Comprehensive Honda GX160 Carb Parts Diagram for Easy Reference

The intricate mechanisms of small engine fuel systems play a crucial role in their overall performance and efficiency. Mastery of these components enables enthusiasts and technicians alike to enhance the functionality of their machines, ensuring smooth operation and longevity.

When it comes to maintaining optimal performance, recognizing the various elements that make up these fuel systems is essential. A comprehensive overview of these components not only aids in troubleshooting but also facilitates informed decisions regarding upgrades and replacements.

Delving into the specifics of each element reveals how they interact to create the ultimate fuel delivery system. This knowledge empowers users to achieve maximum efficiency and reliability from their equipment.

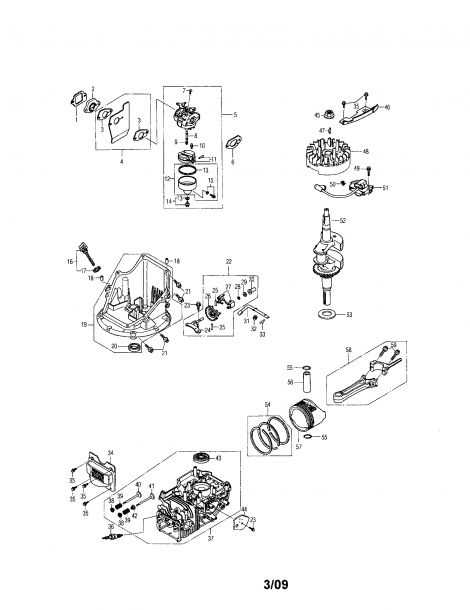

Understanding the GX160 Engine

This section delves into the intricacies of a widely used small power unit, known for its reliability and efficiency. Many applications rely on this engine for optimal performance, making it essential to understand its components and functionality.

Key Features

- Compact design suitable for various machinery

- Powerful output while maintaining fuel efficiency

- Durable construction for longevity in diverse environments

Common Applications

- Pressure washers

- Generators

- Garden tillers

- Concrete mixers

Grasping the essentials of this engine’s design and operation can greatly enhance maintenance and troubleshooting efforts, ensuring longevity and optimal performance in your equipment.

Key Features of Honda GX160

This engine is renowned for its reliability and performance, making it a preferred choice for various applications. Its robust design ensures durability, while innovative engineering provides efficient fuel consumption. Users appreciate its versatility, as it can be utilized in numerous machines and tools.

One of the standout characteristics is its ease of maintenance, allowing for straightforward servicing without extensive technical knowledge. The compact size contributes to its portability, making it ideal for both professional and recreational use. Additionally, it features a powerful output, ensuring effective operation even under demanding conditions.

Safety features are also prominent, enhancing user confidence during operation. Its quiet operation minimizes noise pollution, making it suitable for residential areas. Overall, this engine exemplifies a perfect blend of performance, efficiency, and user-friendly design.

Importance of Carburetor Parts

The functionality of an engine heavily relies on the efficiency of its fuel delivery system. Each component within this system plays a critical role in ensuring optimal performance and longevity. Understanding the significance of these components can greatly enhance maintenance practices and overall engine health.

Key Functions of Essential Components

Each element within the fuel delivery assembly contributes uniquely to the process of mixing air and fuel for combustion. Proper regulation of this mixture is vital for efficient engine operation, influencing factors such as power output, fuel efficiency, and emissions.

Common Issues Arising from Component Failure

Neglecting the maintenance of individual elements can lead to a range of problems, including poor engine performance, increased fuel consumption, and potential damage to the engine itself. Regular inspection and timely replacement of worn or malfunctioning components are crucial for avoiding these issues.

| Component | Function | Signs of Failure |

|---|---|---|

| Throttle Valve | Regulates air intake | Inconsistent engine speed |

| Float Chamber | Maintains fuel level | Fuel overflow or starvation |

| Jet Nozzles | Controls fuel flow | Stalling or sluggish acceleration |

Common Carburetor Issues Explained

Engines often face performance challenges due to various malfunctions within the fuel delivery system. Understanding these common issues can significantly enhance maintenance efforts and prolong the lifespan of the equipment.

- Clogged Jets: Dirt or debris can obstruct fuel flow, leading to erratic engine behavior.

