Comprehensive Guide to Honda HS624 Parts Diagram

Maintaining outdoor machinery can be challenging, yet essential for optimal performance. Having a clear overview of the various elements involved is crucial for effective repairs and upkeep. This knowledge empowers users to troubleshoot issues and streamline maintenance processes.

Each machine comprises numerous integral parts, each serving a specific function. Familiarity with these components not only aids in identifying problems but also enhances the user’s confidence in managing their equipment. A comprehensive guide to the inner workings ensures that every enthusiast can delve deeper into the intricacies of their tools.

Ultimately, understanding how each piece fits together allows for a more efficient approach to maintenance. With the right information at hand, users can take control of their machinery, ensuring longevity and reliability in their outdoor tasks.

Understanding Honda HS624 Components

This section aims to provide insight into the various elements that constitute a well-functioning snow-clearing machine. Each component plays a crucial role in ensuring optimal performance and efficiency during operation. Familiarizing oneself with these parts can greatly enhance maintenance and repair efforts.

| Component | Description |

|---|---|

| Engine | Powers the machine and drives the auger and impeller. |

| Auger | Collects snow and directs it into the impeller. |

| Impeller | Blows the snow out of the discharge chute. |

| Discharge Chute | Controls the direction of the expelled snow. |

| Skid Shoes | Adjustable components that control the height of the auger. |

| Gearbox | Transfers power from the engine to the auger and impeller. |

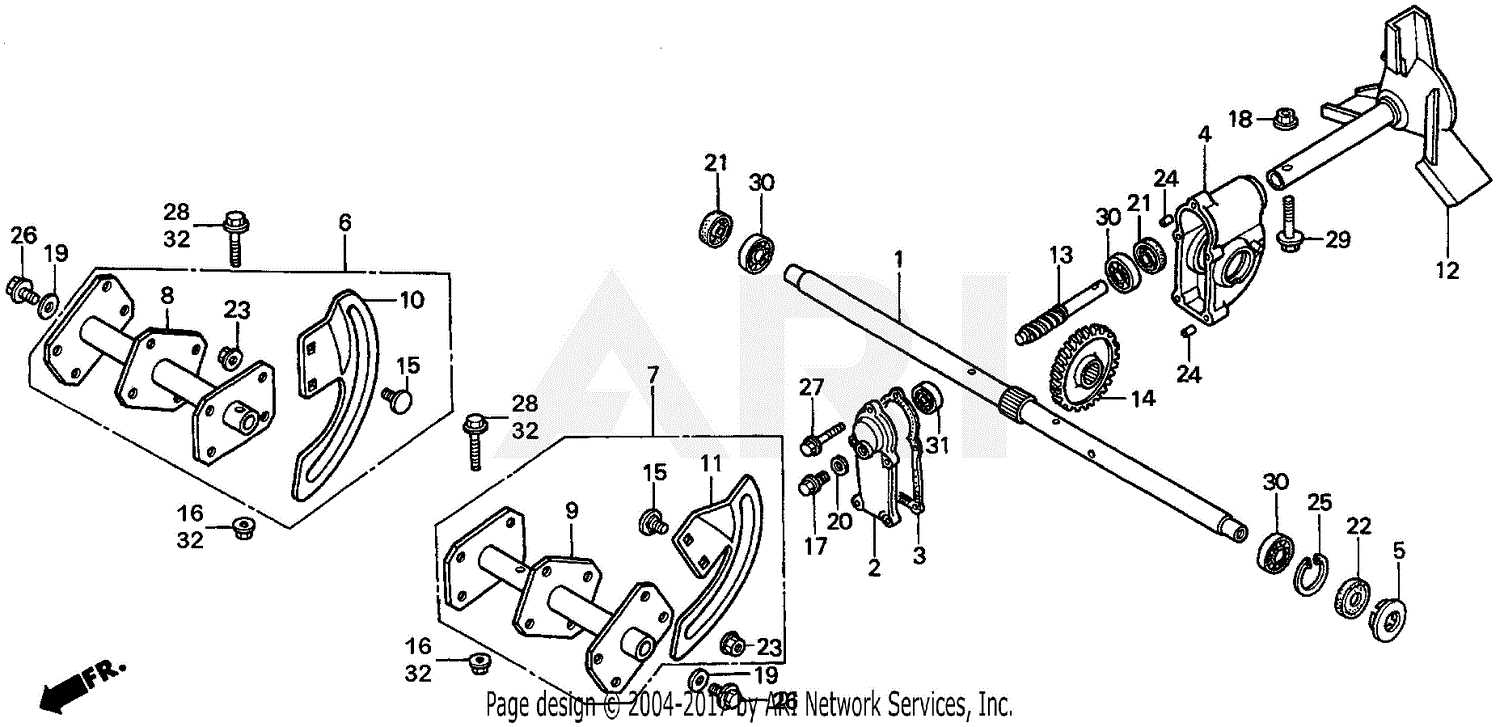

Importance of Parts Diagrams

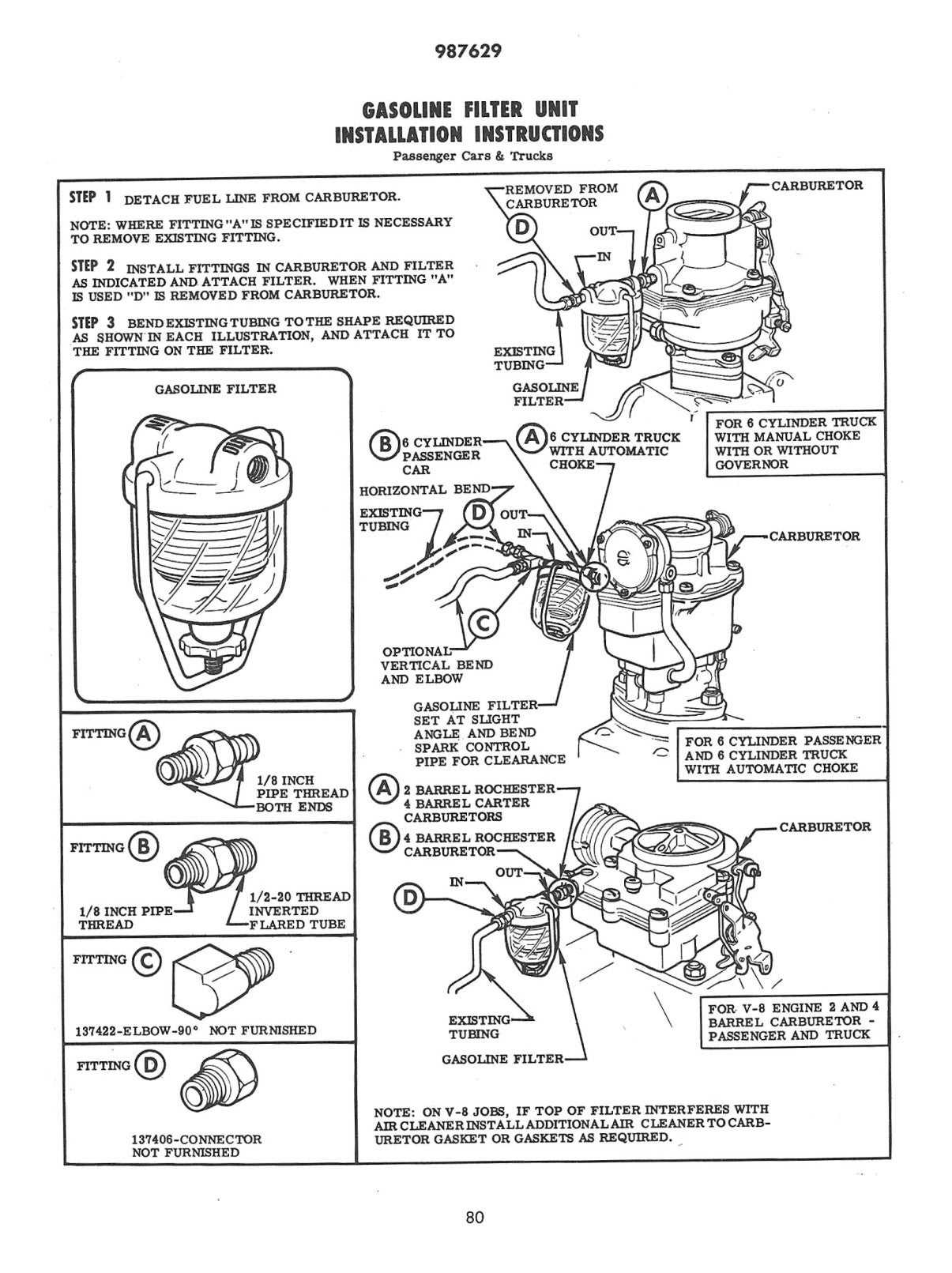

Understanding the intricacies of mechanical assemblies is crucial for effective maintenance and repair. Visual representations of components offer clarity, enabling users to identify each element’s function and location within a system. This knowledge not only aids in troubleshooting but also enhances the efficiency of repair processes.

