Comprehensive Guide to Honda WB20XT Parts Diagram

Exploring the intricate details of mechanical assemblies is essential for effective maintenance and repair. A comprehensive understanding of the various elements involved can greatly enhance operational efficiency. Whether you’re a professional technician or a DIY enthusiast, familiarizing yourself with the components can facilitate smoother troubleshooting and service processes.

In this section, we will delve into the specific components of a popular engine model. By examining the layout and interrelations of each element, you’ll gain insights into their functionalities and roles within the system. This knowledge is crucial for optimizing performance and addressing potential issues swiftly.

Familiarity with the structure of engine assemblies not only empowers you to perform repairs with confidence but also equips you with the skills to make informed decisions regarding upgrades and modifications. Understanding how each part interacts can lead to improved reliability and longevity of your machinery.

Understanding Honda WB20XT Parts

Gaining insight into the components of a specific model is crucial for efficient maintenance and repair. By familiarizing oneself with each element, one can ensure optimal performance and longevity. This section aims to shed light on the various elements that constitute the machinery, allowing users to navigate repairs and upgrades with confidence.

Key Components Overview

Each machine is made up of numerous critical elements that contribute to its overall functionality. Recognizing these components helps in troubleshooting issues effectively.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire unit. |

| Fuel Tank | Stores fuel necessary for operation. |

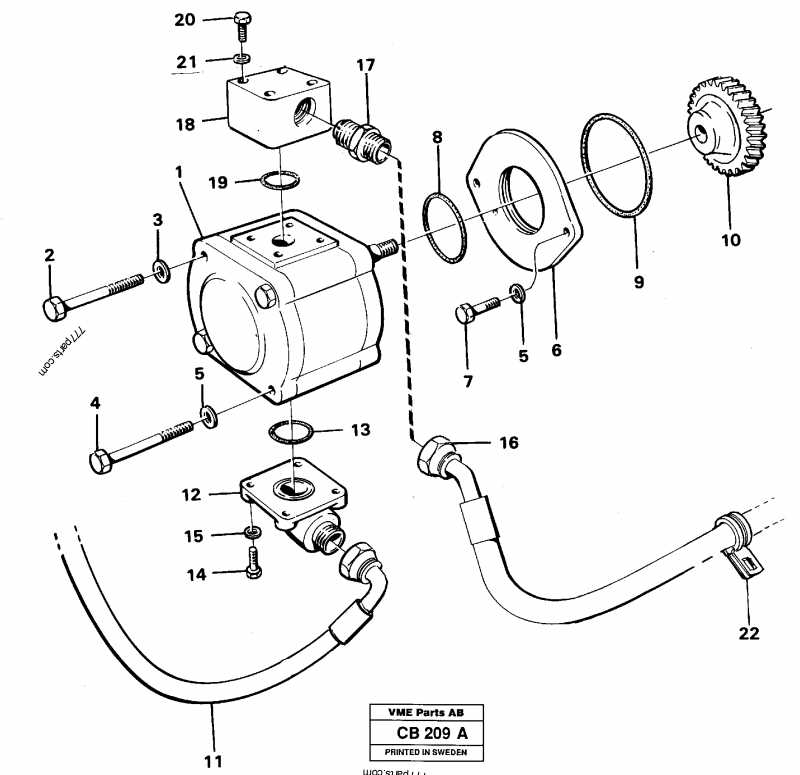

| Pump | Facilitates the movement of fluids or gases. |

| Hoses | Conduct fluids between components. |

Importance of Each Element

Understanding the role of each component aids in preventive maintenance and timely repairs. Regular checks can prevent malfunctions and extend the lifespan of the equipment.

Overview of Honda WB20XT Components

This section provides an insightful examination of the various elements that constitute a specific model of water pump. Understanding these components is essential for both maintenance and effective operation, ensuring the machine performs optimally over time.

