Comprehensive Honda GX140 Parts Diagram for Easy Reference

Exploring the intricacies of small engine assemblies can be both fascinating and essential for maintenance enthusiasts. A comprehensive overview of individual elements within a power unit provides invaluable insight into their functionality and interrelations. This knowledge not only aids in repairs but also enhances overall performance and longevity.

By examining various schematics, one can uncover the ultimate arrangement of components that contribute to efficient operation. Recognizing each part’s role allows for more effective troubleshooting and optimizes the replacement process when necessary. Familiarity with these layouts fosters a deeper appreciation for engineering design.

In this section, we will delve into the specifics of component arrangements, highlighting key features and connections. Understanding how these elements work together is crucial for anyone looking to enhance their mechanical skills or simply maintain their equipment effectively.

Understanding the Honda GX140 Engine

This section explores a specific small engine widely utilized in various applications. Known for its reliability and efficiency, this model has become a popular choice among users in different industries. The engine’s design incorporates several key components that work together to deliver optimal performance and durability.

Key Features

The engine is equipped with a range of features that enhance its functionality. Here are some notable aspects:

| Feature | Description |

|---|---|

| Engine Type | Four-stroke, air-cooled design |

| Displacement | Approximately 140cc |

| Power Output | Up to 4.0 horsepower |

| Fuel System | OHV configuration for improved efficiency |

| Starting System | Recoil starter for easy operation |

Applications

This engine is commonly used in a variety of equipment. Its robust performance makes it suitable for tasks such as powering generators, water pumps, and garden equipment. Users appreciate its ability to handle demanding conditions while maintaining efficiency.

Importance of Parts Diagrams

Understanding the intricacies of mechanical assemblies is crucial for efficient maintenance and repair. Visual representations serve as essential tools, guiding users through the components and their arrangements.

Utilizing these visual aids not only simplifies the identification of individual elements but also enhances the overall comprehension of how systems function together. This clarity can ultimately reduce the likelihood of errors during disassembly and reassembly.

Moreover, these illustrations can serve as valuable resources for troubleshooting, allowing users to pinpoint issues quickly and effectively. By delving into the specifics presented in these visuals, one can ensure optimal performance and longevity of the machinery in question.

