Understanding the Honda Outboard Motor Parts Diagram

When it comes to navigating the waters, having a reliable propulsion system is essential for any boating enthusiast. The intricacies of these systems often involve a variety of components that work harmoniously to ensure optimal performance. This section aims to shed light on the essential elements that constitute a typical marine propulsion unit, providing insights into their functions and interrelationships.

Exploring the Inner Workings of these aquatic machines reveals a complex assembly where each component plays a crucial role. From the power generation unit to the drive mechanism, understanding how these pieces fit together enhances not only the maintenance of the equipment but also the overall boating experience. Clarity in these relationships can lead to improved performance and longevity.

In the upcoming sections, we will delve deeper into the specific components, their functions, and how they can be optimized for better efficiency. Gaining knowledge about these elements empowers users to make informed decisions, ensuring their adventures on the water are both enjoyable and trouble-free.

Understanding Honda Outboard Motors

This section explores the essentials of marine propulsion systems, focusing on their construction, functionality, and maintenance. A well-structured engine not only enhances performance but also ensures reliability and longevity in aquatic environments.

Key Components

- Power Unit: The core element responsible for generating thrust.

- Fuel System: Manages the intake and combustion of fuel for efficient operation.

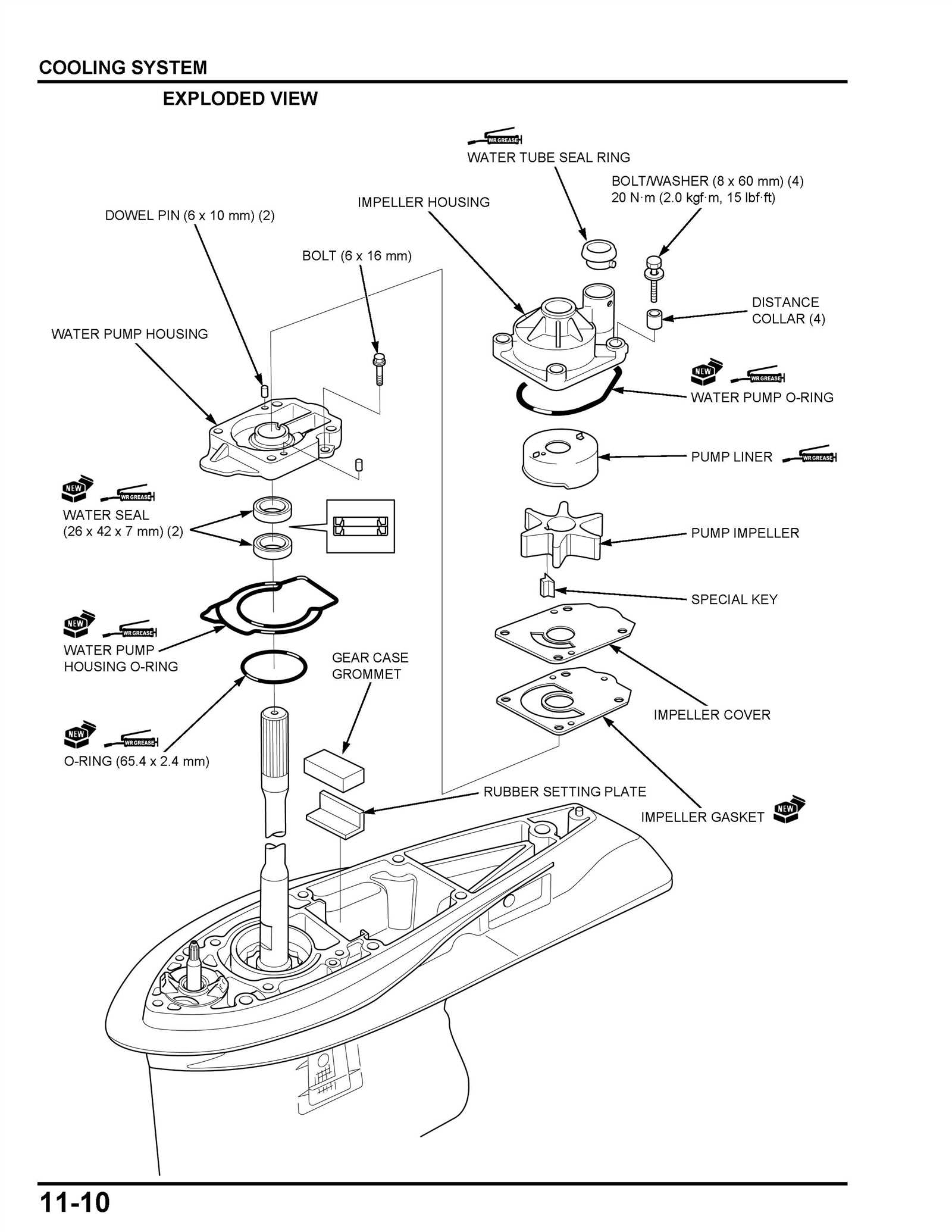

- Cooling System: Prevents overheating and maintains optimal temperature.

- Steering Mechanism: Provides maneuverability and control over direction.

- Trim System: Adjusts the angle of the engine for improved performance.

Maintenance Tips

- Regularly inspect the power unit for wear and tear.

- Change the oil and fuel filters as recommended.

- Keep the cooling system clean and free from debris.

- Check the steering and trim systems for responsiveness.

- Store the unit properly during off-seasons to prevent damage.

Understanding these aspects will help users maintain their marine engines effectively, ensuring a smooth and enjoyable experience on the water.

