Complete Guide to Honda HRR216 Parts Diagram

In the world of lawn care, having a clear understanding of your machine’s components is essential for optimal performance and maintenance. This knowledge empowers users to identify parts easily, facilitating repairs and enhancing the lifespan of the equipment.

Every mower consists of various integral pieces that work in harmony to ensure effective operation. From the cutting blade to the engine, each element plays a crucial role in delivering the ultimate performance, making familiarity with these components invaluable for any owner.

By exploring a visual representation of these essential parts, users can delve into the mechanics of their machine. This guide aims to provide clarity and insight, enabling individuals to tackle maintenance tasks with confidence and precision.

Understanding Honda HRR216 Parts

Familiarity with the components of your mower is essential for maintaining its performance and ensuring longevity. Each element plays a crucial role in the overall functionality, from the cutting system to the engine. By understanding these elements, you can effectively troubleshoot issues and perform necessary repairs or upgrades.

Key Components

The core assembly consists of several vital pieces, including the motor, blades, and wheels. Each part must work in harmony to achieve optimal results. For instance, the engine is responsible for generating power, while the blades are designed for efficient grass cutting. Regular inspection of these elements can prevent unexpected breakdowns.

Maintenance Tips

Regular upkeep is critical for any mechanical device. Keeping the blades sharp, checking the oil levels, and ensuring that all connections are secure are fundamental practices. Neglecting maintenance can lead to diminished performance and costly repairs. Emphasizing these aspects will enhance the lifespan of your equipment and improve its overall effectiveness.

Overview of HRR216 Lawn Mower

This section provides a comprehensive look at a popular gardening tool designed for efficient lawn maintenance. Known for its reliability and performance, this mower has become a favorite among homeowners and landscapers alike.

- Engine Power: Features a robust engine that ensures optimal cutting performance.

- Cutting Width: Designed with a wide cutting deck for quick and effective lawn care.

- Height Adjustment: Offers multiple height settings for versatile grass management.

- Fuel Efficiency: Engineered for lower fuel consumption, promoting eco-friendly usage.

- Durability: Built with high-quality materials to withstand regular use.

With its user-friendly design, this equipment is suitable for both novice and experienced users, making it an ultimate choice for achieving a well-maintained yard.

Main Components of the Mower

Understanding the essential elements of a lawn cutting machine is crucial for efficient operation and maintenance. Each part plays a specific role in ensuring the equipment functions smoothly, contributing to a well-manicured lawn. This section will delve into the primary components, highlighting their functions and importance.

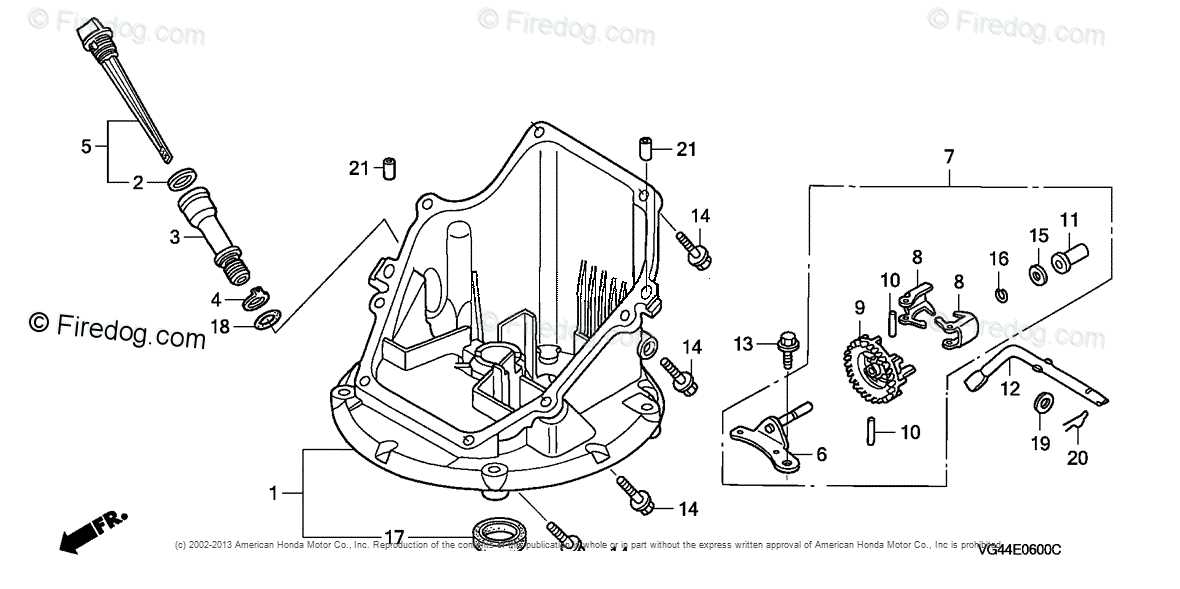

Engine and Power System

The engine serves as the heart of the machine, providing the necessary power for cutting grass and maneuvering across various terrains. It converts fuel into mechanical energy, allowing the blades to rotate at high speeds. A well-maintained power system ensures optimal performance and longevity of the mower.

