Comprehensive Guide to Husqvarna 125BVX Parts Diagram

The inner workings of any complex tool can be broken down into a collection of essential components, each playing a specific role in ensuring optimal functionality. Understanding how these elements fit together is key for proper maintenance and repair. With the right information, you can identify which elements are responsible for various functions and troubleshoot effectively when necessary.

In this section, we will delve into the breakdown of this machine’s internal layout, providing a clear guide for anyone looking to understand how different parts interact. Whether you’re looking to perform maintenance or just curious about its design, this guide will offer a comprehensive look at each element’s purpose and positioning.

Efficiency and performance largely depend on a well-organized structure, making it important to familiarize yourself with each component’s place within the system. Knowing what to look for can help you avoid downtime and keep your tool running smoothly for years to come.

Comprehensive Overview of Husqvarna 125BVX Components

Understanding the individual elements of this powerful equipment is essential for ensuring optimal functionality and longevity. Each component works in harmony to deliver high performance, making it crucial to recognize their significance and how they interact within the entire system.

The design incorporates several key mechanical parts that allow for smooth operation and efficiency. These include elements responsible for the motor’s performance, fuel system, and airflow management, all contributing to the overall reliability of the tool.

By analyzing the various internal and external components, users can better understand maintenance needs and how to troubleshoot issues that may arise. Proper care of these elements ensures that the tool will function at its best for extended periods.

Key Features and Functions of Main Parts

The primary components of this machine work together to ensure efficient performance and user comfort. Each element is designed with specific functions that contribute to the overall reliability and usability, allowing for optimal operation in various conditions. Understanding how these elements interact can provide insight into maintenance and functionality improvements.

- Engine: The power source of the equipment, offering the necessary force for operation. It features a compact design that ensures fuel efficiency while delivering adequate power output.

- Fan Assembly: This element generates airflow, crucial for the device’s primary task. Its aerodynamic structure maximizes efficiency while minimizing noise.

- Air Filter: Protects the engine by preventing debris from entering, ensuring long-term durability and consistent performance.

- Fuel Tank: Holds the fuel required for operation, featuring a transparent design for easy monitoring of fuel levels.

- Throttle Control: Allows the user to regulate engine speed, ensuring precision during operation. Its ergonomic

Understanding the Engine Assembly for Optimal Performance

The efficiency and longevity of any power tool depend heavily on the proper functioning and assembly of its core components. Ensuring that all parts of the motor work in harmony is essential for achieving smooth operation and reliable output. Regular maintenance and a thorough understanding of each section can significantly improve the tool’s overall performance.