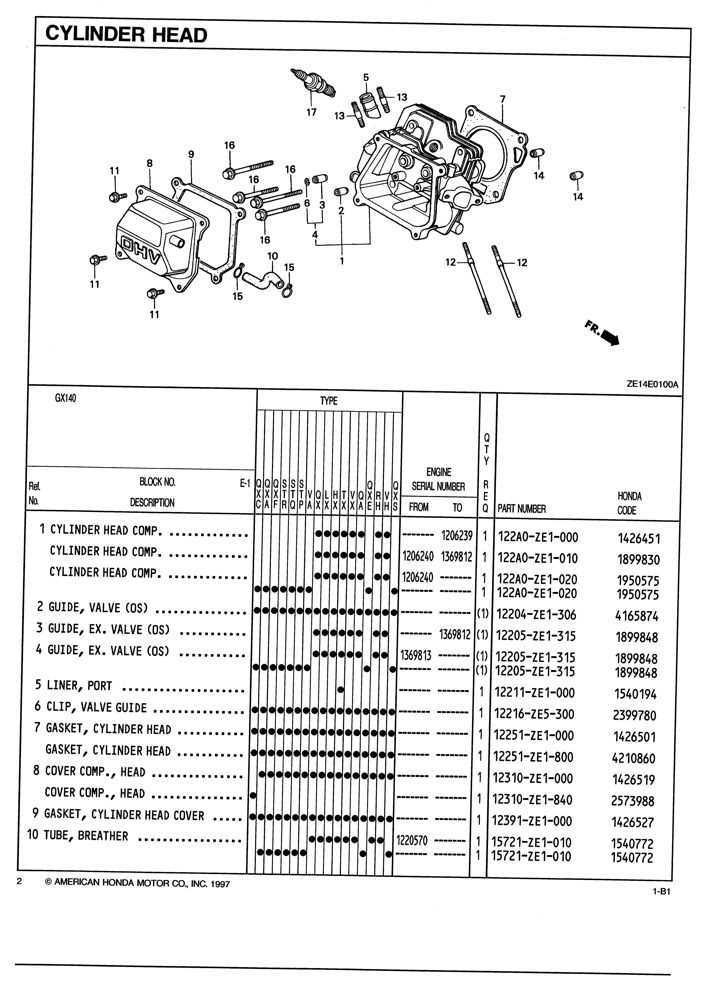

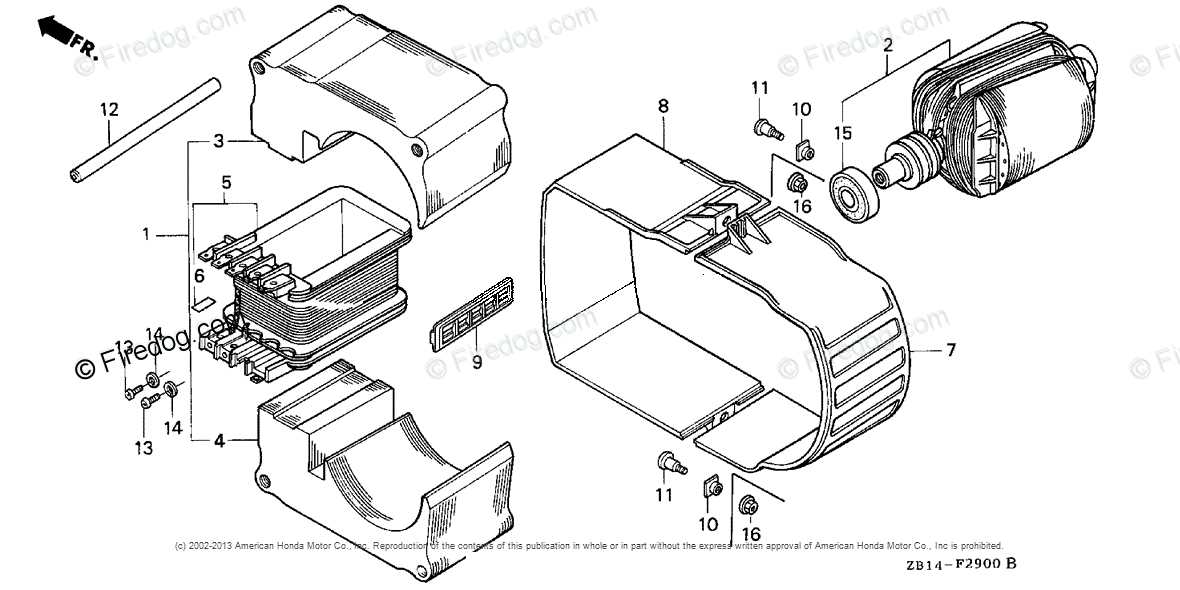

Components of the GX140 Engine

The engine comprises various essential elements that work harmoniously to ensure optimal performance. Each part plays a specific role, contributing to the overall functionality and efficiency of the machine.

One of the primary components is the crankshaft, which converts linear motion into rotational power. Complementing this is the piston, which moves within the cylinder, creating the necessary pressure for combustion. Additionally, the cylinder head houses vital elements such as valves and spark plugs, regulating airflow and ignition.

The fuel system is also crucial, including the carburetor, which mixes air and fuel in the correct proportions. The ignition system, comprising the coil and ignition module, ensures timely spark generation for smooth engine operation. Furthermore, the cooling system, featuring the fan and radiator, prevents overheating during extended use.

Each of these components is integral to the engine’s success, and understanding their functions allows for better maintenance and performance optimization. Exploring these parts provides insight into the ultimate efficiency of the overall system.

