Exploring the Husqvarna 3120XP Parts Diagram for Ultimate Maintenance

The intricate design of power equipment is essential for optimal functionality and longevity. A thorough examination of these machines reveals how each element contributes to their overall performance. By breaking down these structures, users can gain insights into maintenance and upgrades, ultimately enhancing their experience.

In-depth analysis of mechanical configurations can be immensely beneficial for both amateur and professional users. Recognizing how various parts interconnect allows for better troubleshooting and informed decisions regarding repairs or enhancements. This knowledge fosters a deeper appreciation for the craftsmanship involved in high-quality machinery.

Whether you are a seasoned technician or a curious hobbyist, familiarizing yourself with the layout of components can empower you to tackle challenges with confidence. This exploration can serve as the ultimate guide to ensuring that your tools remain efficient and reliable for years to come.

Understanding the Husqvarna 3120XP

This section delves into the key features and components of a powerful tool designed for demanding tasks. With its robust construction and advanced engineering, it stands out in the realm of heavy-duty equipment, making it a preferred choice among professionals and enthusiasts alike.

Key Features

One of the most notable characteristics of this machine is its exceptional performance capabilities. It is engineered to handle large-scale cutting jobs with ease, showcasing a balance of power and efficiency. The thoughtful design incorporates high-quality materials, ensuring durability and longevity even under strenuous conditions.

Component Breakdown

Understanding the various elements that make up this tool is essential for optimal usage and maintenance. Each segment, from the engine to the cutting mechanisms, plays a critical role in its overall functionality. Regular inspection and familiarity with each component will help users maximize performance and extend the lifespan of their equipment.

Overview of Chainsaw Specifications

Understanding the technical details of a cutting tool is essential for both novice and experienced users. The specifications encompass various aspects that influence performance, efficiency, and usability. From engine power to weight and bar length, these elements are crucial in determining the suitability of a model for specific tasks.

Power Output: The engine’s power rating, typically measured in cubic centimeters (cc), plays a significant role in the tool’s cutting capacity. A higher displacement generally means greater torque and the ability to handle tougher materials.

Weight: The overall weight of the device affects maneuverability and user fatigue. Lightweight models are often preferred for extended use, while heavier versions may provide stability for demanding operations.

Bar Length: This specification indicates the length of the cutting chain, impacting the diameter of the wood that can be effectively cut. Longer bars allow for more extensive cuts, whereas shorter bars enhance precision and control.

Chain Speed: Measured in feet per second, the speed at which the chain moves is critical for efficiency. Faster chain speeds enable quicker cutting but may require more skill to maintain control.

Fuel Efficiency: In modern machines, fuel consumption rates are increasingly important. Efficient models reduce operational costs and environmental impact, making them a wise choice for regular use.

In summary, a comprehensive understanding of these specifications helps users select the right model for their needs, ensuring optimal performance and satisfaction.