- Improper Adjustment: Incorrect settings may result in poor air-fuel mixture, affecting acceleration and power.

- Fuel Leaks: Leaks can cause reduced efficiency and potential fire hazards.

- Stale Fuel: Old fuel can lead to varnish buildup, which impedes proper function.

Regular inspections and maintenance can help mitigate these issues, ensuring optimal performance and reliability.

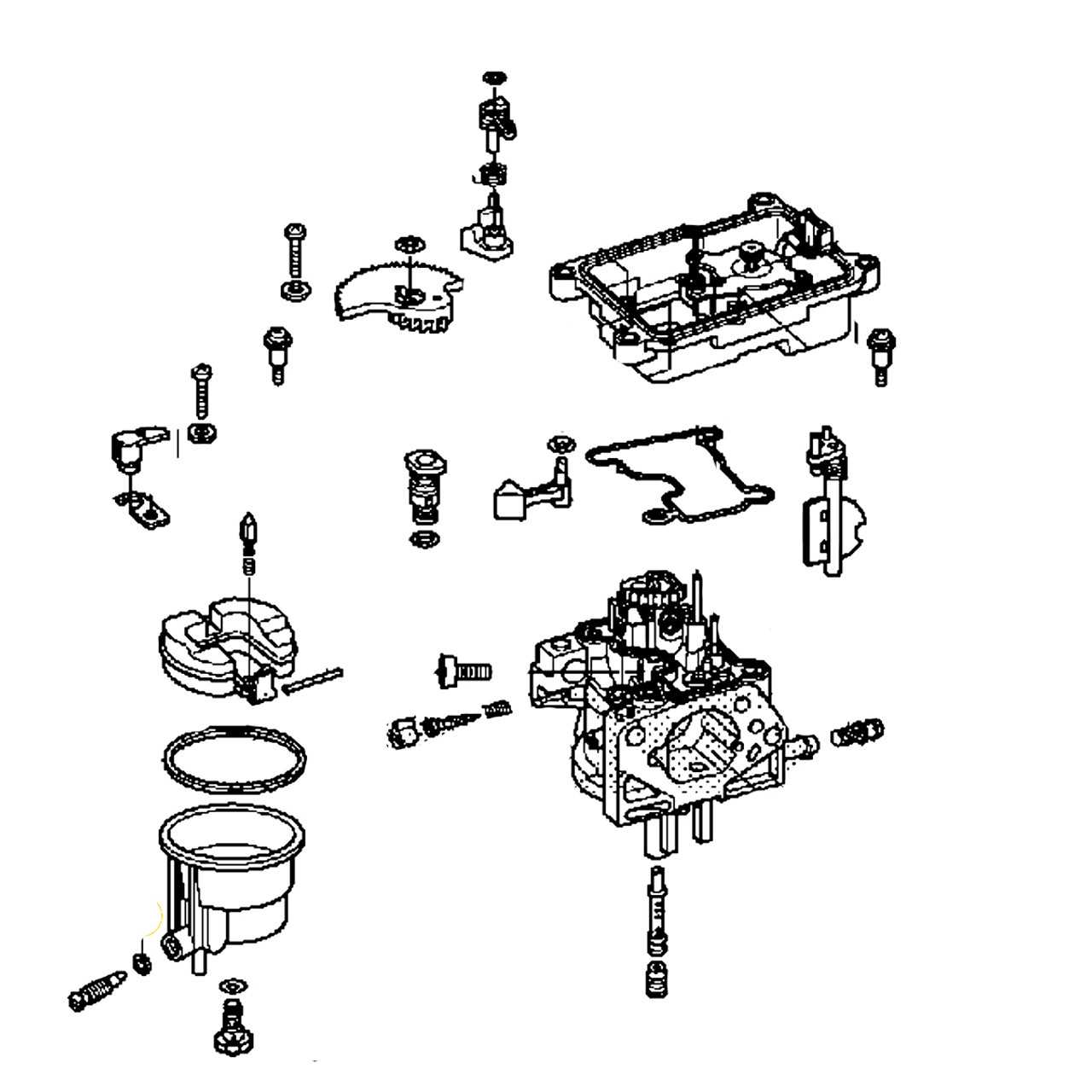

