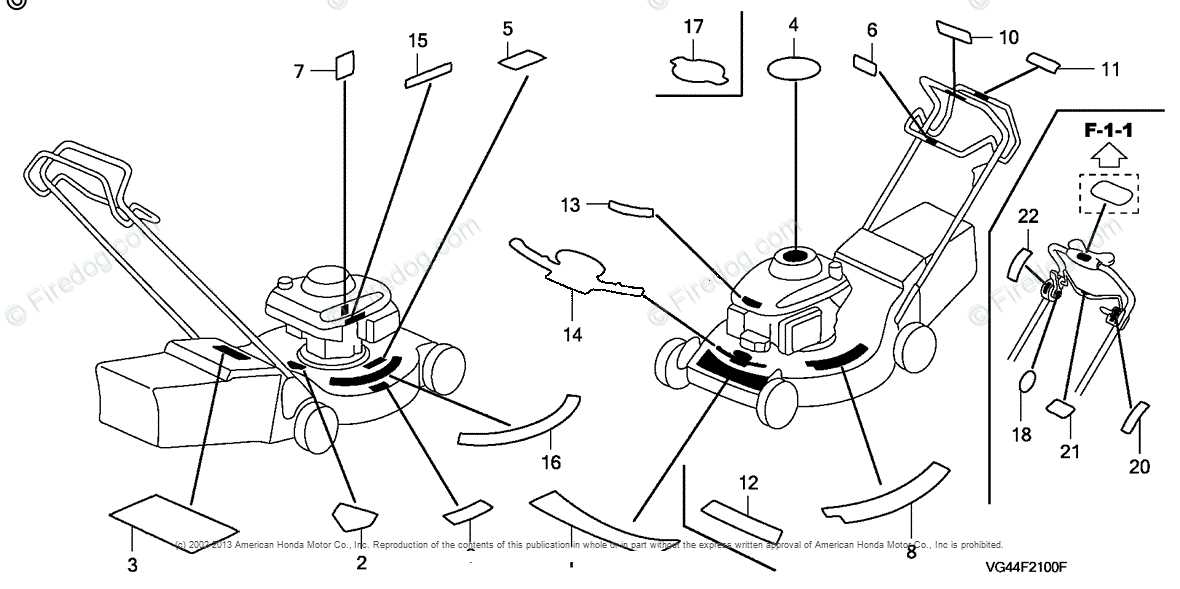

Honda Lawn Mower Parts Diagram for Easy Maintenance

When maintaining outdoor machines, having a clear understanding of how they work is crucial. Every tool you use is made up of several essential elements, and knowing what each does can help you keep your equipment in top shape. Proper maintenance, repair, and upgrades all rely on recognizing the specific elements involved.

Visual guides play a significant role in this process. They offer a straightforward way to familiarize yourself with different mechanical elements and how they interact. With detailed illustrations, even complex mechanisms become easier to understand, which in turn can enhance the efficiency of your work and extend the life of your gear.

Whether you’re handling small repairs or simply curious about the workings of your machine, identifying the structure of each component will allow you to approach maintenance tasks with greater confidence and precision.

Understanding the Basic Components of Honda Lawn Mowers

The core elements of any grass-cutting machine are crucial for its performance and longevity. Each part plays a specific role in ensuring efficient operation, and familiarizing yourself with these essentials can help in maintenance and troubleshooting. Whether you’re dealing with the engine, the cutting blade, or the control levers, understanding how they interact will empower you to keep your equipment in top shape.

Power Source: The motor is the heart of the machine, providing the energy needed for all other functions. Its performance directly impacts the cutting efficiency and ease of use.

Cutting Mechanism: The blade is designed to slice through the grass with precision. Regular sharpening and inspection of this component are necessary to maintain a clean cut and avoid damage.

