Husqvarna 141 Parts Diagram for Easy Maintenance and Repair

In the realm of outdoor machinery, a comprehensive understanding of the intricate assemblies is essential for both maintenance and repair. Recognizing how different elements interact within a power tool can significantly enhance its performance and longevity. Whether you are a seasoned technician or a casual user, grasping the structure of these devices is key to ensuring optimal functionality.

Effective troubleshooting often begins with a detailed exploration of the various segments that constitute a machine. By familiarizing oneself with the arrangement and function of each individual component, one can diagnose issues more accurately and efficiently. This knowledge empowers users to take proactive steps in preserving their equipment, leading to fewer breakdowns and extended service life.

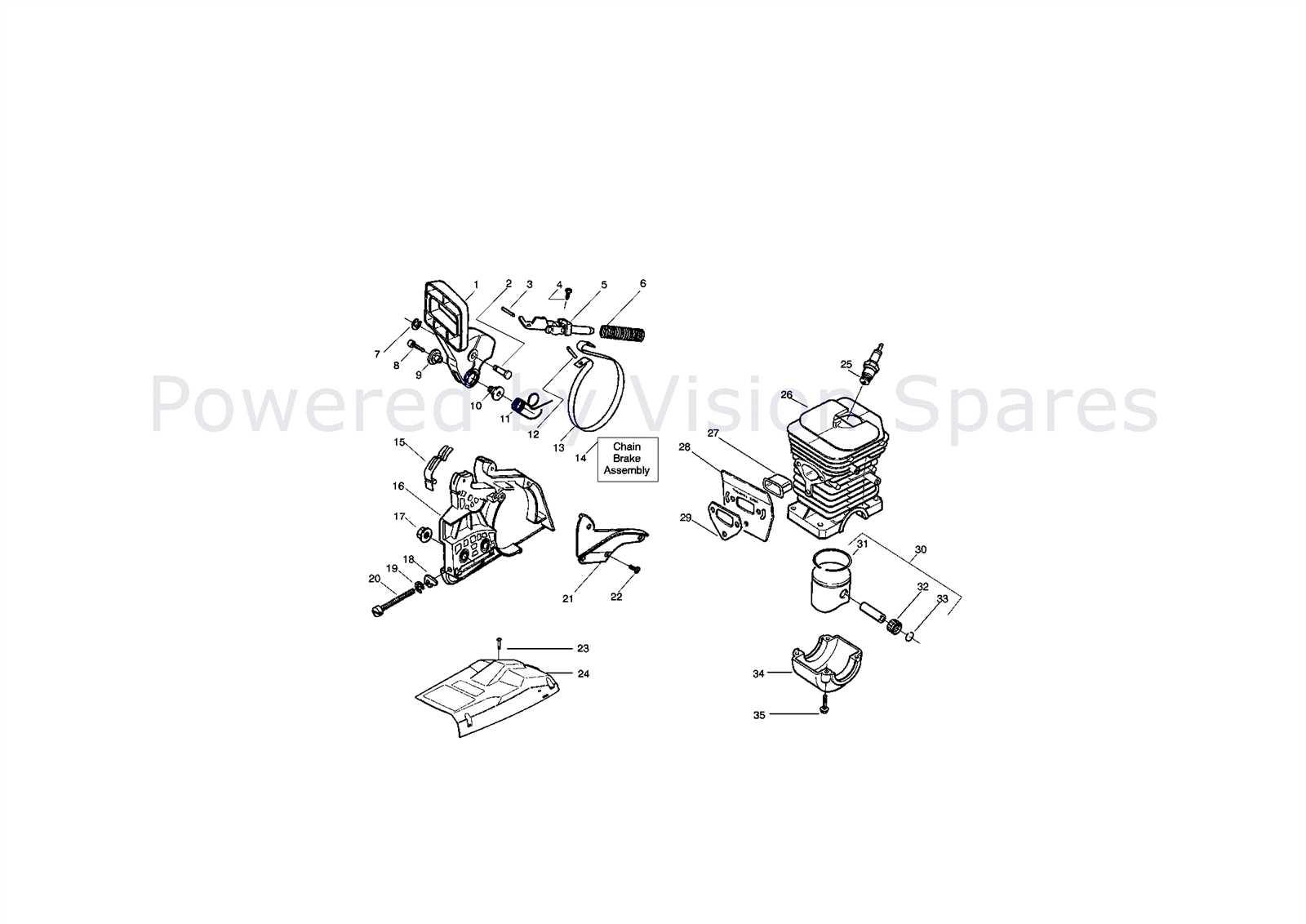

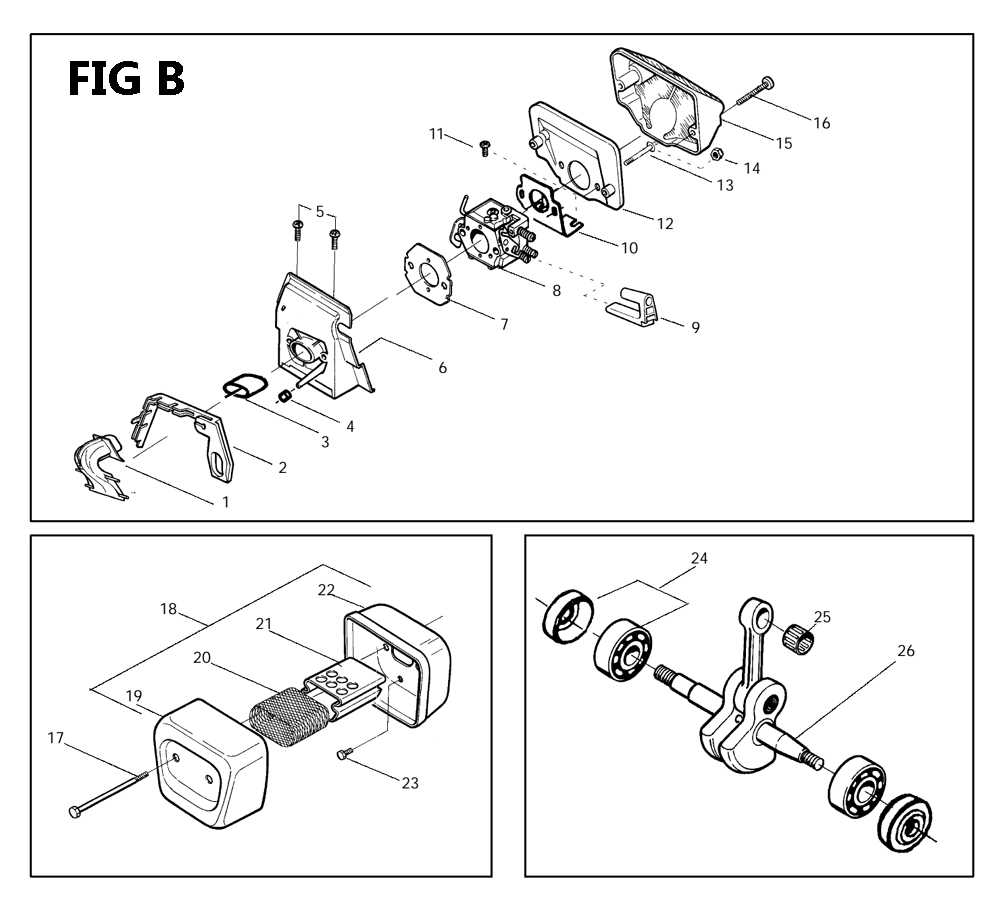

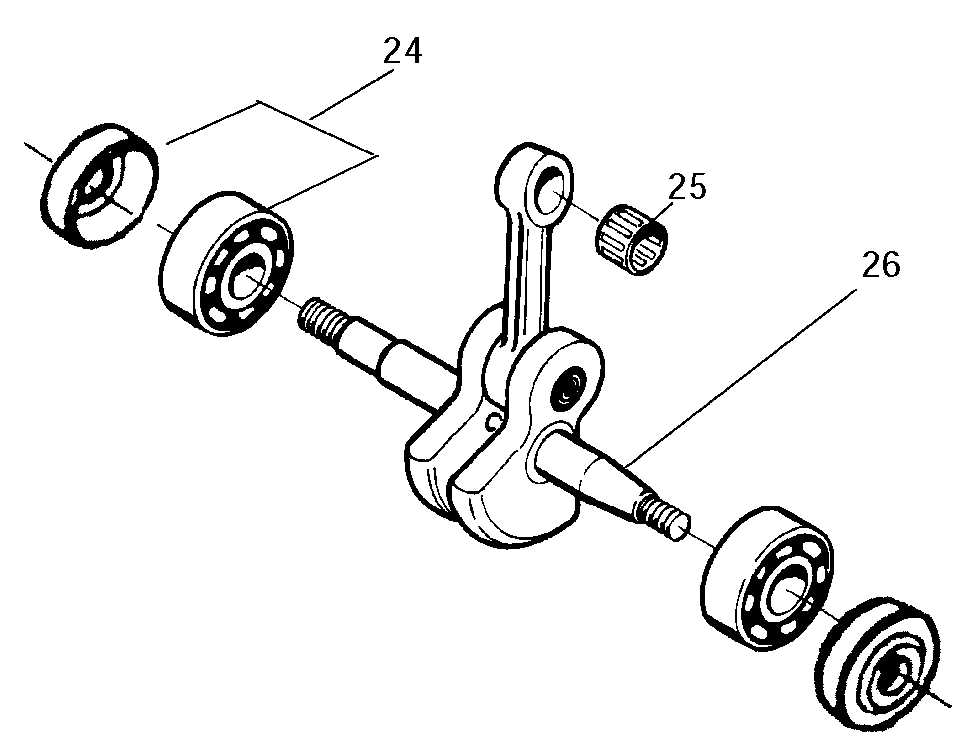

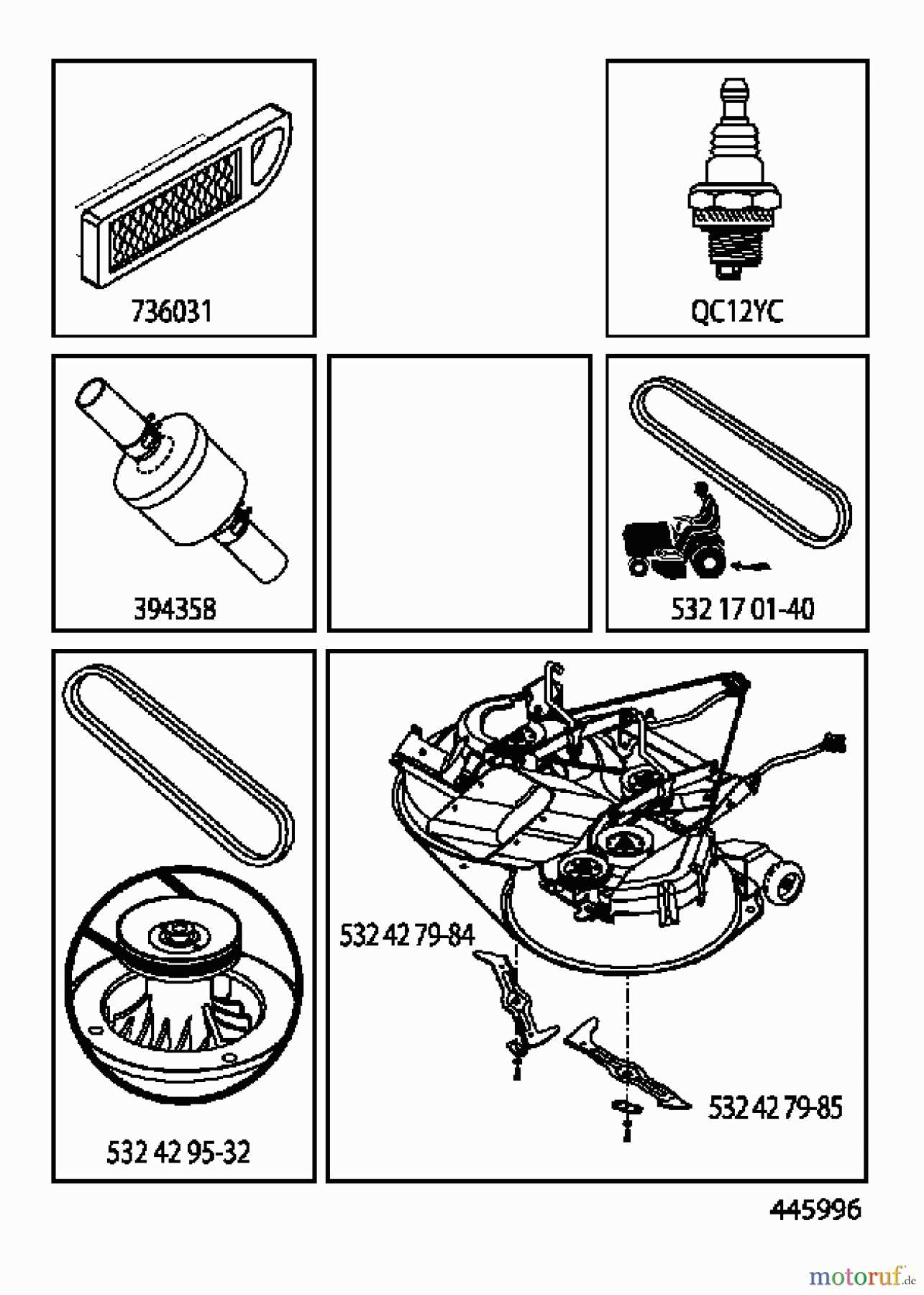

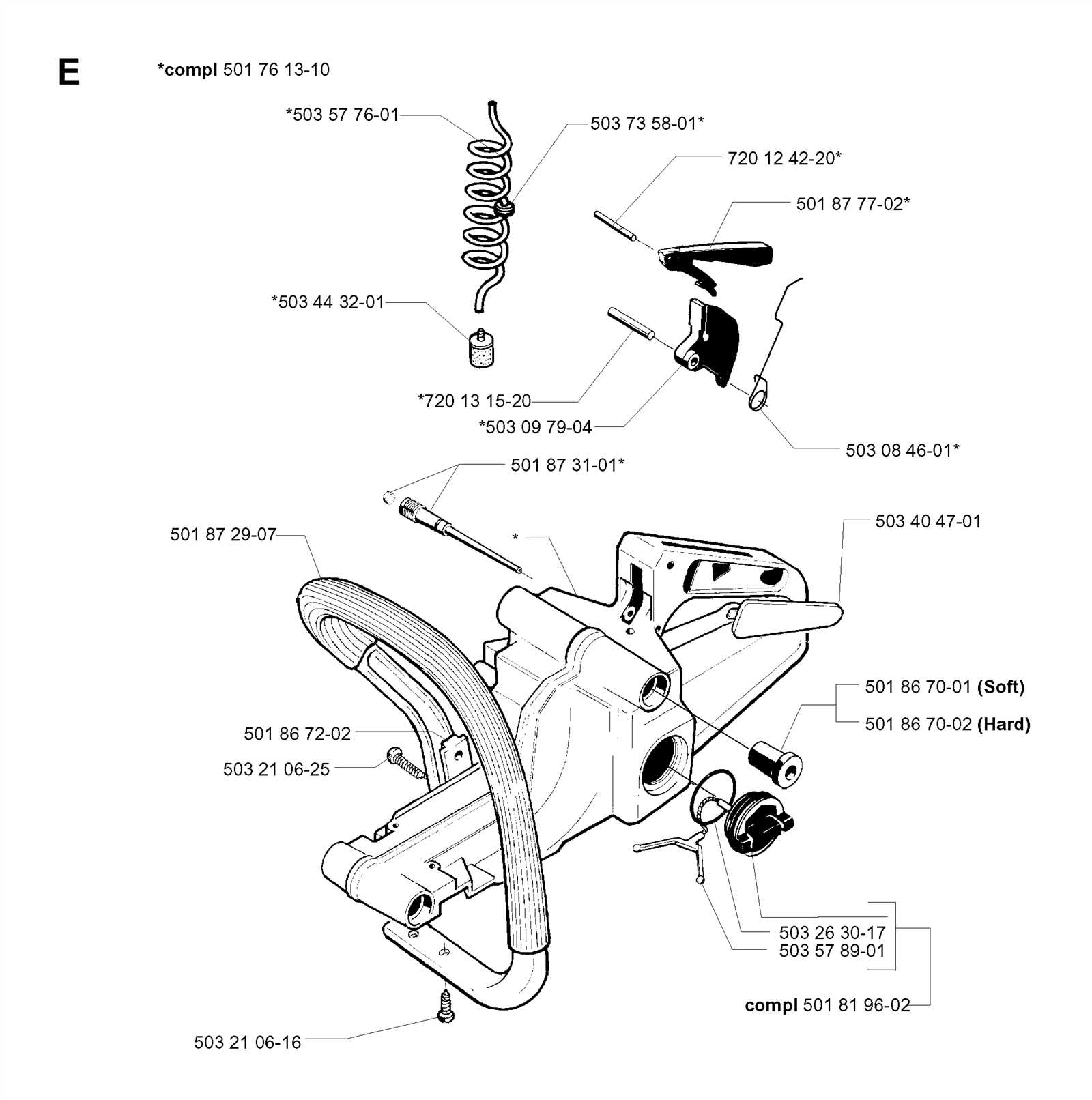

Moreover, visual representations of these configurations serve as invaluable references during the repair process. They provide clarity in identifying specific parts and understanding their roles within the overall assembly. Such resources not only simplify repairs but also enhance the user’s confidence when tackling maintenance tasks.

Understanding Husqvarna 141 Parts Diagram

Comprehending the layout of components in a specific model is essential for effective maintenance and repair. This knowledge not only facilitates troubleshooting but also