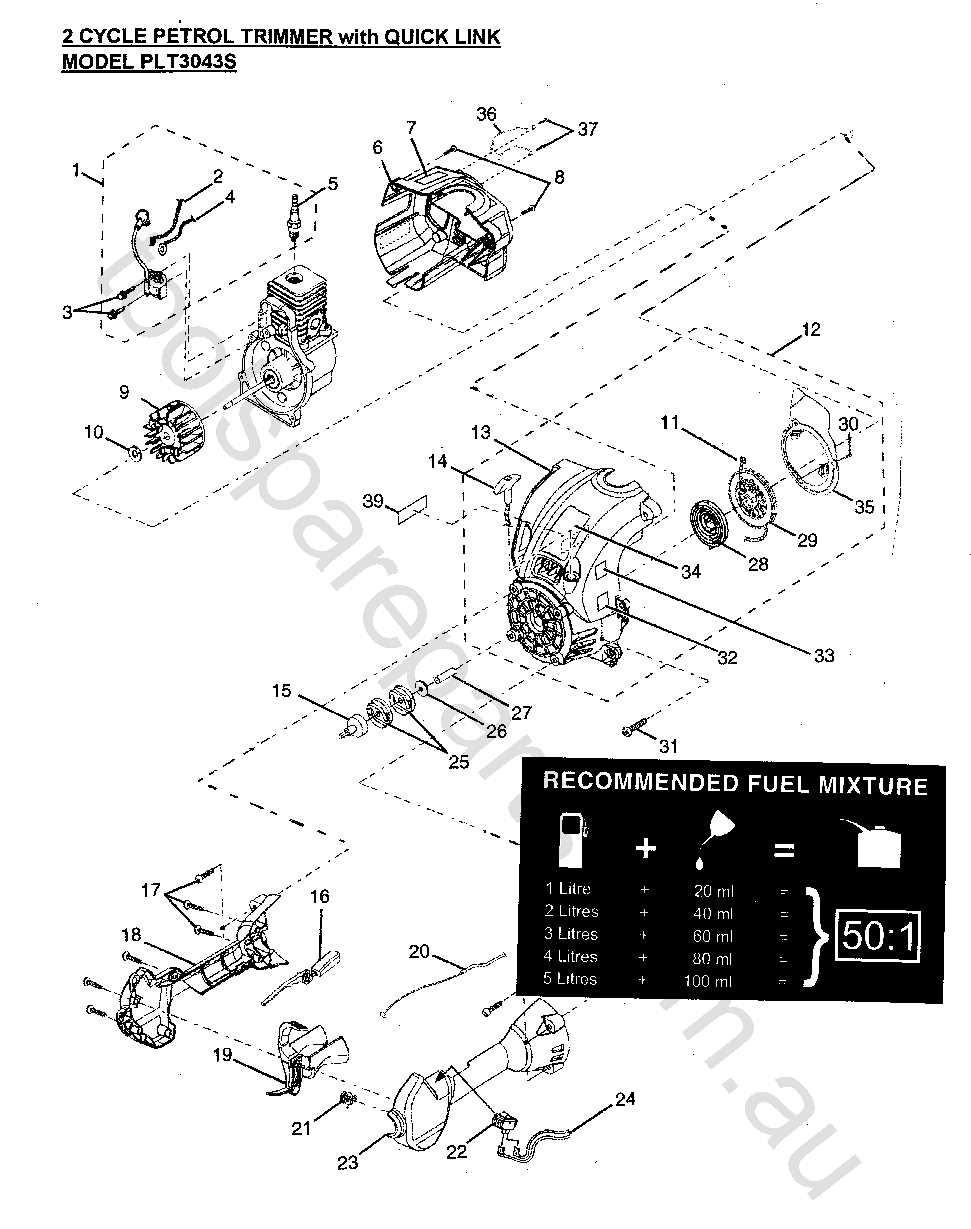

Key Components of the Engine

To maximize operational efficiency, it is crucial to become familiar with the primary elements that drive the machine. The piston, cylinder, crankshaft, and ignition system all contribute to the energy transfer, converting fuel into mechanical motion. When each of these components is in optimal condition, the tool runs smoothly and consistently.

Ensuring Proper Alignment and Maintenance

Proper alignment of internal parts is vital for reducing friction and preventing early wear. Regular inspections, timely lubrication, and correct positioning of these elements help in maintaining a balanced system, ensuring that each part operates within its designated role. This approach not only extends the lifespan of the machine but also improves its performance duri

Air Filter System and Its Maintenance

The air intake mechanism plays a crucial role in the efficient operation of outdoor equipment. Proper airflow ensures optimal performance by preventing debris and dust from entering critical components. Regular upkeep of this mechanism is essential to prolong the life of the machinery and maintain its performance.

Key Components of the System

The air intake system consists of several elements designed to filter out contaminants. These parts work together to protect the internal components and ensure smooth operation. By keeping these elements clean and in good condition, you can improve the overall efficiency of the equipment.

Component Function Filter Element Traps dust, dirt, and small particles to prevent them from entering the engine. Cover Provides protection and keeps the filter securely in place. Housing Encases the filter and directs air through the system. Maintaining the Air Filter System

Regular maintenance of the air filtration unit is necessary to keep the equipment running efficiently. This includes inspecting the filter for wear, cleaning or replacing