Cutting Mechanism

The cutting mechanism consists of the blades and their housing, designed to efficiently trim grass at various heights. The sharpness of the blades and their configuration are critical for achieving a clean cut. Regular inspection and maintenance of this system are essential to prevent damage and ensure a tidy finish.

Importance of a Parts Diagram

Understanding the components of machinery is crucial for effective maintenance and repair. A visual representation that outlines the various elements of a device not only aids in identifying parts but also enhances comprehension of how these components interact. This clarity is vital for anyone working on equipment, whether for personal use or professional tasks.

Enhanced Understanding

A schematic representation allows users to easily grasp the configuration and relationships between different elements. By visualizing the structure, individuals can quickly locate specific pieces and understand their functions within the whole system. This knowledge streamlines both troubleshooting and assembly processes.

Efficient Repairs

When attempting repairs, having a clear reference can save significant time and effort. Instead of guessing which component needs attention, one can refer to a detailed illustration to pinpoint issues more accurately. This precision not only improves efficiency but also reduces the risk of errors during repairs, ensuring that the equipment is restored to optimal working condition.

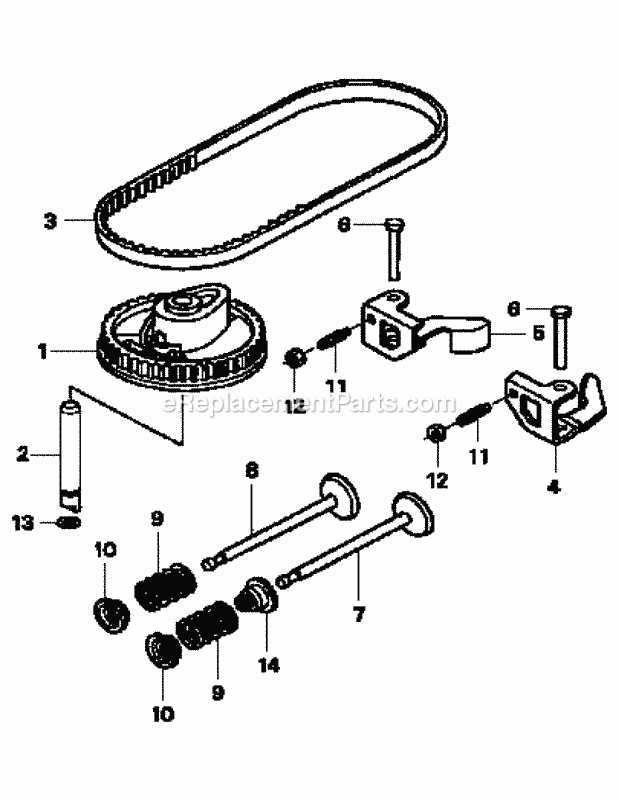

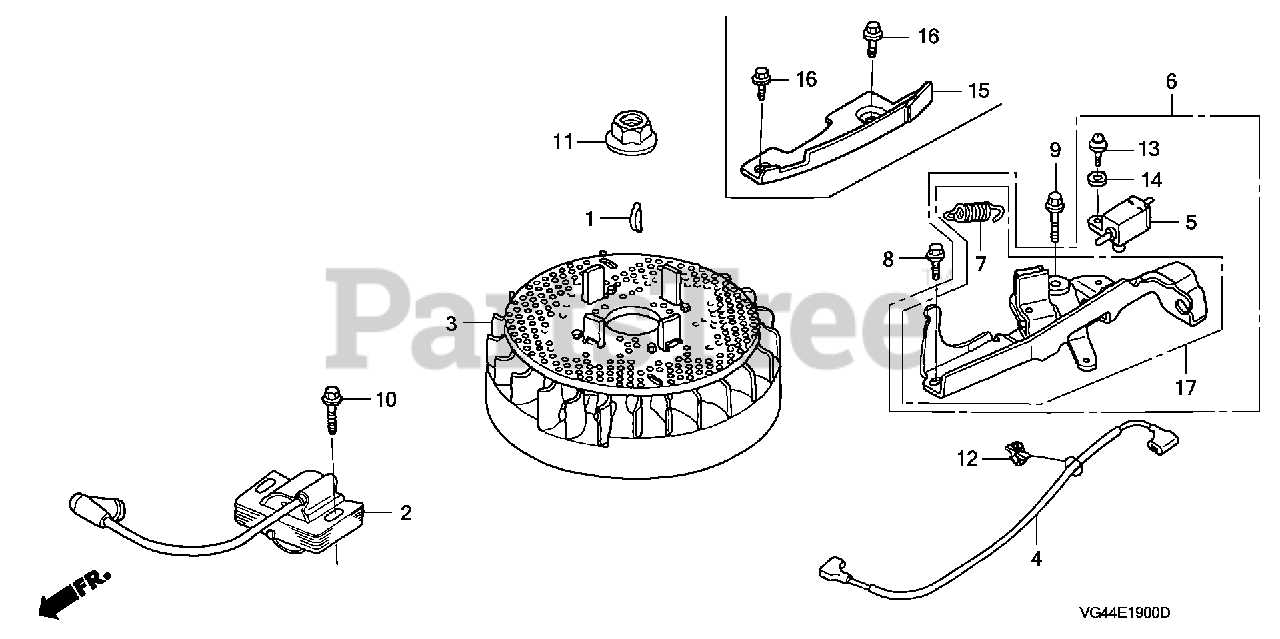

How to Read the Diagram

Understanding a visual representation of components can significantly enhance your ability to troubleshoot and maintain equipment. By familiarizing yourself with the various symbols and annotations, you can effectively identify each part’s function and placement.

Start by examining the layout: Typically, components are arranged in a logical manner, often following the flow of operation. This helps you visualize how each piece interacts with others. Pay attention to labels: These usually provide critical information regarding part numbers and specifications, guiding you in sourcing replacements if needed.

Next, note the connections: Arrows and lines often indicate relationships between parts, showing how they fit together and communicate. Color coding may also be used to differentiate various systems or functionalities, making it easier to navigate the representation.

Finally, practice makes perfect. The more you engage with such illustrations, the better you’ll become at quickly interpreting them. With time, you’ll uncover the ultimate insights into the assembly and functionality of the equipment at hand.

Common Replacement Parts Explained

Maintaining outdoor equipment often requires knowledge about essential components that may need to be replaced over time. Understanding these elements is crucial for ensuring optimal performance and longevity of the machinery. Here, we’ll explore some frequently replaced items and their significance.

