Comprehensive Guide to Husqvarna 385xp Parts Diagram

In the world of outdoor machinery, comprehending the intricate elements that make up your tool is essential for optimal performance and longevity. Knowing how these components interact not only enhances your user experience but also empowers you to maintain and troubleshoot effectively.

Visual representations of these intricate systems serve as invaluable resources, offering clarity and insight into the assembly and function of various pieces. By exploring these illustrations, one can quickly identify essential parts and their roles, leading to more informed decisions regarding repairs and upgrades.

Whether you’re a seasoned user or a newcomer, having access to detailed layouts can significantly enhance your understanding. This knowledge ultimately contributes to a more efficient and enjoyable operation of your equipment, ensuring it remains a reliable ally in your outdoor endeavors.

Understanding Husqvarna 385XP Components

This section explores the essential elements that contribute to the functionality and performance of a specific outdoor power tool. Gaining insight into these components is crucial for maintenance, repair, and optimal operation.

| Component | Function |

|---|---|

| Engine | Powers the device, enabling cutting and trimming tasks. |

| Chain | Facilitates the cutting action by rotating around the guide bar. |

| Guide Bar | Provides a stable surface for the chain to run along. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring efficiency. |

| Fuel Tank | Holds the necessary fuel for the engine’s operation. |

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements allow users to easily identify and locate specific items within a system, enhancing both efficiency and accuracy during work.

Clear visualization aids technicians in comprehending complex assemblies, reducing the likelihood of errors when reassembling or replacing elements. With a detailed illustration, users can delve into the inner workings of the equipment, gaining insights that facilitate troubleshooting.

Furthermore, such resources serve as invaluable references, ensuring that individuals have the necessary information at hand to perform repairs confidently. This ultimately leads to prolonged equipment lifespan and optimal performance.

Key Features of the 385XP Model

This powerful tool is designed to meet the demands of both professionals and enthusiasts, offering exceptional performance and reliability. It combines advanced technology with user-friendly features, making it a versatile choice for various cutting tasks.

One of the standout characteristics is its robust engine, which provides ample power for tackling tough jobs while ensuring efficient fuel consumption. Additionally, the lightweight design enhances maneuverability, reducing fatigue during extended use.

The model also includes an effective vibration dampening system, contributing to user comfort and control. Safety features, such as a quick-stop chain brake, further enhance its usability, allowing users to work with confidence.

Overall, this tool exemplifies a blend of power, efficiency, and safety, making it an ultimate choice for those seeking high performance in their cutting tasks.