Common Issues with Honda GX140

When dealing with small engines, certain recurring problems can often arise, affecting performance and reliability. Understanding these common issues can help in diagnosing and maintaining the machinery effectively.

Frequent Problems

- Starting Difficulties: Many users report trouble when trying to start the engine, often due to fuel or ignition issues.

- Overheating: Engines may overheat due to low oil levels or blocked cooling vents, leading to potential damage.

- Unusual Noises: Grinding or knocking sounds may indicate internal wear or insufficient lubrication.

- Vibration: Excessive vibration can signal misalignment or worn components that need attention.

- Fuel Leaks: Leaking fuel can arise from damaged lines or faulty gaskets, posing safety risks.

Preventive Measures

- Regular Maintenance: Schedule routine inspections and servicing to ensure all components function correctly.

- Proper Storage: Store the equipment in a dry place to prevent corrosion and deterioration.

- Check Oil Levels: Monitor and change oil as needed to keep the engine lubricated.

- Inspect Fuel System: Regularly check fuel lines and filters to prevent blockages and leaks.

- Listen for Changes: Pay attention to any unusual sounds during operation to catch issues early.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. By following a few essential practices, you can enhance performance and extend the lifespan of your machine, making it a reliable asset for years to come.

Regular Inspections

Frequent checks can help identify potential issues before they escalate. Consider the following steps:

- Examine components for signs of wear and tear.

- Ensure all connections are secure and free from rust.

- Inspect fluid levels and quality regularly.

Proper Cleaning

Keeping your equipment clean is vital for optimal performance. Implement these cleaning practices:

- Remove debris and dirt after each use.

- Clean air filters to maintain airflow and efficiency.

- Use appropriate cleaning solutions for specific parts.

By adhering to these guidelines, you can promote the longevity and functionality of your machinery, ensuring it operates effectively throughout its lifespan.