Key Components

- Blades: Sharp and efficient blades are vital for effective cutting. Over time, they can dull or become damaged, requiring replacement to maintain performance.

- Air Filters: These components prevent dirt and debris from entering the engine, ensuring proper airflow. Clogged filters can lead to reduced efficiency and overheating.

- Spark Plugs: Crucial for ignition, worn spark plugs can cause starting issues and decreased power. Regular replacement helps keep the engine running smoothly.

- Belts: Drive and blade belts endure wear from constant movement. Replacing worn belts is essential to avoid slippage and maintain operational efficiency.

Maintenance Tips

- Regularly inspect all components for signs of wear or damage.

- Follow manufacturer guidelines for replacement intervals.

- Keep spare parts on hand to minimize downtime.

- Consult a professional if unsure about replacement procedures.

Being proactive about replacing these common elements will enhance the reliability and functionality of your equipment, allowing for a more efficient and enjoyable experience during use.

Identifying Wear and Tear

Recognizing the signs of deterioration is essential for maintaining optimal performance. Regular inspections can prevent further damage and enhance longevity.

- Visual Inspection: Look for cracks, rust, or discoloration.

- Performance Issues: Notice any decrease in efficiency or unusual noises.

- Wear Patterns: Examine components for uneven wear, which may indicate misalignment.

Addressing these issues promptly can lead to significant improvements and prevent costly repairs in the future.

Finding Genuine Honda Parts

Ensuring the longevity and performance of your equipment requires the use of authentic components. These original elements are specifically designed to fit perfectly and function optimally, providing peace of mind for users who rely on their machinery. Locating these genuine items can significantly enhance the overall experience and efficiency of operation.

Benefits of Using Authentic Components

- Enhanced durability and reliability

- Perfect compatibility with existing machinery

- Maintained warranty coverage

- Improved performance and efficiency

Where to Find Authentic Items

- Authorized dealers and retailers

- Official brand websites

- Reputable online marketplaces

- Local repair shops specializing in the brand

By prioritizing the use of authentic components, users can ensure their equipment remains in peak condition, ultimately saving time and resources in the long run.

Aftermarket vs. Original Parts

The choice between replacement components from the original manufacturer and those produced by third-party suppliers is a significant consideration for many consumers. Each option presents unique benefits and potential drawbacks that can impact both performance and longevity of the equipment.

