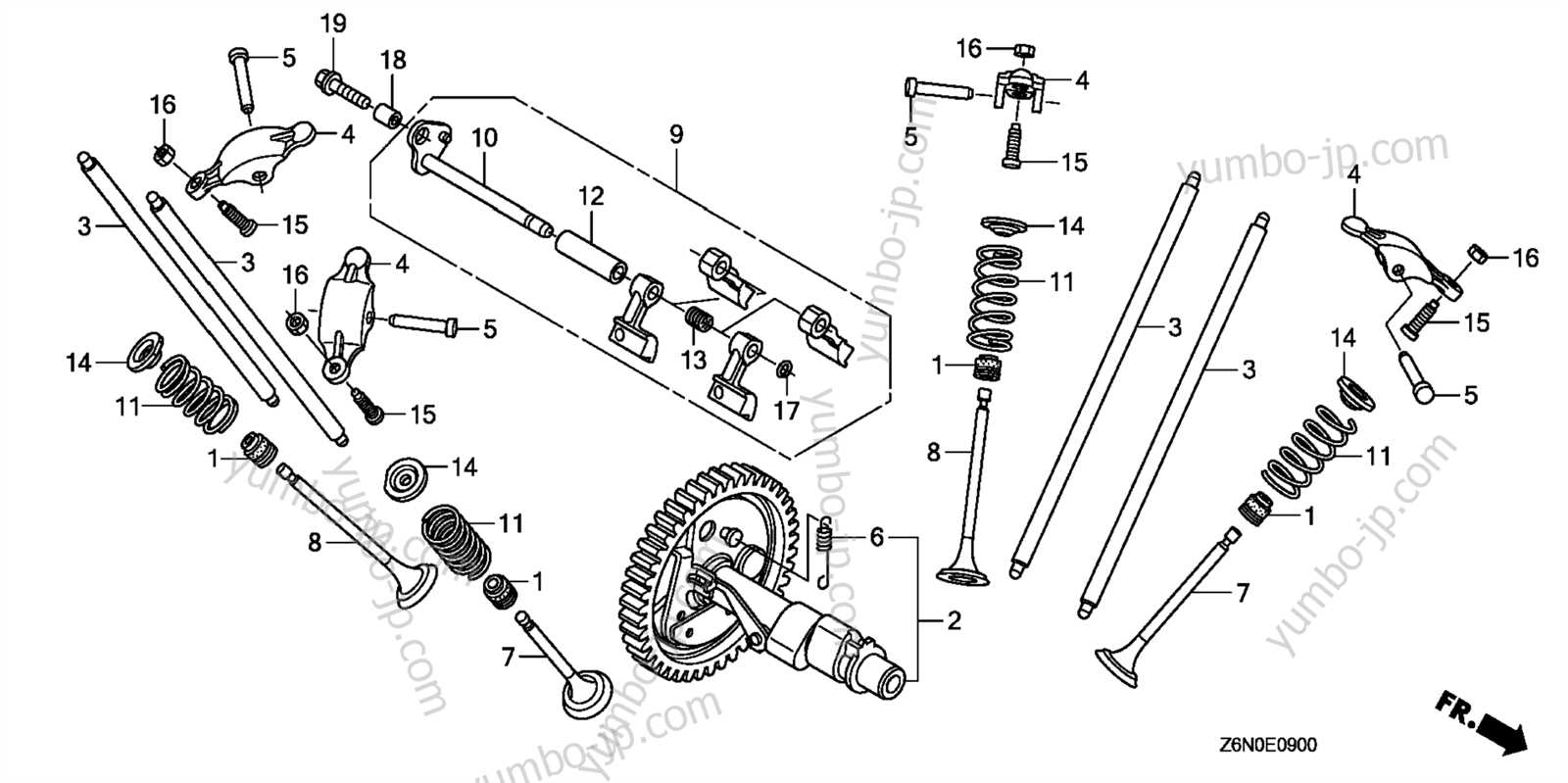

Comprehensive Honda GX630 Parts Diagram Guide

In the realm of small engine maintenance, comprehending the various elements that comprise a power unit is crucial for optimal performance. A clear visualization of these components aids in identifying parts that may require attention or replacement.