Facilitating Maintenance

Visual aids serve as essential tools for technicians and DIY enthusiasts alike. They streamline the maintenance process by allowing individuals to quickly locate and assess specific components. With clear illustrations, the potential for errors during assembly or disassembly is significantly reduced.

Enhancing Learning and Skill Development

Studying these visual resources fosters a deeper understanding of mechanical systems. As individuals engage with these resources, they develop skills that enhance their ability to work on various machinery. This knowledge empowers users, enabling them to undertake repairs with confidence.

| Benefits | Description |

|---|---|

| Clarity | Provides clear understanding of each component’s role. |

| Efficiency | Speeds up the maintenance and repair process. |

| Error Reduction | Minimizes mistakes during assembly or disassembly. |

| Skill Development | Enhances knowledge and technical abilities. |

How to Access the Diagram Online

Finding detailed illustrations for your equipment can enhance your understanding and facilitate repairs. Numerous online resources offer comprehensive visual guides, making it easier to identify individual components and their respective functions. Here’s how you can access these valuable resources efficiently.

Utilizing Manufacturer Websites

One of the most reliable methods to obtain accurate visuals is by visiting the official website of the manufacturer. These platforms often provide access to a variety of resources, including user manuals and technical drawings. Navigate to the support or resources section, where you can typically search for your specific model to find relevant documents.

Exploring Online Forums and Communities