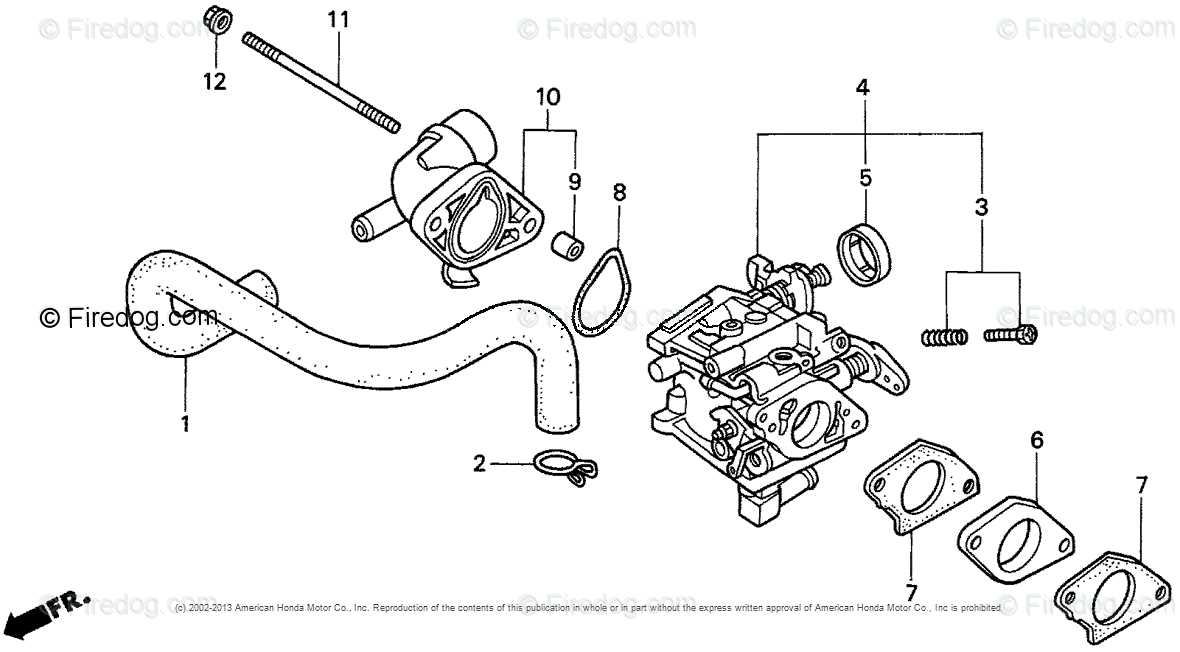

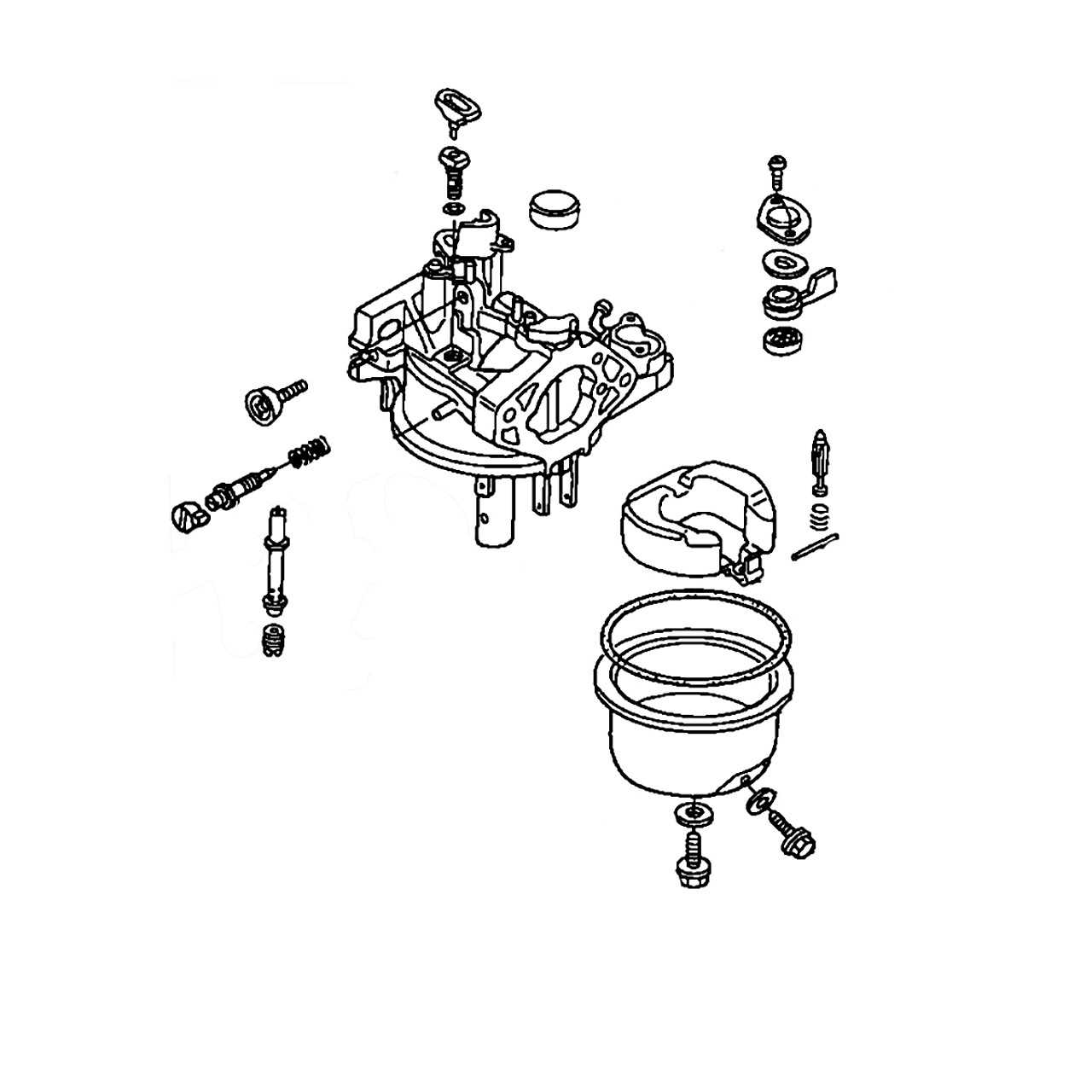

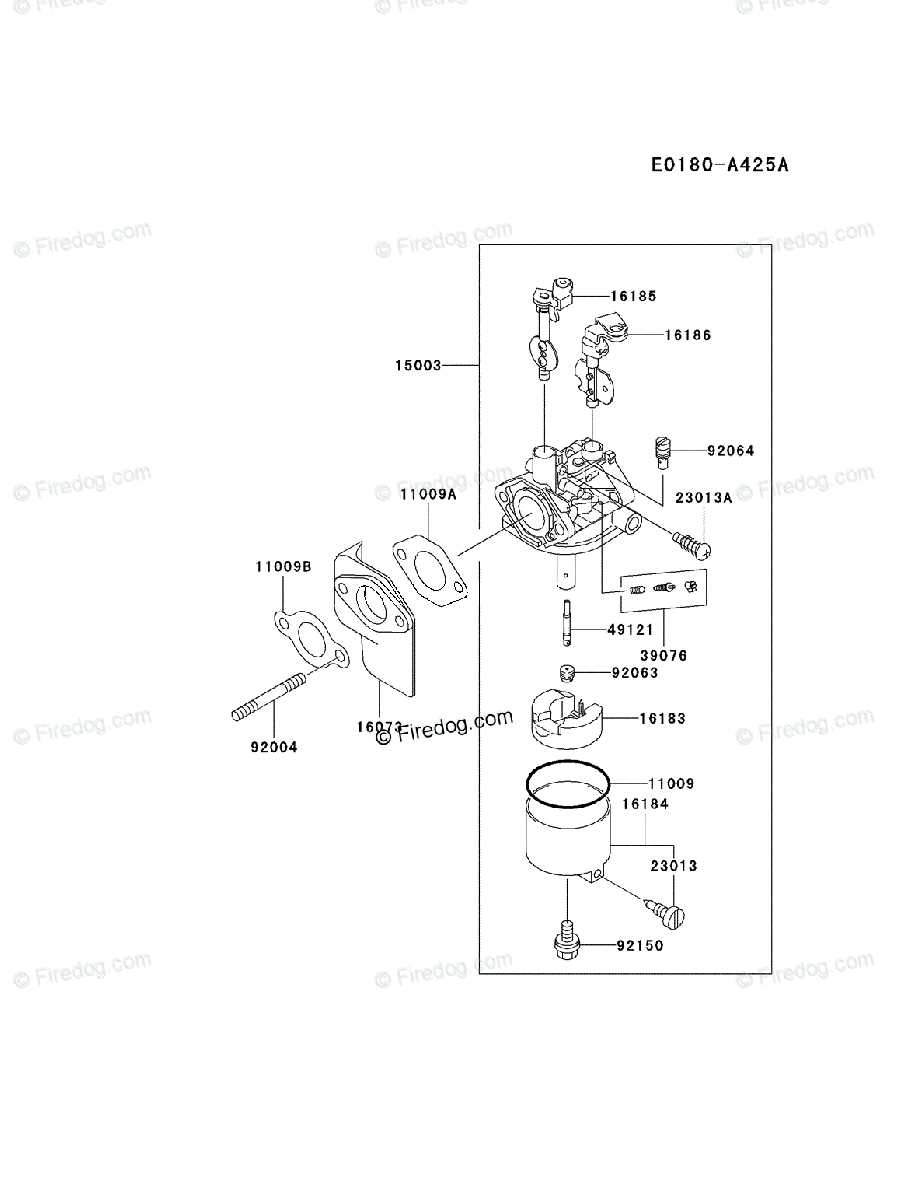

Parts Breakdown: What You Need

Understanding the various components of your engine’s fuel delivery system is crucial for optimal performance and maintenance. Each element plays a specific role in ensuring that fuel flows efficiently and combustion occurs smoothly. Familiarizing yourself with these crucial elements will help you identify issues and carry out effective repairs or replacements.

The assembly includes several key components, such as the throttle mechanism, float chamber, and needle valve, each contributing to the overall functionality. Recognizing how these pieces interact can enhance your troubleshooting capabilities and extend the lifespan of your equipment. A well-maintained fuel system leads to better engine efficiency and reliability.

To ensure that you have everything necessary for proper upkeep, consider acquiring a comprehensive set of replacement components. This will prepare you for any unexpected maintenance needs, allowing for quick resolutions and minimizing downtime. Understanding the specifics of each component will empower you to make informed decisions and maintain your engine in peak condition.