Visual aids play a vital role in simplifying the intricate assembly of engine units, allowing users to easily locate specific elements. By studying these illustrations, one can delve into the workings of their machinery and ultimately enhance their repair skills.

The ability to pinpoint each component contributes not only to effective troubleshooting but also to informed decision-making when acquiring replacements. Gaining insight into this intricate network ultimately empowers users to maintain their engines more efficiently.

Overview of Honda GX630 Engine

This engine is designed to deliver robust performance and reliability for a variety of applications. With a strong emphasis on efficiency and durability, it caters to both commercial and residential needs, making it a preferred choice among many users.

Key features include a powerful twin-cylinder design, which ensures smooth operation even under heavy loads. The advanced technology employed in its construction enhances fuel efficiency and reduces emissions, aligning with modern environmental standards.

Maintenance is simplified through accessible components, allowing users to easily perform routine checks and replacements. Overall, this engine stands out as a reliable solution for those seeking performance without compromising on quality.

Importance of Parts Diagrams

Understanding the components of any machinery is essential for efficient maintenance and repair. Visual representations of these elements facilitate clarity, helping users identify and locate necessary parts with ease. This approach not only enhances the learning process but also ensures that tasks are carried out with precision and confidence.

Benefits of Visual Representations

- Improved Efficiency: Clear illustrations speed up the identification of components, reducing downtime during repairs.

- Enhanced Understanding: Visual aids help users grasp complex assemblies and their functions.

- Accurate Repairs: Detailed images guide users to the correct replacement parts, minimizing errors.

- Cost Savings: Knowledge of specific elements can lead to more effective troubleshooting, ultimately saving time and money.

Usage in Maintenance

- Facilitates regular checks and preventative maintenance.

- Assists in the assembly and disassembly of machinery.

- Provides a reference for troubleshooting issues.