Online forums and communities can also be excellent sources of information. Many enthusiasts share their knowledge and resources, including links to detailed illustrations. Participating in these discussions can yield insights not only on accessing visual guides but also on troubleshooting and maintenance tips from experienced users.

Key Parts of the HS624 Model

This section delves into the essential components that make up the snow clearing machine. Understanding these elements is crucial for effective maintenance and optimal performance, ensuring that users can tackle winter conditions with confidence.

- Engine: The powerhouse responsible for driving the entire unit, providing the necessary torque and speed.

- Auger: The rotating blades that gather snow and propel it through the chute, crucial for efficient clearing.

- Chassis: The sturdy frame that houses all components, ensuring stability and durability during operation.

- Impeller: This component enhances snow discharge, working in tandem with the auger to effectively throw snow away from the path.

- Controls: The user interface that allows for easy operation and adjustment of speed and direction.

Familiarizing oneself with these fundamental elements not only aids in troubleshooting but also enhances the overall understanding of the machinery’s functionality.

Common Issues and Solutions

Many users encounter a range of challenges when maintaining their outdoor equipment. Understanding these frequent problems can lead to effective solutions, ensuring optimal performance and longevity.

- Starting Difficulties:

If the machine fails to start, check the fuel level, spark plug condition, and battery charge.

- Overheating:

Excessive heat may result from clogged air filters or insufficient oil. Regular cleaning and oil checks are essential.

- Inefficient Operation:

Reduced performance could stem from dull blades or improper adjustments. Sharpen or replace blades as needed.

- Strange Noises:

Unusual sounds might indicate loose parts or worn bearings. Inspect and tighten components to resolve these issues.