Key Functional Elements

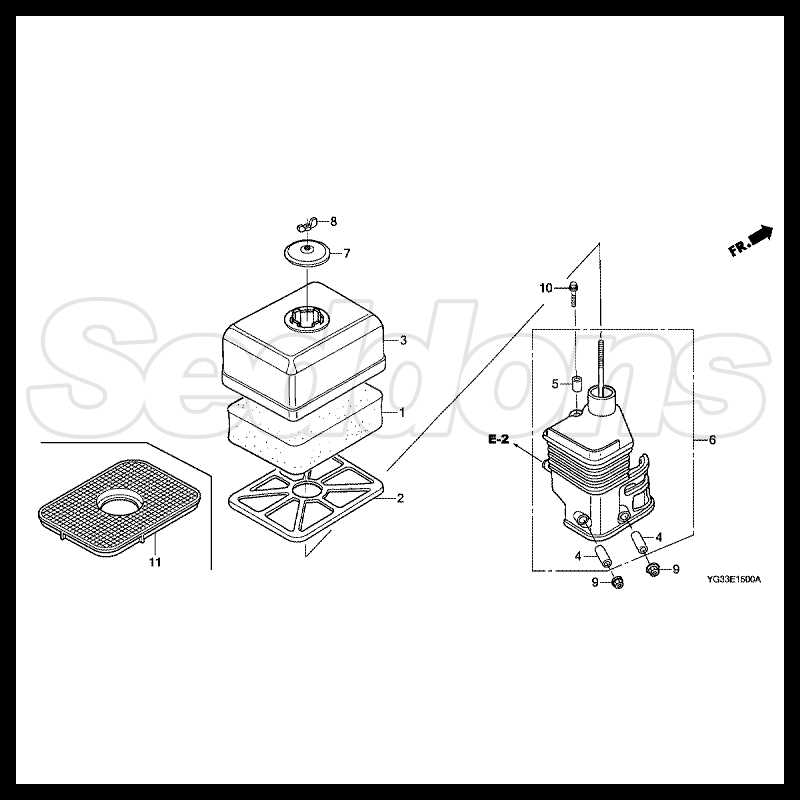

Central to the unit’s operation are the core components that facilitate water movement and engine performance. The impeller plays a critical role in creating the necessary pressure, while the casing protects and houses the internal mechanisms, ensuring durability and efficiency.

Supporting Mechanisms

Additional parts, such as the fuel tank and air filter, are vital for sustaining performance and longevity. The fuel tank supplies energy, while the air filter maintains optimal airflow, preventing debris from entering the system and affecting operation.

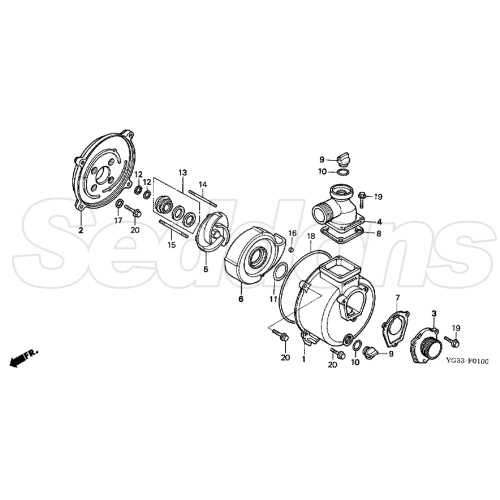

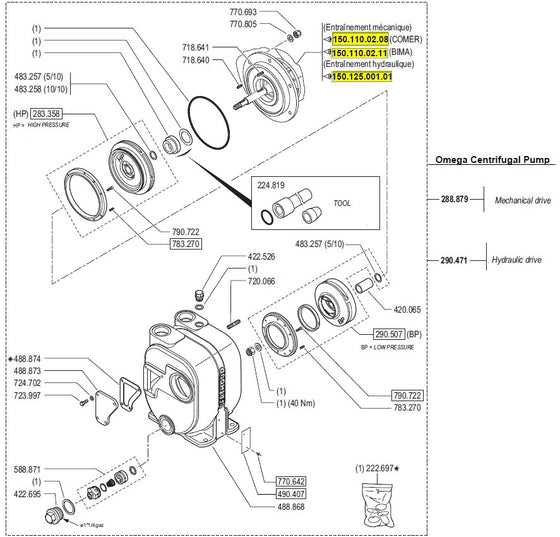

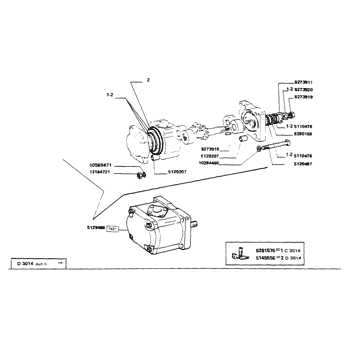

Importance of Parts Diagrams

Understanding the layout and components of any machine is crucial for effective maintenance and repair. Visual representations serve as valuable tools, enabling users to identify individual elements quickly and efficiently. This clarity helps streamline the process of troubleshooting and ensures that all necessary components are accounted for during repairs.