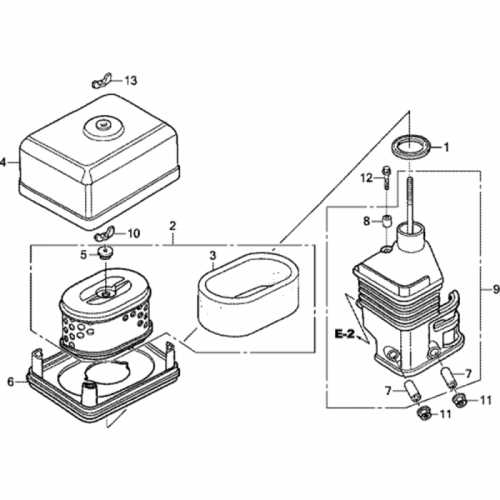

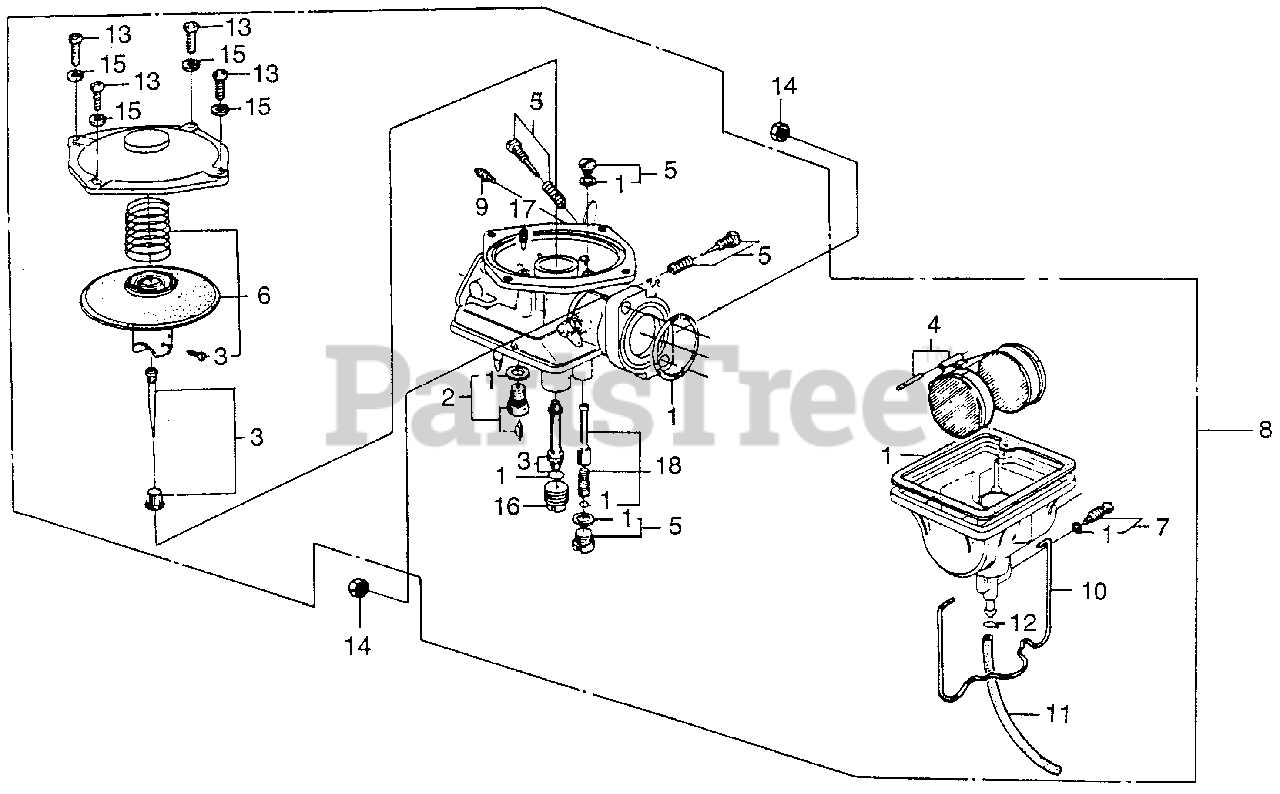

How to Read the Diagram

Understanding a visual representation of components can significantly enhance your ability to work with mechanical systems. These illustrations provide essential information on the arrangement and interaction of various elements, making it easier to identify, assemble, or troubleshoot them. Grasping how to interpret these visuals is crucial for effective maintenance and repair tasks.

Identifying Components

Begin by familiarizing yourself with the various symbols and labels used in the illustration. Each element typically has a designated number or letter that corresponds to a detailed description elsewhere. Pay attention to the orientation and connections indicated; these details are vital for proper assembly and functionality.

Understanding Relationships

Next, focus on the relationships between the different components. Arrows and lines may indicate flow paths or connections, helping you understand how each part interacts with others. Recognizing these relationships can aid in diagnosing issues and ensuring that everything is set up correctly for optimal performance.

In conclusion, by carefully analyzing the visual representation, you can enhance your mechanical knowledge and skills, leading to more efficient repairs and maintenance.

Essential Tools for Repairs

When tackling any maintenance task, having the right equipment at your disposal is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures precision during repairs, ultimately leading to a smoother process.

Start with a reliable set of wrenches and screwdrivers, as these are fundamental for disassembly and reassembly. Include pliers for gripping and manipulating various components, along with a torque wrench to ensure that fasteners are tightened to the correct specifications. Don’t forget to add a fuel line removal tool, which can simplify access to difficult-to-reach areas.

For more intricate work, consider incorporating a diagnostic tool that can help identify issues quickly, saving time in troubleshooting. A clean workspace with organizational trays can further streamline your repair efforts, allowing you to focus on the task at hand without unnecessary distractions.