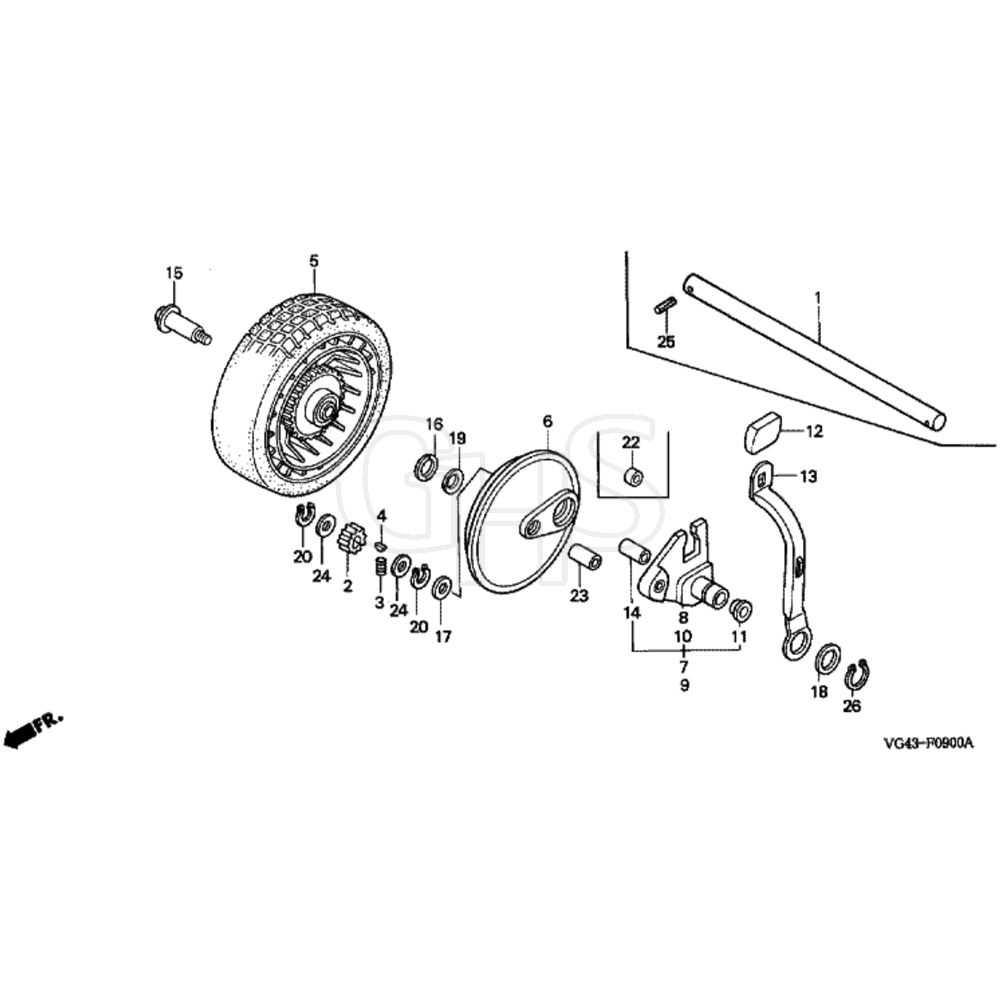

Wheels and Drive System: These ensure mobility across d

How to Identify Key Mower Parts

Understanding the main components of your garden machine is essential for proper maintenance and repair. Each section plays a vital role in ensuring smooth operation and efficient cutting. Recognizing these essential parts helps you diagnose issues quickly and keep your equipment in top shape.

Essential Components to Check

- Engine Assembly: The heart of the machine, responsible for providing power. Regular inspection is crucial to ensure it operates efficiently.

- Cutting Blade: This element does the primary job of trimming grass. Sharpening it regularly ensures cleaner cuts and extends the lifespan of the machine.

- Insufficient fuel flow

- Clogged filters

- Fuel leaks

- Faulty fuel lines

- Contaminated fuel

Engine Parts Breakdown for Honda Lawn Mowers

The core of any outdoor machine relies heavily on its internal components to ensure smooth functionality. Understanding the key elements involved in this system can be crucial for both maintenance and repairs. Each segment plays a distinct role, working in harmony to deliver efficient performance. Below, we explore the individual components that make up the power unit, highlighting their importance and how they contribute to overall operation.

Cylinder Block: The foundation of the entire mechanism, this section houses other vital components. Its durable construction ensures the unit withstands various external pressures while maintaining optimal internal processes.

