Comprehensive Guide to Husqvarna 288xp Parts Diagram

Maintaining optimal performance in any power tool requires a thorough understanding of its individual elements. A clear visual representation of these components can significantly enhance the efficiency of repairs and upgrades. This section delves into the intricacies of a particular model, providing insights into its assembly and the function of each segment.

Recognizing the Layout of the tool is essential for both novice and seasoned users. By examining the arrangement of parts, one can identify potential issues that may arise during operation. This knowledge empowers owners to take proactive measures in maintenance, ensuring longevity and reliability.

Exploring the various sections involved in the machinery reveals the importance of each component in the overall functionality. Understanding how these pieces interconnect allows for better troubleshooting and more informed decisions when seeking replacements or upgrades. This comprehensive overview serves as a valuable resource for anyone looking to enhance their expertise in chainsaw maintenance.

Understanding the Husqvarna 288XP Model

The subject at hand revolves around a powerful and reliable tool designed for cutting tasks in various environments. This model is revered among professionals and enthusiasts alike for its robust performance and efficiency. Delving into its components and mechanics can significantly enhance the user experience and maintenance practices.

This tool boasts a unique design that integrates advanced engineering techniques, ensuring optimal functionality. With an impressive engine capacity, it delivers substantial power, making it ideal for heavy-duty applications. The user-friendly interface further facilitates ease of operation, allowing even novice users to handle it with confidence.

Understanding the inner workings is crucial for anyone looking to maintain or troubleshoot the equipment. Familiarity with its structure not only aids in identifying potential issues but also empowers users to carry out repairs and replacements with precision. This knowledge ultimately contributes to extending the lifespan of the tool and enhancing overall performance.

Key Components of the Chainsaw

Understanding the essential elements of a cutting tool can significantly enhance its efficiency and performance. Each part plays a crucial role in the overall functionality and effectiveness of the machine.

- Engine: The powerhouse that drives the saw, converting fuel into mechanical energy.

- Guide Bar: The long metal bar that directs the chain during operation, ensuring stability and precision.

- Chain: A loop of interconnected links that cuts through wood as it rotates around the guide bar.