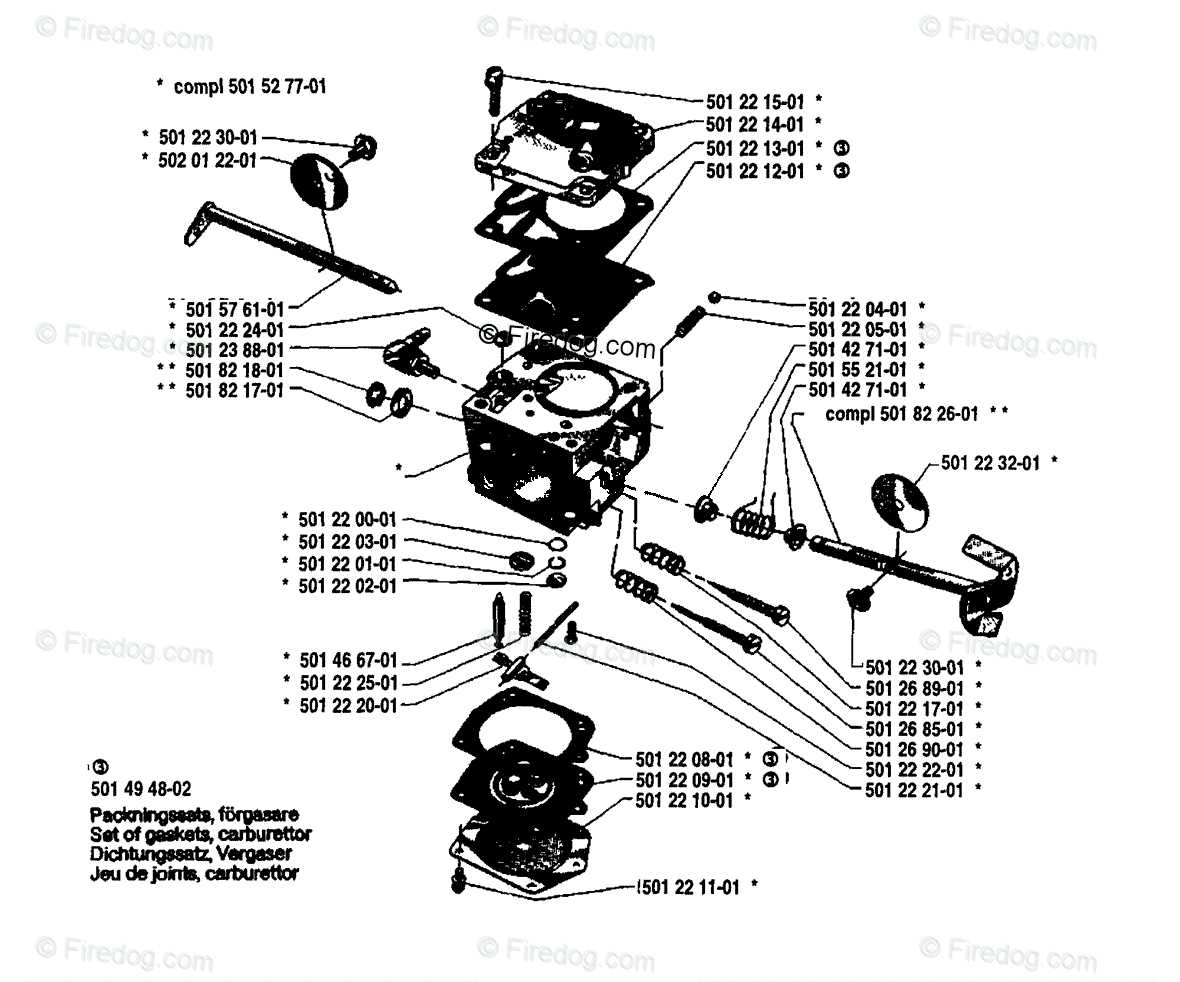

Step-by-Step Carburetor Assembly

Assembling a fuel mixing component requires attention to detail and a systematic approach. Each step ensures that the mechanism operates efficiently, enhancing performance and longevity. Follow these instructions carefully to achieve a successful assembly.

- Gather Your Tools:

- Screwdriver set

- Wrench

- Clean cloth

- Safety goggles

- Clean All Components:

Before beginning the assembly, make sure all components are thoroughly cleaned. Use a suitable cleaner to remove any residue or debris.

- Inspect the Gaskets:

Check the gaskets for wear and tear. Replace any damaged gaskets to ensure a proper seal.