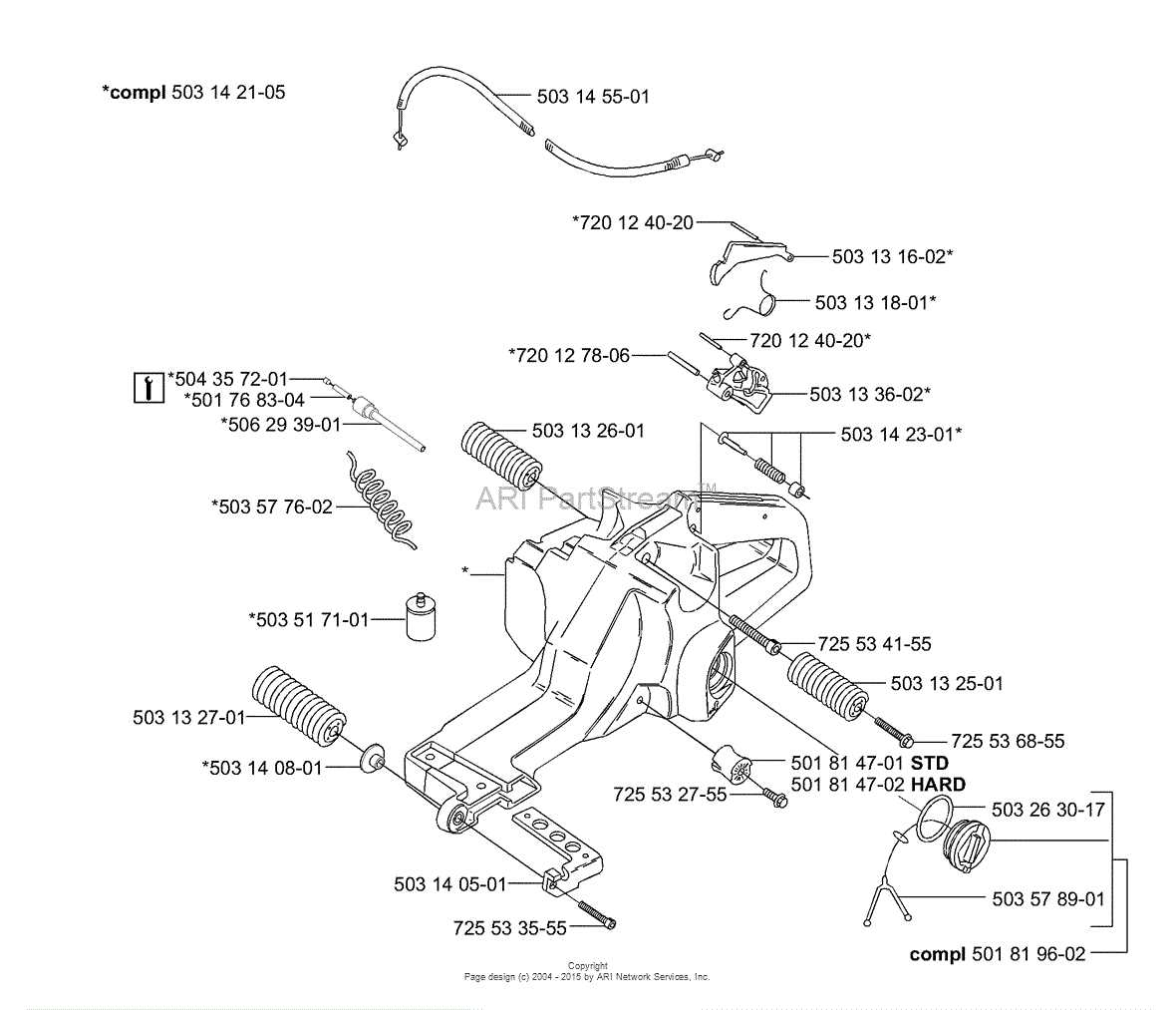

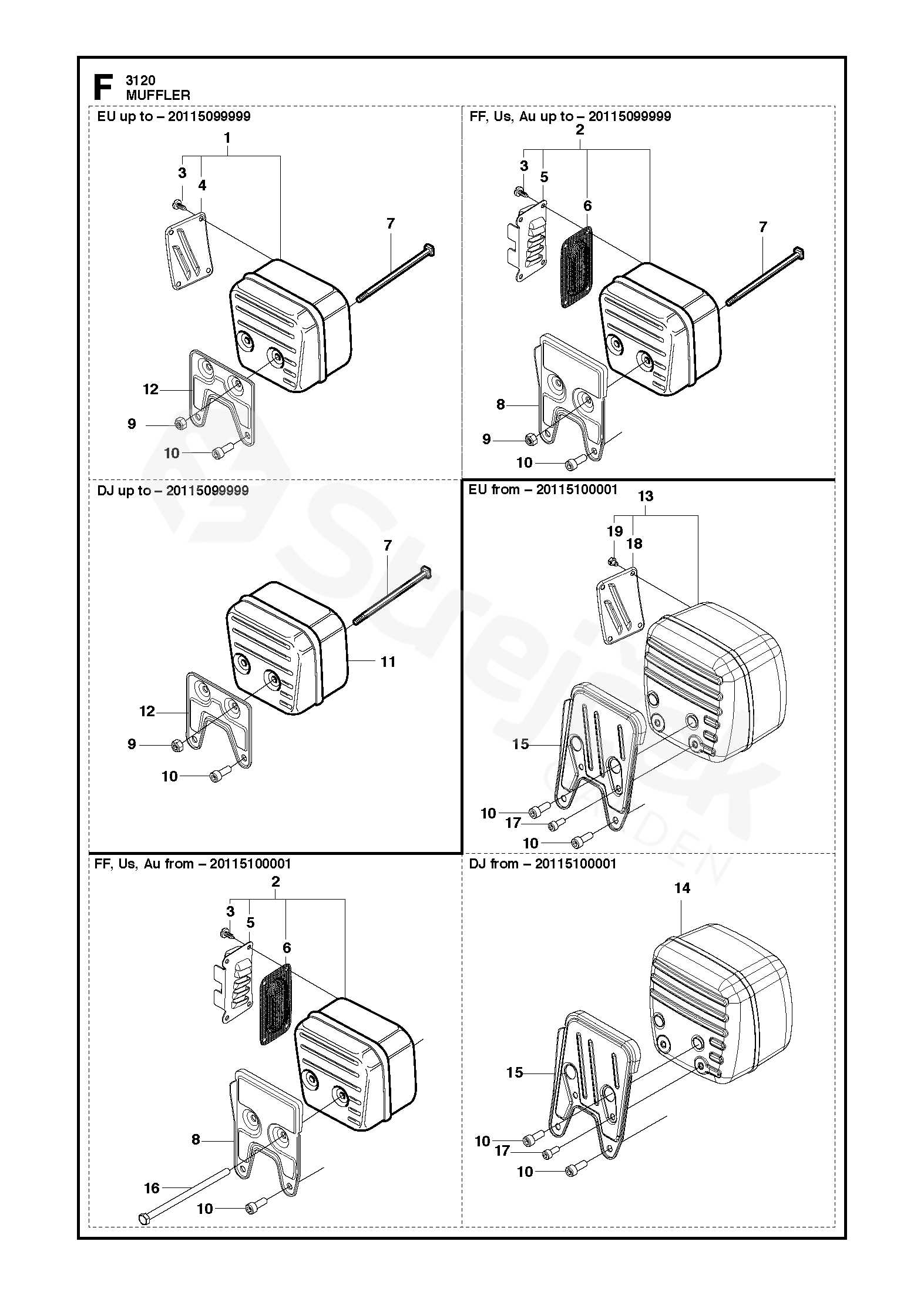

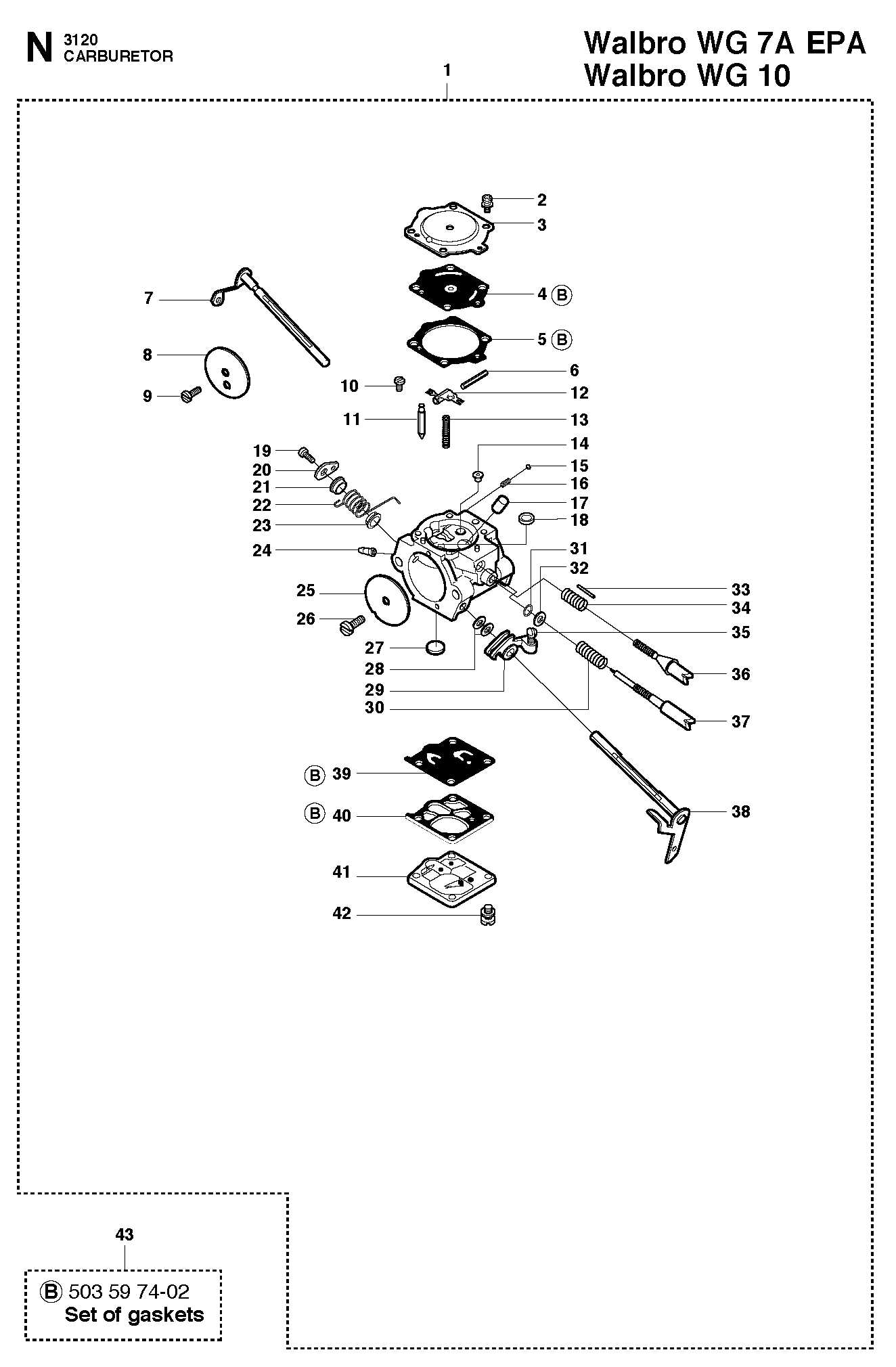

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of complex machinery. These illustrations not only facilitate efficient identification of individual elements but also enhance comprehension of how various pieces interact within a system. This understanding is essential for effective maintenance, repair, and assembly, ensuring that users can navigate their equipment with confidence.

Moreover, such schematics serve as invaluable references when troubleshooting issues. By pinpointing specific sections, users can quickly identify potential problems, streamline repairs, and reduce downtime. Clear visual guides also aid in ordering the correct replacements, minimizing the risk of errors that could lead to further complications.

Additionally, these resources promote a greater appreciation of the engineering behind the machinery. Users become more familiar with the design and operational principles, which can inspire confidence in both their skills and the equipment they rely on. Overall, visual representations are not merely tools; they are essential assets in the effective management of machinery.