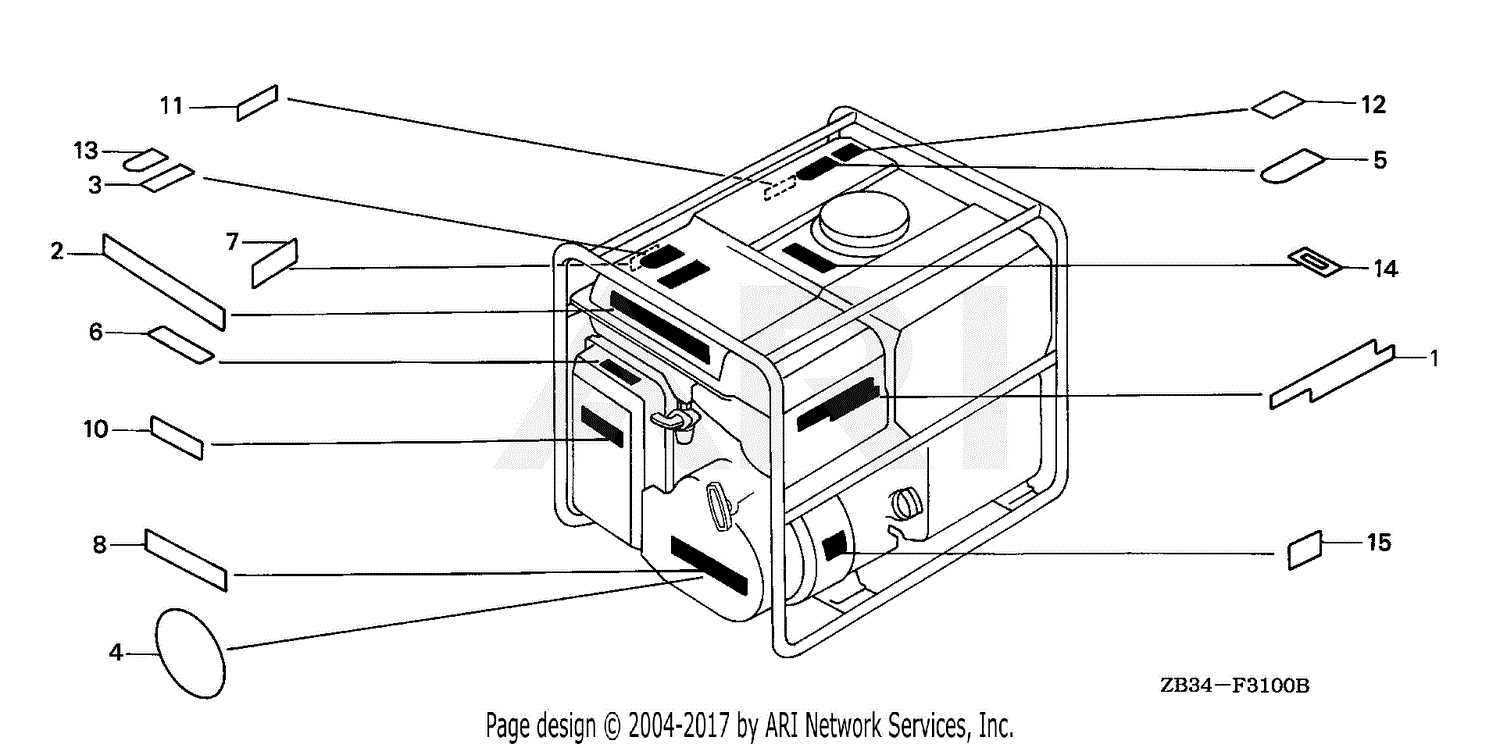

Finding Authentic Replacement Parts

When it comes to maintaining equipment, sourcing genuine components is crucial for optimal performance and longevity. Using authentic items ensures compatibility and reliability, reducing the risk of malfunctions.

Here are some tips for locating quality replacements:

- Check manufacturer websites for official listings.

- Visit authorized dealers to guarantee authenticity.

- Consult user manuals for specific recommendations.

Additionally, consider the following:

- Read reviews and ratings of suppliers.

- Verify warranty and return policies.

- Engage with online forums for community insights.

By following these guidelines, you can ensure that your machinery remains in top condition with the right components.

