Comprehensive Guide to Honda HRM215 Parts Diagram

The efficient operation of outdoor machinery relies heavily on a comprehensive understanding of its internal structures. A well-organized representation of these components can significantly enhance the maintenance and troubleshooting processes for users. This resource serves as a guide to navigate through the essential elements of such equipment.

By examining the intricate arrangements and functions of each section, one can delve into the ultimate mechanics behind performance. Whether you are a seasoned technician or a novice enthusiast, familiarizing yourself with these layouts will empower you to make informed decisions regarding repairs and upgrades.

In this exploration, we aim to provide clarity on the various elements that contribute to optimal functioning. Understanding how these pieces interact with one another is key to ensuring longevity and reliability in your outdoor tasks.

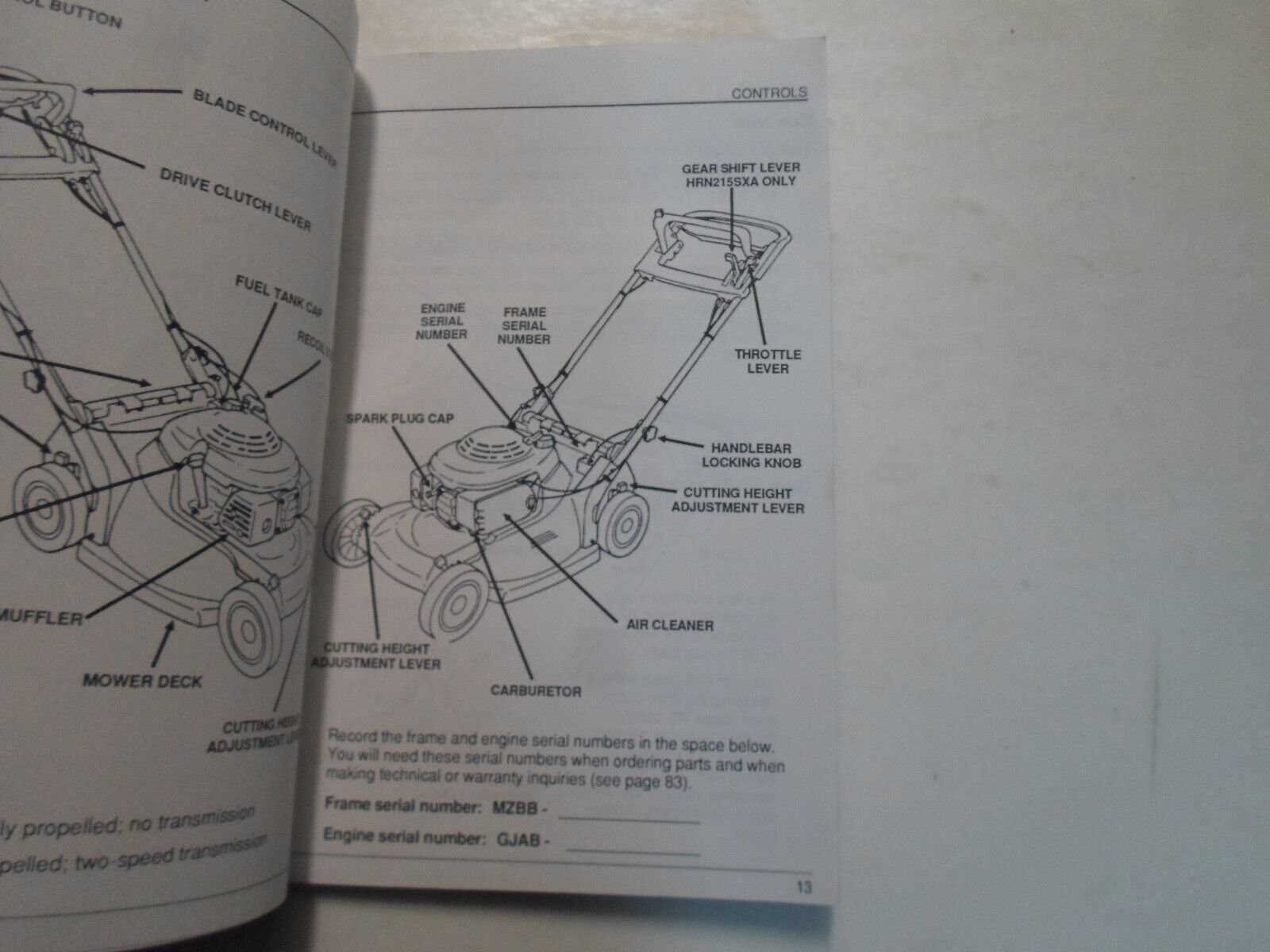

Understanding the Honda HRM215 Design

The design of this popular lawn maintenance tool reflects a blend of functionality and innovation. Every component is meticulously crafted to ensure optimal performance, allowing users to achieve pristine results with ease. From the engine’s efficiency to the ergonomic handles, each feature has been thoughtfully engineered to enhance user experience.

