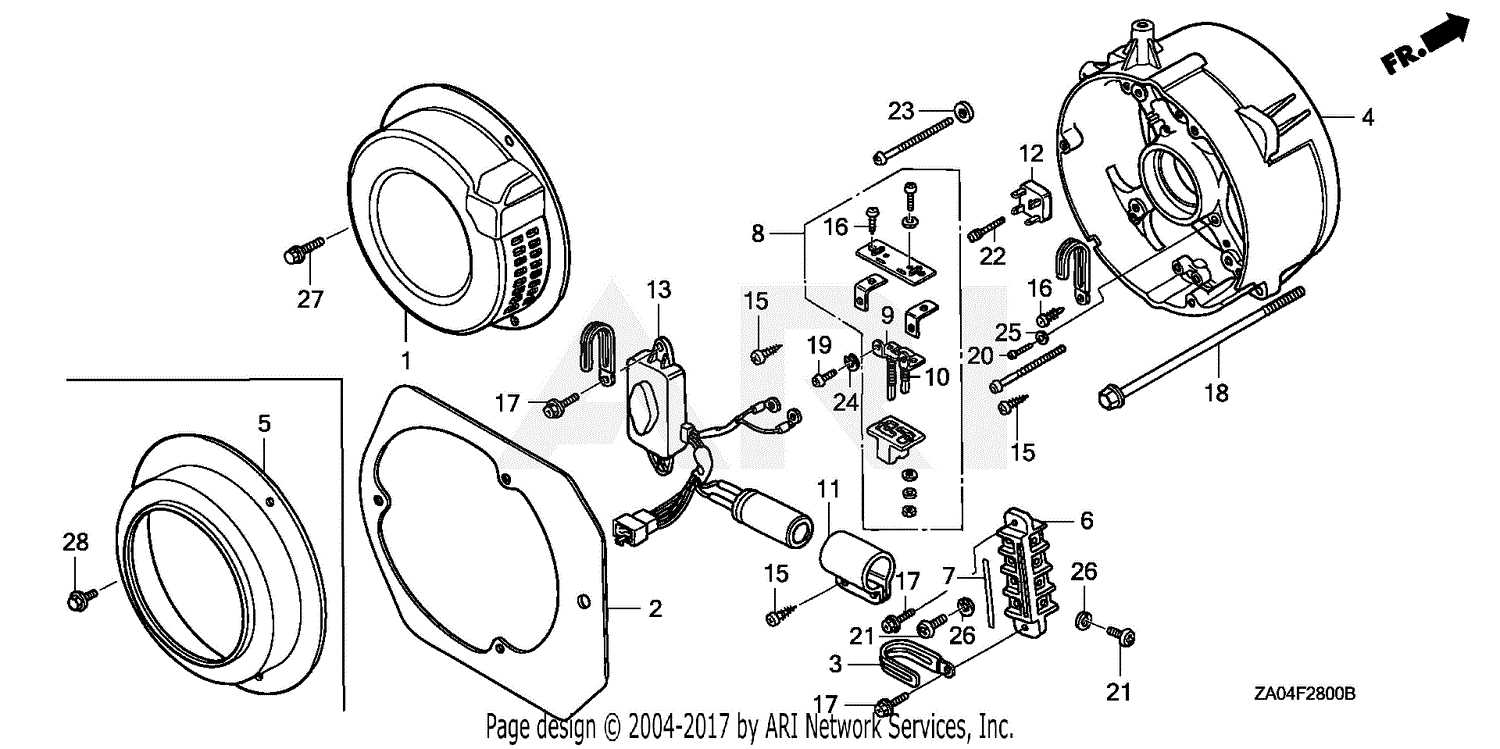

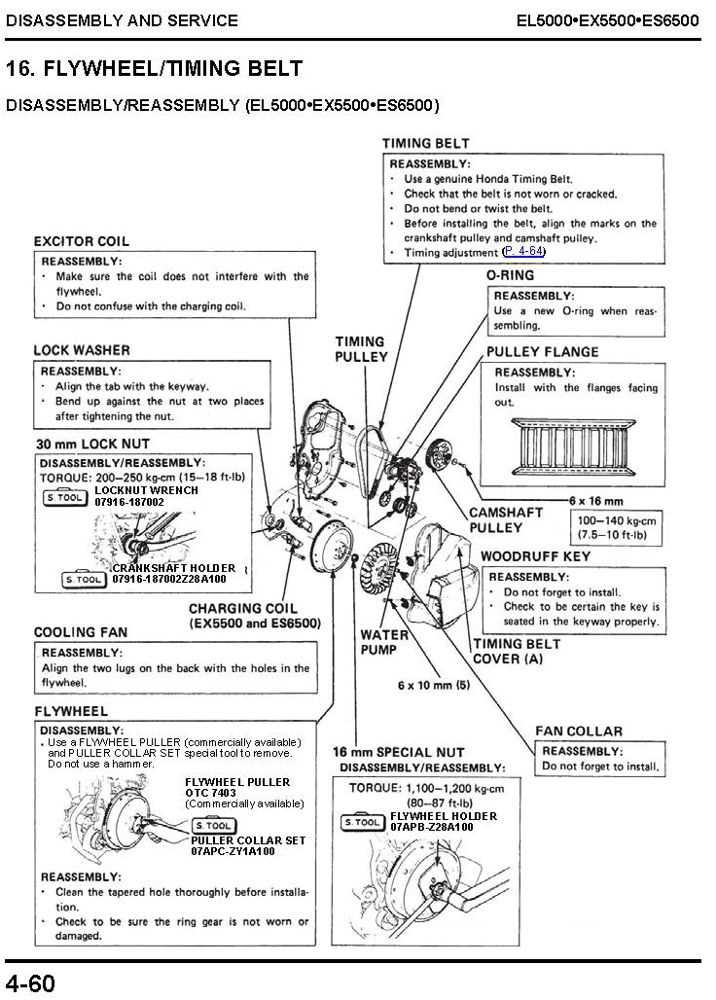

Parts Breakdown for Honda Generators

Understanding the components of portable power units is essential for effective maintenance and repair. Each machine consists of various elements that work together to ensure optimal performance. Familiarity with these parts helps users diagnose issues and enhance the longevity of the equipment.