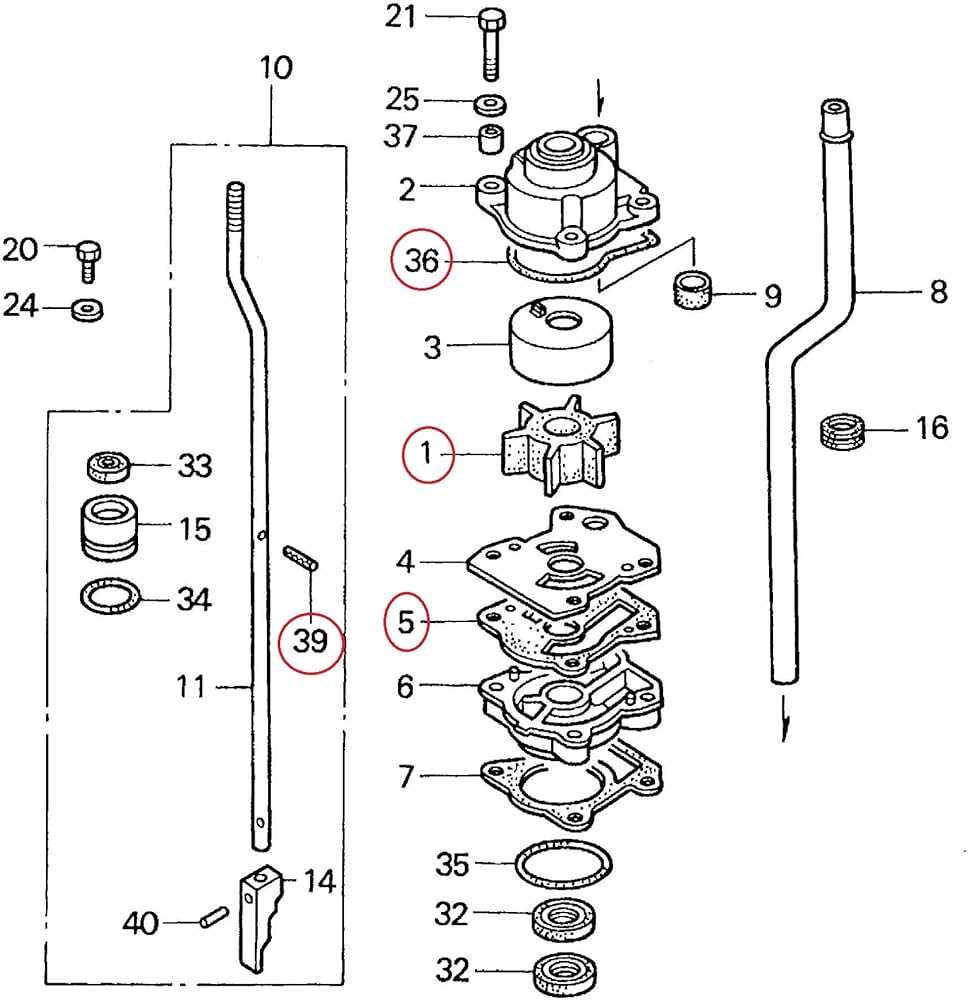

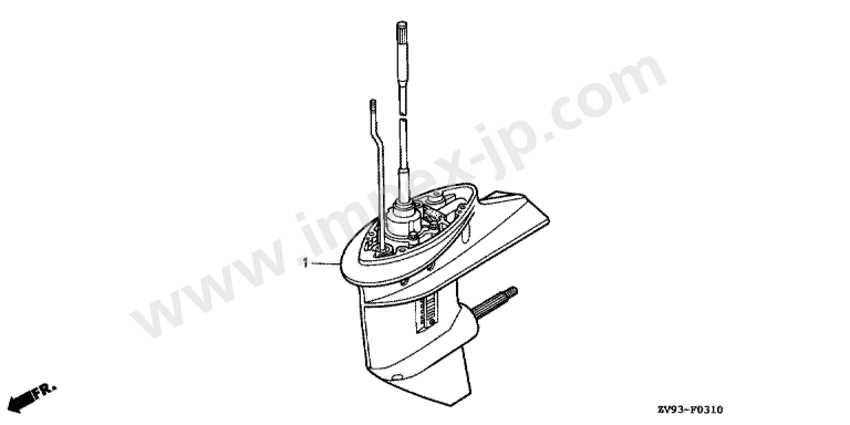

Essential Components of Outboard Motors

Understanding the key elements of marine propulsion systems is crucial for maintenance and performance optimization. Each component plays a vital role in ensuring smooth operation and reliability on the water. Familiarity with these elements can enhance both safety and efficiency during use.

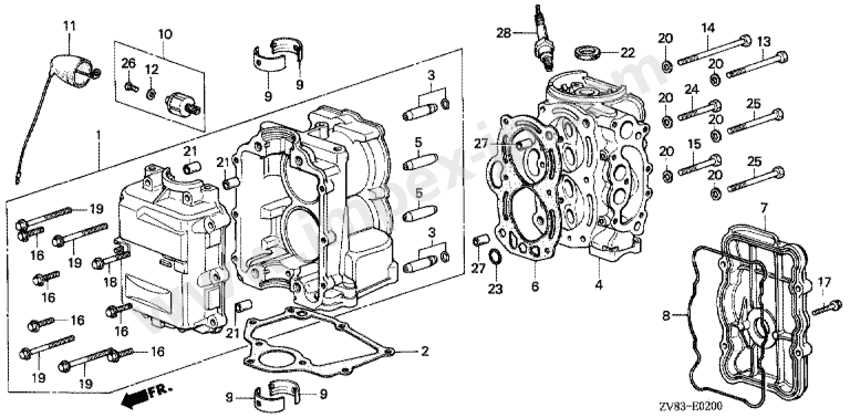

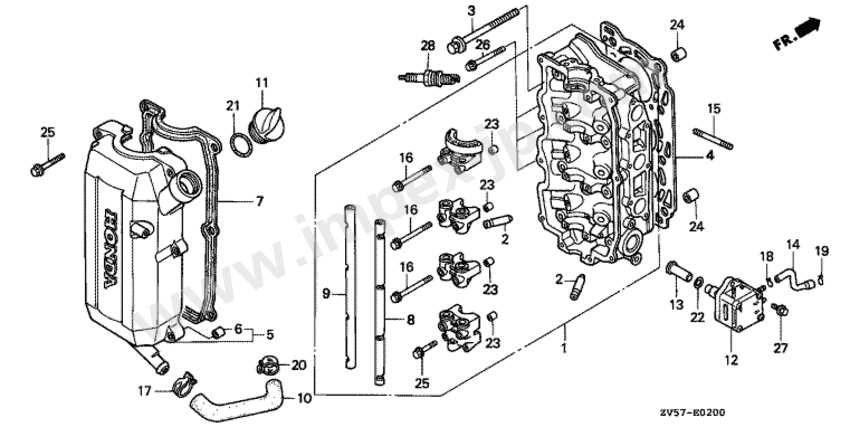

- Powerhead: The powerhouse that houses the engine and is responsible for generating thrust.

- Lower Unit: Contains the gearing system and propeller shaft, essential for transferring power to the propeller.

- Propeller: The rotating blade that propels the vessel forward through water.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Fuel System: Ensures a steady supply of fuel to the engine for efficient combustion.

- Ignition System: Initiates combustion in the engine cylinders, crucial for starting and running the system.

- Steering System: Allows for maneuverability and control of direction during operation.

