Filter Placement

Air Filter Maintenance Tips

Proper air filter care is essential for keeping outdoor power tools running smoothly. A clean filter ensures efficient airflow, which helps maintain engine performance and prevents unnecessary wear. Regular maintenance reduces the risk of blockages, ensuring longer equipment life and consistent functionality.

How to Clean the Air Filter

Remove the filter carefully to avoid spreading dust and debris into the engine. Use a soft brush or compressed air to clear out any dirt buildup. If the filter is washable, rinse it gently with water and allow it to dry fully before reinstalling. Never operate the tool with a wet or damaged filter, as this can reduce efficiency and lead to engine issues.

When to Replace the

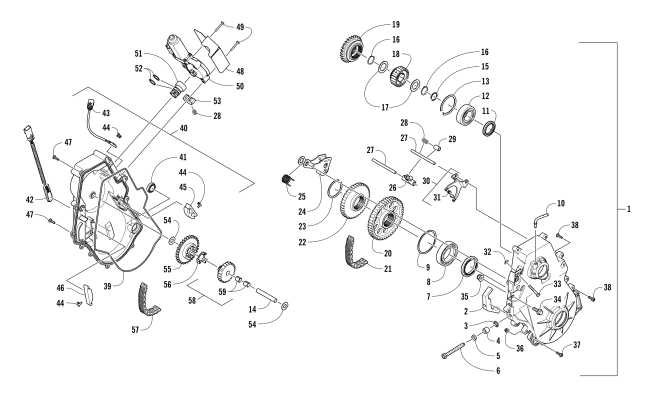

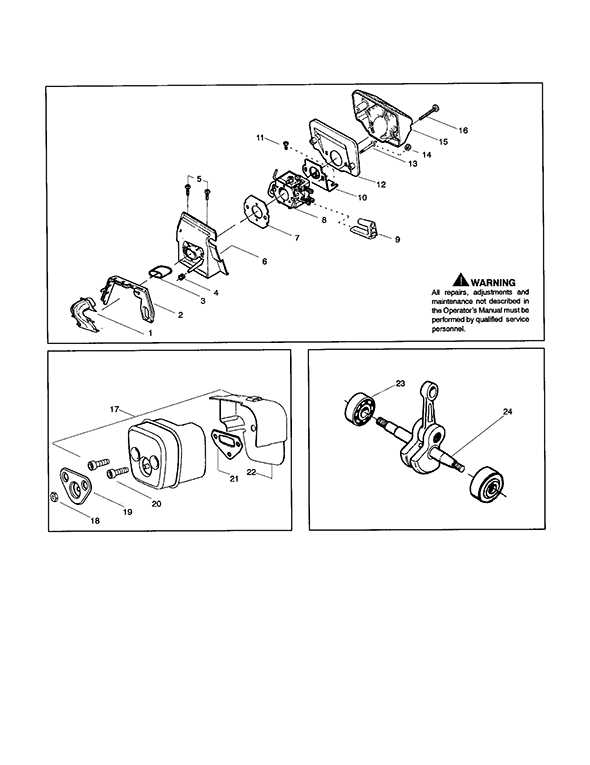

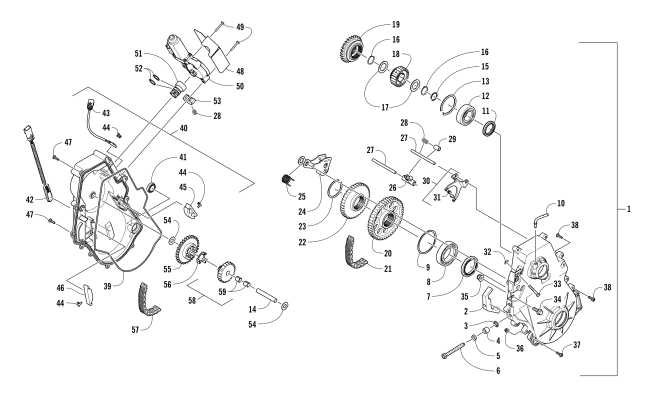

