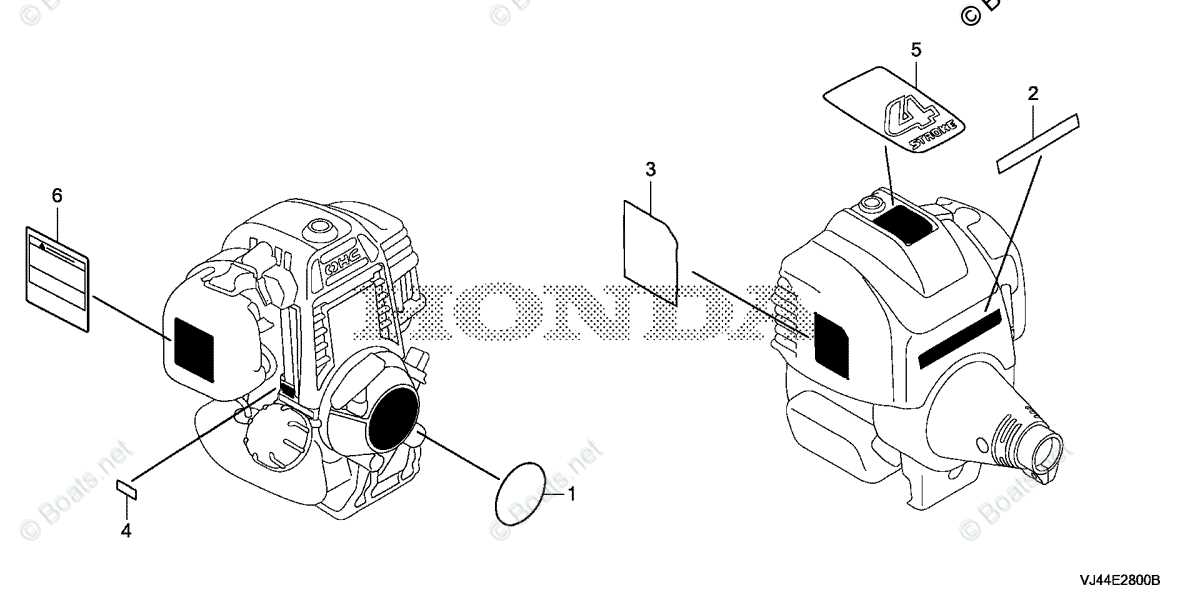

Parts Diagram for Honda HHT25S Trimmer

Understanding the various elements and their functions within a specific mechanical system is crucial for effective maintenance and repair. Comprehensive visual representations serve as valuable resources, guiding users through the intricacies of assembly and disassembly.

In this section, we will explore detailed illustrations that highlight each segment’s role and interconnections. These visuals are essential for both novice and experienced technicians, ensuring a clearer grasp of the overall structure and functionality.

By delving into these visual aids, users can better appreciate how individual components work in harmony. This knowledge not only enhances troubleshooting skills but also promotes efficient servicing practices, ultimately prolonging the lifespan of the equipment.

Overview of Honda HHT25S Parts

This section provides a comprehensive look at the essential components that make up a specific model of outdoor equipment. Understanding these elements is crucial for maintenance and repair tasks, ensuring optimal performance and longevity.

The main components can be categorized into several groups, each serving a unique function:

- Engine Assembly: The heart of the machinery, responsible for generating power.

- Cutting Mechanism: Includes blades and attachments, designed for effective trimming and cutting.

- Fuel System: Comprises the tank and lines, essential for storing and delivering fuel.

- Drive System: Involves parts that transfer power from the engine to the cutting components.

- Frame and Housing: The structural elements that provide support and protection to internal components.

Familiarity with these categories allows users to identify specific elements when troubleshooting issues or performing routine checks. Each component plays a vital role in ensuring the equipment functions efficiently, making knowledge of them beneficial for both novice and experienced users.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functioning of machinery. These illustrations serve as essential tools for both novice users and experienced technicians, enabling them to navigate complex systems with ease.

