Husqvarna 351 Parts Diagram Guide

Maintaining outdoor machinery can be a daunting task, especially when it comes to identifying the various components that contribute to its performance. A clear visual representation of each element can greatly enhance your understanding and facilitate effective repairs. By familiarizing yourself with these essential components, you can ensure your equipment operates smoothly and efficiently.

In this section, we delve into a comprehensive overview of the key elements involved in your machinery’s design. Understanding how each piece interacts not only aids in troubleshooting but also empowers you to make informed decisions about maintenance and upgrades. Visual aids serve as invaluable tools for both novices and seasoned users alike.

Whether you’re looking to replace a worn-out piece or simply wish to deepen your knowledge, a well-structured overview of the various elements can guide you through the intricacies of your equipment. With the right information at hand, you’ll be better equipped to tackle any challenges that arise during operation or upkeep.

Understanding Husqvarna 351 Components

When exploring the intricate machinery of outdoor equipment, it’s essential to familiarize oneself with the various elements that contribute to its functionality. Each component plays a crucial role, ensuring seamless operation and efficiency. By delving into the specifics, users can enhance their understanding and maintenance of their tools.

Power Unit: At the heart of any tool lies its engine, which converts fuel into mechanical energy. This core element is vital for powering the device and directly influences performance.

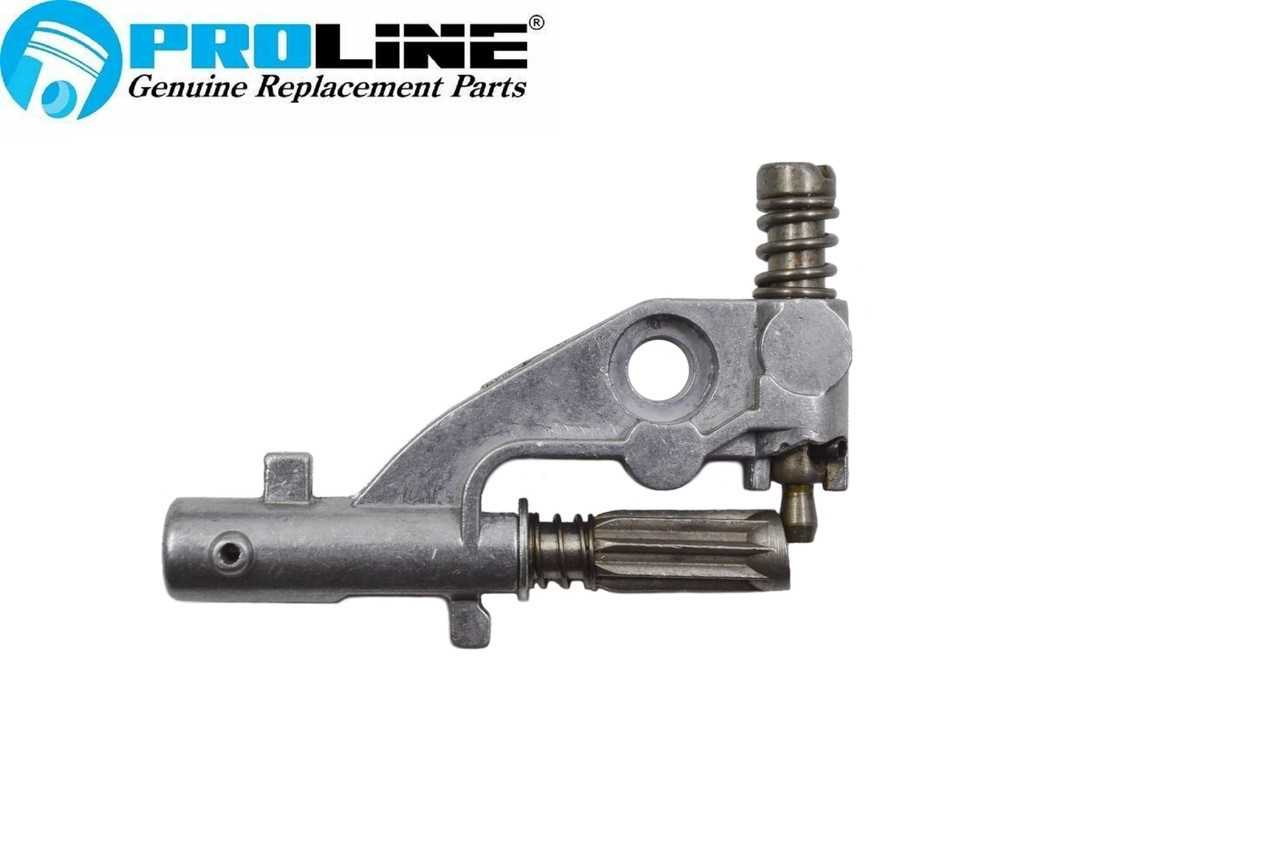

Cutting Mechanism: The cutting system, often equipped with sharp blades or chains, is designed to handle various materials. Understanding its configuration can lead to better performance and durability.

Control Features: The control system allows users to manage speed and power effectively. Familiarity with throttle and ignition mechanisms ensures safe and optimal usage.

Chassis and Frame: The structural integrity of the device is provided by the frame, which supports all components. A well-designed chassis contributes to stability and ease of handling.

Fuel System: This system encompasses the tank, lines, and filters, which work together to deliver the necessary fuel. Regular checks and maintenance can prevent issues and enhance efficiency.