Enhanced Efficiency in Repairs

When faced with a malfunction, having a clear visual reference allows technicians to pinpoint issues more rapidly. This leads to a reduction in downtime, as they can easily locate and replace defective components. An organized illustration can significantly simplify complex tasks, making it easier to follow procedures and ensuring that nothing is overlooked.

Facilitation of Ordering Components

Visual aids are not only beneficial during repairs but also play a critical role when ordering replacements. By referring to a detailed image, users can accurately specify what they need, reducing the likelihood of errors in ordering. This precision is essential in maintaining the functionality and performance of the equipment.

How to Read the Diagram

Understanding a visual representation of components can greatly enhance your maintenance and repair skills. This section will guide you through the essentials of interpreting such illustrations, enabling you to identify parts and their connections efficiently.

Key Elements to Look For

- Labels: Each item will typically have a unique identifier, which makes it easier to reference in manuals or parts catalogs.

- Lines and Arrows: These indicate connections and flow between different elements, showing how they interact with one another.

- Legend: Most visuals will include a legend or key to explain symbols, aiding in the overall comprehension of the illustration.

Steps to Follow

- Start by identifying the main components depicted in the illustration.

- Follow the lines to understand how each part relates to others.

- Use the labels to cross-reference with your service manual for detailed specifications.

- Take notes on any components that may require replacement or further inspection.

Main Engine Parts Explained

This section delves into the essential components that make up a typical engine, providing insights into their functions and significance. Understanding these elements is crucial for anyone interested in mechanical performance and maintenance.

- Cylinder: The chamber where fuel and air mix for combustion, driving the pistons.

- Piston: A moving part that converts energy from combustion into mechanical work.

- Crankshaft: Transforms the up-and-down motion of the pistons into rotational energy.

- Valves: Control the intake of air and fuel, as well as the exhaust of combustion gases.

- Camshaft: Operates the valves in sync with the pistons, ensuring efficient timing.

- Spark Plug: Ignites the air-fuel mixture, initiating the combustion process.

Each of these components plays a vital role in the overall functionality of the engine, and knowledge of their operation can aid in troubleshooting and repairs.