Engine: The heart of the system, responsible for converting fuel into mechanical energy. Its efficiency greatly influences overall functionality.

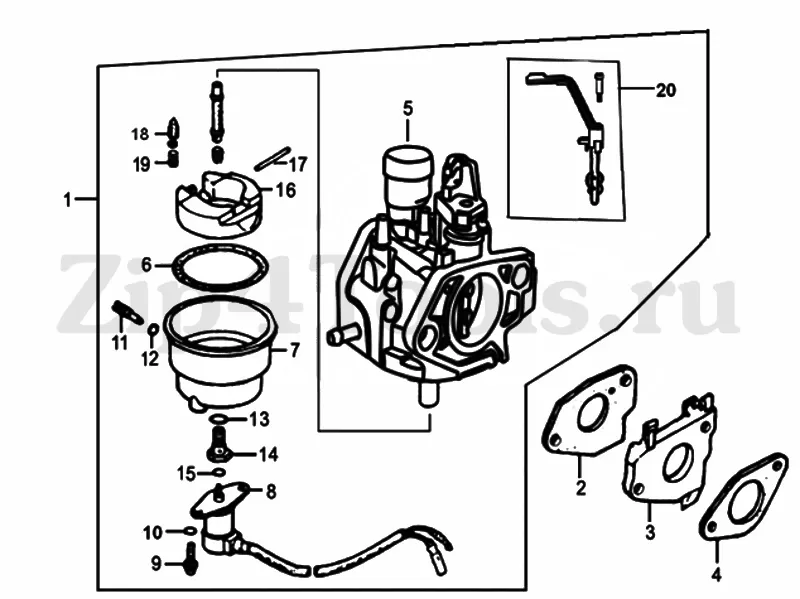

Fuel System: Comprising the tank, lines, and carburetor, this setup manages the delivery of fuel to the engine. Proper maintenance is crucial to avoid blockages and ensure smooth operation.

