Complete Guide to Honda GX200 Parts Diagram

In the realm of small machinery, comprehending the intricate layout of engine elements is essential for maintenance and repair. Every engine is a complex assembly of various components that work in unison to ensure optimal performance. By gaining insight into these structures, enthusiasts and professionals alike can enhance their understanding and troubleshoot issues more effectively.

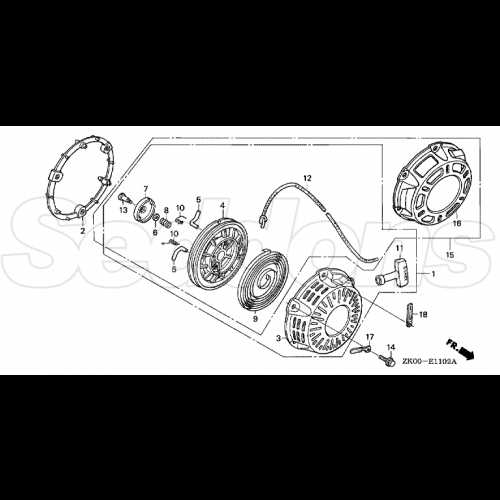

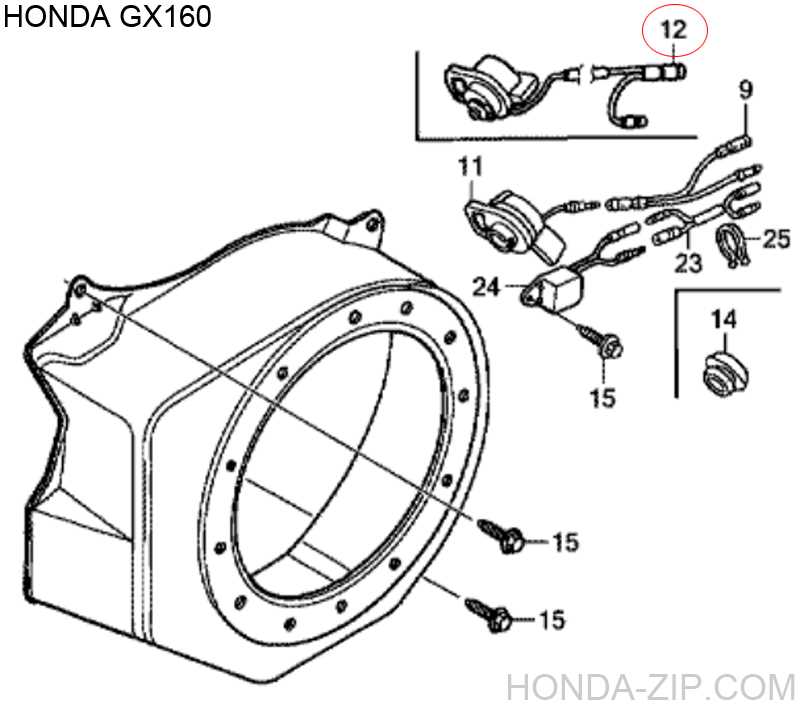

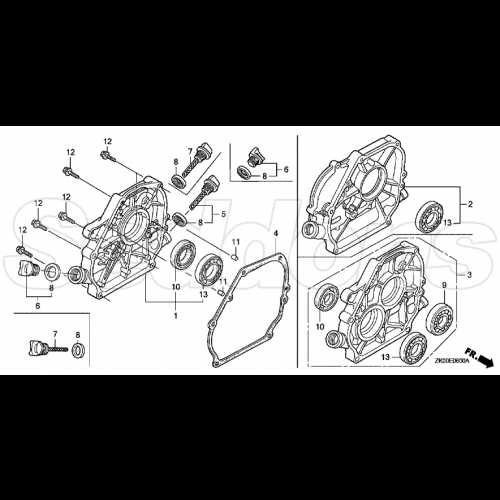

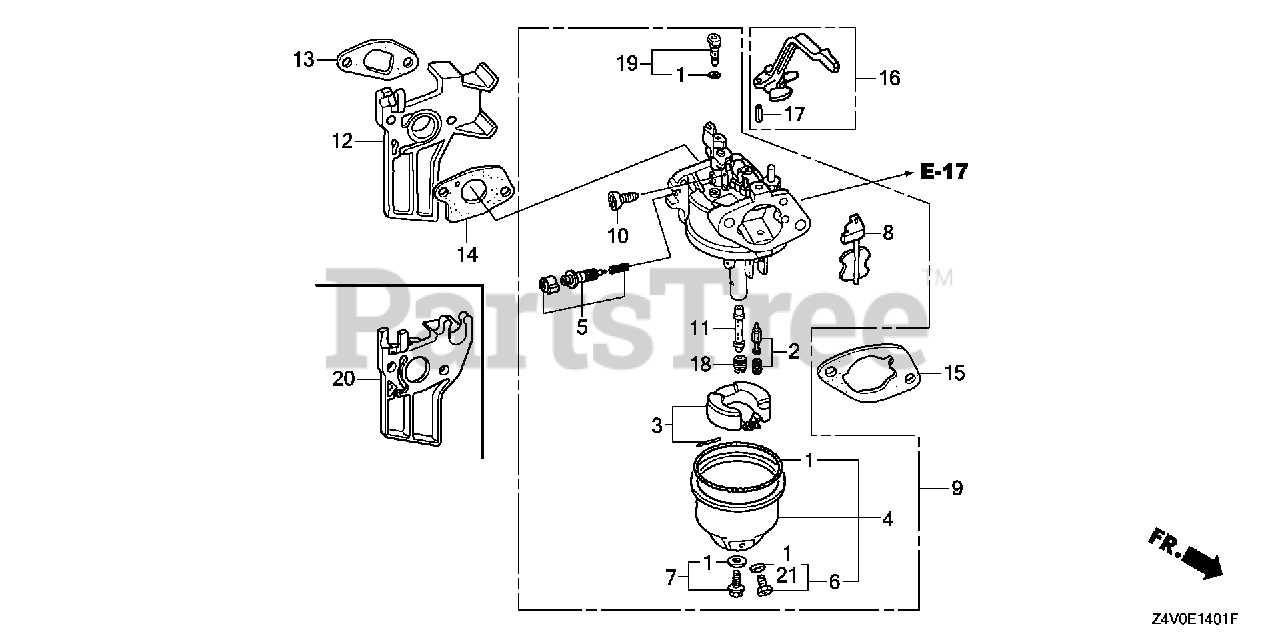

Detailed illustrations that showcase the configuration of these engine components serve as invaluable resources. Such visual aids not only help in identifying individual parts but also clarify how they interact with one another. This knowledge is crucial for anyone involved in the upkeep or modification of these mechanical systems.

Exploring these layouts can empower users to make informed decisions when it comes to repairs or upgrades. Whether one is a seasoned technician or a novice, familiarity with the specific arrangement of engine elements can lead to improved functionality and longevity of the machinery. The journey of understanding these configurations is both rewarding and essential for effective engine management.

Understanding the Honda GX200 Engine

This section explores the intricacies of a popular small engine, focusing on its design, functionality, and applications. Recognizing its components and how they interact can enhance maintenance and operational efficiency.

Key features of this engine include:

- Robust construction for durability

- Efficient fuel consumption