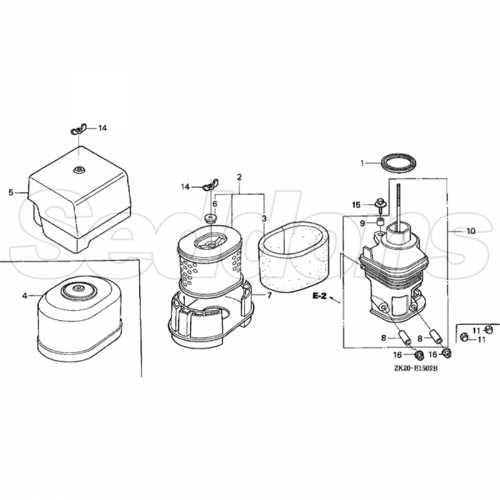

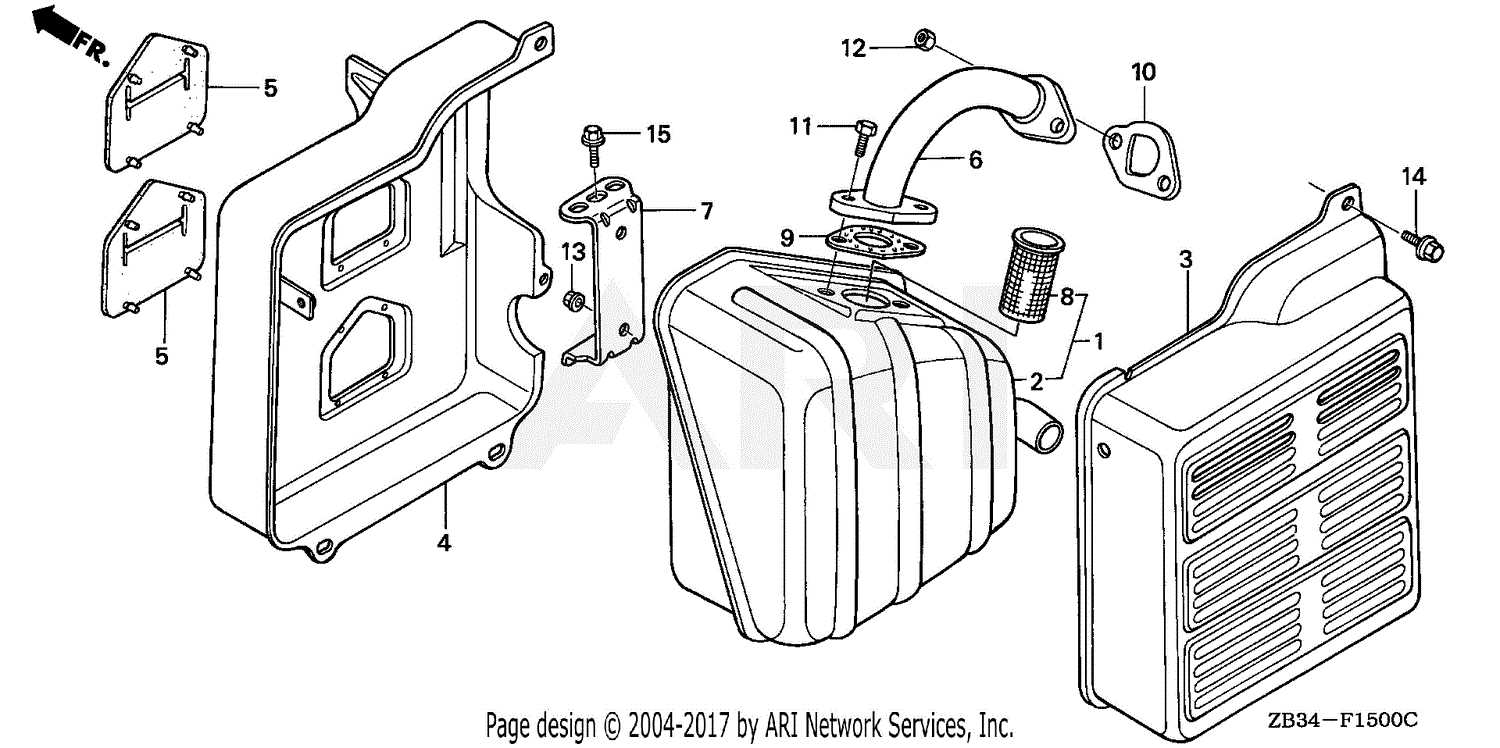

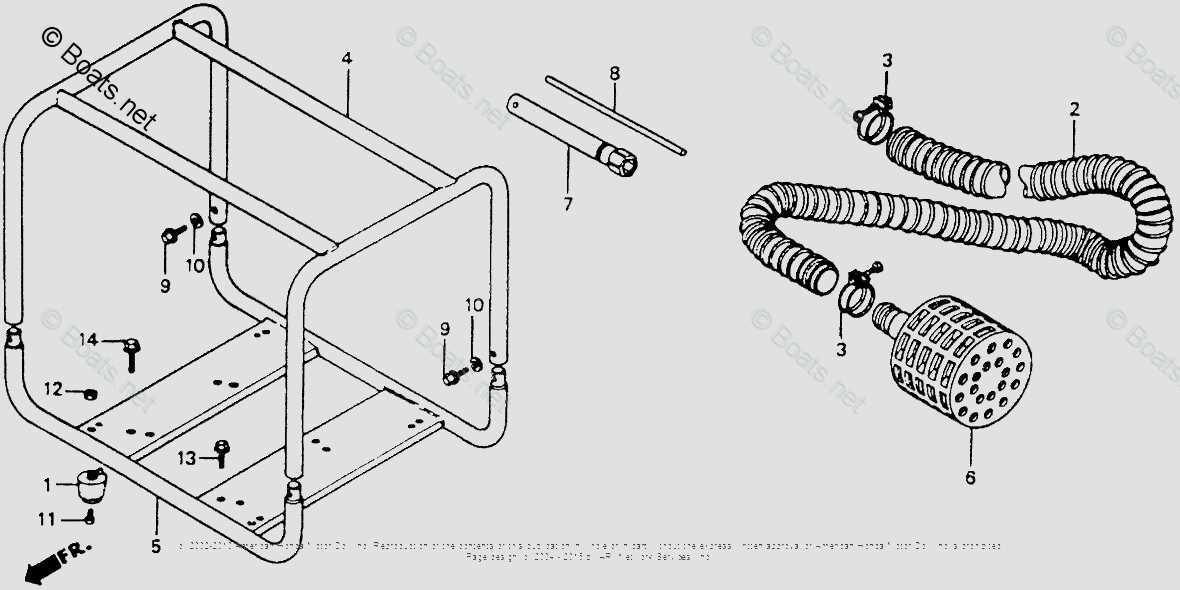

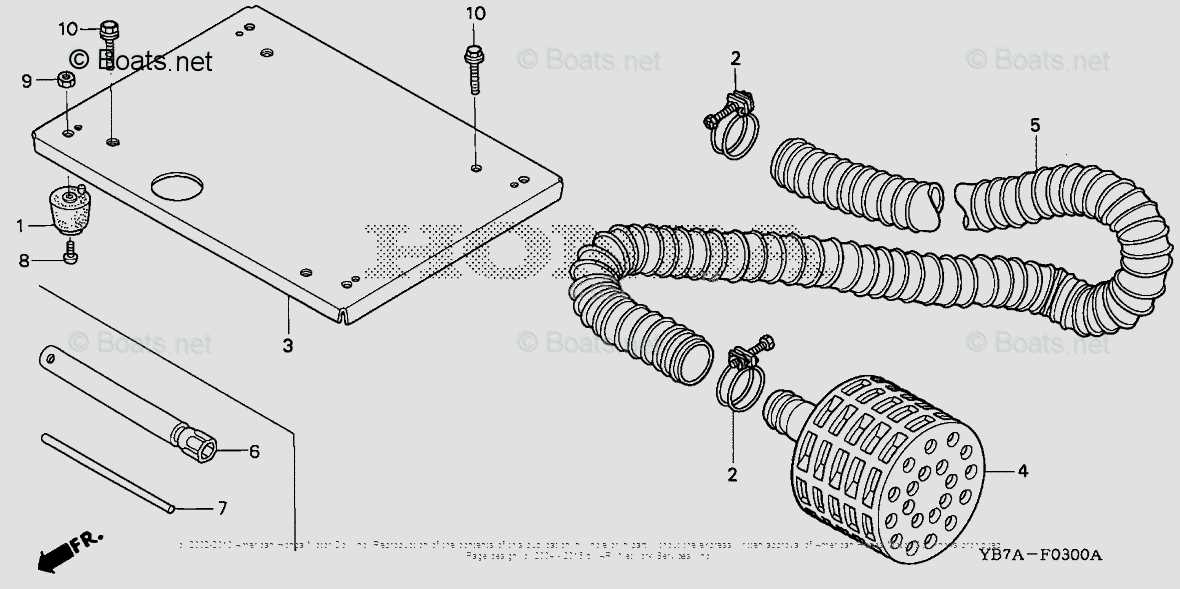

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as guides to identify individual elements, their arrangements, and how they interact within a larger assembly. Mastering this skill can significantly enhance your ability to troubleshoot and perform necessary replacements.