Cooling and Exhaust Systems: Effective heat management and proper exhaust disposal are essential for prolonged operation. Understanding these systems can help prevent overheating and ensure compliance with environmental standards.

By recognizing the importance of each segment within the machinery, users can better appreciate their tool’s functionality and invest in appropriate care and maintenance strategies.

Overview of Husqvarna 351 Features

This section delves into the remarkable characteristics of a specific model renowned for its performance and reliability. Designed for both casual users and professionals, it offers an impressive blend of power and efficiency, making it a preferred choice in various applications.

The engine boasts advanced technology that enhances fuel efficiency while minimizing emissions. The lightweight construction ensures easy maneuverability, allowing users to operate the tool for extended periods without fatigue.

| Feature | Description |

|---|---|

| Engine Power | High-performance engine designed for maximum efficiency. |

| Weight | Lightweight build for enhanced portability and ease of use. |

| Fuel Efficiency | Optimized fuel consumption for longer operation between refuels. |

| Emissions Control | Low emissions technology to comply with environmental standards. |

| Ergonomic Design | Comfortable handle and balanced weight distribution for user comfort. |

Overall, this model exemplifies a commitment to innovation and user satisfaction, making it a valuable asset for a variety of tasks.

Common Parts and Their Functions

Understanding the various components of a machine and their respective roles is crucial for efficient operation and maintenance. Each element contributes to the overall performance and reliability, making it essential to recognize their functions.

Key Components

Here is a brief overview of some fundamental elements and what they do:

| Component | Function |

|---|---|

| Engine | Provides the power needed for operation. |

| Carburetor | Mixes air and fuel for combustion. |

| Chain | Transfers power from the engine to the cutting mechanism. |

| Bar | Holds the chain in place while guiding the cutting process. |

| Fuel Tank | Stores fuel necessary for engine operation. |

Maintenance Tips

Regularly checking these components can enhance performance and extend the lifespan of the equipment. Pay attention to wear and tear, and ensure that each part is functioning correctly to prevent operational issues.