Key Components of the GX630

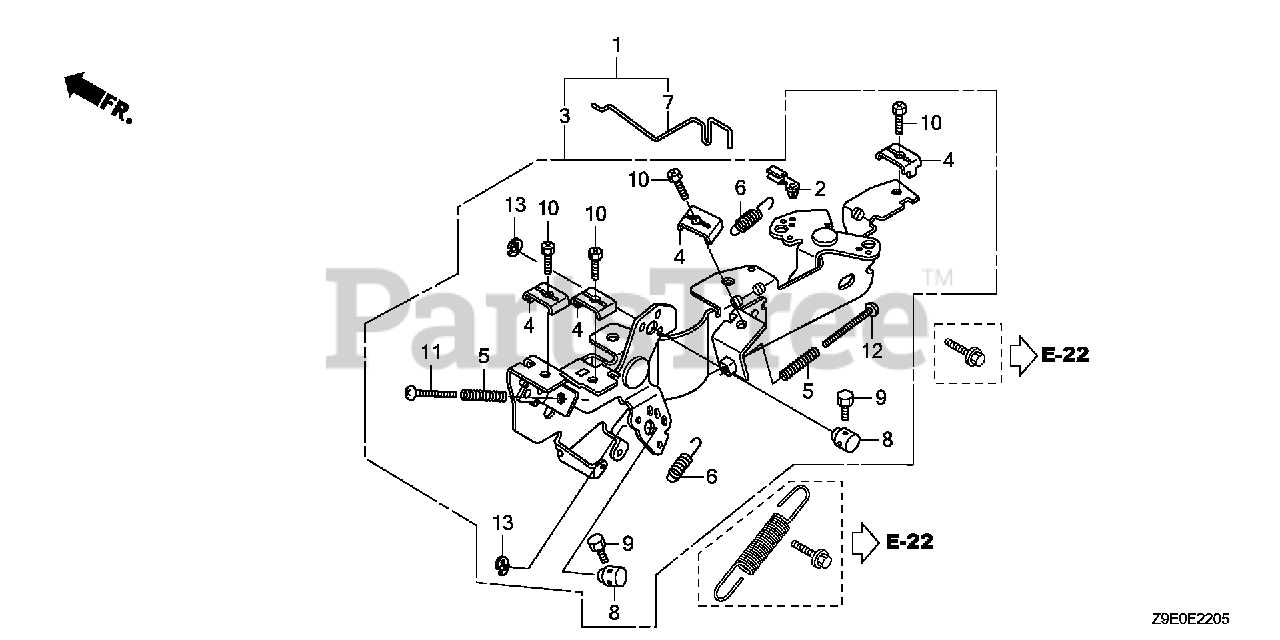

This section highlights the essential elements that contribute to the functionality and performance of the engine. Understanding these components is crucial for maintenance and optimal operation.

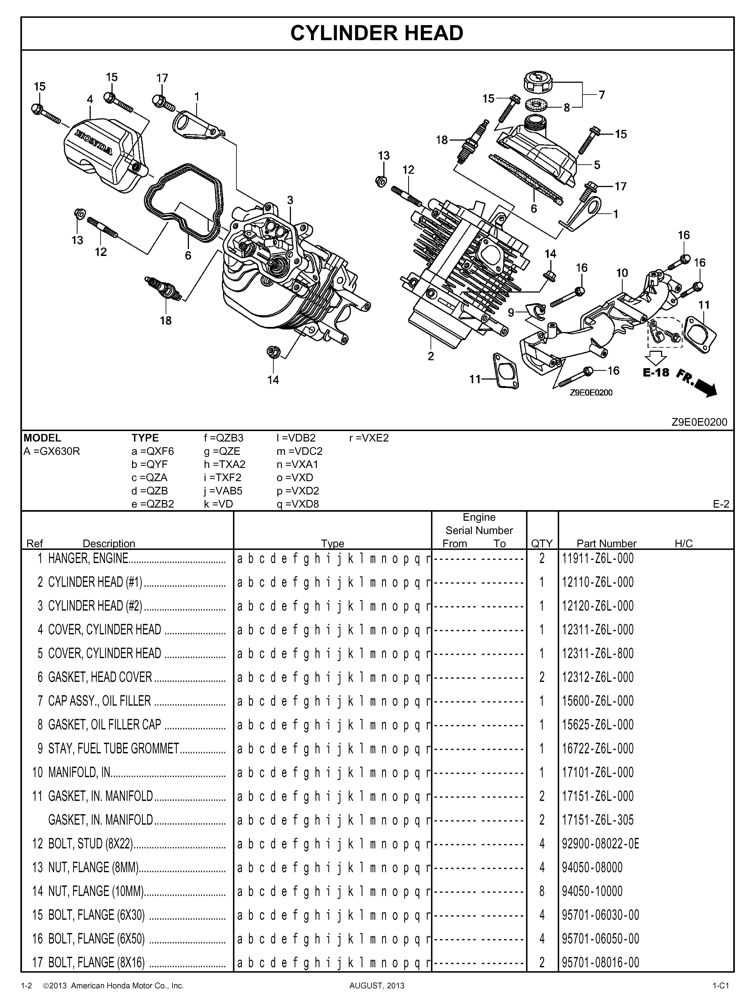

Engine Block and Cylinder Head

The engine block houses the cylinders where combustion occurs, while the cylinder head plays a vital role in the air-fuel mixture and exhaust flow. Together, they form the core of the power generation process, making their condition critical for efficiency.