Key Components of Husqvarna 3120XP

This section explores the essential elements of a powerful cutting tool, highlighting the critical components that contribute to its performance and efficiency. Understanding these features is vital for optimal maintenance and operation.

| Component | Description |

|---|---|

| Engine | High-performance power unit designed for maximum output and durability. |

| Bar | Robust guide designed to hold the cutting chain, available in various lengths for versatility. |

| Chain | Sharp cutting tool that moves around the bar, engineered for efficiency and precision. |

| Handle | Ergonomic grip ensuring comfort and control during use, enhancing user experience. |

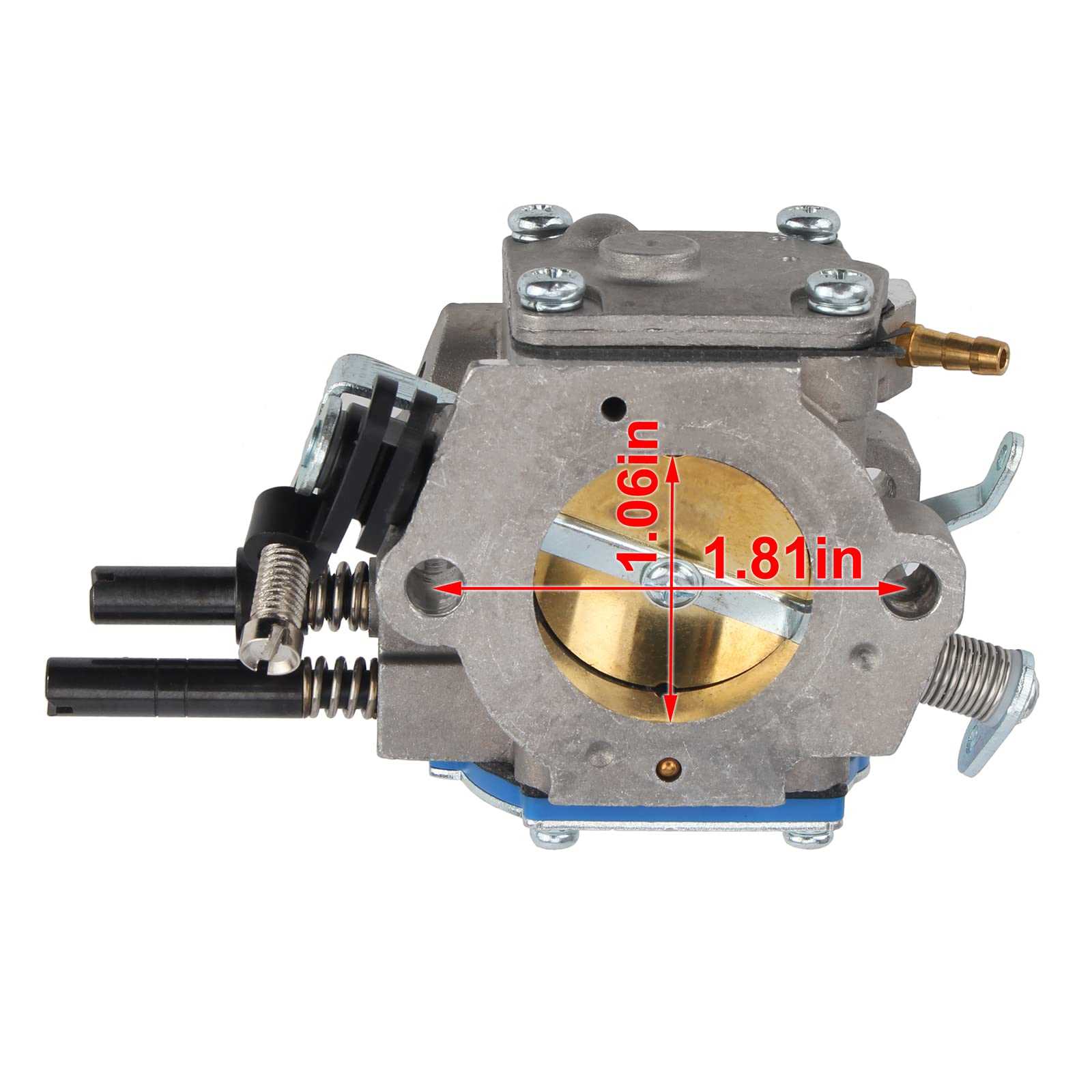

| Fuel System | Efficient delivery system for a mix of fuel and oil, ensuring optimal engine performance. |

How to Read a Parts Diagram

Understanding an illustration of components is essential for efficient assembly, maintenance, and repair of machinery. This visual representation helps users identify each element, ensuring that they can locate and replace parts with accuracy. Familiarity with this tool can significantly enhance the repair process, saving time and effort.