One of the standout aspects is the lightweight construction, which facilitates easy maneuverability across various terrains. The durable materials used in its assembly ensure longevity and resilience, making it a reliable choice for both residential and commercial use. Attention to detail is evident in the arrangement of parts, which promotes seamless operation and minimal maintenance.

Furthermore, the design incorporates advanced features such as adjustable cutting heights, allowing for customization based on the specific needs of the lawn. Such adaptability not only enhances functionality but also contributes to a well-groomed appearance, catering to diverse landscaping requirements.

Ultimately, the engineering behind this tool exemplifies a commitment to quality and efficiency, making it a valuable asset for anyone looking to maintain their outdoor space effectively.

Essential Components of the HRM215

Understanding the fundamental elements of this popular lawn care machine is crucial for maintenance and optimal performance. Each component plays a significant role in the overall functionality, ensuring efficiency in operation and durability over time.

Here are the key elements to consider:

- Engine: The heart of the machine, providing the necessary power for cutting.

- Blades: Sharp and durable, they ensure clean and precise cutting of grass.

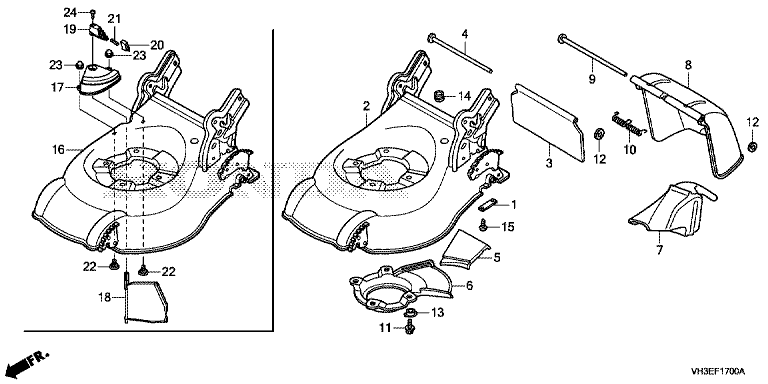

- Deck: The housing that supports the blades and engine, designed for durability and ease of cleaning.

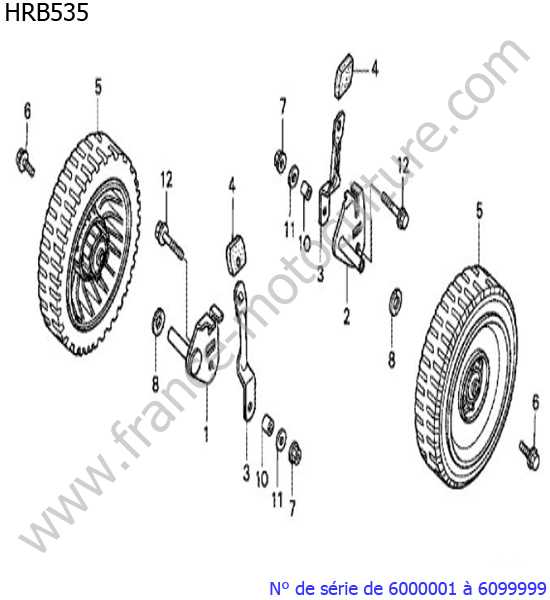

- Wheels: Essential for maneuverability, allowing smooth navigation across various terrains.

- Handles: Ergonomically designed for comfortable operation, often adjustable for user convenience.

- Fuel System: Responsible for storing and supplying fuel to the engine, critical for performance.

- Air Filter: Keeps the engine clean by filtering out debris, essential for maintaining efficiency.

Each of these components contributes to the machine’s effectiveness, and regular inspection can prevent potential issues, ensuring a long lifespan and top performance.