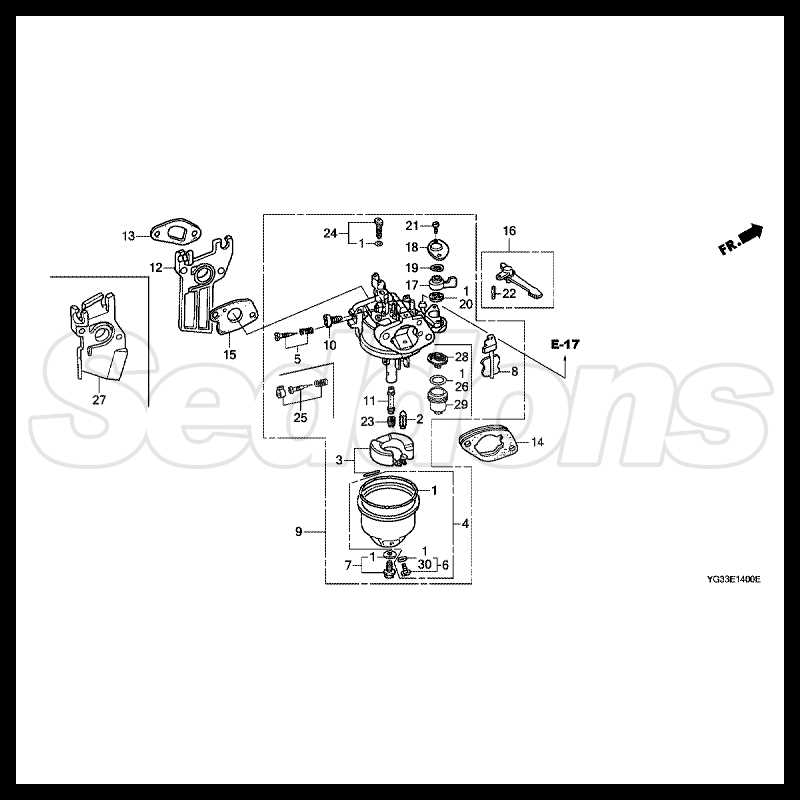

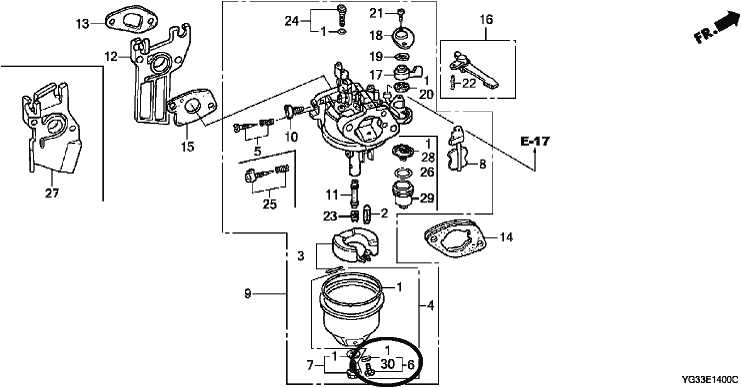

Fuel System Components Breakdown

This section provides an overview of the essential elements that make up the fuel delivery system in small engines. Understanding each component’s role is crucial for maintaining optimal performance and ensuring reliable operation.

The fuel tank is the primary storage unit, holding the gasoline until it is needed. Connected to the tank, the fuel line transports the liquid to the engine. Inline filters are essential for removing impurities, safeguarding the engine from damage.

At the heart of the system is the carburetor, which blends air and fuel in the correct ratio for combustion. Additionally, the fuel pump ensures a steady flow of fuel, maintaining pressure and efficiency throughout operation.

Regular inspection of these components can prevent issues such as clogging and leakage, ultimately extending the lifespan of the engine. Keeping each part clean and functional is key to achieving peak performance.

Electrical Parts and Their Functions

This section explores the crucial components of the electrical system, detailing their roles and how they contribute to overall functionality. Understanding these elements is essential for effective maintenance and troubleshooting.

- Battery: Provides the necessary power to start the engine and operate electrical accessories.

- Starter Motor: Engages the engine when the ignition is activated, enabling the unit to start.

- Ignition Coil: Converts low battery voltage into high voltage, necessary for spark generation.

- Wiring Harness: Connects various electrical components, ensuring efficient power distribution and communication.

- Fuse Box: Houses fuses that protect the electrical circuits from overload and short circuits.

- Regulator: Maintains the voltage level within the system, preventing damage from fluctuations.

Each component plays a vital role in ensuring reliable operation, and awareness of their functions aids in diagnosing issues and performing repairs effectively.

Identifying Wearable Parts

Understanding the components that experience regular wear is crucial for maintaining optimal performance and longevity of your equipment. Recognizing these elements helps in timely replacements, ensuring efficient operation and preventing costly breakdowns.

Common Wearable Components

- Seals and Gaskets

- Filters

- Belts and Hoses

- Bearings

- Plugs and Caps

Signs of Wear

- Cracking or brittleness in rubber parts

- Excessive noise during operation

- Fluid leaks around seals

- Difficulty in moving parts

- Visible wear patterns or fraying

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires consistent upkeep and attention to detail. Regular maintenance not only enhances efficiency but also prevents potential issues from escalating into major repairs. By following a few key practices, you can significantly extend the life of your machinery.

Routine Inspections

Conduct frequent checks on vital components to identify wear and tear early. Look for signs of rust, loose connections, or leaks. Keeping a maintenance log can help track these inspections and remind you of upcoming tasks.

Proper Storage

When not in use, store your equipment in a clean, dry environment to protect it from environmental damage. Covering machinery can prevent dust accumulation and minimize exposure to harsh weather conditions, ensuring it remains in optimal condition for future use.

Common Replacement Parts Needed

When maintaining a reliable engine system, certain components frequently require replacement to ensure optimal performance. These essential elements contribute significantly to the overall functionality and longevity of the equipment.

One of the most commonly replaced components is the fuel filter, which plays a crucial role in preventing impurities from entering the engine. Additionally, air filters are vital for maintaining airflow and preventing debris from causing damage.

Another important element is the spark plug, which ignites the fuel-air mixture, and its regular replacement can enhance starting and overall efficiency. Moreover, gaskets and seals are essential for preventing leaks and ensuring proper pressure within the system.

Finally, belts and hoses should be inspected and replaced as needed to avoid breakdowns and ensure smooth operation. Regular maintenance of these components can help extend the lifespan of the machinery and reduce the likelihood of unexpected failures.