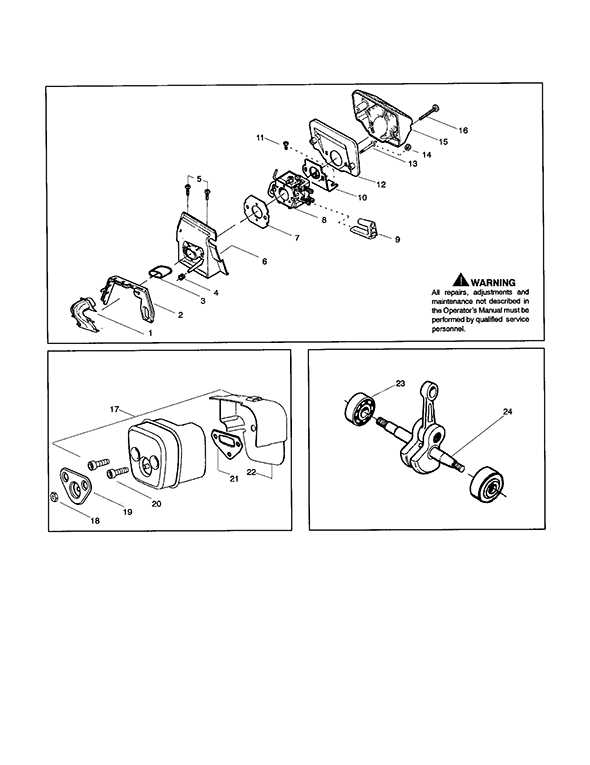

Chain Brake Mechanism Details

The chain brake system is a crucial safety feature in many cutting tools. This mechanism is designed to quickly halt the movement of the cutting chain in emergency situations, thereby reducing the risk of accidents. Understanding its components and functionality is essential for maintenance and effective operation.

The main components of the chain brake mechanism include:

| Component |

Function |

| Brake Band |

Engages with the clutch drum to stop chain movement. |

| Brake Handle |

Manually activates the brake system when pulled. |

| Spring |

Helps return the brake band to its original position after activation. |

| Brake Lever |

Controls the application of the brake band on the clutch drum. |

Regular inspection and maintenance of these components ensure reliable operation and enhance the safety of the cutting tool.