One of the primary advantages of these visual aids is their ability to simplify intricate structures. By breaking down a machine into its individual elements, users can:

- Quickly identify specific components.

- Gain insights into how various parts interact with one another.

- Streamline the repair and maintenance process.

Additionally, these visuals enhance communication among team members and facilitate effective training for new personnel. When everyone has access to the same reference material, misunderstandings are minimized, leading to improved efficiency and productivity.

In summary, well-crafted visual representations not only aid in the comprehension of machinery but also contribute significantly to the overall effectiveness of maintenance and repair tasks.

Identifying Key Components

Understanding the essential elements of a machinery system is crucial for effective operation and maintenance. Recognizing these components helps in troubleshooting, ensuring longevity, and optimizing performance. This section focuses on the vital parts of the specified equipment, providing insights into their functions and interrelationships.

Overview of Main Parts

The machinery consists of various integral parts, each serving a specific purpose. Familiarity with these components enables users to identify issues quickly and make informed decisions regarding repairs or replacements.

Functionality and Importance

Each component plays a significant role in the overall functionality of the device. Proper understanding of their roles aids in ensuring efficient operation and minimizing downtime.

| Component Name | Function | Importance |

|---|---|---|

| Engine | Provides power to the system | Essential for operation |

| Fuel Tank | Stores the necessary fuel | Critical for energy supply |

| Blade Assembly | Facilitates cutting action | Key for performance |

| Handle | Enables user control | Important for maneuverability |

Common Replacement Parts Explained

Understanding the various components that may need replacement over time is crucial for maintaining optimal performance and longevity of your equipment. Regular wear and tear can lead to a need for replacements, ensuring everything operates smoothly and efficiently.

Here are some frequently replaced components that you might encounter:

- Air Filters: These elements play a vital role in keeping the engine free of debris and contaminants. Replacing them regularly enhances air quality and performance.

- Fuel Lines: Essential for transporting fuel, these tubes can degrade over time, leading to leaks or blockages. Timely replacements are necessary to avoid issues with fuel delivery.

- Blades: Sharp, effective blades are crucial for achieving clean cuts. Dull or damaged blades can hinder performance and require frequent replacement.

- Spark Plugs: Responsible for igniting the fuel-air mixture, worn spark plugs can lead to starting difficulties and decreased efficiency. Regular inspection and replacement are advisable.

- Drive Belts: These belts facilitate the transfer of power from the engine to various components. If they show signs of wear or cracking, it’s important to replace them to maintain functionality.

By staying aware of these common replacement items, you can ensure your equipment continues to function effectively and reliably.

Maintenance Tips for Longevity

To ensure the extended lifespan of your outdoor equipment, regular upkeep and attention to detail are essential. Implementing a consistent maintenance routine can prevent wear and tear, enhance performance, and ultimately save you from costly repairs.

- Regular Cleaning: Remove debris and dirt after each use to prevent buildup that can hinder functionality.

- Check Fluids: Inspect oil and fuel levels regularly, and replace them as necessary to maintain optimal performance.

- Inspect Components: Periodically examine critical parts such as the blades, filters, and belts for signs of damage or wear.

- Sharpen Blades: Keeping blades sharp ensures efficient operation and reduces strain on the engine.

- Store Properly: When not in use, store the equipment in a dry, sheltered area to protect it from harsh weather conditions.

- Follow Manufacturer Recommendations: Adhere to the guidelines provided by the manufacturer for specific maintenance tasks and intervals.

By following these tips, you can enhance the reliability and longevity of your equipment, ensuring it performs efficiently for years to come.

Where to Find Authentic Parts

Locating genuine components for outdoor equipment is essential for maintaining optimal performance and longevity. Authentic replacements ensure compatibility and reliability, which are crucial for efficient operation. Here are some recommended sources to consider when searching for high-quality substitutes.

Authorized Dealers

One of the most reliable ways to obtain genuine components is through authorized distributors. These dealers are sanctioned by the manufacturer and can provide:

- Verified quality assurance

- Comprehensive product information

- Warranty options on purchased items

Online Retailers

Reputable online platforms also offer a wide selection of genuine components. When shopping online, it is advisable to:

- Verify seller ratings and reviews.