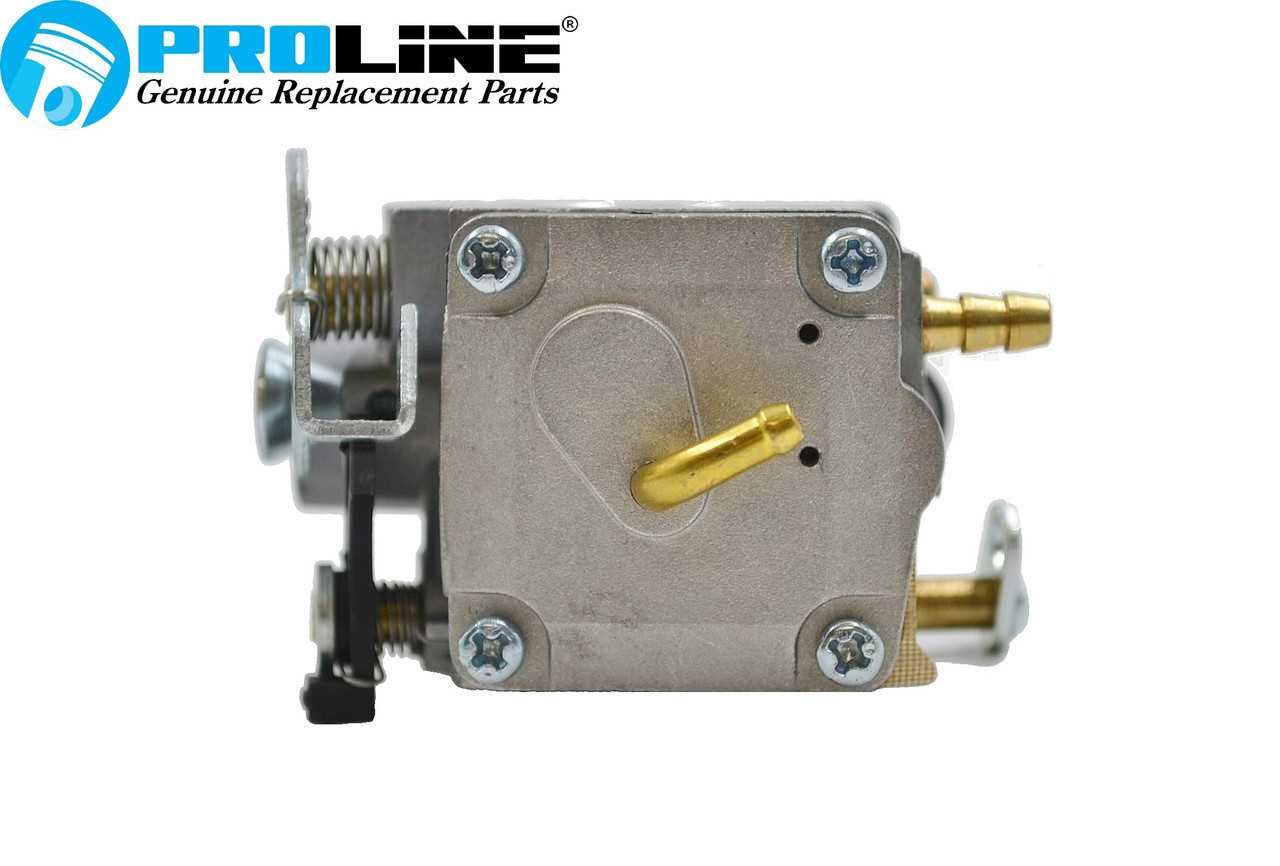

Common Replacement Parts for 385XP

In the world of outdoor power equipment, maintaining optimal performance often necessitates the timely replacement of various components. Understanding which elements are prone to wear and tear can help users ensure their tools remain efficient and reliable. This section explores frequently replaced items that contribute to the longevity and functionality of these machines.

Essential Components

Key elements such as filters, spark plugs, and fuel lines are vital for smooth operation. These components should be regularly inspected and replaced as needed to avoid potential breakdowns and maintain peak performance. Investing in quality replacements can significantly enhance the tool’s lifespan and efficiency.

Performance Enhancers

Additionally, items like chains, bars, and drive systems play a crucial role in cutting efficiency and ease of use. Upgrading or replacing these parts can lead to improved performance, ensuring that tasks are completed effectively and with minimal effort.