- Ease of maintenance and repairs

Common applications for this type of engine involve:

- Generators

- Lawn equipment

- Construction machinery

Understanding these elements can ultimately improve performance and longevity.

Key Components of the GX200

The small engine is built with several crucial elements that work together to ensure optimal performance and reliability. Understanding these components is essential for effective maintenance and troubleshooting, as each part plays a vital role in the engine’s overall functionality.

Fuel System: This system is responsible for delivering the right amount of fuel to the combustion chamber. It typically includes a fuel tank, carburetor, and fuel lines. Proper functioning of this system ensures efficient operation and power generation.

Ignition System: The ignition system initiates combustion within the engine. It consists of the spark plug, ignition coil, and associated wiring. A reliable ignition system is critical for starting the engine and maintaining consistent performance.

Cylinder Head: This component houses the intake and exhaust valves, which regulate airflow in and out of the combustion chamber. Its design significantly impacts engine efficiency and power output.

Crankshaft: Acting as the heart of the engine, the crankshaft converts the linear motion of the pistons into rotational motion. This transformation is essential for driving various mechanical components attached to the engine.

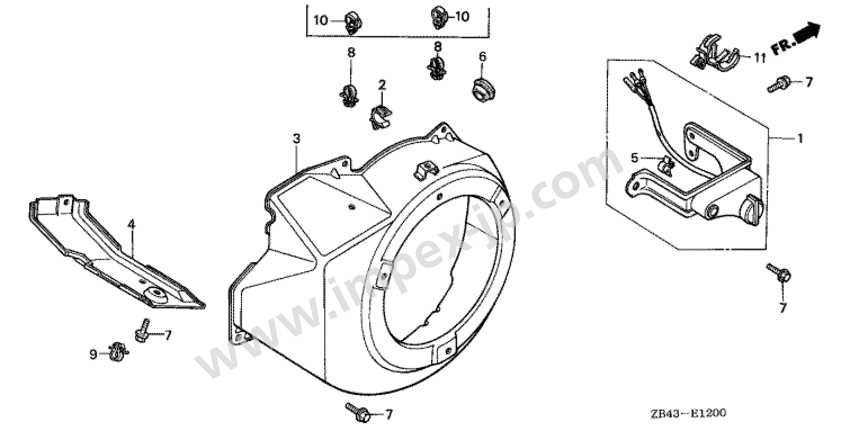

Cooling System: Effective cooling is vital to prevent overheating. This system often includes a fan and a cooling shroud to dissipate heat generated during operation, ensuring the longevity of the engine.