enhances the efficiency of replacements. A clear visualization allows users to identify individual pieces and their interconnections, ensuring a smoother process during disassembly and reassembly.

Visual aids play a pivotal role in grasping the relationship between various elements. By studying a comprehensive representation, one can easily navigate through complex mechanisms, making it simpler to locate and understand each segment’s function. This ultimately leads to better care and longevity of the equipment.

Moreover, having access to an organized chart fosters confidence in handling repairs. Users can delve into specifics, knowing precisely where each part fits within the overall system. This strategic insight not only saves time but also minimizes the risk of errors during maintenance tasks.

Key Components of Husqvarna 141

Understanding the essential elements of a powerful outdoor tool is crucial for effective maintenance and optimal performance. Each component plays a significant role in ensuring the efficiency and longevity of the machinery. Familiarity with these parts allows users to troubleshoot issues and perform necessary repairs.

Engine: The heart of the device, providing the necessary power for cutting and trimming tasks. A well-maintained engine enhances performance and reduces operational strain.

Bar and Chain: These are vital for cutting through wood and other materials. Regular inspection and proper tensioning are essential for safety and effectiveness.

Fuel System: This includes the fuel tank, filter, and lines, which are critical for delivering power. Clean fuel components help prevent clogging and ensure smooth operation.

Air Filter: Essential for maintaining optimal airflow to the engine, a clean filter prevents debris from entering the system, which can enhance performance and prolong engine life.

Starter Mechanism: This component facilitates easy ignition of the machine. Proper functioning ensures quick starts and reduces wear on the engine.

How to Read Parts Diagrams

Understanding component illustrations is essential for efficient maintenance and repair tasks. These visual representations provide critical information about various elements of machinery, making it easier to identify and replace worn or damaged components. Mastering the ability to interpret these graphics can significantly enhance your repair experience and ensure your equipment functions optimally.