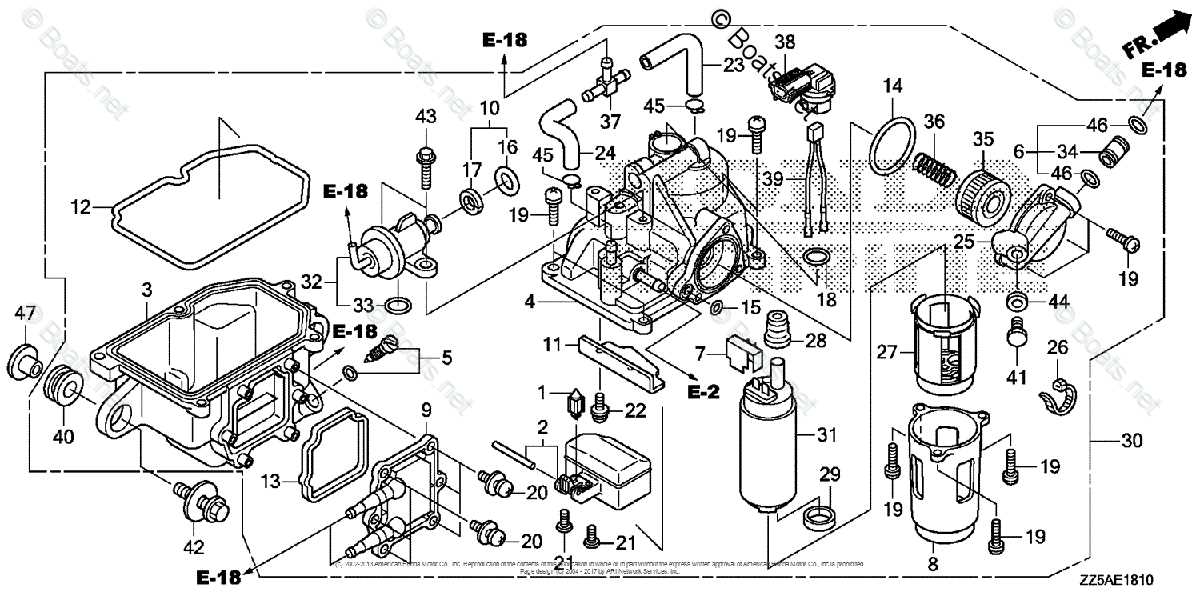

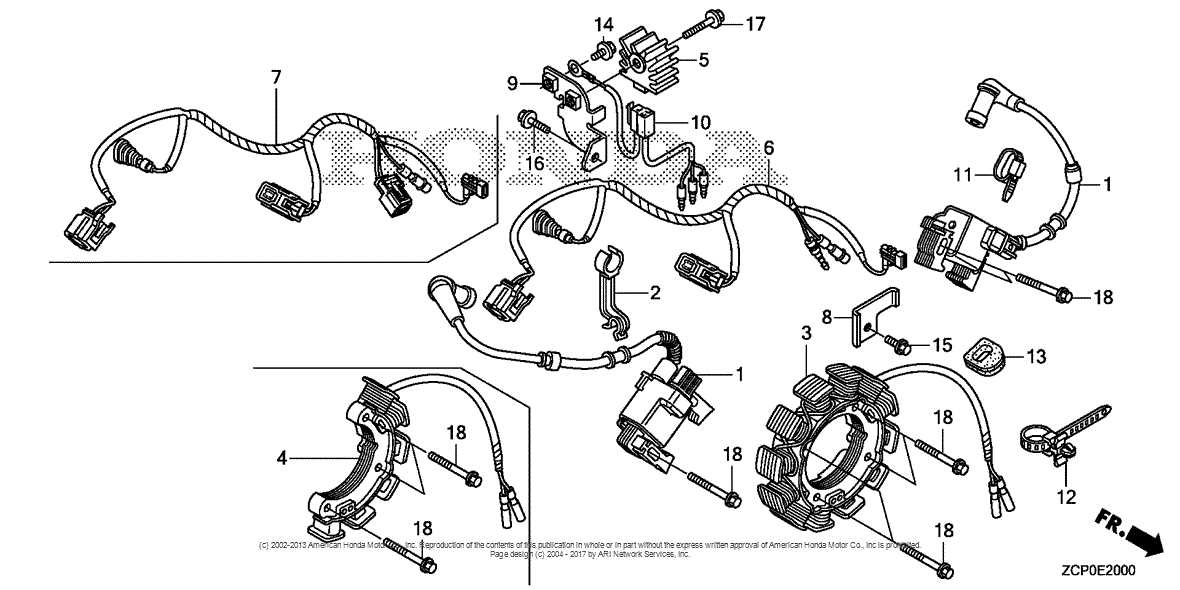

Fuel System and Ignition

The fuel system ensures a proper supply of fuel, while the ignition system is responsible for initiating combustion. Both systems are intricately linked, impacting the overall performance and reliability of the engine.

Understanding Engine Assembly

The assembly of a power unit involves the intricate arrangement and interaction of numerous components, each playing a vital role in the overall functionality. A clear grasp of how these parts fit together is essential for maintenance, troubleshooting, and optimization of performance. This section delves into the fundamental aspects of engine construction, highlighting key elements that contribute to efficient operation.

Key Components

At the core of any engine are critical elements such as the cylinder block, pistons, and crankshaft. The cylinder block houses the cylinders where combustion occurs, while the pistons convert the energy from this process into mechanical motion. The crankshaft then translates this motion into rotational energy, enabling the machine to perform its intended tasks. Understanding the relationship and interaction among these parts is crucial for effective maintenance and repair.

Assembly Process

The assembly process is a meticulous procedure that requires precision and attention to detail. Each component must be fitted correctly to ensure optimal performance and longevity. Proper alignment and torque specifications are essential to prevent issues such as vibrations or leaks. Familiarity with the assembly sequence and the role of each part helps in both the assembly and disassembly processes, allowing for efficient repairs when necessary.

Common Replacement Parts

When maintaining small engines, certain components often require replacement due to wear and tear. Understanding these elements can enhance performance and longevity, ensuring efficient operation.

Air Filter: A clean filter is essential for optimal airflow, preventing contaminants from entering the engine. Regular replacement helps maintain efficiency.

Spark Plug: This crucial component ignites the fuel-air mixture. Regularly replacing spark plugs can lead to smoother starts and improved fuel economy.