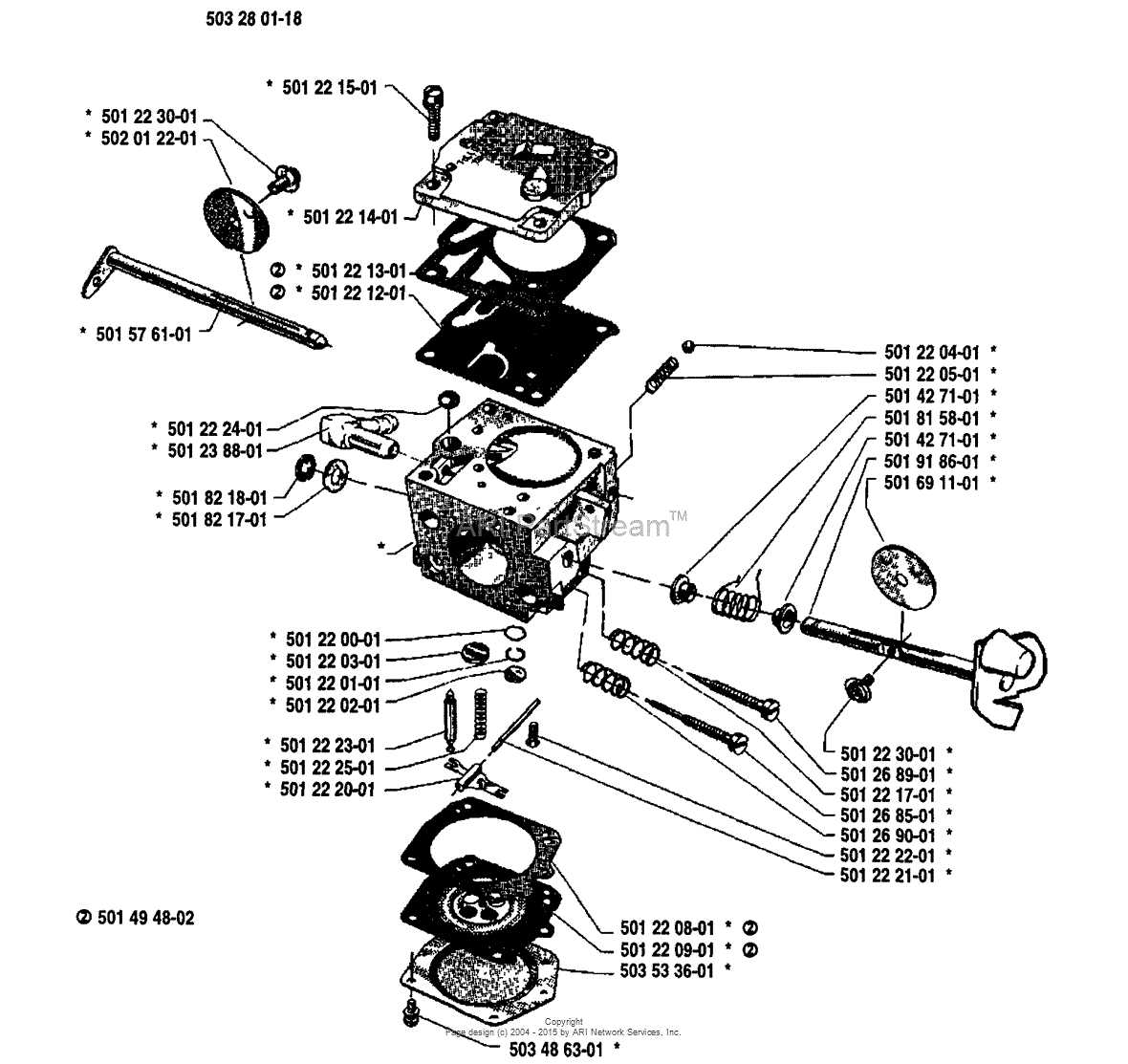

- Carburetor: Responsible for mixing air and fuel, ensuring optimal combustion for efficient performance.

- Clutch: Engages and disengages the chain from the engine, allowing for safe operation.

Each component is designed to work in harmony, contributing to the ultimate effectiveness of the tool.

Importance of a Parts Diagram

Understanding the components of a machine is crucial for effective maintenance and repair. A visual representation of each element not only aids in identifying individual pieces but also enhances the efficiency of assembly and disassembly processes. When issues arise, having a clear layout can save time and reduce frustration.

Furthermore, such illustrations play a vital role in ensuring that the correct replacements are used, ultimately prolonging the lifespan of the equipment. They facilitate better communication among technicians and provide a reliable reference during troubleshooting. Investing time in studying these visuals can lead to a more streamlined approach to machinery care.