Familiarize Yourself with the Layout

Most visual guides are organized in a systematic way. Here are some key aspects to consider:

- Sectioning: Components are often grouped by their function or location within the machine.

- Labels: Look for annotations that indicate specific items or part numbers.

- Orientation: Pay attention to the direction the components are facing, as this can affect assembly.

Interpreting Symbols and Notations

Different symbols and notations can indicate various things. Understanding these can help clarify the information presented:

- Numbers: These typically correspond to specific parts or kits.

- Lines: Solid or dashed lines may represent different types of connections or relationships between components.

- Color Coding: Some visuals use color to differentiate between various systems or types of parts.

By carefully analyzing these elements, you can effectively navigate the visuals and ensure successful repairs or replacements.

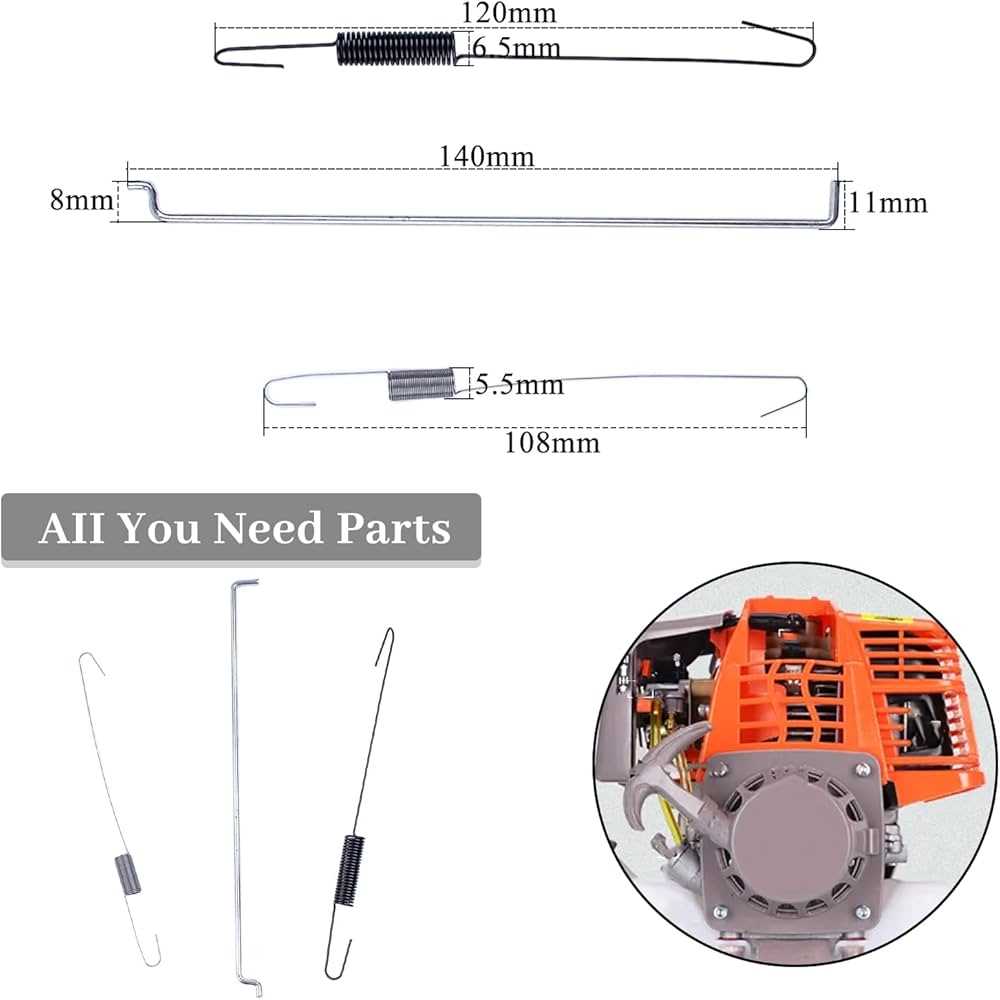

Top Aftermarket Options Available

When seeking enhancements for your small engine, exploring aftermarket alternatives can significantly boost performance and longevity. These options often provide superior quality and innovative features compared to standard components, ensuring your machine runs smoothly and efficiently.