Key Elements to Look For

When examining these visual guides, focus on several key aspects. First, familiarize yourself with the numbering system used to reference each component. This system usually correlates with a list detailing specifications or part names, allowing for quick identification. Additionally, pay attention to the connections and layout of the components. Understanding how parts fit together is crucial for successful assembly and disassembly.

Common Symbols and Notations

These illustrations often include specific symbols and notations that provide further insights. Look for icons indicating orientation, fastening methods, and other important details. Familiarizing yourself with these symbols can save time and prevent confusion during repairs. By learning to read and interpret these guides effectively, you can ensure your machinery remains in top condition.

Common Issues with Husqvarna 141 Parts

When maintaining outdoor power tools, users often encounter several recurring challenges related to components and their performance. Understanding these frequent problems can help in effective troubleshooting and prolonging the lifespan of the equipment.

| Issue | Description | Possible Solutions |

|---|---|---|

| Fuel System Blockage | Clogs in the fuel delivery mechanism can hinder operation and lead to performance issues. | Regularly clean or replace filters; ensure fuel is fresh and free of contaminants. |

| Starting Difficulties | Problems initiating the engine can stem from worn ignition components or improper fuel mixture. | Inspect the spark plug and replace if necessary; check the fuel mixture ratio. |

| Chain Tension Problems | An inadequately adjusted chain can cause excessive wear or damage, affecting cutting efficiency. | Regularly check and adjust chain tension according to the manufacturer’s guidelines. |

| Overheating | Excessive heat generation may result from improper lubrication or blockages in airflow. | Ensure adequate oil levels and clear any obstructions in the cooling system. |

| Wear and Tear | Components can deteriorate over time, leading to reduced functionality and reliability. | Conduct routine inspections and replace worn components promptly to maintain performance. |

Where to Find Replacement Parts

When your outdoor equipment requires new components, locating reliable sources for replacements is essential. Various options are available, catering to different needs and preferences, ensuring you can restore your device to optimal performance.

Authorized Dealers are often the most reliable option. These retailers specialize in genuine components, guaranteeing compatibility and quality. Visiting a local dealer can provide personalized assistance and expert advice, enhancing your repair experience.

Online Marketplaces have become increasingly popular for sourcing replacements. Websites like e-commerce platforms offer a vast selection, often at competitive prices. However, it’s crucial to verify the seller’s credibility and read customer reviews to ensure the authenticity of the items purchased.

Specialty Shops focus on specific brands and models, making them a valuable resource for hard-to-find components. These shops typically have knowledgeable staff who can help identify the right items and may offer additional services, such as installation or maintenance tips.

Salvage Yards can be a treasure trove for those seeking economical options. While the components may not be brand new, many parts are still in excellent condition and can be sourced at a fraction of the cost. This route also promotes sustainability by reducing waste.

Regardless of where you choose to look, conducting thorough research and ensuring the quality of the components will lead to a successful repair and prolonged life for your equipment.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures optimal performance and longevity for your machinery. These components are specifically designed and manufactured to meet the exact specifications of your equipment, providing a seamless fit and reliable operation. By choosing these authentic replacements, you can maintain the integrity and efficiency of your tools.

Quality Assurance

One of the primary advantages of using original components is the assurance of quality. OEM products undergo rigorous testing and adhere to strict manufacturing standards, which guarantees:

- Durability under various operating conditions

- Consistent performance over time

- Safety compliance with industry regulations

Cost-Effectiveness

While initial costs may seem higher, investing in original components can lead to long-term savings. Consider the following:

- Reduced risk of premature failure

- Minimized maintenance and repair expenses

- Extended lifespan of your equipment

In summary, opting for original components not only enhances the functionality of your machinery but also provides peace of mind and financial benefits over time.

Tools Needed for Assembly

When undertaking the assembly of a machinery unit, having the right tools is essential for ensuring a smooth and efficient process. A well-equipped workspace can significantly reduce assembly time and enhance the overall quality of the final product.