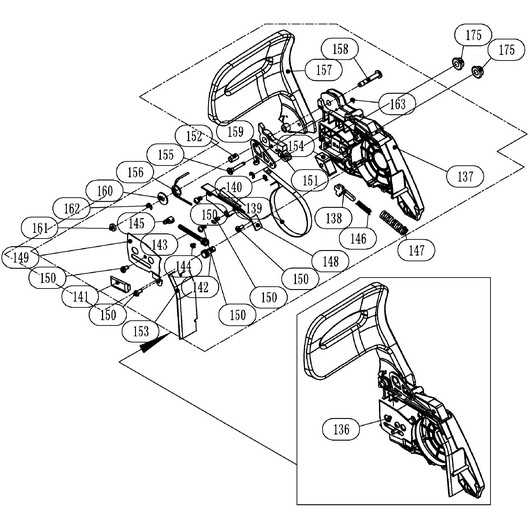

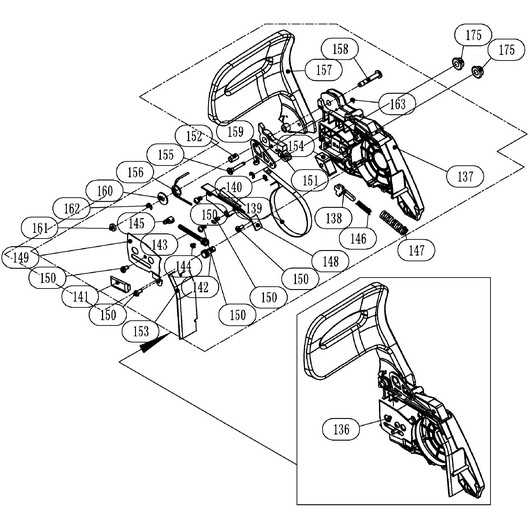

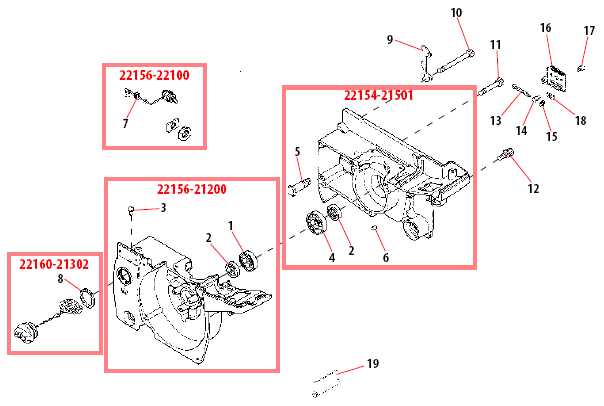

Handle Assembly and Vibration Reduction

The assembly responsible for the gripping mechanism of cutting tools plays a crucial role in ensuring user comfort and operational efficiency. This component not only provides control during use but also contributes to minimizing vibrations that can affect performance and fatigue. Understanding the design and function of this assembly is essential for both maintenance and effective usage of the equipment.

Design and Functionality

The handle assembly is engineered to allow for a secure and comfortable grip, which is vital for prolonged use. Its design often includes features that help dampen vibrations, enhancing the overall user experience. By integrating materials that absorb shock, manufacturers aim to reduce the transfer of vibrations from the tool to the user’s hands, decreasing the risk of discomfort or injury during operation.

Importance of Vibration Reduction

Reducing vibrations is not merely a comfort issue; it has significant implications for safety and performance. High levels of vibration can lead to fatigue, impacting the user’s ability to operate the tool effectively over time. Effective vibration dampening mechanisms within the handle assembly can significantly improve control, precision, and overall satisfaction, making it an important aspect of tool design.

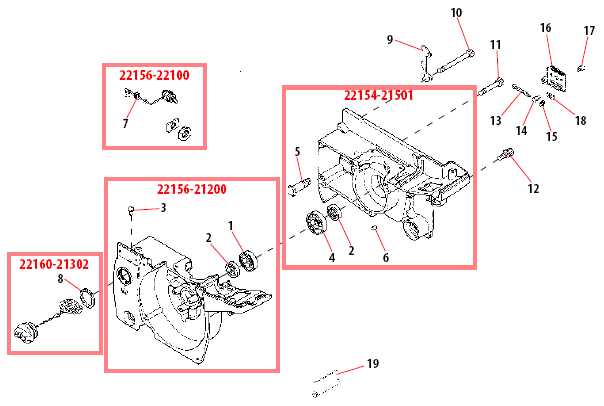

Carburetor Adjustment Guidelines

Proper calibration of the fuel delivery system is essential for optimal engine performance. Adjustments ensure that the mixture of air and fuel is balanced, which can lead to enhanced efficiency, smoother operation, and reduced emissions. This section outlines the key considerations and steps for making these adjustments effectively.

Before starting the adjustment process, it is crucial to understand the specific components involved in the calibration. These include the idle speed screw, mixture adjustment screw, and other related elements. Each plays a vital role in determining how the engine operates under various conditions.

| Component |

Function |

| Idle Speed Screw |

Controls the engine’s idle RPM. |

| Mixture Adjustment Screw |

Modifies the air-fuel ratio for optimal combustion. |

| Choke |

Aids in starting the engine by enriching the fuel mixture. |

To achieve the best results, follow these basic steps:

- Start the engine and allow it to warm up to operating temperature.

- Adjust the idle speed screw to set the desired RPM.

- Fine-tune the mixture adjustment screw until the engine runs smoothly.

- Test the engine under load to ensure the adjustments have improved performance.

Regular maintenance and adjustment can lead to improved longevity and efficiency of the engine. Always refer to the manufacturer’s guidelines for specific settings and procedures to ensure the best results.