- Control Cables: Connect the helm to the propulsion unit, facilitating gear shifts and throttle adjustments.

Each of these components must be regularly inspected and maintained to ensure optimal functionality and longevity of the entire system.

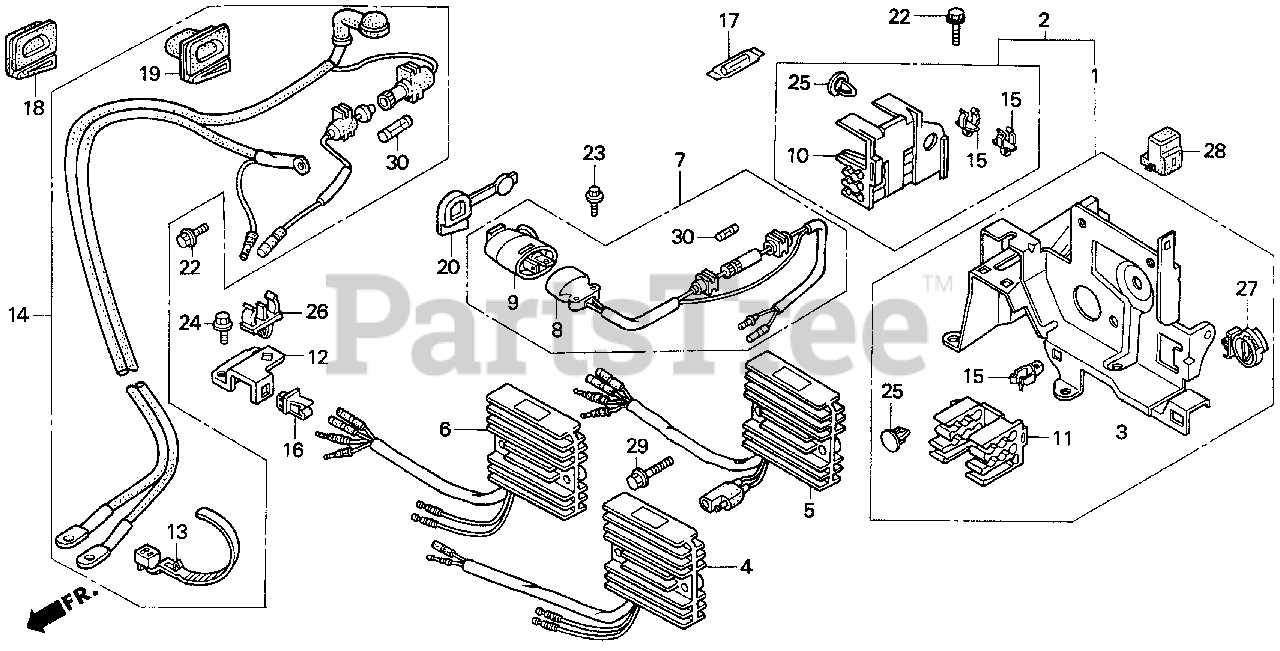

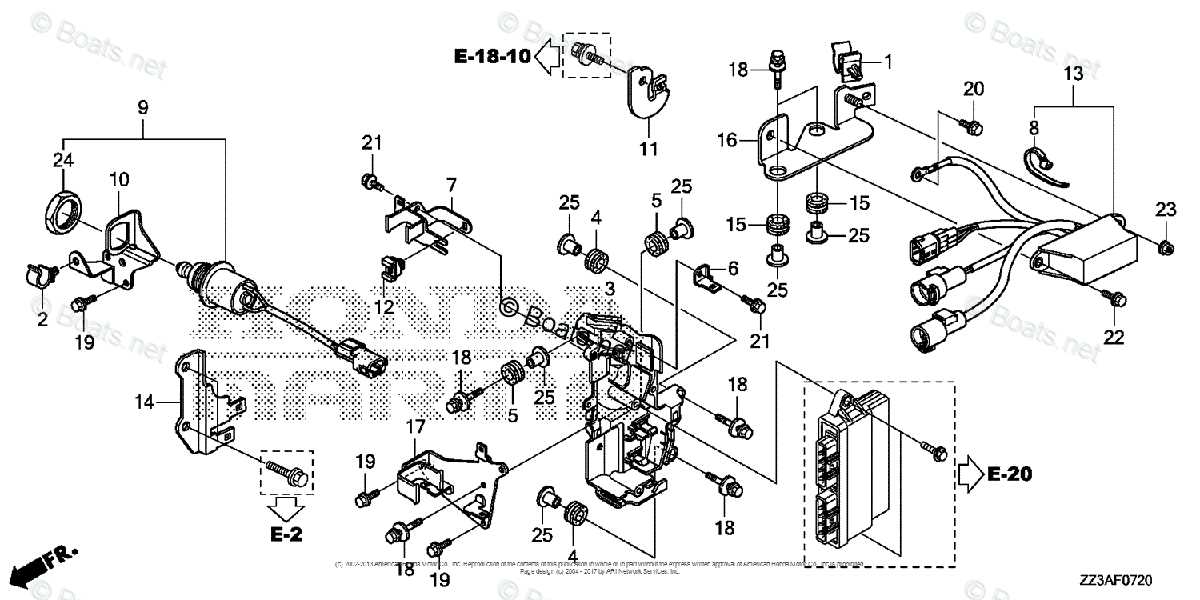

How to Read Motor Diagrams

Understanding technical illustrations is essential for anyone working with engines or mechanical devices. These visuals provide crucial information about components and their interrelations, facilitating maintenance, repair, and assembly tasks. By mastering the art of interpreting these images, you can enhance your efficiency and effectiveness in troubleshooting.

Here are some key aspects to consider when examining such illustrations:

- Symbols and Legends: Familiarize yourself with the common symbols used to represent various components. Many diagrams include a legend that explains these symbols, making it easier to identify parts.

- Component Labels: Pay attention to the labels associated with each element. These can provide vital information, including part numbers and specifications.

- Connection Lines: Observe the lines that depict connections between parts. Solid lines typically represent physical connections, while dashed lines may indicate electrical paths or functional relationships.

- Orientation and Viewpoints: Understand the perspective from which the illustration is drawn. Different viewpoints can affect how components are positioned and relate to one another.

By utilizing these strategies, you can effectively decode technical illustrations and apply the knowledge gained to your practical tasks.

Common Issues with Honda Parts

When dealing with various components of marine propulsion systems, users often encounter several recurring challenges that can impact performance and reliability. Understanding these issues can help in effective troubleshooting and maintenance, ensuring a smoother operation in aquatic environments.

Wear and Tear