Crankshaft: This essential part converts the linear motion of the pistons into rotational force, allowing the system to produce usable energy. It’s a key driver of motion and a critical point for

Essential Maintenance Tips for the Engine

Proper care of your engine is key to ensuring its long-lasting performance and efficiency. Regular upkeep can prevent potential issues, extend its operational life, and help you avoid unexpected breakdowns. Below are several important practices that can make a significant difference in maintaining its reliability and functionality.

Check and Replace the Oil

Changing the oil is a fundamental part of keeping your engine running smoothly. Old or dirty oil can lead to poor performance and even permanent damage. Make it a habit to inspect the oil level and condition regularly, replacing it when necessary to maintain optimal performance.

Air Filter Maintenance

The air filter plays a critical role in preventing dirt and debris from entering the engine. Over time, the filter can become clogged, restricting airflow and reducing efficiency. Regularly cleaning or replacing the filter is essential to keep the

Honda Mower Blades: Types and Uses

Blades are essential for any cutting equipment, as their quality and design determine the effectiveness and precision of grass trimming. The right selection can ensure a clean and even cut, while improper choices may lead to uneven surfaces and damaged plants. Understanding the various types available and their specific applications can greatly enhance the efficiency of your machine.

One of the most common variations is the standard type, designed for general cutting tasks. These are ideal for maintaining a well-groomed yard under regular conditions. For tougher situations or areas with thicker vegetation, mulching variants can be more effective. These options finely chop clippings, allowing them to decompose naturally, enriching the soil with nutrients.

For those seeking greater versatility, multi-purpose options are available, combining features for both cutting and mulching. These

How to Replace a Mower Blade

Changing the cutting edge of your grass trimming device is essential for maintaining its efficiency and ensuring a clean cut. Over time, the blade can become dull or damaged, which affects the performance of the equipment. Knowing how to properly replace this component will not only enhance your tool’s functionality but also prolong its lifespan.

Before starting, gather all necessary tools, including a wrench, safety gloves, and a new cutting edge. Make sure the equipment is turned off and disconnected from any power source to avoid accidents. Once prepared, tilt the machine onto its side to access the underside where the blade is located.

Locate the fastening bolt that secures the cutting edge in place. Using the wrench, carefully loosen and remove the bolt, taking care to support the blade as it becomes detached. Once removed, inspect the mounting area for any debris or damage that may need addressing before installing the new blade.

Position the new cutting edge, ensuring it aligns correctly with the mounting hole. Secure it in place by threading the bolt back in and tightening it firmly but not overly so, as this could lead to future damage. After reassembling, return the equipment to its upright position and reconnect any power source.

Finally, conduct a quick test to ensure everything operates smoothly. Regular maintenance of this kind will keep your trimming tool in optimal condition, enabling you to achieve a well-manicured outdoor space.

Troubleshooting Honda Mower Fuel System

When encountering issues related to the fuel delivery mechanism of your machine, it’s essential to systematically diagnose and resolve potential problems. Understanding how various components interact can significantly aid in restoring optimal performance.

Common Issues

Steps for Diagnosis

- Check the fuel level in the tank to ensure there is enough liquid available.

- Inspect the fuel filter for clogs; replace it if necessary.

- Examine the fuel lines for cracks or leaks that could impede flow.

- Flush the fuel system to remove any contaminants or sediment.

- Test the fuel pump operation, ensuring it functions correctly and provides adequate pressure.

By following these steps, you can effectively identify and address issues within the fuel delivery system, ensuring your equipment operates smoothly and efficiently.

Common Fuel Line and Filter Issues

Fuel delivery systems are critical for the efficient operation of outdoor machinery. Common complications in these systems can lead to performance issues, reduced efficiency, or complete breakdowns. Identifying and resolving these challenges promptly can enhance the longevity and reliability of the equipment.

Clogs and Blockages: Over time, debris and contaminants can accumulate in the fuel lines and filters, leading to significant obstructions. This can restrict fuel flow, resulting in poor engine performance or difficulty starting. Regular maintenance is essential to prevent such build-ups.