- Check return policies for unsatisfactory products.

- Look for detailed product descriptions and specifications.

By utilizing these resources, you can ensure that your equipment remains in top condition with authentic replacements.

Visual Representation in Diagrams

Visual aids play a crucial role in conveying complex information effectively. By utilizing illustrations, one can simplify intricate concepts, making them more accessible to the audience. These graphical tools serve as a bridge between technical details and user understanding.

When examining mechanical components, visual representations help to highlight the relationships between different elements. They can illustrate how parts interact, their placement, and the overall assembly process. Here are several key benefits of utilizing visual representations:

- Enhanced Clarity: Diagrams reduce confusion by providing a clear view of the structure and function of each component.

- Efficient Learning: Users often grasp information quicker through visual means than through text alone.

- Improved Retention: Visuals aid memory retention, allowing users to recall information more effectively.

- Streamlined Troubleshooting: Clear illustrations help identify issues more quickly, facilitating faster repairs and maintenance.

In summary, employing visual tools significantly aids in understanding mechanical systems. They transform complex information into digestible content, benefiting both users and technicians alike.

Understanding Component Compatibility

When working with various mechanical devices, it is essential to recognize how different elements can work together effectively. Ensuring that components are compatible with each other can significantly enhance performance and extend the lifespan of the equipment. This section will explore the fundamental aspects of compatibility and its importance in maintaining optimal functionality.

Key Considerations for Compatibility

- Specifications: Each component has specific requirements regarding size, shape, and functionality. Verifying these details is crucial.

- Material Compatibility: The materials used in the construction of components must interact well to prevent wear and tear.

- Performance Standards: Understanding the performance criteria ensures that parts will function correctly under expected conditions.

Assessing Compatibility

- Review the manufacturer’s guidelines for each component.

- Consult with technical experts or resources to verify compatibility.

- Test components in a controlled environment before full implementation.

By following these steps and being mindful of the characteristics of each element, users can ensure that their mechanical systems operate smoothly and efficiently.

Using Diagrams for Troubleshooting

Visual representations are invaluable tools in the maintenance and repair of various equipment. They provide a clear layout of components, aiding users in identifying issues more efficiently. By consulting these illustrations, one can understand the interconnections and functions of different parts, which is essential for effective problem-solving.

When attempting to resolve technical difficulties, consider the following benefits of utilizing visual aids:

- Clarity: Visual guides simplify complex systems, making it easier to locate specific elements.

- Efficiency: Quickly pinpointing faulty components minimizes time spent on troubleshooting.

- Enhanced Understanding: Diagrams facilitate a better grasp of how various parts interact within the machinery.

- Step-by-Step Guidance: Many illustrations provide sequential instructions, helping users follow a logical repair process.

Incorporating visual resources into the troubleshooting process empowers individuals to address problems with confidence. By leveraging these aids, users can ensure that repairs are conducted accurately and effectively, ultimately extending the lifespan of the equipment.

Frequently Asked Questions on Components

This section addresses common inquiries regarding various components used in specific machinery. Understanding these elements is crucial for effective maintenance and optimal performance. Below are some frequently encountered questions and their corresponding answers.

General Queries

- What types of elements are typically needed for repairs?

Repair requirements may vary based on the machinery in question. Common items include:

- Engines

- Belts

- Filters

- Wiring harnesses

- How can I ensure the quality of the components I purchase?

To guarantee quality, consider the following:

- Buy from reputable suppliers.

- Check for warranties or guarantees.

- Read customer reviews.

- Inspect items for any visible damage.

Specific Concerns

- Are there recommended maintenance schedules for different parts?

Yes, maintenance schedules depend on the component and usage frequency. Regular inspections can help identify when replacements are necessary.

- Where can I find a reliable source for replacement items?

Consider the following options:

- Authorized dealerships

- Online marketplaces

- Local repair shops

- Manufacturer websites