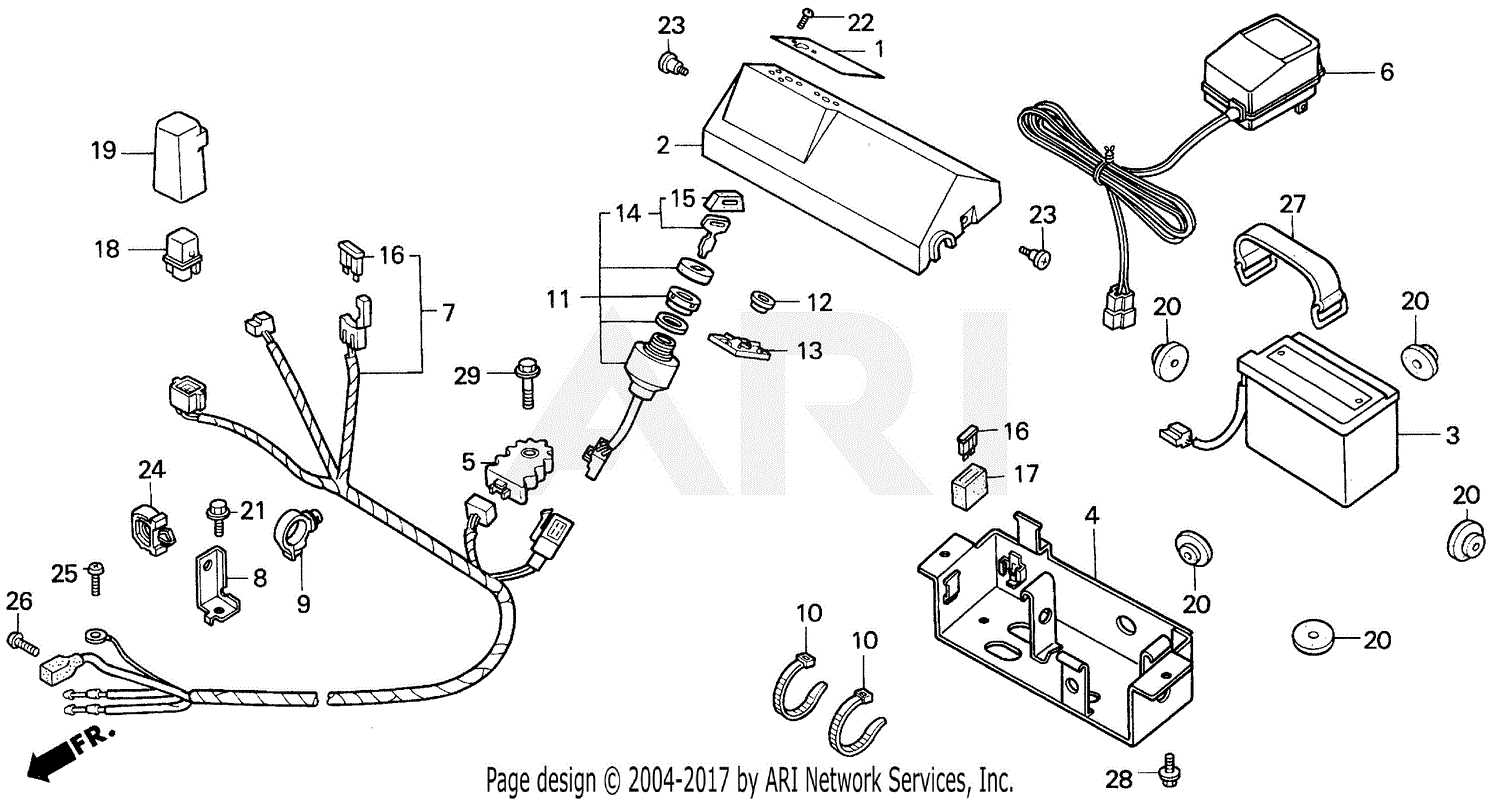

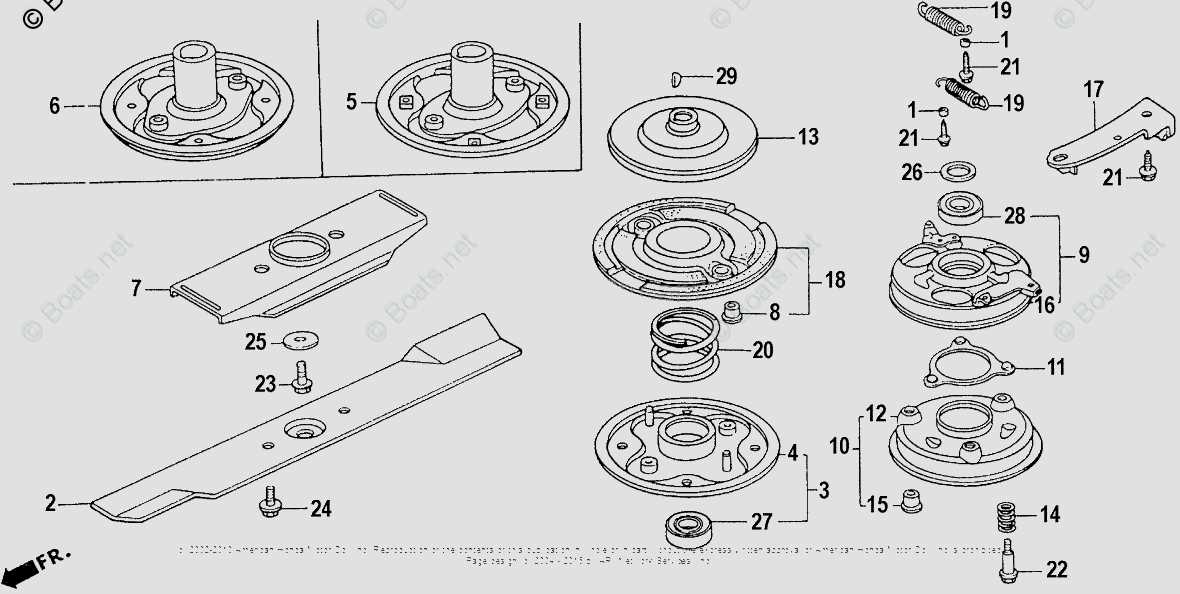

How to Read Parts Diagrams

Understanding visual schematics is crucial for anyone looking to repair or maintain machinery. These illustrations serve as guides, helping users identify components and their relationships within a system. By becoming familiar with these visuals, you can streamline your repair process and ensure accurate assembly.

Key Elements to Focus On

Start by noting the labels and numbers associated with each component. These identifiers often correspond to a list, making it easier to locate the specific pieces you need. Pay attention to the overall layout, as it provides insight into how parts interact, ensuring you grasp the ultimate function of the entire assembly.

Practice Makes Perfect

Regularly referring to these visuals will enhance your comprehension over time. Attempting to visualize the assembly in real-world applications solidifies your understanding. The more you delve into different schematics, the more proficient you will become at interpreting them efficiently.

Common Issues with HRM215 Parts

Maintenance and repair of lawn equipment can reveal several frequent challenges that users encounter. Understanding these issues is crucial for ensuring optimal performance and longevity of the machine. This section explores typical problems related to the components of this specific model.

1. Deterioration of the Cutting Blade: Over time, the cutting blade can become dull or even damaged, leading to inefficient grass cutting. Regular inspection and sharpening are essential to maintain its effectiveness.

2. Fuel System Complications: Blockages or leaks in the fuel system may arise, causing the engine to underperform or fail to start. Keeping fuel lines clean and ensuring proper sealing can mitigate these risks.