Leaks: Cracks or damage in the fuel lines can result in leaks, causing fuel to escape and potentially creating hazardous conditions. Inspecting the lines regularly for signs of wear or degradation is crucial to maintaining safe operation.

Filter Contamination: Filters play a vital role in trapping impurities before they reach the engine. If a filter becomes excessively dirty or clogged, it can hinder fuel flow, causing the engine to run poorly. Regular replacement of filters is recommended to ensure optimal performance.

Fuel Type Mismatch: Using the incorrect fuel type can lead to complications within the delivery system. It is important to use the manufacturer’s recommended fuel to avoid damage and maintain operational efficiency.

By understanding these common issues, operators can take proactive measures to ensure their equipment remains in peak condition, ultimately leading to a more efficient and safer experience.

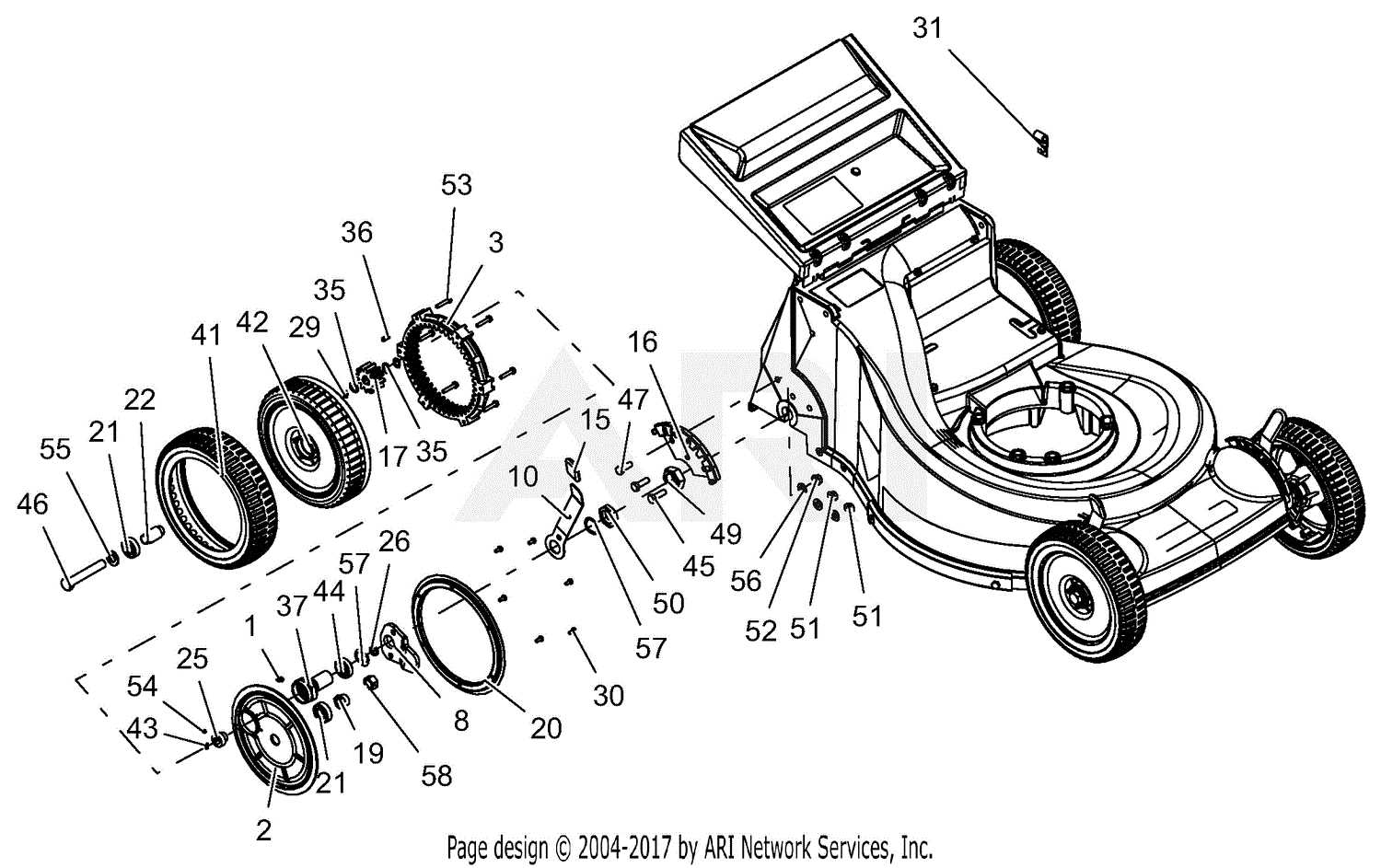

How to Maintain the Drive System on Honda Mowers

Ensuring optimal performance of your equipment’s propulsion mechanism is essential for its longevity and efficiency. Regular maintenance can prevent unexpected breakdowns and improve overall functionality. By following a systematic approach, you can enhance the durability of the drive system and ensure smooth operation throughout the cutting season.

Inspecting Components: Start by regularly examining the essential elements of the drive assembly. Look for signs of wear or damage, particularly in the belts and gears. If you notice any fraying, cracking, or excessive wear, it may be time for replacements to avoid further complications.

Cleaning and Lubrication: Keeping the drive system clean is vital for its proper function. Remove any debris that may accumulate around moving parts. Additionally, apply appropriate lubricants to the pivot points and gears to ensure they operate smoothly. This reduces friction and helps prevent overheating.

Adjusting Tension: The tension of the drive belts should be checked periodically. A belt that is too loose may slip, leading to inefficient power transfer, while one that is too tight can cause undue stress on components. Refer to the manufacturer’s specifications for proper tension settings and make adjustments as necessary.

Routine Testing: After performing maintenance, conduct routine tests to ensure the drive system is functioning correctly. Engage the drive mechanism and observe for any irregularities in performance. If any issues arise, investigate further to determine the cause and address it promptly.

By incorporating these practices into your maintenance routine, you can significantly extend the life of the drive system and ensure your equipment operates at peak performance.