One of the most prevalent problems stems from normal wear and tear associated with frequent usage. Components are subjected to harsh conditions, including exposure to saltwater, which can lead to corrosion and degradation over time. Regular inspections can help identify signs of fatigue, allowing for timely replacements to maintain optimal functionality.

Compatibility Issues

Another significant concern involves compatibility of replacement components. Using non-original or mismatched items may result in improper fitment, affecting overall performance. Ensuring that all installed components are designed to work together is crucial for avoiding operational disruptions and enhancing longevity.

In summary, being aware of these common pitfalls can empower users to take proactive measures, ensuring that their aquatic systems remain in top condition.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your aquatic propulsion system requires consistent care and attention. Regular maintenance not only enhances performance but also prevents costly repairs and replacements. By following a few essential practices, you can keep your equipment running smoothly for years to come.

Routine Checks

Performing periodic inspections is crucial for identifying potential issues before they escalate. Here are key components to monitor:

| Component | Recommended Frequency | Notes |

|---|---|---|

| Fuel System | Every Use | Check for leaks and ensure fuel quality. |

| Cooling System | Weekly | Inspect for blockages and ensure proper flow. |

| Battery | Monthly | Test charge and clean terminals. |

| Propeller | After Each Trip | Look for damage and debris. |

Seasonal Maintenance

As seasons change, so do the requirements for upkeep. Performing comprehensive maintenance at the start and end of each season can prevent long-term issues. Key actions include:

- Draining and replacing fluids.

- Inspecting and replacing worn components.

- Cleaning or replacing filters.

- Testing the electrical system.

By adopting these practices, you can significantly enhance the reliability and durability of your equipment, ensuring enjoyable experiences on the water for years to come.