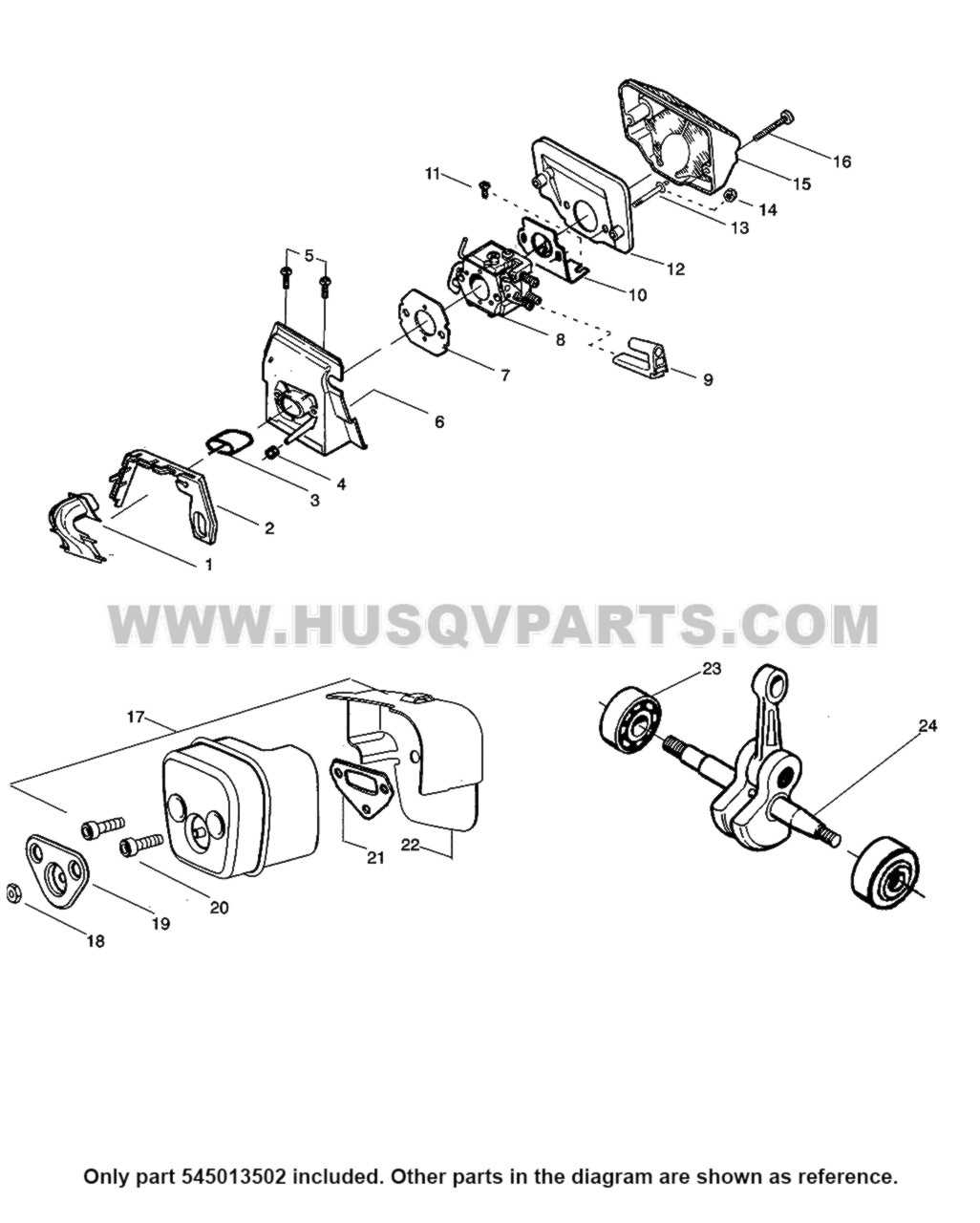

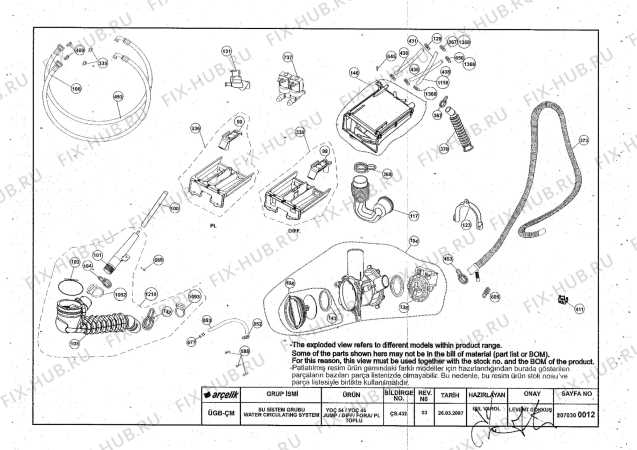

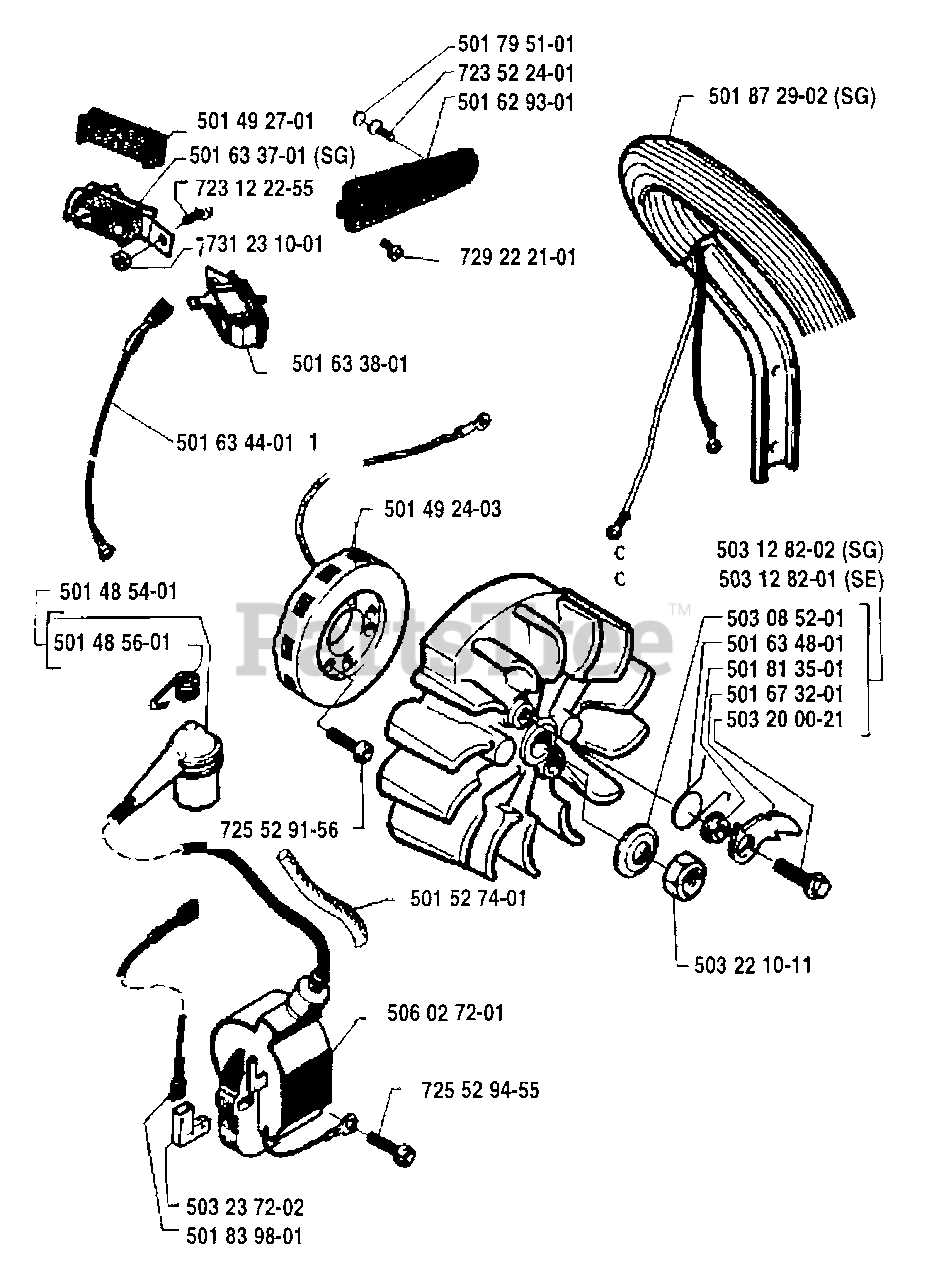

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to maintain or repair machinery. These illustrations provide a comprehensive overview of components, helping users identify each piece and its function within the assembly. By mastering the art of interpretation, you can effectively plan maintenance and troubleshoot issues.