Each of these elements is integral to the smooth operation of the engine, and understanding their functions can greatly assist in maintenance and repairs.

How to Read Parts Diagrams

Understanding assembly illustrations is essential for anyone looking to maintain or repair machinery. These visuals provide a clear representation of components and their relationships, making it easier to identify what you need.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Each visual may use unique symbols to represent different elements. Take time to understand what each symbol means.

- Identify Key Sections: Break down the illustration into sections to simplify your understanding of how components interact.

- Refer to the Legend: Most illustrations include a legend that provides additional information on the parts and their functions.

- Follow the Order: Many visuals are organized in a logical order, helping you see the assembly or disassembly sequence.

By following these guidelines, you can effectively delve into the intricacies of mechanical visuals, ensuring you have the ultimate knowledge to proceed with repairs or replacements.

Common Replacement Parts for GX200

Regular maintenance often requires swapping out key components to ensure optimal performance and longevity of small engines. Understanding which elements typically wear out can help you stay ahead of potential issues.

Air Filter: This essential component keeps contaminants from entering the engine, maintaining efficiency. A clean filter is crucial for smooth operation.

Spark Plug: A vital piece for ignition, it can degrade over time, affecting starting and overall functionality. Regular checks and replacements are advisable.

Fuel Filter: This component safeguards the engine by trapping impurities in the fuel. Replacing it periodically can prevent clogs and improve fuel flow.

Oil Filter: Ensuring clean oil circulation is vital for engine health. A fresh oil filter aids in reducing wear and prolongs the life of internal components.

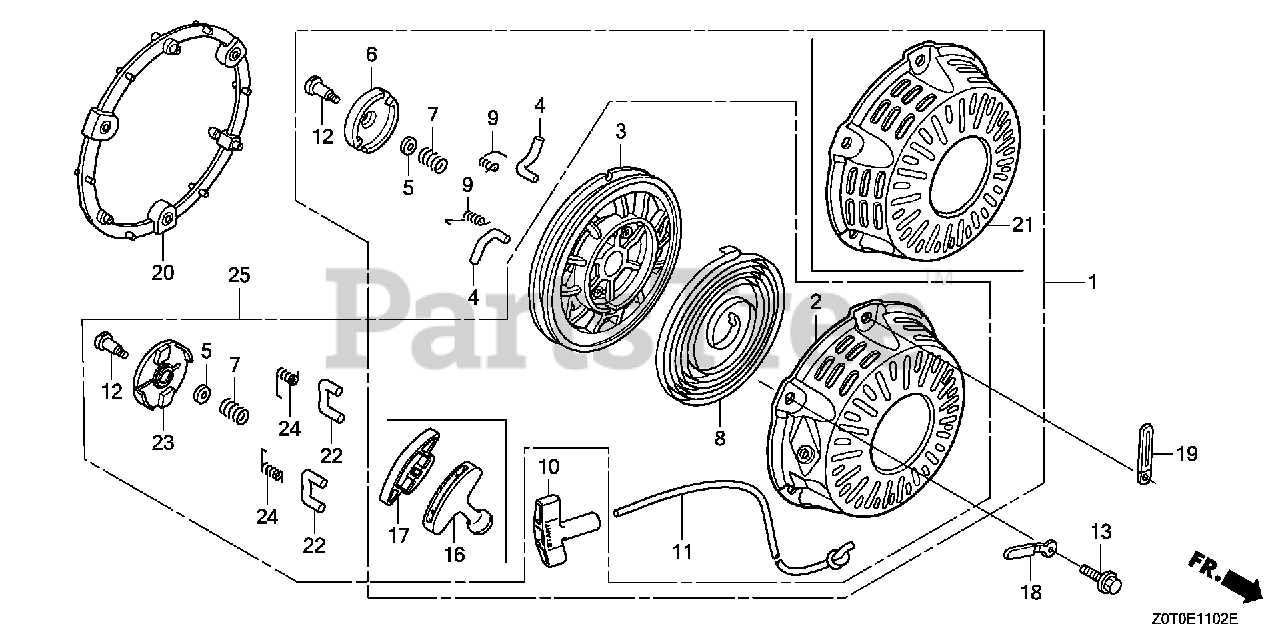

Starter Recoil: Over time, this mechanism can become less reliable. A replacement ensures that starting the engine remains effortless and efficient.

By being proactive and replacing these common elements, you can maintain your engine’s performance and prevent costly repairs down the line.