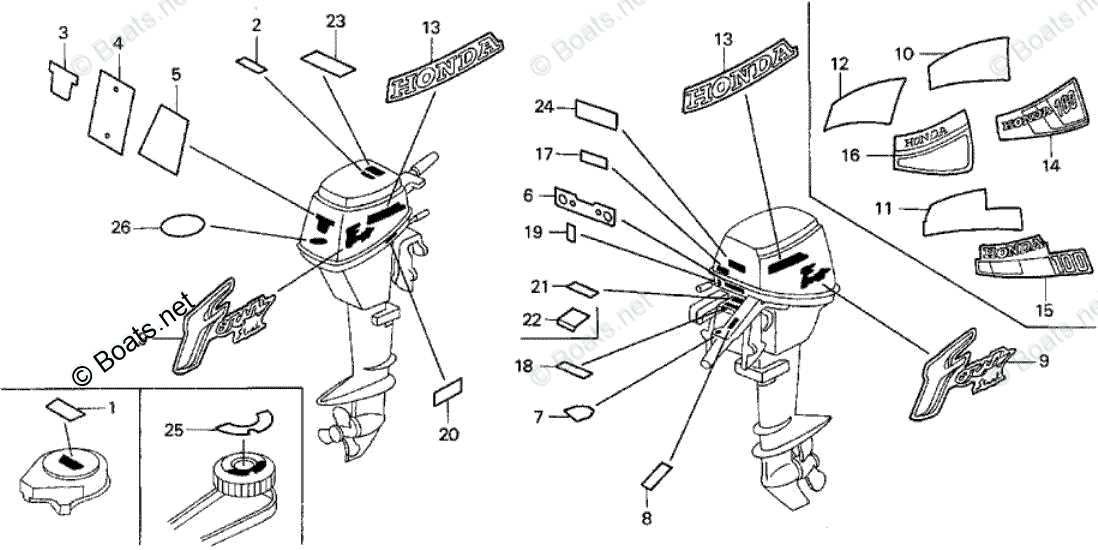

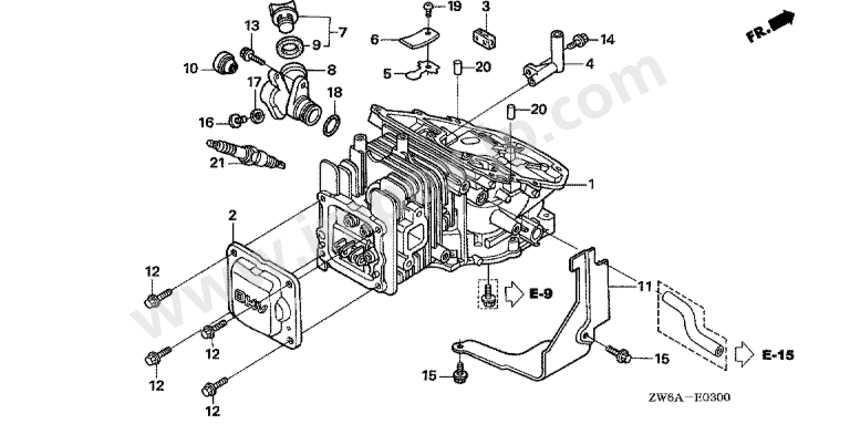

Identifying Parts by Diagram Sections

Understanding the layout of various components is crucial for effective maintenance and repair. Each segment of the visual representation serves a specific purpose, making it easier to locate and identify individual elements. By analyzing these sections, users can gain insights into the functionality and interconnections of the various components.

Section Analysis: The breakdown into sections allows for a systematic approach to identification. Each part is categorized based on its role, such as propulsion, steering, or fuel management. This organization not only simplifies the identification process but also enhances comprehension of how each element contributes to overall performance.

Practical Application: When examining the visual guide, focus on familiarizing yourself with each section’s unique characteristics. Note any labels or numbers associated with components, as these will assist in cross-referencing with manuals or replacement guides. Such a methodical approach ensures accurate diagnostics and effective repairs.

Upgrading Your Honda Outboard System

Enhancing your aquatic propulsion system can significantly improve performance and efficiency. Whether you are seeking better speed, increased fuel economy, or enhanced reliability, upgrading components is a smart investment for any enthusiast.

First and foremost, consider the benefits of modern technology. Newer components often feature advanced materials and designs that can lead to substantial improvements in durability and functionality. Investing in high-quality upgrades not only optimizes performance but also extends the lifespan of your system.

Another important aspect to focus on is compatibility. When selecting new components, ensure they are designed to work seamlessly with existing systems. This will minimize installation challenges and maximize operational efficiency. Consulting a detailed guide can provide clarity on suitable options and configurations.