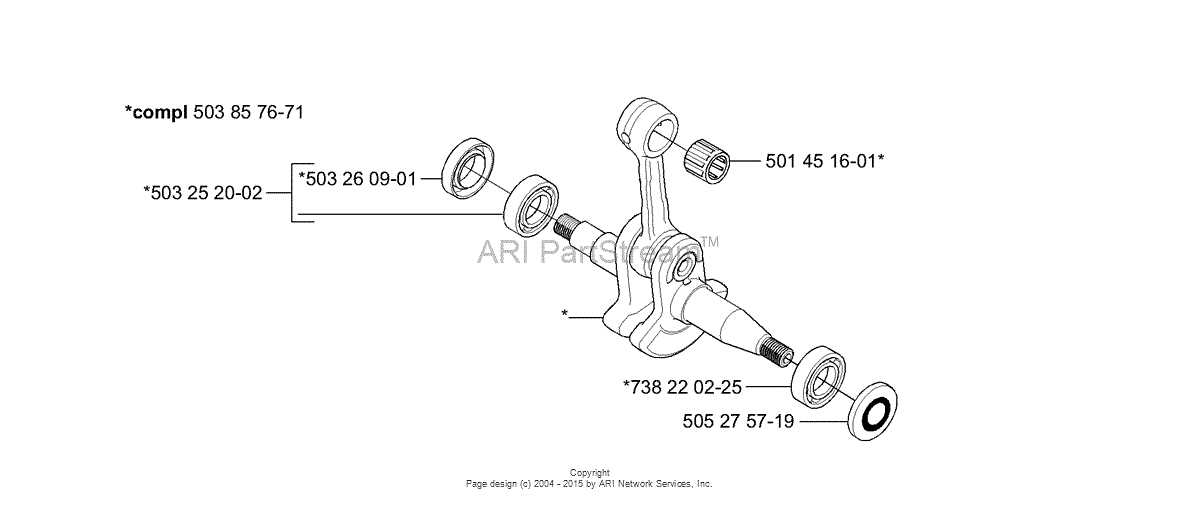

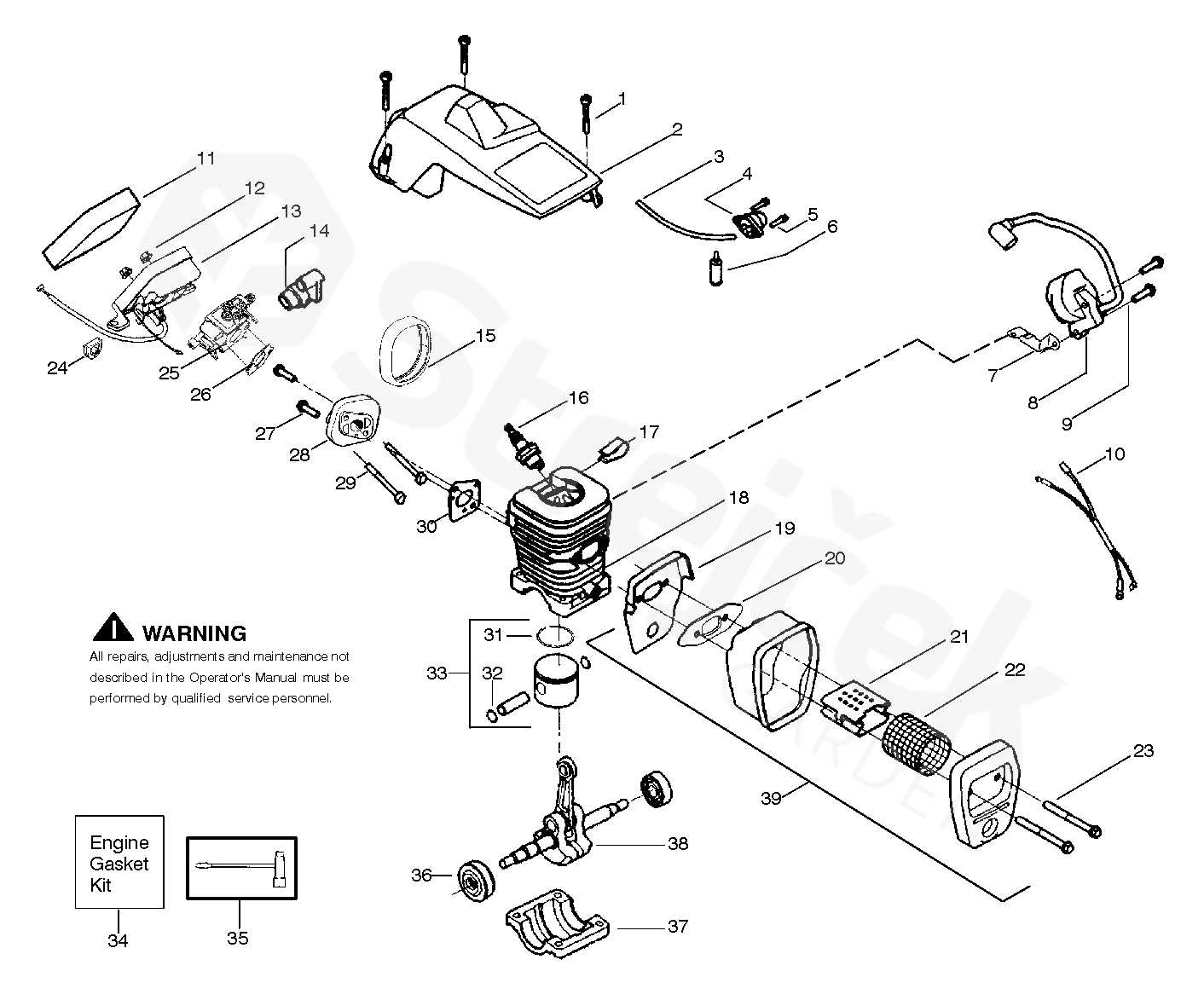

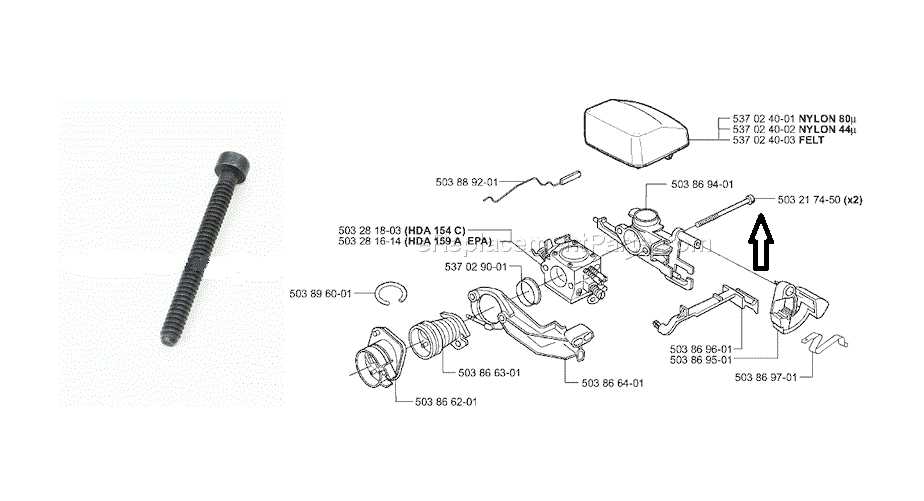

Exploring the Parts Diagram

Understanding the intricate layout of components within a mechanical device is essential for effective maintenance and repairs. By examining the schematic representation of elements, users can gain insights into how each part interacts and contributes to the overall functionality. This knowledge is invaluable for anyone looking to optimize performance or address issues that may arise during operation.

Benefits of Familiarity with Component Layouts

Acquaintance with the arrangement of elements offers several advantages. Firstly, it aids in identifying wear and tear or potential malfunctions. Secondly, it streamlines the process of sourcing replacements, ensuring that the right components are acquired without unnecessary delays. Finally, this understanding enhances DIY repair confidence, empowering users to undertake maintenance tasks effectively.