Oil Filter: Keeping the oil clean is vital for engine health. A new oil filter ensures that lubricants remain effective, reducing friction and wear.

Fuel Filter: This part safeguards the fuel system by trapping impurities. Replacing it periodically helps maintain proper fuel flow and engine performance.

Battery: A reliable power source is essential for starting the engine. Regular checks and replacements can prevent unexpected failures.

Maintenance Tips for Longevity

Ensuring the durability and efficient performance of your equipment requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery while minimizing the risk of costly repairs. Regular maintenance not only enhances functionality but also contributes to safety during operation.

Here are some key maintenance tips to keep your equipment running smoothly:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil to prevent overheating and ensure proper lubrication. |

| Air Filter Cleaning | Every 50 hours | Clean or replace the air filter to maintain optimal airflow and performance. |

| Fuel System Inspection | Every season | Check fuel lines and filters for leaks or blockages to ensure efficient operation. |

| Spark Plug Replacement | Every 200 hours | Inspect and replace spark plugs to promote reliable starting and efficient combustion. |

| Battery Maintenance | Monthly | Check battery terminals and charge levels to prevent unexpected failures. |

By adhering to these maintenance guidelines, you can ensure that your machinery remains in peak condition, providing reliable service for years to come. Regular inspections and timely interventions are key to avoiding more significant issues down the line.

Where to Find Diagrams

Locating detailed illustrations and schematics for machinery components can greatly aid in repairs and maintenance. Various resources are available for enthusiasts and professionals alike, making it easier to access the necessary visual aids for any project.

Online Resources

- Manufacturer Websites: Many producers provide comprehensive documentation, including images and assembly instructions, directly on their official sites.