Where to Find Genuine Parts

Locating authentic components for your equipment can be crucial for ensuring optimal performance and longevity. Whether you are looking to replace worn-out items or enhance functionality, knowing the right sources can save time and effort.

Reputable dealers and authorized retailers are among the best options for sourcing genuine components. These establishments often provide not only quality products but also reliable customer support to assist with any inquiries.

| Source | Description |

|---|---|

| Authorized Dealers | These businesses are certified to sell original components and often have a comprehensive inventory. |

| Manufacturer’s Website | The official website typically offers a dedicated section for genuine components, including specifications and ordering options. |

| Online Marketplaces | Reputable online platforms can provide access to authentic items, but it’s essential to verify seller ratings and reviews. |

| Local Repair Shops | Local service centers often have access to genuine items and can assist in installation, ensuring proper functionality. |

By choosing the right sources, you can confidently obtain the components necessary to maintain your equipment’s performance and reliability.

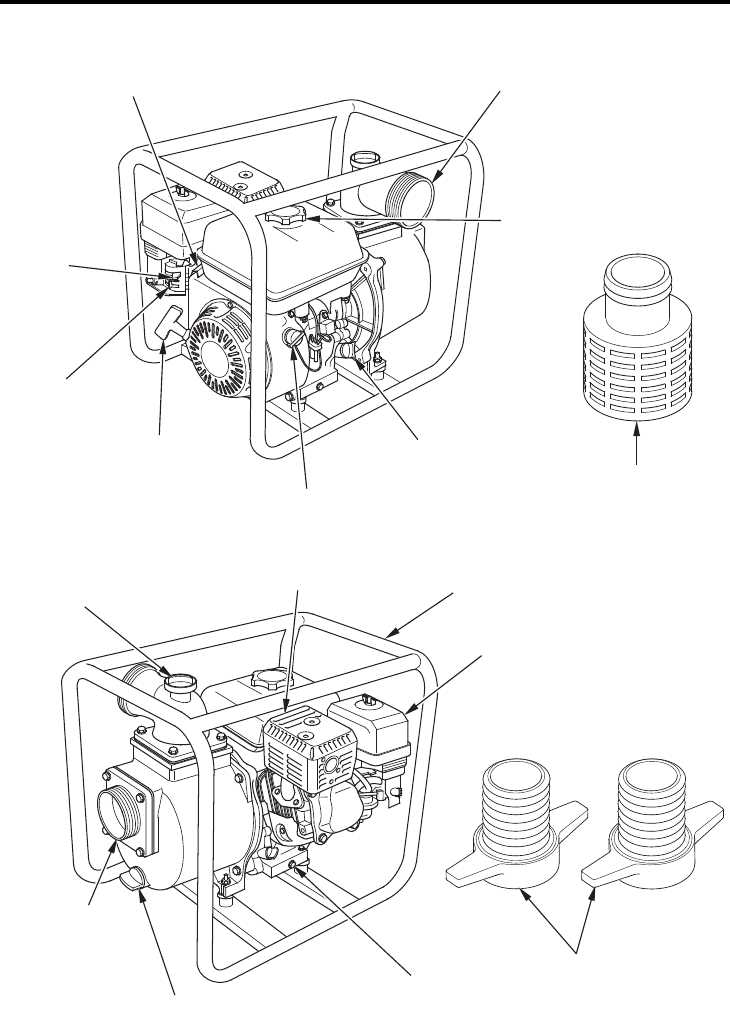

Assembling Your Honda WB20XT

Putting together your equipment involves several steps to ensure everything is functioning optimally. Careful attention to each component will lead to a successful assembly and enhance the overall performance of the unit.

Start by gathering all necessary items and reviewing the assembly guide. This will give you a clear understanding of the sequence of steps and the tools required. Following the guidelines methodically will prevent common mistakes and streamline the process.

| Step | Description |

|---|---|

| 1 | Lay out all components on a clean surface for easy access. |

| 2 | Begin by attaching the base securely to ensure stability. |

| 3 | Connect the relevant parts according to the guide, ensuring each piece fits correctly. |

| 4 | Check for any loose connections and tighten them as needed. |

| 5 | Perform a final inspection to confirm that all components are assembled correctly. |

By following these steps, you’ll create a reliable setup that performs effectively in various applications. Regular maintenance after assembly will further enhance longevity and functionality.