Key Elements in the Schematic

When analyzing the visual representation, several critical sections are often highlighted:

| Section | Description |

|---|---|

| Engine Assembly | The core unit that powers the device, including key operational features. |

| Fuel System | Components responsible for fuel delivery and management, crucial for efficient performance. |

| Drive Mechanism | The assembly that translates engine power into movement, vital for overall functionality. |

| Chassis | The framework that houses and supports all other elements, providing stability and durability. |

By delving into these sections, users can cultivate a comprehensive understanding of their equipment, ultimately leading to enhanced longevity and performance.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the prolonged functionality and efficiency of any equipment. Neglecting maintenance can lead to unforeseen breakdowns and reduced performance, ultimately shortening the lifespan of the machinery. By dedicating time to routine inspections and care, users can prevent costly repairs and extend the useful life of their devices.

Benefits of Routine Care

- Enhances performance and efficiency

- Reduces the likelihood of unexpected failures

- Increases safety during operation

- Preserves resale value

Key Maintenance Practices

- Regular cleaning to remove debris and dirt

- Checking and replacing worn-out components

- Lubricating moving parts to minimize friction

- Storing equipment in a suitable environment to prevent damage

Implementing these practices not only safeguards the equipment but also contributes to a more efficient and reliable operation. A commitment to maintenance ensures that the investment made in machinery pays off over the long term.

How to Read the Diagram Effectively

Understanding a schematic representation is crucial for anyone looking to maintain or repair machinery. These visual guides provide a comprehensive overview of components and their relationships, enabling users to identify parts quickly and efficiently. Familiarizing oneself with the layout can significantly enhance the repair process, reducing confusion and saving time.

Begin by identifying the legend: Most illustrations come with a legend or key that explains symbols and labels. This section is vital for comprehending what each symbol represents, helping you decode the rest of the visual.

Next, follow the flow: Observing how components connect and interact can offer insights into the functioning of the entire system. Pay attention to lines and arrows indicating movement or relationships, as these are essential for understanding the overall operation.

Focus on grouping: Components are often organized into sections based on their functions. Recognizing these clusters can simplify your approach to troubleshooting and repairs, allowing you to concentrate on specific areas without feeling overwhelmed.

Take notes: As you analyze the schematic, jot down any unfamiliar parts or symbols. This practice will aid in your research and provide a reference for future tasks. Familiarity with terminology is key to effective maintenance.

By applying these strategies, you can navigate any schematic representation with confidence, enhancing your ability to tackle repairs and maintenance tasks efficiently.

Where to Find Replacement Parts

Locating components for your outdoor equipment can seem daunting, but there are various reliable sources available to help you maintain and restore your machinery. Whether you need a specific piece or general accessories, exploring multiple avenues can ensure you find what you’re looking for efficiently.

Online Retailers

The internet offers a vast array of shops specializing in outdoor equipment and machinery components. Here are some popular options:

- Specialty e-commerce sites

- General online marketplaces

- Manufacturer websites

Local Stores

If you prefer a more hands-on approach, consider visiting local retailers. These establishments often carry a range of items and may provide helpful guidance:

- Home improvement centers

- Tool supply shops

- Outdoor equipment dealers

By exploring these avenues, you can ensure your equipment remains in optimal condition with the necessary replacements easily accessible.

Tips for Ordering the Right Components

When seeking to acquire the correct items for your equipment, precision is crucial. Understanding the specifications and features of the components can greatly influence the performance and longevity of your machinery. Here are some essential tips to ensure you make the right choices when placing your order.

Understand Your Needs

- Identify the specific issues you are experiencing with your equipment.

- Determine whether you need replacement parts or upgrades for enhanced functionality.

- Consult your user manual for guidance on compatible items.

Research and Verify

- Look for reputable suppliers that specialize in the components you require.

- Read reviews and ratings to gauge the reliability of products.