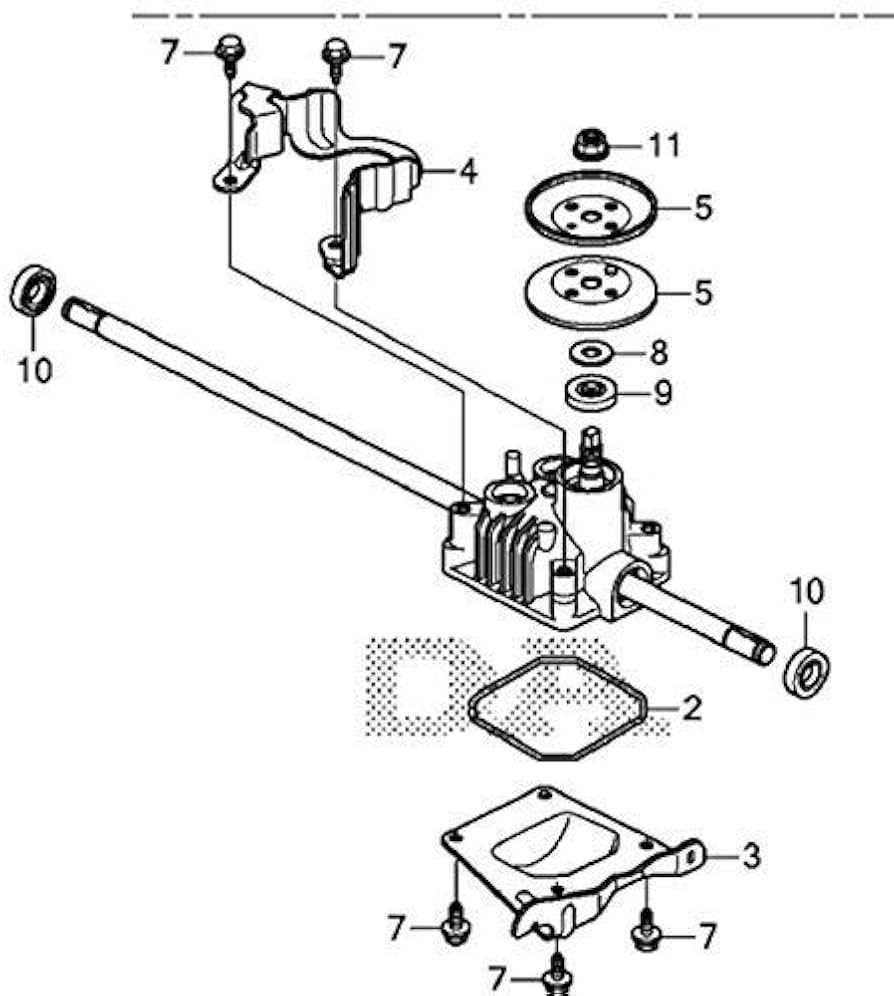

Fixing Transmission and Drive Belt Problems

When dealing with issues related to the drive mechanism and transmission, it is essential to understand the components involved and how they interact. Problems in this area can lead to reduced performance and difficulty in maneuvering the equipment. By diagnosing the root cause of these issues, you can ensure optimal functionality and prolong the life of your machine.

Common Symptoms of Drive Issues

- Sluggish movement or inability to move

- Unusual noises during operation

- Difficulty shifting gears

- Vibration or shaking while in use

Troubleshooting Steps

- Inspect the drive belt for wear or damage. Look for fraying, cracks, or signs of stretching.

- Check the tension of the drive belt. A loose belt can lead to slippage and inefficient power transfer.

- Examine the transmission fluid level and condition. Low or dirty fluid can cause shifting problems.

- Look for blockages in the drive system that may prevent smooth operation.

- Consult the manufacturer’s manual for specifications on the correct tension and installation of components.

By following these troubleshooting steps and addressing any identified issues promptly, you can enhance the performance and reliability of your equipment. Regular maintenance and timely repairs are key to preventing future complications.

Electrical Components of a Honda Lawn Mower

The efficient functioning of outdoor equipment relies heavily on various electrical elements that ensure seamless operation. Understanding these components is essential for maintenance and troubleshooting, enabling users to maximize performance and extend the life of their machinery.

Key electrical components include:

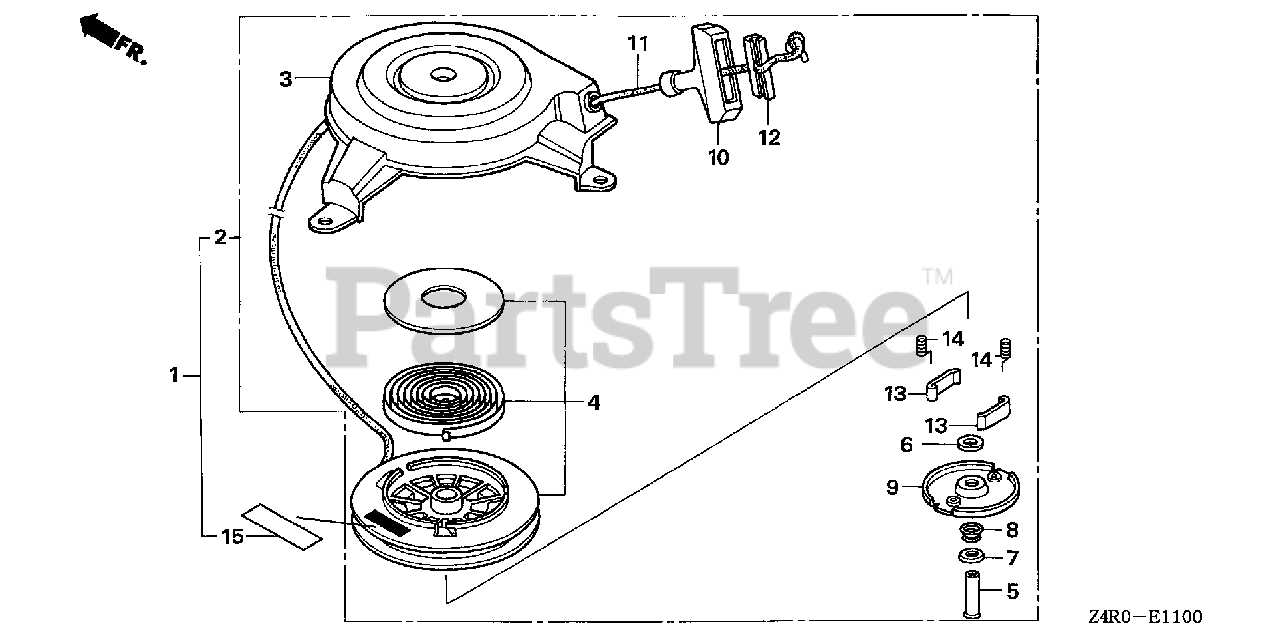

- Ignition System: This crucial element generates the spark necessary for combustion, playing a vital role in starting the engine.

- Starter Motor: Responsible for initiating engine operation, the starter motor engages the flywheel to crank the engine.

- Battery: The energy source for the electrical system, providing power to the starter motor and ignition components.

- Wiring Harness: A network of wires that connects various electrical components, ensuring efficient communication and power distribution.

- Alternator: This component generates electricity to recharge the battery and power electrical accessories during operation.

Regular inspection and maintenance of these elements can prevent potential failures and ensure optimal performance.

For effective troubleshooting, users should consider the following steps:

- Check the battery for charge and connections.

- Inspect the wiring harness for damage or corrosion.

- Test the ignition system for proper functioning.

- Evaluate the starter motor for efficiency.

By understanding and maintaining these electrical components, users can enhance the reliability and longevity of their outdoor machinery.

Battery, Wiring, and Ignition System Overview

The components responsible for powering, connecting, and igniting machinery play a crucial role in ensuring efficient performance and reliability. A thorough understanding of these systems can enhance the operation and maintenance of various equipment.

Battery systems serve as the primary energy source, storing electrical energy that is essential for starting engines and powering electrical components. A well-maintained battery ensures smooth operation and longevity, minimizing the risk of unexpected failures.

Wiring acts as the nervous system, facilitating the flow of electricity throughout the machinery. Proper wiring is vital for seamless communication between components, and any issues within this network can lead to operational disruptions. Regular inspections and maintenance are recommended to prevent potential hazards and ensure optimal functionality.