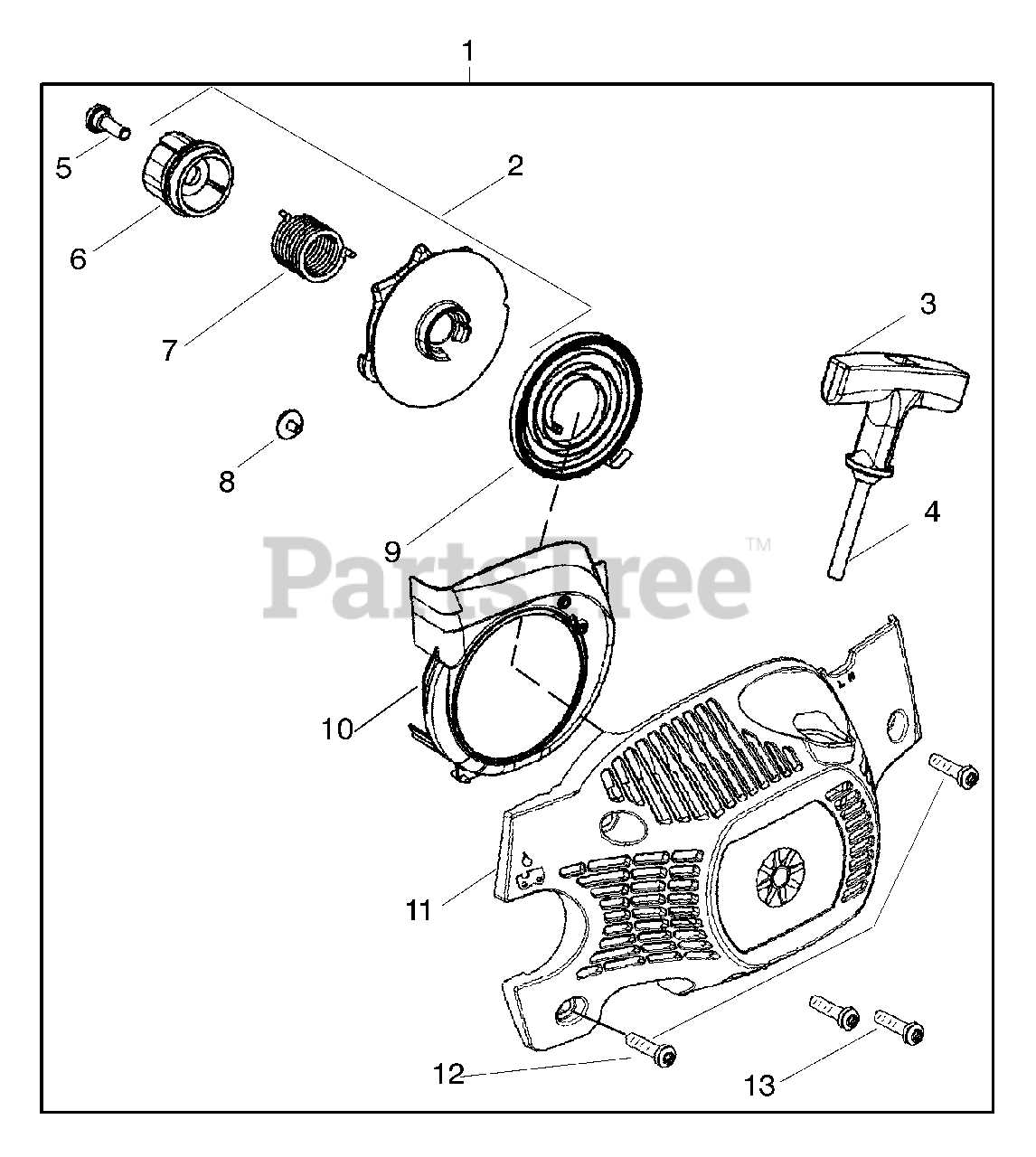

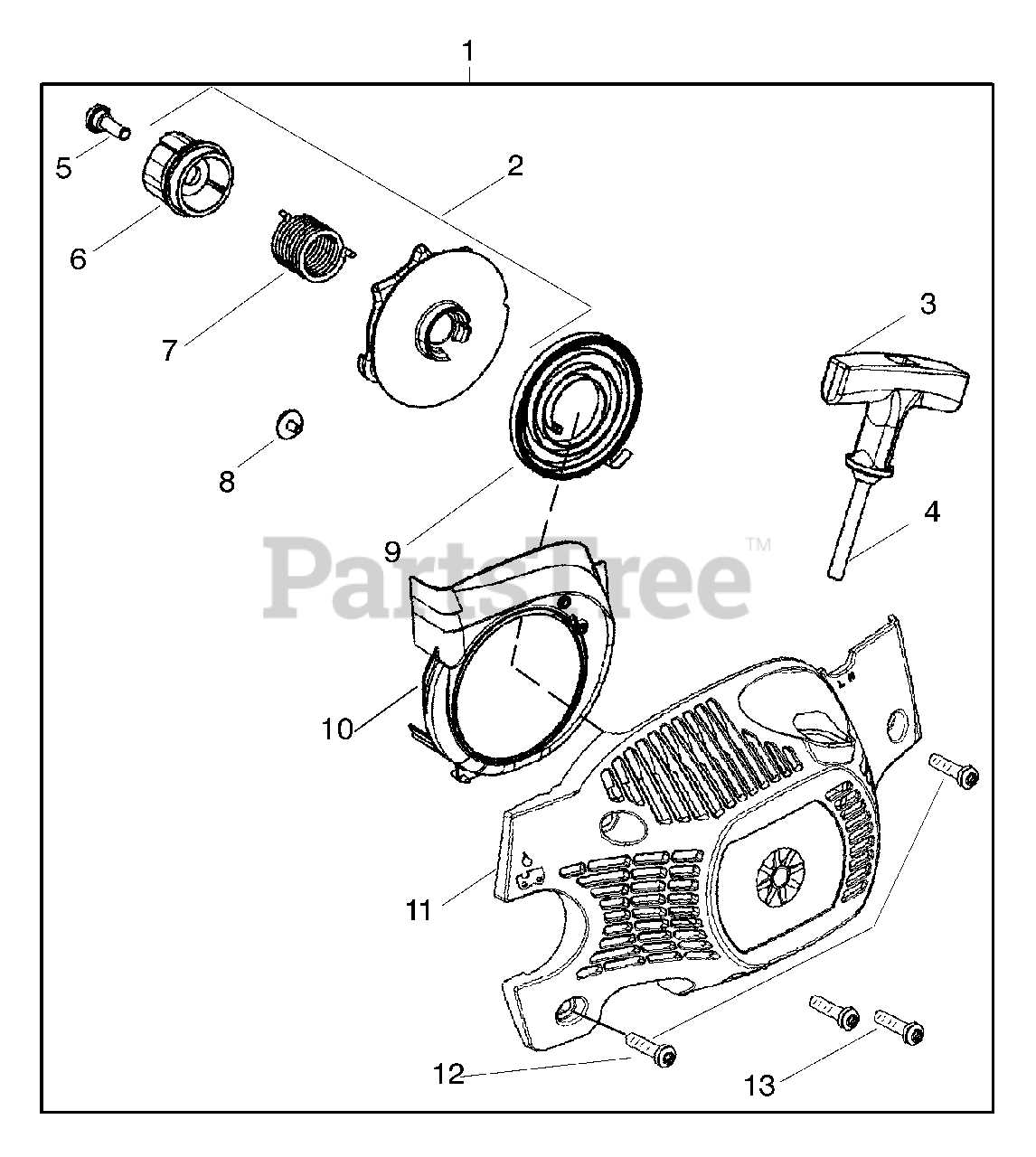

Recoil Starter Functionality

The recoil starter plays a crucial role in the operation of small engine equipment, providing an efficient means to initiate the engine’s operation. This mechanism utilizes a coiled spring and a pull cord to engage the engine, allowing for a straightforward starting process. When the cord is pulled, the spring unwinds, which turns the engine over and creates the necessary ignition to begin operation.