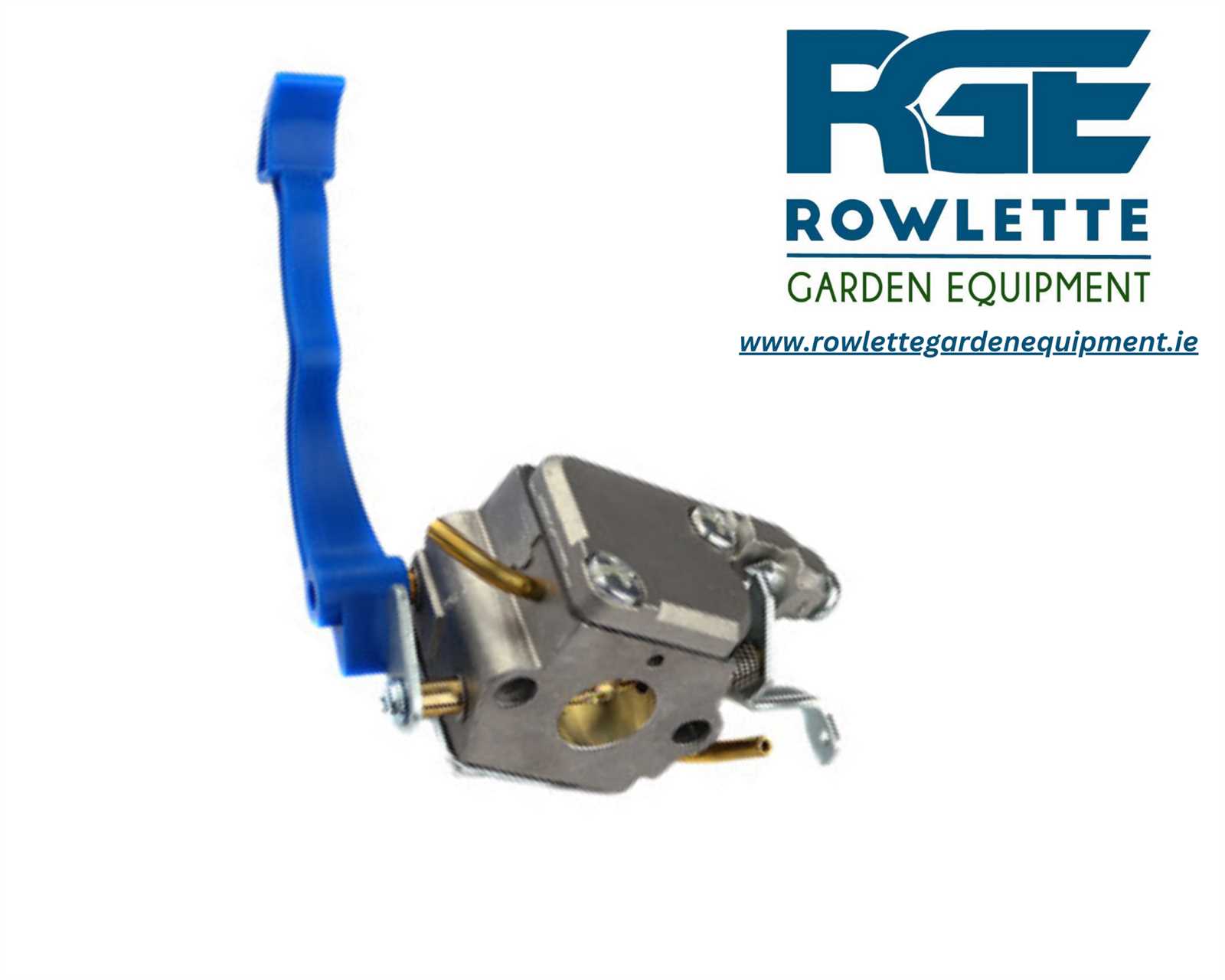

Exploring the Carburetor Mechanism

The internal workings of the carburetor play a crucial role in managing fuel and air mixture for optimal engine performance. This mechanism ensures that the right balance of elements is achieved to maintain smooth operation, especially under varying conditions. Understanding its components and how they function together is key to improving overall efficiency and troubleshooting potential issues.

Key Components and Functions

The carburetor consists of various interconnected parts that control the flow of fuel and air. The throttle valve regulates airflow, while jets control the fuel supply, creating a precise blend that enters the combustion chamber. The float chamber maintains the necessary fuel level, ensuring continuous supply even during fluctuating engine demands.

Common Issues and Maintenance

Over time, dirt and debris can obstruct jets, leading to improper fuel flow. Regular cleaning and maintenance of the carburetor are essential to prevent such issues. Ensuring proper adjustments of the throttle and other critical components can significantly enhance engine reliability and performance.

Fan Housing and Its Importance in Airflow

The fan enclosure serves as a critical component in optimizing airflow within various machinery. Its design and structure significantly influence the efficiency of air circulation, directly affecting the performance and effectiveness of the equipment. By directing and channeling airflow, the housing ensures that the internal mechanisms receive adequate cooling and that debris is effectively expelled from the system.

One of the primary functions of the fan housing is to create a controlled environment for air movement. It minimizes turbulence and maximizes the velocity of air directed toward the necessary areas. This streamlined airflow not only enhances cooling efficiency but also contributes to the overall longevity of the machinery by preventing overheating and maintaining optimal operational conditions.

Moreover, a well-designed fan enclosure helps reduce noise levels generated during operation. By containing and directing airflow, it dampens sound, leading to a more pleasant working environment. Additionally, it plays a vital role in protecting the internal components from dust and debris, ensuring that the machinery operates smoothly and without interruptions.

Guide to Replacing Fuel System Components

Maintaining optimal performance in outdoor power equipment often involves timely replacement of critical fuel-related elements. This section focuses on understanding the essential components that make up the fuel delivery system and the steps necessary for their effective replacement. Proper care in this area ensures that your device operates smoothly and efficiently.

Identifying Key Components

The fuel system typically comprises several vital elements, including the fuel filter, pump, and lines. Each of these components plays a crucial role in ensuring the smooth flow of fuel to the engine. Recognizing the symptoms of wear or damage is the first step toward effective maintenance. Common signs include difficulty starting, reduced power output, and fuel leaks. Addressing these issues promptly can prevent further damage and ensure longevity.