- Install the Main Body:

Begin by attaching the main body to the mounting surface, securing it with the appropriate screws. Ensure that it is tight but not over-tightened to avoid damage.

- Add the Float Assembly:

Insert the float assembly into the designated compartment, ensuring that it moves freely and does not stick.

- Attach the Needle Valve:

Carefully install the needle valve into its position, making sure it aligns properly with the float assembly.

- Install the Jets:

Position the jets into their respective slots, ensuring they are securely fastened but not overly tightened.

- Reassemble the Top Cover:

Place the top cover back on the main body and secure it with the screws provided. Verify that all components fit snugly.

- Final Checks:

Once assembly is complete, double-check all connections and fittings to ensure nothing is loose or misaligned.

Following these steps will help you achieve a well-assembled fuel mixing component that performs reliably and efficiently.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the prolonged functionality of your equipment. By implementing a few key practices, you can significantly enhance performance and extend the lifespan of your machinery.

Routine Inspections

Frequent examinations can help identify potential issues before they escalate. Check for wear and tear, and ensure all components are secure and free from debris.

Proper Cleaning

Maintaining cleanliness is vital. Accumulated dirt can hinder performance and lead to corrosion. Regularly clean all accessible areas and replace filters as needed.

| Maintenance Task | Frequency |

|---|---|

| Check Oil Level | Every use |

| Inspect Fuel Lines | Monthly |

| Clean Air Filter | Every 25 hours |

| Replace Spark Plug | Every 100 hours |

When to Replace Components

Understanding the right time to change essential elements in small engines is crucial for maintaining optimal performance. Regular inspection and awareness of wear signs can help prevent major issues and extend the lifespan of your equipment. Knowing when to replace specific components ensures efficiency and reliability during operation.

Signs of Wear

- Visible Damage: Cracks, dents, or corrosion can indicate that a component has reached the end of its usable life.

- Decreased Performance: If the engine struggles to start or runs poorly, it may be time to check for worn elements.

- Unusual Noises: Grinding or rattling sounds often signal that internal parts are failing and need replacement.

- Fuel Leaks: Any leakage around connections or seals can lead to reduced efficiency and should be addressed promptly.

Regular Maintenance Schedule

- Inspect components every 50 hours of operation.

- Replace filters and seals at least once a season.

- Evaluate performance and replace any part showing signs of wear immediately.

- Follow manufacturer guidelines for specific replacement intervals.

Finding Quality Replacement Parts

Ensuring optimal performance and longevity of your equipment often hinges on sourcing high-quality components. With a multitude of options available, it’s crucial to navigate through choices effectively, prioritizing durability and reliability.

Researching Suppliers

Start by exploring various suppliers, both online and offline. Look for reputable vendors who offer genuine merchandise, as well as user reviews that reflect satisfaction and quality. Verification of supplier credibility can save time and resources.

Understanding Compatibility

Before making a purchase, confirm that the replacement components are compatible with your specific model. Consulting user manuals or expert guides can help you delve deeper into specifications, ensuring you make the ultimate choice for your needs.

Troubleshooting Carburetor Problems

Addressing fuel delivery issues is crucial for maintaining optimal engine performance. Identifying common symptoms can help in diagnosing and resolving these challenges effectively.

Common Symptoms

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Clogged fuel pathways |

| Inconsistent idling | Air leaks or dirty components |

| Excessive fuel consumption | Improper adjustments |

| Black smoke from exhaust | Overly rich mixture |

Steps for Resolution

Start by cleaning or replacing the necessary components. Ensure all connections are tight and free of leaks. Finally, adjust the mixture to the manufacturer’s specifications for optimal performance.

Resources for Further Learning

Exploring the intricacies of engine components can greatly enhance your understanding and maintenance skills. Numerous resources are available to provide insights and guidance for both beginners and experienced enthusiasts alike.

Online forums and communities offer a wealth of shared knowledge, where individuals discuss common issues and solutions. YouTube channels dedicated to mechanical repairs present visual step-by-step tutorials that can clarify complex processes.

Additionally, instructional books and manuals can serve as invaluable references, providing detailed explanations and diagrams to aid in assembly and troubleshooting. Engaging with these materials can ultimately empower you to tackle projects with confidence.