3. Electrical System Failures: Issues with the ignition system or battery can lead to starting problems. Routine checks of wiring and connections are advisable to avoid unexpected breakdowns.

4. Air Filter Clogging: A clogged air filter restricts airflow, which can impact engine performance. Regular cleaning or replacement of the air filter ensures optimal operation.

5. Wheel and Chassis Wear: Over time, wheels and chassis components may wear down, affecting maneuverability. Inspecting these parts regularly can prevent serious performance issues.

By being aware of these common challenges and conducting routine maintenance, users can enhance the reliability and functionality of their equipment.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By implementing simple yet effective maintenance strategies, you can enhance performance and prevent potential issues, allowing your machine to operate at its best.

Routine Inspections

Conduct frequent checks on key components to identify wear and tear early. This includes examining belts, blades, and filters to ensure they function smoothly. Keeping these parts in top shape will significantly improve overall efficiency.

Cleaning and Lubrication

Maintain cleanliness by removing debris and dirt that can hinder operation. Additionally, apply appropriate lubricants to moving parts to reduce friction and wear, ensuring smooth functionality and prolonging the lifespan of your equipment.

Where to Find Genuine Parts

When searching for authentic components, it’s essential to consider several reliable sources to ensure quality and compatibility. Obtaining the right items is crucial for optimal performance and longevity of your equipment.

- Authorized Dealers: Visiting certified retailers guarantees that you receive original products that meet the manufacturer’s standards.