Step-by-Step Replacement Process

Once the components needing attention have been identified, the next step is to replace them systematically. Start by ensuring the equipment is powered off and completely cooled. Disconnect any fuel lines and carefully remove the old components. When installing new parts, follow the manufacturer’s guidelines closely to avoid improper connections. Double-checking all connections and seals will help prevent future leaks or malfunctions. Regular inspections and replacements will significantly enhance performance and reliability.

How the Ignition System Powers the Blower

The ignition mechanism serves as a crucial component in the operation of handheld blowing devices, enabling them to function effectively. By generating the necessary spark, it initiates combustion within the engine, transforming fuel into energy. This process not only powers the engine but also facilitates the movement of air, allowing the blower to perform its intended tasks efficiently.

Understanding the Ignition Process

At the core of the ignition system lies the spark plug, which plays a vital role in igniting the fuel-air mixture within the combustion chamber. When the engine is started, a voltage is generated, sending an electrical current to the spark plug. This current produces a spark that ignites the mixture, leading to a rapid expansion of gases that drive the piston down. This movement, in turn, produces the rotational force needed to operate the blower’s fan.

The Role of Fuel and Air Mixture

For optimal performance, the ignition system relies on the precise mixture of fuel and air. A well-balanced ratio ensures efficient combustion, resulting in more power output. If the mixture is too rich or too lean, it can lead to poor performance or even engine misfires. Therefore, maintaining the correct mixture is essential for the reliable operation of the blower.

In summary, the ignition system is fundamental to the effective functioning of a blower. By creating the necessary conditions for combustion, it allows the device to generate the airflow required for various cleaning and maintenance tasks.

Throttle Controls and Cable Adjustments

The functionality and responsiveness of a handheld engine device are largely influenced by the mechanisms governing throttle operation and the corresponding cable settings. These components are essential for regulating power output and ensuring smooth operation during use. Proper adjustments can significantly enhance performance and user experience.

Understanding the Throttle Control System is crucial for effective operation. This system typically consists of a lever or trigger that the user manipulates to manage engine speed. A well-functioning throttle control allows for precise adjustments, enabling the operator to respond to varying demands during operation.

Proper Cable Tension is vital for maintaining optimal performance. Over time, cables can stretch or become misaligned, leading to sluggish throttle response. Regular inspections and adjustments ensure that the cables are neither too tight nor too loose, allowing for efficient energy transfer and control.

It is advisable to consult the manufacturer’s specifications for recommended settings and adjustment procedures. Maintaining the integrity of the throttle controls and cables not only prolongs the lifespan of the equipment but also ensures a safe and enjoyable user experience.

Maintaining the Blower Tube and Nozzle Attachments

Proper upkeep of the blower’s tube and nozzle accessories is essential for optimal performance and longevity. Regular maintenance ensures that these components remain free of debris and function effectively, allowing for efficient operation during various tasks. By following a few straightforward steps, users can maintain their equipment and achieve better results with less effort.

Cleaning the Tube and Nozzles

Cleaning the tube and nozzles is crucial to prevent blockages that can hinder airflow. After each use, inspect the attachments for any accumulated dirt or leaves. To clean, use a soft brush or cloth to wipe down the surfaces. For stubborn residue, a mild soap solution can be applied. Ensure that all components are completely dry before reassembly to avoid moisture-related issues.

Inspecting for Damage

Regularly check the blower tube and nozzles for signs of wear or damage. Look for cracks, breaks, or other deformities that could affect performance. If any component is damaged, it is advisable to replace it promptly to maintain efficiency. Proper inspection helps in identifying potential issues before they become significant problems.

Maintenance Task Frequency Tools Needed Cleaning After each use Soft brush, cloth Inspection for damage Weekly None Replacement of damaged parts As needed Replacement parts Troubleshooting Common Issues in Husqvarna 125BVX

When operating outdoor equipment, encountering difficulties can be frustrating. Understanding the typical problems that may arise and how to address them can significantly enhance performance and longevity. This section will explore common challenges users face and provide practical solutions to keep your equipment running smoothly.

Common Problems

- Starting Issues

- Check the fuel level; insufficient fuel can prevent ignition.

- Inspect the spark plug for wear or carbon buildup.

- Ensure the choke is in the correct position for starting.

- Power Loss

- Examine the air filter; a clogged filter can restrict airflow.

- Look for fuel line obstructions that may limit fuel flow.

- Check for leaks in the exhaust system that can hinder performance.

- Excessive Vibration

- Inspect the blades for damage or imbalance.

- Tighten any loose components that may cause instability.

- Ensure all screws and fasteners are secure.

Maintenance Tips

- Regularly clean the equipment after use to prevent buildup.

- Perform routine checks on filters and spark plugs to ensure optimal operation.

- Store the equipment in a dry, sheltered location to protect it from weather damage.

- Starting Issues