Benefits of Regular Maintenance

Consistent upkeep of machinery significantly enhances performance and longevity. By adhering to a routine schedule, users can prevent minor issues from escalating into costly repairs, ensuring optimal functionality.

| Benefit | Description |

|---|---|

| Increased Efficiency | Regular servicing helps maintain peak performance, leading to better fuel efficiency and lower operational costs. |

| Extended Lifespan | Timely maintenance minimizes wear and tear, prolonging the lifespan of the equipment. |

| Safety Assurance | Routine checks ensure all components function correctly, reducing the risk of accidents or malfunctions. |

| Cost Savings | Preventive maintenance often costs less than emergency repairs, making it a financially wise decision. |

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining optimal performance in small engines. Regular inspection can prevent costly repairs and ensure longevity.

Common indicators of wear include:

- Unusual noises during operation

- Decreased efficiency or power output

- Visible cracks or damage on external components

To assess wear effectively, consider the following steps:

- Perform visual inspections regularly.

- Listen for any irregular sounds while the engine runs.

- Check fluid levels and conditions frequently.

By taking these measures, you can delve deeper into the health of your equipment and address issues before they escalate.

Where to Purchase Genuine Parts

When it comes to maintaining and repairing your equipment, sourcing authentic components is crucial for optimal performance and longevity. Relying on original items ensures compatibility and enhances the reliability of your machinery. In this section, we will explore various avenues for obtaining these essential elements, guaranteeing peace of mind and high-quality results.

Authorized Dealers

One of the most reliable sources for authentic components is authorized dealerships. These establishments not only stock original items but also provide expert guidance and support. Purchasing from an authorized dealer ensures that you are getting components that meet the manufacturer’s specifications, which can significantly impact the efficiency of your machine.

Online Retailers

In today’s digital age, many reputable online platforms offer a wide range of original components. It is essential to choose well-established websites that specialize in machinery supplies. Look for customer reviews and verify the seller’s reputation to ensure that the items are genuine. Many of these retailers also provide detailed descriptions and specifications, making it easier to find the exact parts you need.

DIY Repair Tips for GX200

When tackling repairs on small engines, having a solid approach can make all the difference. This guide provides practical advice for enthusiasts looking to enhance their mechanical skills while ensuring optimal performance of their equipment.

Essential Tools and Preparation

Before starting any maintenance, gather necessary tools like wrenches, screwdrivers, and a torque wrench. A clean, well-lit workspace is crucial. Preparation involves understanding the assembly and having a reliable manual for reference, which can help you navigate repairs effectively.

Common Issues and Solutions

Many users encounter issues such as fuel leaks or starting difficulties. Regularly inspect the fuel lines and carburetor for blockages. Cleaning these components can often restore functionality. Additionally, check the ignition system; replacing spark plugs is a simple yet effective solution for performance issues.

Common Issues and Solutions

When dealing with small engine machinery, various challenges may arise that can impact performance and efficiency. Understanding these common problems and their remedies can significantly enhance the longevity and reliability of the equipment.

One frequent issue is difficulty in starting the engine. This can stem from fuel delivery problems, such as clogged filters or stale gasoline. To resolve this, ensure that fresh fuel is used and that all filters are clean and unobstructed.

Another common concern is irregular operation or stalling. This may be attributed to air leaks in the intake or issues with the spark plug. Regular maintenance, including inspecting gaskets and replacing worn plugs, can help maintain consistent performance.

Overheating is also a notable problem, often caused by insufficient lubrication or debris blocking airflow. Checking oil levels and ensuring the cooling system is clear can prevent overheating and potential engine damage.

Finally, unusual noises during operation can indicate wear or damage to internal components. Conducting routine inspections and replacing any worn parts promptly can mitigate serious issues and extend the life of the machinery.

Upgrading Your GX200 Performance

Enhancing the capabilities of your engine can significantly improve efficiency and output. By exploring various modifications, you can unlock its full potential, making it more responsive and powerful. Whether it’s through improving airflow, optimizing fuel delivery, or enhancing ignition timing, each upgrade contributes to a smoother and more robust performance.

Start with a high-quality air filter to increase airflow and reduce restrictions. Coupled with a performance exhaust system, these changes can lead to noticeable gains in power. Additionally, considering a carburetor adjustment can ensure optimal fuel mixture, further boosting efficiency and throttle response.

For those seeking even more power, investing in a high-performance ignition system may yield significant benefits. Upgrading to a better spark plug and ignition coil can improve combustion efficiency, resulting in enhanced performance and reliability.

Finally, regular maintenance remains crucial to keep your modifications functioning at their best. Regular oil changes and valve adjustments will not only prolong the lifespan of your engine but also ensure that all upgrades perform optimally over time.