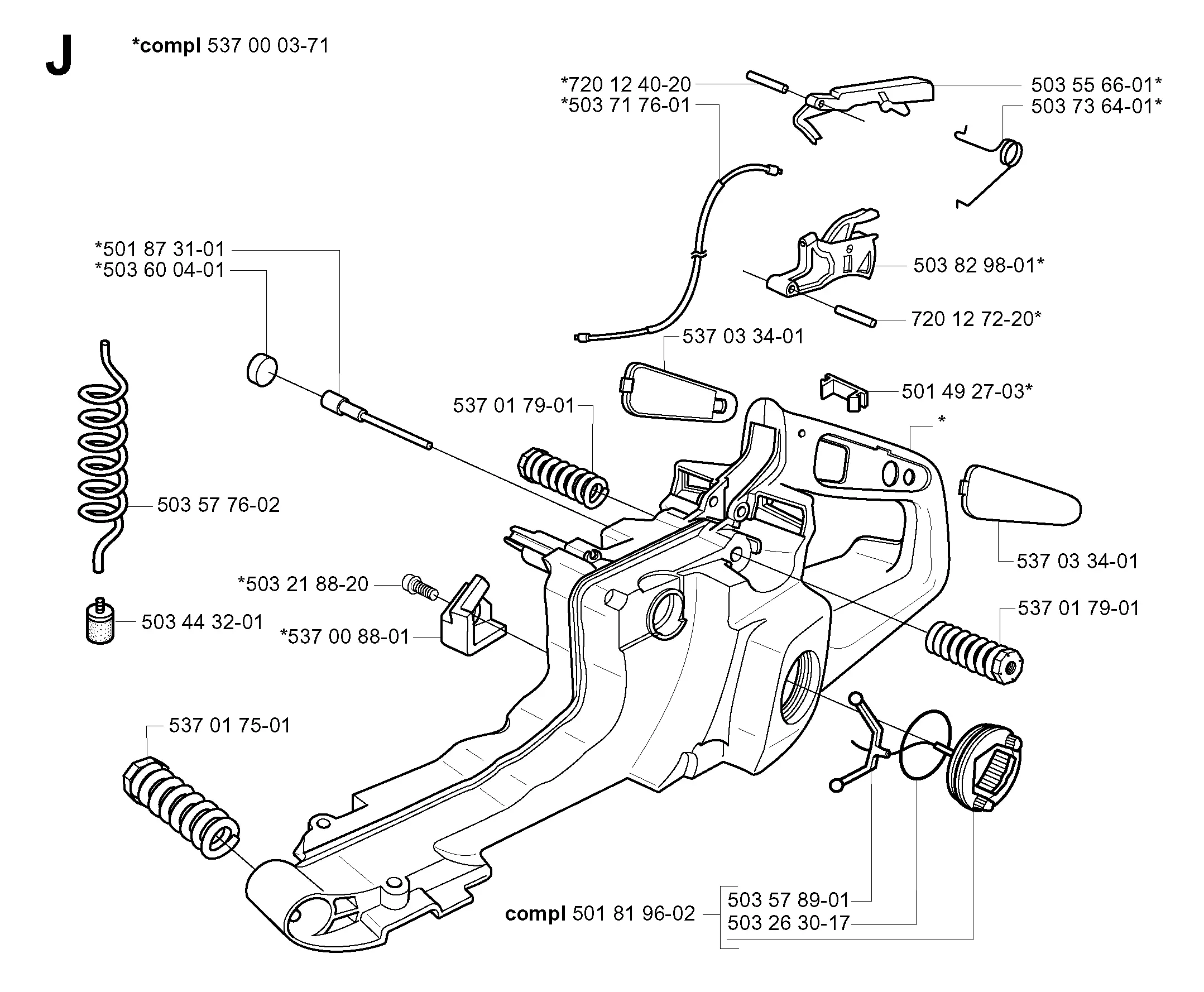

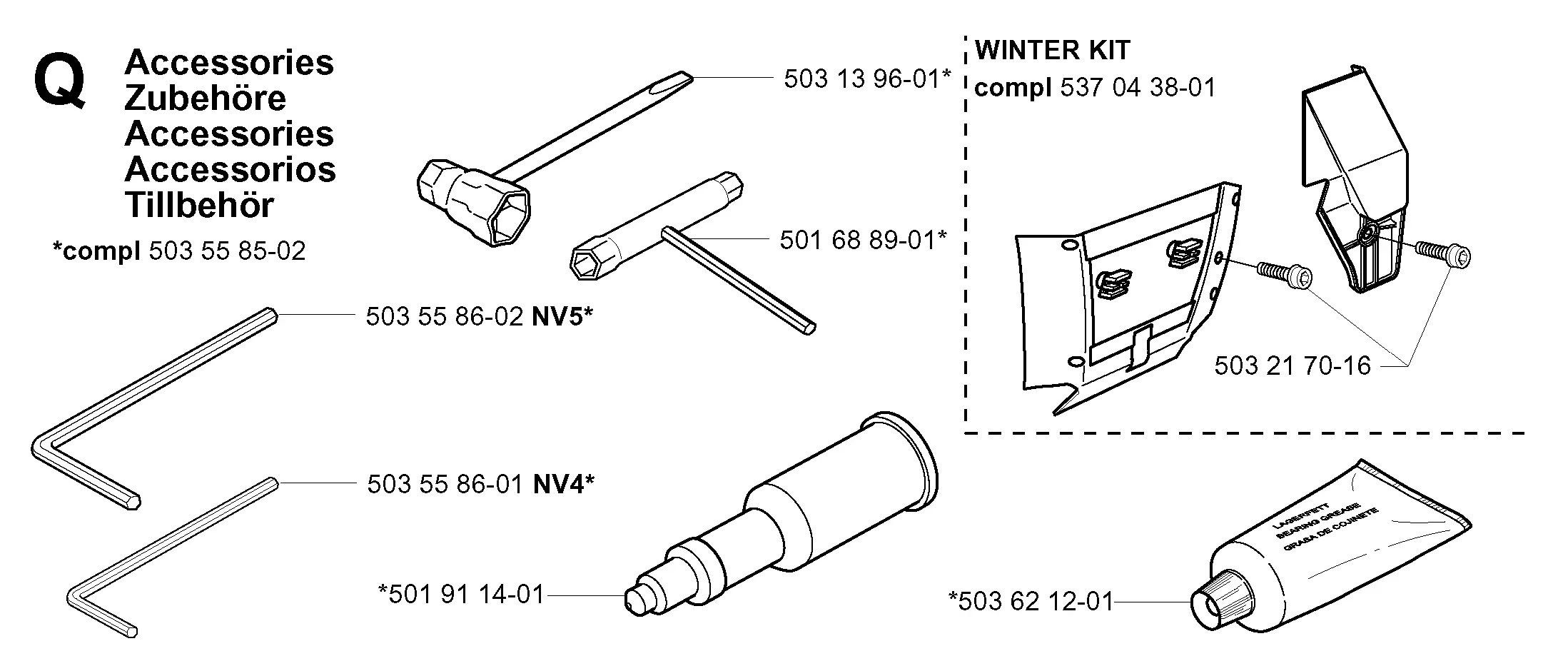

How to Read Parts Diagrams

Understanding technical illustrations is crucial for efficient maintenance and repair of machinery. These visual representations provide valuable insights into the components and their arrangements, aiding in identifying necessary replacements and facilitating assembly tasks. Mastering this skill can save time and enhance your overall efficiency.