Identifying Components

Start by familiarizing yourself with the various sections of the illustration. Each part is usually labeled with numbers or letters that correspond to a list. Take note of these identifiers, as they are crucial for sourcing replacements. Pay attention to the layout, as it often indicates how the components fit together.

Understanding Relationships

Next, observe how the parts interact with one another. Look for arrows or lines that show connections and movements. This will help you grasp the assembly’s functionality, making it easier to spot potential issues. Analyzing these relationships provides a deeper understanding of how to approach repairs or replacements effectively.

Common Issues with Husqvarna 288XP

This section addresses frequent problems encountered by users of a specific high-performance chainsaw model. Understanding these challenges can help in troubleshooting and maintaining optimal functionality.

- Starting Difficulties:

Many users report issues with the initial startup. Common causes include:

- Clogged air filters

- Improper fuel mixtures

- Faulty spark plugs

- Chain Tension Problems:

Maintaining the right chain tension is crucial. Issues may arise from:

- Worn sprockets

- Incorrect adjustment techniques

- Improper chain type

- Vibration and Noise:

Excessive vibration or noise can indicate underlying mechanical problems, such as:

- Loose components

- Unbalanced chains

- Worn bearings

- Fuel Leaks:

Leaks can lead to performance issues and pose safety hazards. Potential sources include:

- Damaged fuel lines

- Faulty gaskets

- Improperly sealed fuel tanks

Addressing these common concerns with proper maintenance and timely repairs can enhance the longevity and efficiency of the equipment.

Replacement Parts Availability

Access to essential components is crucial for maintaining the performance and longevity of your equipment. Finding reliable sources for these items ensures that users can effectively address any wear or damage that may occur during operation. Various options are available for obtaining replacements, from authorized dealers to online retailers, making it easier to keep your machinery in optimal condition.

| Source Type | Description | Advantages |

|---|---|---|

| Authorized Dealers | Official vendors who offer genuine components. | Guaranteed quality and compatibility. |

| Online Retailers | Web-based platforms that stock a wide variety of items. | Convenience and often competitive pricing. |

| Local Repair Shops | Independent businesses specializing in repairs. | Expert advice and support available. |

| Aftermarket Suppliers | Manufacturers providing alternative components. | Potentially lower costs with varied options. |

Evaluating these sources can help you choose the best option for your needs, ensuring your tools remain functional and effective throughout their lifespan.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. By following a few simple strategies, you can prevent premature wear and maintain efficiency over time.

Regular Cleaning

Routine cleaning removes debris and contaminants that can affect functionality. Pay special attention to air filters and cooling systems, as these areas can accumulate dust and hinder performance.

Timely Inspections

Conduct regular inspections to identify any signs of wear or damage. Addressing minor issues promptly can prevent more significant problems down the line, ensuring your machinery operates at peak condition.

Using OEM vs. Aftermarket Parts

When it comes to maintaining and repairing outdoor equipment, the choice between original components and alternative replacements can significantly impact performance and longevity. Understanding the differences between these options is crucial for ensuring that machinery operates at its best.

Advantages of Original Components

- Quality Assurance: Manufactured by the original brand, these components are designed to meet specific standards, ensuring reliability and durability.

- Perfect Fit: Tailored to fit the equipment precisely, reducing the risk of compatibility issues.

- Warranty Coverage: Often covered by manufacturer warranties, providing peace of mind for users.

Benefits of Alternative Replacements

- Cost-Effectiveness: Typically priced lower than original parts, making them an attractive option for budget-conscious consumers.

- Availability: Frequently more accessible through various retailers, allowing for quicker repairs.

- Variety: A wider range of options may be available, offering flexibility in choosing components that suit individual needs.