- Online Marketplaces: Reputable e-commerce platforms often feature sections dedicated to original merchandise, allowing for convenient comparisons and reviews.

- Manufacturer Websites: Directly exploring official websites can provide valuable resources, including a catalog of available items and contact information for support.

- Local Repair Shops: Trusted mechanics or repair specialists frequently stock genuine components or can order them for you.

Ensuring authenticity in your purchases not only promotes reliability but also enhances overall satisfaction with your machinery.

Comparing HRM215 with Other Models

When assessing various lawn maintenance machines, it’s essential to understand the differences and similarities between models. Each variant offers unique features tailored to specific needs, making it crucial for users to evaluate their options carefully. This section highlights key aspects to consider when comparing this particular model with others in its class.

Performance and Efficiency

Performance is a significant factor when selecting a mower. The discussed machine boasts a powerful engine, allowing for effective cutting even in challenging conditions. In contrast, other models may prioritize lightweight designs, which can compromise power but enhance maneuverability. Users must decide whether they prefer robust cutting ability or agility in tight spaces.

Durability and Maintenance

Another vital consideration is durability and maintenance requirements. The highlighted model is known for its sturdy construction and longevity, which can reduce the frequency of repairs. Alternatively, some competitors might use lighter materials, which could affect their lifespan but offer lower initial costs. Understanding the trade-offs in durability and ease of upkeep can help users make informed choices based on their long-term usage plans.

Upgrades for Enhanced Efficiency

Improving performance and functionality can significantly impact the overall effectiveness of your equipment. By focusing on specific enhancements, users can achieve optimal results and prolong the lifespan of their machinery. Below are some recommended modifications that can lead to better efficiency.

| Upgrade | Description |

|---|---|

| High-Performance Blades | Switching to sharper, durable blades can reduce effort and improve cutting precision. |

| Air Filter Upgrade | A premium air filter can enhance airflow and boost engine performance. |

| Fuel Additives | Using quality fuel additives can help maintain engine cleanliness and efficiency. |

| Throttle Control Kit | This kit allows for finer adjustments to power output, improving fuel economy. |

DIY Repair Techniques for Owners

For those looking to tackle maintenance tasks independently, understanding essential repair methods can save both time and money. Empowering oneself with the right techniques enhances the overall ownership experience and prolongs the lifespan of equipment.

Here are some fundamental strategies to consider:

- Regular Inspection: Periodically check for wear and tear to catch issues early.

- Basic Tools: Equip yourself with necessary tools such as wrenches, screwdrivers, and pliers.

- Consult Manuals: Utilize manuals for guidance on specific repairs and adjustments.

- Watch Tutorials: Online videos can provide visual aids for complicated procedures.

- Practice Safety: Always prioritize safety by wearing protective gear and working in a well-lit area.

By applying these techniques, owners can confidently delve into maintenance tasks, ensuring optimal performance and reliability.

Identifying Wear and Tear Signs

Recognizing the signs of deterioration is essential for maintaining equipment efficiency and longevity. By observing key indicators, users can address potential issues before they escalate, ensuring optimal performance.

Common Indicators of Deterioration

- Excessive noise during operation

- Visible cracks or damages on components

- Decreased performance or efficiency

- Unusual vibrations while in use

Regular Maintenance Checks

- Inspect all moving parts for signs of wear.

- Check fluid levels and look for leaks.

- Clean components regularly to prevent buildup.

- Test functionality to ensure proper operation.

Tools Needed for HRM215 Repairs

Effective maintenance requires the right instruments to ensure smooth functionality and longevity. Having a well-organized toolkit can significantly simplify the repair process, making it more efficient and less time-consuming.

Essential Instruments

Start with basic hand tools, including wrenches, screwdrivers, and pliers. These are crucial for disassembling components and making necessary adjustments. Additionally, a socket set is invaluable for tackling various fasteners.

Advanced Equipment

For more intricate repairs, consider having a multimeter for electrical diagnostics and a cleaning kit for maintaining parts. A torque wrench will ensure that components are tightened to the manufacturer’s specifications, preventing damage.

Warranty Information and Support Services

This section provides essential details regarding protection plans and assistance options available to ensure your equipment remains in optimal condition. Understanding these services can significantly enhance your experience and peace of mind.

Warranty Coverage

- Duration of coverage

- What is included in the warranty

- Exclusions and limitations

Support Options

- Customer service contacts

- Online resources and FAQs

- Repair and service centers