- Specialty Forums: Online communities dedicated to equipment and machinery often share resources, including illustrations submitted by users.

- Instructional Videos: Platforms like YouTube feature tutorials that may include visual references, demonstrating assembly or disassembly processes.

Print Resources

- Repair Manuals: Printed guides often contain detailed illustrations and are available at bookstores or online retailers.

- Library Archives: Local libraries may have technical manuals or books that feature schematics for a variety of machinery.

- Trade Magazines: Publications focused on industry advancements sometimes include supplementary materials with diagrams and technical drawings.

Using Diagrams for Repairs

Visual representations are invaluable tools when it comes to the maintenance and repair of machinery. These illustrations provide clarity and precision, allowing users to identify components and understand their relationships within complex systems. By utilizing these resources, individuals can streamline their repair processes and enhance their overall effectiveness.

Benefits of Using Visual Aids

- Enhanced Understanding: Visual aids clarify the layout and function of various parts, making it easier to grasp how they interact.

- Time Efficiency: Quickly locating components reduces the time spent searching for specific pieces, accelerating the repair process.

- Minimized Errors: Clear illustrations help prevent mistakes, ensuring that assembly and disassembly are conducted correctly.

- Step-by-Step Guidance: Many visual resources offer sequential instructions that guide users through the repair process systematically.

Tips for Effective Use

- Familiarize Yourself: Take time to study the visual aid before beginning repairs to understand the layout thoroughly.

- Keep It Accessible: Have the illustration handy during repairs to refer back to it as needed.

- Highlight Key Areas: Mark crucial components on the visual aid to streamline the focus during the repair process.

- Combine with Manuals: Use diagrams alongside written manuals for a comprehensive understanding of the repair steps.

Identifying OEM vs. Aftermarket Parts

When it comes to machinery components, distinguishing between original equipment manufacturer offerings and alternatives is crucial for ensuring performance and longevity. Understanding the differences can help users make informed decisions tailored to their needs.

Quality and Reliability

Original components are designed to meet specific standards, providing a reliable performance that is often backed by warranties. In contrast, alternative options may vary in quality, which can affect functionality and durability.

Cost Considerations

While original parts typically come at a premium price, they often represent an investment in quality. Alternative components may offer cost savings, but potential trade-offs in performance should be carefully evaluated before making a choice.

Common Issues with GX630 Engines

Engines of this type often encounter several recurring problems that can affect performance and longevity. Identifying these issues early can help prevent extensive repairs and ensure smooth operation.

Frequent Problems

- Overheating due to insufficient cooling or low fluid levels.

- Starting difficulties caused by electrical issues or fuel delivery problems.

- Excessive vibration resulting from imbalanced components or wear.

- Oil leaks from gaskets or seals leading to lubrication issues.

Maintenance Tips

- Regularly check and replace air filters to ensure proper airflow.

- Monitor fluid levels and change oil as recommended by the manufacturer.

- Inspect belts and hoses for wear and replace them as necessary.

- Clean or replace spark plugs to maintain efficient combustion.

Benefits of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. By adhering to a routine maintenance schedule, operators can identify potential issues early and avoid costly repairs. This proactive approach not only enhances reliability but also contributes to overall efficiency.

Improved Performance

Regular service helps maintain peak operational efficiency. When components are cleaned, lubricated, and replaced as necessary, equipment runs smoother and uses less energy. This leads to better fuel efficiency and reduced operational costs.

Increased Lifespan

Frequent inspections and timely interventions can significantly extend the lifespan of equipment. By addressing wear and tear early, operators can prevent serious damage that could result in the need for premature replacement.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 50 hours | Reduces engine wear, improves efficiency |

| Filter Replacement | Every 100 hours | Ensures clean operation, prevents blockages |

| Belt Inspection | Every 200 hours | Prevents failures, ensures smooth operation |

| Fuel System Check | Every 100 hours | Maintains optimal performance, prevents corrosion |