Addressing these common concerns promptly can enhance the functionality and reliability of your equipment.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By adopting proactive maintenance practices, you can prevent breakdowns and enhance performance over time. This section provides essential guidelines for keeping your machinery in optimal condition.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify wear and tear before they escalate into major issues. |

| Clean Air Filters | Replace or clean filters regularly to ensure efficient airflow and prevent engine strain. |

| Check Oil Levels | Maintain appropriate oil levels and replace oil at recommended intervals for optimal lubrication. |

| Sharpen Blades | Keep blades sharp to enhance cutting efficiency and reduce strain on the motor. |

| Winter Storage | Store equipment properly during off-seasons to protect against environmental damage. |

Where to Buy Replacement Parts

Finding suitable components for your equipment can be a straightforward process if you know where to look. Various sources offer quality items, ensuring your machine continues to operate efficiently.

Online Retailers: The internet is a treasure trove for sourcing new components. Websites dedicated to outdoor equipment often provide a wide selection and convenient delivery options.

Local Dealers: Visiting nearby authorized distributors can be beneficial. They often stock genuine items and can offer expert advice on compatibility and installation.

Aftermarket Suppliers: Many independent vendors supply alternative components that may be more cost-effective. Be sure to check reviews and warranties for assurance.

Forums and Community Groups: Engaging with online communities can yield valuable insights. Members often share their experiences and recommend trustworthy sources for acquiring necessary items.

By exploring these avenues, you can ultimately ensure your machinery is well-maintained and ready for use.