Ultimately, the decision should be based on factors such as the specific equipment in use, budget constraints, and personal preferences regarding quality and reliability. Each option has its merits, and careful consideration can lead to more informed purchasing choices.

Identifying Genuine Husqvarna Parts

Ensuring the authenticity of components is crucial for optimal performance and longevity of outdoor equipment. Recognizing original items can enhance functionality and prevent potential issues arising from counterfeit alternatives.

Visual Inspection

Examine the packaging and labeling closely. Authentic products typically feature high-quality prints and clear branding. Look for serial numbers and manufacturer details that are consistent with official specifications.

Source Verification

Purchase from authorized dealers or reputable online retailers. Research the seller’s credibility and read reviews to confirm their trustworthiness. Genuine components often come with warranties, adding an extra layer of assurance.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your outdoor power equipment, ensuring optimal performance and longevity. Each step is designed to be straightforward, allowing both novices and experienced users to effectively tackle common issues.

Step 1: Begin by gathering all necessary tools and replacement components. A well-prepared workspace enhances efficiency and safety.

Step 2: Carefully consult the user manual to understand the assembly and disassembly processes specific to your machine. Familiarizing yourself with its structure is crucial for effective repair.

Step 3: Proceed to detach the damaged parts, taking care to note their arrangement. Utilizing a labeled system for organization can significantly simplify reassembly.

Step 4: Inspect all components for wear and damage. Replace any faulty elements to ensure that your equipment operates at its best.

Step 5: Reassemble the unit, following the documented layout. Ensure that all fasteners are secure and that no parts are left out.

Step 6: Finally, conduct a thorough test to confirm that everything functions correctly. Regular maintenance checks will help prolong the life of your machinery.

Tools Required for Repairs

Effective maintenance and restoration of outdoor equipment necessitate a specific set of instruments. Having the right tools not only simplifies the process but also ensures precision and safety during repairs. Whether you’re tackling minor adjustments or extensive overhauls, a well-equipped toolkit is essential.

Basic Hand Tools: Essential hand tools such as screwdrivers, wrenches, and pliers are fundamental for disassembly and assembly. These tools enable you to access various components easily.

Specialty Tools: Certain repairs may require unique instruments, such as torque wrenches or chain saw sharpening kits. Investing in these can significantly enhance your ability to perform detailed tasks.

Safety Gear: Always prioritize safety by using protective equipment like gloves, goggles, and ear protection. These items help prevent injuries while working on machinery.

Cleaning Supplies: Keeping parts clean is crucial for optimal performance. Use brushes, cloths, and solvents to maintain components in good condition.

In conclusion, preparing a comprehensive set of tools and safety gear is the ultimate step towards successful repairs and long-term maintenance.

Online Resources for Parts Lookup

Finding the right components for machinery can be a challenging task. Fortunately, various online platforms simplify the search process by providing detailed catalogs and specifications. These resources cater to both seasoned professionals and casual users, ensuring everyone has access to necessary information.

Key Websites to Explore

- Manufacturer’s Official Site

- Authorized Dealers

- Specialized Forums and Communities

Tips for Effective Searching

- Utilize specific model numbers for accuracy.

- Check for user reviews to gauge reliability.

- Compare prices across different platforms.

Customer Reviews and Feedback

This section explores the opinions and experiences of users regarding a popular outdoor power tool. Their insights help potential buyers make informed decisions and enhance their understanding of the product’s performance.

Many users highlight the following aspects:

- Durability: Several reviews commend the longevity of the equipment even under heavy use.

- Ease of Use: Many appreciate the intuitive design, making it accessible for both beginners and experienced users.

- Performance: Customers often mention the efficiency and power, which exceed their expectations.

However, some feedback includes:

- Maintenance Challenges: A few users note that certain components require regular upkeep to ensure optimal functionality.

- Weight Considerations: Some find the tool a bit heavy, impacting prolonged usage.

Overall, the feedback indicates a generally positive reception, with recommendations for improvements in specific areas.