First and foremost, a set of screwdrivers, including both flathead and Phillips types, is crucial for tightening or loosening screws. Pliers, especially needle-nose varieties, are also beneficial for gripping and manipulating small components. Additionally, a torque wrench is recommended to apply the correct amount of force when securing bolts, preventing damage from over-tightening.

A reliable socket set can streamline the process, allowing for quick adjustments and repairs. For those intricate parts that require precision, a set of hex keys is invaluable. Finally, having a good-quality workbench with ample space will provide a stable platform for assembling components safely and efficiently.

Maintenance Tips for Husqvarna 141

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular attention to maintenance tasks can prevent common issues and enhance efficiency, making your work experience more enjoyable.

Regular Inspections

- Check for wear and tear on components.

- Inspect the cutting mechanism for sharpness.

- Look for any signs of leaks or damage.

Cleaning Procedures

- Remove debris after each use to avoid buildup.

- Clean air filters regularly to ensure airflow.

- Wipe down surfaces to prevent rust and corrosion.

Comparing Models: Husqvarna 141 vs Others

In the world of outdoor power equipment, various models cater to different needs and preferences. This section explores the similarities and differences between one specific model and its competitors, highlighting key features, performance metrics, and user experiences. Understanding these nuances can help consumers make informed decisions when choosing the right tool for their tasks.

When examining specifications, the engine power and weight play crucial roles in determining usability and efficiency. Some models may offer superior power output, while others are designed for lightweight operation, enhancing maneuverability. Comparing these attributes allows users to find a balance between strength and ease of handling, depending on their specific applications.

Another important aspect to consider is the range of available accessories and compatibility with various attachments. Some models excel in versatility, providing a wider array of options for different tasks, while others may focus on specialized features that cater to particular needs. This factor can significantly influence a user’s choice, especially for those who require multifunctionality.

Durability and maintenance requirements also differ across the board. While some units are built to withstand harsh conditions with minimal upkeep, others might necessitate regular servicing to maintain optimal performance. This aspect can impact long-term satisfaction and operational costs, making it a vital consideration for potential buyers.

Finally, user feedback and reviews serve as valuable resources when evaluating equipment. Insights from other users can reveal practical advantages and drawbacks that may not be immediately apparent through specifications alone. By examining firsthand accounts, prospective buyers can gain a clearer picture of how different models stack up in real-world scenarios.

Frequently Asked Questions about Parts

This section aims to address common inquiries related to components for outdoor machinery. Understanding these queries can help users make informed decisions and enhance their maintenance experience.

What should I consider when ordering components? It’s essential to verify compatibility with your specific model to ensure proper functionality.

How can I identify the correct component for my equipment? Refer to the manufacturer’s manual or a reliable online resource to locate the appropriate identifiers.

Are there any tips for maintaining my machinery? Regular inspections and timely replacements can prolong the life of your equipment significantly.

Where can I find quality replacements? Authorized dealers and reputable online retailers are excellent sources for reliable alternatives.

Expert Recommendations for Users

When maintaining outdoor power equipment, having a clear understanding of its components is crucial for optimal performance and longevity. This section provides insightful tips to help users navigate the complexities of their machinery, ensuring they can tackle repairs and enhancements with confidence.

Regular Maintenance: Schedule routine check-ups to inspect essential elements such as filters, spark plugs, and fuel systems. This proactive approach prevents unexpected breakdowns and extends the lifespan of your equipment.

Utilize Quality Components: Always opt for high-grade replacements. Using inferior parts may lead to malfunctions and can compromise the overall efficiency of the machine.

Refer to Manuals: Keep the user manual handy. It is an invaluable resource that provides detailed information about assembly, maintenance, and troubleshooting, tailored specifically for your equipment.

Seek Expert Advice: Don’t hesitate to consult professionals when faced with complex issues. Their expertise can save time and ensure proper handling of repairs that may be beyond the average user’s skill set.

Document Repairs: Maintain a log of repairs and replacements. This practice helps track the history of your machine and can be beneficial for future maintenance decisions.

Stay Informed: Join online forums or local groups related to your equipment. Sharing experiences and knowledge with other users can provide new insights and solutions to common problems.