Finally, regular maintenance plays a crucial role in the overall enhancement process. Upgrading certain components while adhering to a consistent maintenance schedule can yield remarkable results. By staying proactive, you can enjoy improved performance and reliability on the water.

Where to Find Replacement Parts

When your aquatic equipment requires new components, locating reliable sources for high-quality replacements is essential. Whether you are looking for essential elements to maintain performance or specific accessories for upgrades, understanding your options will save you time and ensure compatibility.

Here are some common sources to consider:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often provide original components and accessories, ensuring optimal fit and performance. |

| Online Marketplaces | Websites like eBay and Amazon offer a wide selection of components, often at competitive prices. |

| Local Marine Supply Stores | Neighborhood shops may have a selection of necessary items and can provide expert advice. |

| Specialty Websites | Numerous online platforms focus exclusively on aquatic equipment, providing detailed catalogs and resources. |

| Salvage Yards | For budget-conscious consumers, these locations may have used components in good condition at reduced prices. |

By exploring these options, you can find the right components to keep your equipment in top shape and ready for your next adventure on the water.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining and repairing machinery, the choice between original equipment manufacturer (OEM) components and third-party alternatives often arises. Each option presents its own set of advantages and considerations that can significantly impact performance, reliability, and overall satisfaction.

OEM components are designed and produced by the same manufacturer that created the original equipment. This ensures a precise fit and adherence to specific quality standards. Users often benefit from enhanced durability and performance, as these components are tailored for compatibility with the machinery they support.

On the other hand, aftermarket alternatives can provide cost savings and increased availability. Many of these options are developed by independent manufacturers who strive to deliver competitive performance. For some users, the variety offered by aftermarket options allows for customization and potential enhancements not available in OEM choices.

Ultimately, the decision between OEM and aftermarket components should consider factors such as budget, performance expectations, and the specific needs of the machinery. Understanding the trade-offs can help ensure optimal functionality and longevity in the long run.

Step-by-Step Assembly Guide

Assembling your aquatic propulsion system can seem daunting, but with the right approach, it becomes a straightforward task. This guide provides a detailed roadmap to ensure each component is correctly fitted for optimal performance. Follow the steps below for a successful assembly process.

-

Gather Required Tools:

- Wrenches

- Screwdrivers

- Pliers

- Torque wrench

- Lubricant

-

Inspect Components:

Before starting, check all elements for any signs of wear or damage. Ensure that each part is clean and free of debris.

-

Start with the Base:

Secure the base unit on a stable surface. This foundation will support the entire assembly.

-

Attach the Drive System:

Carefully position the drive mechanism and align it with the designated mounts. Fasten using the appropriate screws and ensure a snug fit.

-

Install the Cooling System:

Connect the cooling components to prevent overheating. Ensure all hoses are properly secured and free of leaks.

-

Connect Electrical Wiring:

Follow the wiring schematic to connect electrical elements. Ensure all connections are tight and insulated to avoid short circuits.

-

Final Adjustments:

Check all fasteners for tightness. Make any necessary adjustments to ensure smooth operation.

-

Testing:

Once assembled, conduct a test run in a controlled environment to verify proper functionality. Monitor for any irregularities.

By following these steps, you can ensure a successful assembly that will enhance the efficiency of your aquatic experience.

Resources for Further Learning

Understanding the intricacies of marine engines can greatly enhance your maintenance and repair skills. A variety of resources are available to deepen your knowledge and provide valuable insights into the components and functionalities of these machines.

Online Forums and Communities: Engaging with fellow enthusiasts in online platforms can offer practical advice and troubleshooting tips. These communities often share personal experiences, enhancing your understanding through real-world applications.

Instructional Videos: Platforms like YouTube feature a wealth of tutorials that cover everything from basic upkeep to complex repairs. Visual guides can be especially helpful in grasping intricate processes that text alone may not fully convey.

Technical Manuals: Obtaining official documentation can be invaluable. These manuals typically include detailed descriptions and schematics, enabling you to familiarize yourself with the specific elements and their functions within the system.

Workshops and Classes: Local institutions or community colleges often offer hands-on courses aimed at developing practical skills. Participating in these workshops can provide direct experience and mentorship from industry professionals.

Books and Publications: A range of literature exists, covering fundamental theories and advanced techniques related to marine engine technology. Investing time in reading can significantly enhance your theoretical knowledge and practical application.

Utilizing these resources will not only improve your technical skills but also instill confidence in your ability to manage and troubleshoot various engine-related issues.