Electrical System: This includes the alternator and wiring, which convert mechanical energy into electrical power. Understanding this system can assist in troubleshooting electrical failures.

Cooling Mechanism: Essential for preventing overheating, this system often includes fans and vents that maintain optimal operating temperatures during use.

Frame: The structure that houses and protects internal components, ensuring stability and portability. A robust frame is vital for the durability of the entire unit.

By gaining insight into these key components, users can enhance their ability to maintain and troubleshoot their machines effectively.

Maintenance Tips for ES6500 Parts

Regular upkeep is essential to ensure optimal performance and longevity of your equipment. A proactive approach to care can prevent common issues and enhance efficiency. Understanding the key components and how to maintain them will lead to a smoother operation and fewer breakdowns.

Start by inspecting filters regularly, as clean filters promote better airflow and efficiency. Replace them as needed to maintain optimal functioning. Additionally, checking and changing the oil is crucial; fresh oil reduces wear and keeps the internal parts lubricated.

Don’t overlook the importance of the battery. Ensure it’s clean and fully charged to avoid starting issues. Tightening any loose connections will help maintain a stable power supply.

Lastly, periodic examination of belts and hoses can prevent unexpected failures. Look for any signs of wear or damage, and replace them promptly to keep everything running smoothly.

Common Issues with Honda Generators

Many portable power sources face a variety of challenges that can affect their performance and reliability. Understanding these issues can help users maintain their equipment effectively and avoid downtime.

Fuel Problems: One of the most prevalent issues is related to fuel quality. Stale or contaminated fuel can lead to hard starting or stalling.

Electrical Failures: Users often encounter electrical malfunctions, such as blown fuses or damaged circuits, which can disrupt power delivery and require troubleshooting.

Noise and Vibration: Excessive noise and vibration can be indicative of mechanical wear or improper setup, which can affect user experience and overall efficiency.

Overheating: If airflow is obstructed or the unit is overloaded, overheating can occur, potentially leading to permanent damage.

Maintenance Neglect: Regular maintenance is crucial. Neglecting routine checks and servicing can result in various performance issues over time.

How to Identify ES6500 Parts

Recognizing the individual components of a specific model can be crucial for maintenance and repair tasks. By understanding the layout and function of each element, users can ensure optimal performance and longevity. This section will guide you through effective methods to pinpoint essential elements of your machine.

Begin with the manual: Always refer to the user manual, as it typically contains detailed illustrations and descriptions of each component. This resource is invaluable for both novice and experienced users alike.

Use online resources: Numerous websites offer visual aids and breakdowns of various models. Searching for labeled images can provide a clear view of what you need to identify.

Examine physical characteristics: Pay attention to the size, shape, and color of each element. These attributes can help distinguish between similar-looking components.

Seek community support: Engaging with online forums or local groups can yield helpful insights. Experienced users often share their knowledge and can assist in identifying tricky components.

Label components: If you are disassembling your machine for maintenance, consider labeling each part as you go. This practice will simplify the reassembly process and help in recognizing parts in the future.

By following these steps, you will enhance your ability to identify crucial components, ultimately improving your experience and maintenance efficiency.

Ordering Replacement Parts Easily

When it comes to maintaining your equipment, acquiring the right components can make all the difference. Whether you’re facing wear and tear or simply seeking to upgrade, ensuring that you have access to the correct pieces is essential for optimal performance.

Finding the Right Source

Start by identifying reliable suppliers who specialize in your specific equipment. Look for online retailers or local stores that offer comprehensive catalogs and customer support to assist you in locating the ideal replacements.