Components of the Recoil Starter

Several key components work together within the recoil starter system. The pulley holds the pull cord and facilitates the winding and unwinding motion. The spring is responsible for retracting the cord after each pull, ensuring it is ready for the next starting attempt. Additionally, a pawl engages with the engine flywheel to transfer the rotational force, further aiding in the starting process.

Importance of Maintenance

Regular maintenance of the recoil starter is essential for optimal performance. Over time, components can wear out or become damaged, leading to difficulties in starting the engine. Inspecting the cord for frays, ensuring the spring is intact, and checking the engagement of the pawl can significantly enhance reliability. Proper upkeep prevents potential issues and extends the lifespan of the equipment.

Bar and Chain Compatibility

When selecting a cutting tool, ensuring the right fit between the guide and the chain is essential for optimal performance. Compatibility affects not only the efficiency of the tool but also the safety and ease of use. Various factors must be considered when choosing the appropriate components to achieve the best results.

Factors to Consider

- Length: The length of the guide plays a significant role in determining compatibility. Measuring the bar accurately helps in selecting the correct size.

- Gauge: This refers to the width of the groove in the guide. It’s crucial to match the gauge of the chain to ensure proper fitting and function.

- Pitch: The distance between the drive links impacts how the chain interacts with the bar. It’s important to choose a chain that matches the pitch of the guide.

- Type of Chain: Different chain types serve various purposes, such as cutting efficiency or speed. Selecting the right type enhances cutting performance.

Maintaining Compatibility

Regular maintenance is vital to ensure continued compatibility between the guide and chain. Checking for wear and tear can prevent operational issues and extend the life of the tool. Proper lubrication and tension adjustment are also essential for optimal functioning.

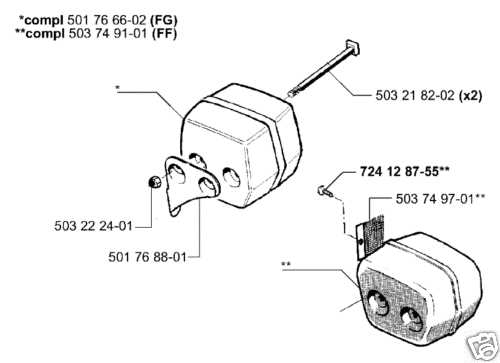

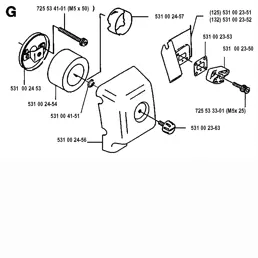

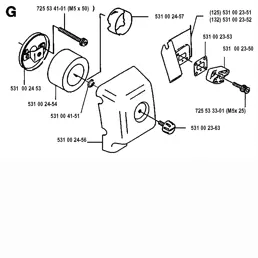

Muffler and Exhaust System Design

The muffler and exhaust system are essential components in managing the performance and sound output of combustion engines. This system plays a critical role in reducing noise pollution while ensuring efficient exhaust gas expulsion. An effective design enhances engine performance, optimizes fuel efficiency, and minimizes environmental impact.

Key Components of the Exhaust System

Understanding the various elements of the exhaust system is crucial for effective maintenance and performance optimization. Each part contributes to the overall functionality and efficiency of the engine.

| Component |

Function |

| Muffler |

Reduces engine noise and improves sound quality. |

| Exhaust Pipe |

Channels exhaust gases away from the engine. |

| Manifold |

Collects exhaust gases from multiple cylinders and directs them to the exhaust pipe. |

| Catalytic Converter |

Reduces harmful emissions by converting exhaust gases into less harmful substances. |

Importance of Proper Design

A well-designed exhaust system not only improves engine performance but also contributes to fuel efficiency. By optimizing the flow of exhaust gases, the system can reduce back pressure, allowing the engine to operate more efficiently. Moreover, effective muffler design minimizes noise levels, contributing to a more pleasant working environment.