Original components are designed specifically for a particular model, ensuring a precise fit and adherence to manufacturer standards. This often translates to better reliability and performance, as these items are rigorously tested to meet the specifications set forth by the creator. However, they typically come with a higher price tag, which can deter some buyers.

On the other hand, aftermarket alternatives offer a more budget-friendly option, often at a fraction of the cost. Many of these replacements are designed to meet or exceed the quality of the originals, and they may provide a wider variety of choices. Nonetheless, the risk of variability in quality exists, and not all aftermarket products are guaranteed to perform as well as their original counterparts.

Ultimately, the decision hinges on personal priorities–whether one values cost savings or the assurance of manufacturer-quality components. Understanding these differences is crucial for making an informed choice that aligns with one’s needs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your outdoor equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents potential issues that may arise from neglect. By following a few essential practices, you can keep your machine in optimal condition for years to come.

Regular Cleaning

One of the most crucial steps in upkeep is routine cleaning. After each use, remove grass clippings, dirt, and debris from the exterior and undercarriage. This prevents rust and corrosion, allowing components to function smoothly. Use a soft brush and water for this task, ensuring all parts are dried thoroughly before storage.

Periodic Inspection and Lubrication

Conduct periodic inspections to identify any wear or damage. Check belts, blades, and other moving parts for signs of deterioration. Additionally, regular lubrication of mechanical components minimizes friction and extends their operational life. Utilize appropriate lubricants, following manufacturer guidelines for best results.

By incorporating these practices into your maintenance routine, you can significantly enhance the durability and reliability of your equipment.

Tools Required for Repairs

Proper maintenance and repair of machinery necessitate a selection of essential instruments to ensure efficient and safe operation. Having the right tools at hand not only facilitates the repair process but also enhances the overall experience, making it smoother and more effective.

Basic Tools

For most repair tasks, a set of fundamental instruments is crucial. These typically include wrenches, screwdrivers, and pliers. A reliable socket set can also be invaluable, allowing for easier access to hard-to-reach fasteners.

Specialized Equipment

In addition to basic tools, certain specialized equipment may be necessary. A multimeter can help diagnose electrical issues, while replacement parts are vital for ensuring optimal performance. Additionally, a quality toolbox helps keep everything organized and easily accessible.

Step-by-Step Repair Process

Undertaking repairs can seem daunting, but a systematic approach makes the task manageable and efficient. By breaking down the process into clear, actionable steps, you can restore functionality and prolong the lifespan of your equipment. This guide will provide you with a structured method to tackle common issues effectively.

Preparation and Assessment

Before diving into repairs, gather all necessary tools and materials. Conduct a thorough assessment of the machine to identify the root cause of the problem. This initial evaluation is crucial for determining which components need attention. Document any findings, as this will aid in the reassembly process later.

Disassembly and Replacement

Carefully disassemble the unit, taking care to label and organize parts as you go. This will simplify reassembly and ensure that no components are misplaced. Once disassembled, replace any damaged or worn-out parts with suitable replacements. Follow manufacturer specifications to ensure compatibility. After replacing the necessary components, reassemble the unit methodically, ensuring all screws and fasteners are secured properly.

Finally, conduct a thorough test of the equipment to confirm that all repairs were successful. With proper maintenance, your equipment will perform optimally for years to come.

Resources for Further Assistance

When it comes to maintaining and repairing your outdoor machinery, having access to reliable resources is essential. Whether you are looking for specific components or troubleshooting tips, numerous platforms can offer valuable information and support. Here, we highlight some of the most useful avenues for obtaining assistance with your equipment.

Online Forums: Engaging with communities dedicated to machinery enthusiasts can provide practical insights. These forums often feature discussions about common issues, upgrades, and replacement options, allowing users to share their experiences and solutions.

Manufacturer’s Website: Visiting the official site of the manufacturer can be a treasure trove of information. From manuals to maintenance tips, you can find detailed resources that cater to your specific model. Many manufacturers also provide customer support contacts for personalized assistance.

Retail Outlets: Local and online retailers often have knowledgeable staff who can assist you in finding the right components. They may also offer repair services or workshops, giving you hands-on experience with your machinery.

Video Tutorials: Platforms like YouTube host a plethora of instructional videos. These visual aids can guide you through repairs, assembly, and maintenance procedures, making complex tasks easier to understand and execute.

Social Media Groups: Joining groups on platforms like Facebook or Reddit can connect you with fellow users. These groups often share tips, experiences, and advice, creating a supportive environment for troubleshooting and improvement.

By utilizing these resources, you can enhance your knowledge and skills, ensuring that your outdoor equipment remains in optimal condition for years to come.