Performance Enhancements

Upgraded carburetors are among the most sought-after modifications, allowing for improved fuel flow and better throttle response. Additionally, high-performance air filters can increase airflow, resulting in enhanced power output and efficiency.

Durability and Reliability

Choosing reinforced gaskets and heavy-duty bearings can extend the lifespan of your engine by reducing wear and tear. These durable components are designed to withstand harsher conditions, making them ideal for intensive usage.

Tools Needed for Repairs

Having the right instruments is essential for effective maintenance and repair tasks. Whether you’re addressing minor issues or conducting major overhauls, the proper equipment can make the process smoother and more efficient. This section outlines the necessary tools to ensure your repair endeavors are successful.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are crucial for any repair job. These items allow for the tightening, loosening, and manipulation of various components. Investing in a quality set will facilitate easier access to hard-to-reach areas and enhance overall precision.

Power Tools and Equipment

For more extensive repairs, power tools like drills and impact wrenches can save time and effort. These devices increase efficiency, especially when dealing with stubborn or rusted parts. Selecting the right power tools tailored to your specific tasks will yield the ultimate results.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with small engines. By following a systematic method, you can efficiently diagnose and fix problems, ensuring optimal performance and longevity. Each step is designed to guide you through the repair process, making it accessible even for those with limited mechanical experience.

Step 1: Gather Your Tools

Before starting any repair, assemble the necessary tools. Typical items include wrenches, screwdrivers, pliers, and a torque wrench. Having everything ready will streamline the process and prevent interruptions.

Step 2: Safety First

Always prioritize safety. Wear protective gear such as gloves and goggles. Ensure the engine is off and cool before beginning any work. Disconnect the spark plug to prevent accidental starts.

Step 3: Identify the Issue

Carefully observe the engine’s symptoms. Common issues may include difficulty starting, unusual noises, or poor performance. Documenting these signs will help in troubleshooting.

Step 4: Consult the Manual

Refer to the user manual for specifications and troubleshooting tips specific to your engine model. This resource can provide valuable insights into common issues and their solutions.

Step 5: Disassemble Carefully

If disassembly is necessary, proceed with caution. Label all parts and screws as you remove them to simplify reassembly. Take photos if needed to remember the configuration.

Step 6: Inspect Components

Check all parts for wear and damage. Look for cracks, corrosion, or broken pieces. Replace any components that do not meet the required standards, as this will help restore functionality.

Step 7: Clean and Reassemble

Clean all components before reassembly. Use appropriate cleaning agents and tools to remove dirt and debris. Follow your documentation carefully to ensure everything is reassembled correctly.

Step 8: Test the Engine

Once reassembled, reconnect the spark plug and start the engine. Monitor its operation closely. If issues persist, re-evaluate your work and consider consulting a professional if needed.

By following these steps, you can effectively manage repairs and maintain the performance of your small engine. Regular maintenance will also prevent future problems and enhance durability.

Upgrading Your GX140 Engine

Enhancing the performance of your small engine can significantly improve its efficiency and longevity. By focusing on key modifications and component upgrades, you can unlock greater power and reliability for various applications. This section will explore effective strategies for achieving optimal performance.

Key Performance Modifications

One of the ultimate ways to boost your engine’s capabilities is through carburetor tuning and enhancing airflow. Consider installing a high-performance air filter and adjusting the carburetor for optimal fuel delivery. These changes can lead to improved throttle response and power output.

Durability Enhancements

Investing in upgraded ignition components can also yield significant benefits. High-quality spark plugs and ignition coils can enhance combustion efficiency and overall engine reliability. Additionally, consider utilizing a more robust oil for better lubrication, which is essential for extending the life of your engine.