- Double-check the part numbers and specifications before finalizing your purchase.

By following these guidelines, you can ensure that the items you order will fit seamlessly into your equipment, enhancing its overall performance.

Identifying Wear and Tear Issues

Recognizing signs of deterioration is crucial for maintaining the longevity and performance of your equipment. Regular inspection can help detect minor problems before they escalate into major repairs. Understanding common indicators of wear will aid in ensuring optimal functionality and safety.

One of the first signs of wear is unusual noise. If your machine starts making grinding, rattling, or excessive vibration sounds, this may indicate that components are loose or damaged. Additionally, visual inspection can reveal cracks, chips, or discoloration on parts that experience high levels of stress.

Another important factor to consider is reduced efficiency. If your equipment struggles to perform tasks it once handled easily, this could signify that certain elements are worn out. Look for issues like overheating or a decrease in power, as these are clear indicators of underlying problems.

Regular maintenance practices, such as cleaning and lubrication, also play a vital role in preventing wear. Accumulated dirt and debris can accelerate deterioration, while lack of lubrication can lead to friction-related damage. Staying vigilant about these factors will help extend the lifespan of your machinery.

DIY Repair and Replacement Guide

Maintaining your outdoor equipment can seem daunting, but with the right approach and tools, it becomes a manageable task. This guide will empower you to perform repairs and swaps on your machinery efficiently. By understanding the components and their functions, you can enhance the longevity of your equipment and ensure optimal performance.

Essential Tools for Your Repair Kit

Before starting any maintenance work, it’s crucial to gather the necessary tools. A basic toolkit should include screwdrivers, wrenches, pliers, and a socket set. Additionally, having a cleaning brush and lubricants on hand will help keep the parts in good condition. Consider investing in a repair manual specific to your model, which can provide valuable insights and troubleshooting tips.

Step-by-Step Repair Process

Begin your repair by disconnecting the power source to ensure safety. Carefully disassemble the components, taking note of their arrangement for easier reassembly. Inspect each part for wear and damage, replacing any that show signs of deterioration. When reassembling, follow the reverse order of disassembly, making sure to tighten all connections securely. Finally, test your equipment to confirm that everything is functioning as intended.

Frequently Asked Questions About Parts

This section addresses common inquiries related to components for outdoor equipment. Understanding the essentials can help users make informed decisions and ensure optimal performance of their machines.

- What should I consider when selecting components?

- Compatibility with your specific model.

- Quality and durability of the materials.

- Manufacturer recommendations for replacements.

- How can I identify the right component?

- Refer to the user manual for specifications.

- Check the original parts for identifying numbers.

- Consult with authorized dealers for guidance.

- Are aftermarket components reliable?

- Quality can vary; research brands before purchasing.

- Read reviews from other users for insights.

- Look for warranties or guarantees offered.

- What is the best way to maintain my equipment?

- Regular cleaning and inspection of components.

- Timely replacement of worn or damaged items.

- Following the maintenance schedule outlined in the manual.

- Where can I purchase quality components?

- Authorized dealers and retailers.

- Reputable online marketplaces.

- Specialty stores focusing on outdoor equipment.

Benefits of Using Original Parts

Utilizing authentic components in machinery maintenance ensures optimal performance and longevity. These original items are designed specifically for each model, offering numerous advantages over generic alternatives.

- Compatibility: Genuine parts are crafted to fit seamlessly, reducing the risk of operational issues.

- Quality Assurance: Original components meet stringent quality standards, ensuring durability and reliability.

- Warranty Protection: Using authentic items often helps maintain manufacturer warranties, safeguarding your investment.

- Performance Optimization: Original parts enhance the overall efficiency of equipment, leading to better output and reduced downtime.

- Resale Value: Machines with original components tend to retain higher resale value, appealing to future buyers.

Incorporating genuine components into repairs and maintenance is a wise choice that promotes long-term satisfaction and effectiveness in operation.