Key Elements to Identify

- Labels: Each component is typically marked with a unique identifier. Pay attention to these labels as they correspond to specific items in the parts list.

- Connections: Lines and arrows indicate how various parts are interconnected. Understanding these connections is crucial for disassembly and reassembly.

- Symbols: Various icons may represent different types of components. Familiarize yourself with common symbols to interpret the illustration correctly.

Steps for Effective Reading

- Start by examining the entire illustration to get an overview of the arrangement of components.

- Identify and note the labeled parts, matching them with the corresponding list provided.

- Analyze the connections and symbols to understand how each component interacts with others.

- Refer back to the list for specifications and ordering information as needed.

Common Replacement Parts Needed

When maintaining high-performance machinery, certain components are prone to wear and tear and may require regular replacement. Understanding which elements commonly need to be changed can enhance the lifespan of the equipment and ensure optimal functionality. Below are some frequently needed items that can help keep your tool running smoothly.

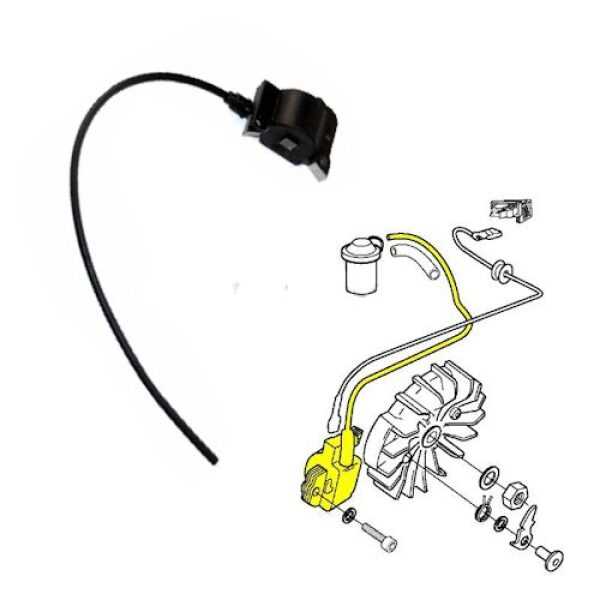

Engine Components

The heart of any powerful machine is its engine. Key elements such as spark plugs, air filters, and fuel filters often need replacement to maintain efficiency and performance. Regularly checking these components can prevent engine failures and ensure reliable operation.

Cutting Equipment

For tools designed for cutting, blades and chains are essential parts that endure significant stress. Dull or damaged cutting edges can hinder performance and may require frequent replacement. Staying ahead of wear on these items will lead to better results and a safer working environment.

Identifying Original vs. Aftermarket Parts

When it comes to maintaining equipment, distinguishing between genuine components and alternatives can significantly impact performance and longevity. Original items are typically designed for specific models, ensuring compatibility and reliability, while aftermarket options may offer cost savings but can vary in quality and fit. Understanding these differences is crucial for making informed purchasing decisions.

One key factor in recognizing authentic parts is their branding and packaging. Genuine components often come with specific logos and high-quality packaging, while aftermarket items may lack these features. Additionally, examining the material and craftsmanship can reveal inconsistencies often present in non-original alternatives.

Warranties and guarantees also serve as indicators; original parts usually come with manufacturer-backed warranties, whereas aftermarket options may not provide the same level of assurance. Always consider the source of purchase as reputable dealers are more likely to offer authentic components, ensuring peace of mind and optimal functionality.

Tools Required for Maintenance

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Utilizing the right instruments not only simplifies the maintenance process but also enhances safety and efficiency. This section outlines the necessary tools that facilitate effective servicing and repairs.