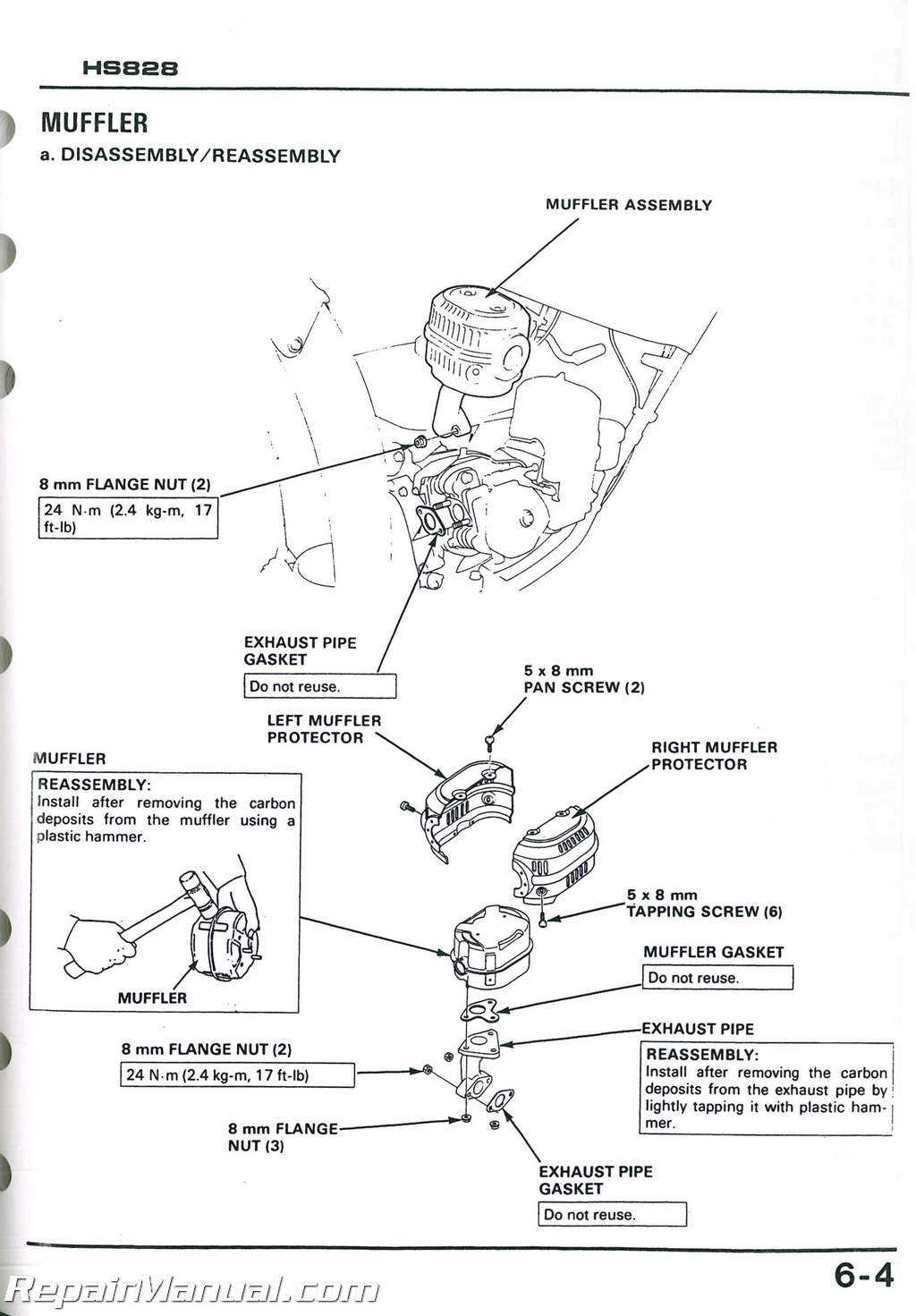

DIY Repairs Using the Diagram

Understanding the layout of components can greatly enhance your ability to tackle maintenance and repair tasks. By referring to a well-structured visual representation, you can identify parts easily and gain insights into their function, leading to more efficient and effective repairs. This section will explore practical steps for executing repairs with confidence.

Step-by-Step Guide

Begin by gathering the necessary tools and materials. Familiarize yourself with the layout to pinpoint the specific areas needing attention. Follow these steps:

| Step | Action |

|---|---|

| 1 | Identify the part to be repaired or replaced. |

| 2 | Gather the required tools, such as wrenches and screwdrivers. |

| 3 | Carefully disassemble the relevant components. |

| 4 | Replace or repair the identified part. |

| 5 | Reassemble and test for functionality. |

Tips for Success

Ensure you keep track of small components during disassembly. Document your process with photos for reference during reassembly. Familiarity with the arrangement will ultimately enhance your repair experience.

Comparing HS624 with Other Models

When evaluating various snow-clearing machines, it’s essential to understand how specific models stack up against one another. Each unit brings unique features and capabilities that cater to different needs and preferences. This section explores the distinctive aspects of a particular model in relation to its peers, highlighting strengths and weaknesses.

Performance and Efficiency

One of the primary factors to consider is the performance of each machine. The discussed model is renowned for its exceptional clearing efficiency, making it suitable for larger driveways and heavy snowfall. In contrast, some alternatives may offer adequate power but fall short in terms of speed and maneuverability. Users looking for a robust solution often find that performance metrics can significantly influence their decision.

Features and Usability

Another critical aspect is the features that enhance user experience. The model in question typically includes intuitive controls, adjustable settings, and durable components, which contribute to its ease of use. Some competitors might lack such thoughtful design, making operation less straightforward. Additionally, features like electric start and self-propulsion can set a model apart, providing convenience that many users appreciate during harsh winter conditions.

Customer Reviews on HS624 Performance

Feedback from users regarding the efficiency and reliability of this snow-clearing equipment provides valuable insights into its performance in various conditions. Many customers share their experiences with its ability to handle heavy snowfall and navigate different terrains, highlighting both strengths and weaknesses.

Strengths Noted by Users

Many reviews praise the machine’s powerful engine and its capability to clear snow quickly. Users appreciate its maneuverability, especially in tight spaces, making it a favorite for residential driveways and sidewalks. The ease of operation is frequently mentioned, allowing even those new to such equipment to manage it effectively.

Areas for Improvement

Some customers point out issues related to maintenance and part availability, expressing a desire for more accessible resources. A few reviews note that, while effective in lighter snow, performance can decline in extremely heavy conditions. Overall, these insights reflect a balanced view of the equipment’s capabilities and areas that could benefit from enhancements.

Expert Recommendations for Users

For individuals seeking to enhance their experience with outdoor machinery, understanding key components and their maintenance is crucial. This section provides valuable insights to ensure optimal performance and longevity.

Key Maintenance Tips

- Regularly inspect the engine and fuel systems for any signs of wear.

- Keep blades sharp to ensure efficient cutting and reduce strain on the engine.

- Check and replace filters periodically to maintain airflow and performance.

Choosing Quality Components

- Opt for original equipment manufacturer (OEM) items for guaranteed compatibility.

- Research user reviews to find reliable aftermarket alternatives.

- Consult with experts for recommendations tailored to your specific model.