Using Diagrams for Clarity

Consulting detailed schematics can significantly simplify the ordering process. These visual aids allow you to pinpoint the exact components you need, ensuring accuracy and preventing potential errors in your selections.

Tools Needed for ES6500 Repairs

To effectively perform maintenance and repairs on your equipment, it’s essential to have the right tools at your disposal. A well-equipped toolkit not only ensures efficiency but also enhances safety during the repair process. Here’s a comprehensive list of essential instruments that can aid in your repair tasks.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle nose and regular)

- Hammer

Specialized Tools

- Multimeter (for electrical diagnostics)

- Torque wrench

- Fuel line clamp

- Oil filter wrench

- Diagnostic software (if applicable)

Having these tools ready will enable you to tackle various issues effectively and keep your machinery running smoothly.

Upgrading Honda Generator Components

Enhancing the efficiency and performance of your power equipment can significantly extend its lifespan and improve functionality. This section explores various methods to elevate key elements, ensuring optimal operation and reliability. By focusing on quality enhancements and replacements, users can experience a noticeable difference in performance.

One essential area to consider is the fuel system. Upgrading components like the carburetor or fuel filter can lead to improved fuel efficiency and smoother operation. Additionally, investing in high-quality spark plugs can enhance ignition reliability, ultimately contributing to better performance.

Moreover, evaluating the electrical system is crucial. Replacing old wiring with more durable options can reduce the risk of failures and ensure a consistent power supply. Upgrading the battery to a higher capacity version can also yield better performance during peak demands.

Finally, don’t overlook the cooling and exhaust systems. Improved cooling fans or exhaust systems can enhance airflow and reduce overheating, leading to prolonged equipment life. By making these strategic upgrades, users can achieve the ultimate functionality and longevity of their machinery.

Safety Precautions During Maintenance

Proper upkeep of equipment is essential for optimal performance and longevity. However, it is crucial to prioritize safety throughout the maintenance process. By adhering to specific precautions, users can minimize the risk of accidents and injuries.

Here are key safety measures to consider:

- Always turn off the machine and disconnect it from the power source before beginning any maintenance tasks.

- Use appropriate personal protective equipment (PPE), such as gloves, goggles, and hearing protection.

- Ensure the work area is well-ventilated to avoid the accumulation of harmful fumes.

Furthermore, following these guidelines can enhance safety:

- Consult the user manual for specific maintenance instructions and safety warnings.

- Inspect tools and equipment for any damage before use, replacing or repairing as necessary.

- Keep flammable materials away from the work area to prevent fire hazards.

By implementing these safety precautions, individuals can effectively reduce risks and ensure a safe maintenance experience.

Resources for Honda Generator Owners

For individuals who rely on portable power solutions, having access to comprehensive resources can enhance the ownership experience. Whether you’re seeking maintenance tips, troubleshooting guidance, or upgrades, a variety of materials are available to assist users in maximizing the performance and longevity of their equipment.

Online Forums and Communities: Engaging with fellow enthusiasts can provide valuable insights. Many forums host discussions on common issues, modifications, and user experiences, making them an excellent source of shared knowledge.

Manufacturer Websites: Official websites often feature manuals, FAQs, and support sections that detail specifications and offer troubleshooting advice. These resources are crucial for understanding the intricacies of your equipment.

Video Tutorials: Platforms like YouTube host a myriad of instructional videos that cover everything from basic maintenance to complex repairs. Visual guides can be particularly helpful for those who prefer hands-on learning.

Local Repair Shops: Establishing a relationship with a nearby service center can provide personalized assistance. Professionals can offer expert advice and perform repairs to ensure your equipment runs smoothly.

Parts Suppliers: Reliable vendors specializing in components can be found both online and locally. Access to quality replacements ensures that your equipment remains in optimal condition, helping you avoid potential downtime.

Utilizing these resources can significantly enhance your experience, enabling you to take full advantage of your portable power source.