Essential Instruments

To maintain your machinery, a variety of tools are needed. Below is a list of the most important items that should be part of your maintenance toolkit:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Used for removing and fastening screws. |

| Fuel Canister | For safe storage and transportation of fuel. |

| Oil Can | Essential for lubricating moving parts. |

| Chain Tool | For adjusting and maintaining the cutting chain. |

| Safety Gear | Includes gloves, goggles, and ear protection to ensure safety during maintenance. |

Additional Recommendations

Along with the essential tools listed above, having a cleaning kit and a measuring tool can further enhance your maintenance routine. Regular cleaning prevents buildup, while measurements help in precise adjustments, ensuring your machinery runs smoothly.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment effectively. By following a systematic process, you can ensure that each component is addressed properly, enhancing the overall performance and longevity of your machine.

Start by gathering all necessary tools and replacement components. Having everything within reach will streamline the repair process and minimize interruptions.

Next, carefully disassemble the unit, noting the arrangement of parts. A methodical approach will help you avoid confusion during reassembly.

Inspect each piece for wear or damage. This is crucial for identifying what needs replacing and ensuring optimal functionality.

Once you’ve assessed the condition, replace any faulty components with new ones. Follow the manufacturer’s specifications for each part to ensure compatibility and reliability.

After replacing the necessary items, reassemble the equipment step by step, referring to your notes to ensure accuracy. Double-check that everything is secure before moving on.

Finally, conduct a thorough test of the unit to confirm that all repairs have been successful and the machine is operating smoothly.

Where to Find Replacement Parts

Finding the right components for your equipment can greatly enhance its performance and longevity. Knowing where to search for these items is essential for maintenance and repairs.

Online Retailers

- Specialty websites dedicated to outdoor machinery.

- Major e-commerce platforms offering a wide range of components.

- Manufacturer’s official website for authentic items.

Local Shops

- Authorized dealers that provide genuine replacements.

- Local hardware stores with a selection of compatible components.

- Salvage yards that may have used options at lower prices.

Benefits of Regular Maintenance

Consistent upkeep of equipment plays a crucial role in ensuring optimal performance and longevity. By dedicating time to regular inspections and servicing, users can prevent unexpected breakdowns and costly repairs. This proactive approach not only enhances functionality but also fosters safety during operation.

Enhanced Performance

Routine maintenance significantly boosts the efficiency of machinery. Clean components and properly lubricated parts work seamlessly together, resulting in improved output and reduced energy consumption. This not only saves time but also lowers operational costs over time.

Increased Longevity

Taking care of equipment through regular check-ups prolongs its lifespan. By addressing minor issues before they escalate, users can enjoy years of reliable service, maximizing their investment. Regular care ultimately leads to a more dependable and effective tool, ready for any task.

Customer Reviews and Experiences

Gathering insights from users can provide valuable perspectives on the reliability and performance of various tools. This section highlights feedback from individuals who have utilized these machines, showcasing their personal experiences and observations.

Many users appreciate the efficiency and durability of their equipment. Common themes in reviews include:

- Performance: Users frequently comment on the robust power and speed, noting that it meets the demands of heavy-duty tasks.

- Ease of Use: Several reviews highlight the intuitive design, making operation straightforward even for those new to such machinery.

- Maintenance: Feedback often emphasizes the simplicity of upkeep, with many finding that routine servicing is manageable and less time-consuming than expected.

- Support: Customers have noted the availability of resources and assistance, helping them navigate any issues they encounter.

However, some reviews do express concerns. Commonly mentioned points include:

- Weight: A few users find the equipment to be on the heavier side, which can impact maneuverability during prolonged use.

- Cost: Some feedback points to the investment required, with users weighing the initial expense against long-term value.

- Noise Level: Certain individuals have noted that the sound produced during operation can be quite loud, suggesting the need for hearing protection.

Overall, the experiences shared by customers reflect a mix of satisfaction and areas for improvement, providing prospective buyers with a well-rounded view of what to expect.