Ignition systems are integral for initiating the combustion process, transforming stored energy into mechanical power. Understanding the various types of ignition mechanisms and their components can help in troubleshooting and repairs, ensuring that the engine starts reliably every time.

In summary, a comprehensive grasp of battery, wiring, and ignition systems not only enhances performance but also extends the lifespan of equipment. Regular maintenance and timely interventions can prevent issues, ensuring that machinery operates at its best.

Cleaning and Replacing the Air Filter

The air filter is a crucial component of any engine, playing a vital role in maintaining optimal performance. A clean filter ensures that the engine receives the right amount of air, which is essential for efficient combustion. Over time, dirt and debris can accumulate, restricting airflow and leading to potential damage or decreased efficiency.

Regular maintenance of the air filter can prevent such issues. Here’s a guide on how to clean and replace it effectively:

-

Gather the Necessary Tools:

- New air filter (if replacement is needed)

- Cleaning brush or soft cloth

- Screwdriver (if required for access)

- Safety gloves

-

Locate the Air Filter:

Identify the air intake cover and remove it to access the filter. This is usually found on the side of the engine.

-

Remove the Air Filter:

Carefully take out the air filter from its housing. Be cautious not to let any debris fall into the engine.

-

Cleaning the Filter:

If the filter is reusable, gently clean it with a brush or soft cloth. Make sure to remove all dirt and debris.

-

Inspect for Damage:

Check for any tears or significant wear. If the filter is damaged, it should be replaced with a new one.

-

Replace or Reinstall:

If using a new filter, ensure it fits snugly in the housing. If cleaning, reinstall the filter carefully, making sure it is secure.

-

Reattach the Cover:

Put the air intake cover back in place and secure it properly. This ensures the engine remains protected from dust and debris.

Following these steps regularly will help maintain engine efficiency and prolong its lifespan. Always consult your equipment’s manual for specific instructions and recommendations regarding the air filtration system.