Key Elements of Technical Illustrations

- Reference Numbers: Each element is usually assigned a unique identifier that corresponds to a parts list, making it easier to find specific items.

- Legends and Annotations: Many illustrations include legends that explain symbols, colors, or special notes that are essential for interpretation.

- Component Groupings: Parts are often grouped by function or location, helping users understand how different elements interact.

Steps to Effectively Interpret Illustrations

- Familiarize Yourself with the Layout: Begin by studying the overall structure to grasp how components are organized.

- Identify Key Elements: Use the reference numbers to locate specific items in the accompanying list.

- Cross-Reference with the Manual: Always compare findings with the user manual for additional context and details.

- Take Notes: Document any observations or questions that arise during your analysis for future reference.

Maintenance Tips for Husqvarna Chainsaws

Proper upkeep of your chainsaw is essential for ensuring its longevity and optimal performance. Regular care helps prevent issues, improves efficiency, and keeps your tool in prime condition for various tasks. By following these maintenance tips, you can significantly extend the life of your saw and ensure it operates safely and reliably.

Clean the air filter regularly: A clogged air filter can reduce engine efficiency, leading to overheating and decreased power. Cleaning or replacing the filter ensures proper airflow and prevents damage to the engine.

Sharpen the chain frequently: A dull chain can cause unnecessary strain on the motor and increase the risk of accidents. Ensure your cutting blade is sharp and properly tensioned for smooth, precise cutting.

Check the fuel mix: Always use the correct fuel mixture as specified in the user manual. An improper blend can cause engine malfunctions or reduce the lifespan of the motor.

Inspect the bar and chain oil levels: Proper lubrication is vital for the bar and chain to reduce friction and prevent overheating

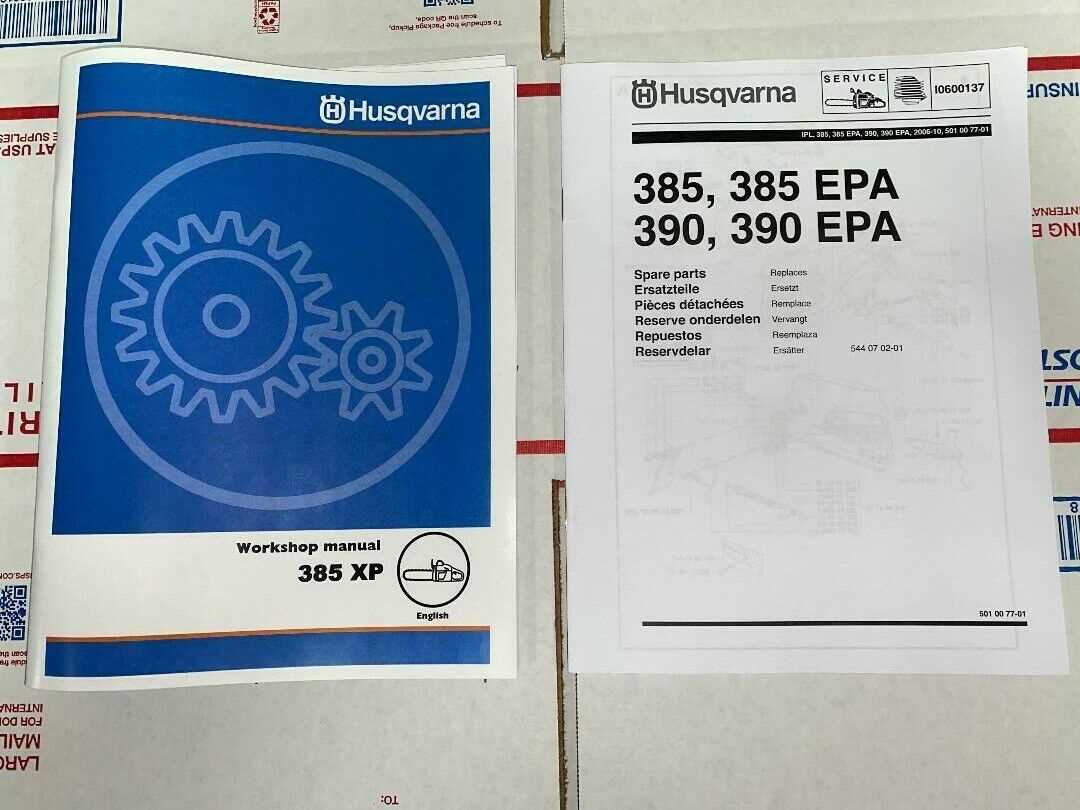

Finding Genuine Replacement Parts

Ensuring the longevity and optimal performance of your equipment requires using authentic components when replacements are needed. With the wide variety of options available, it’s essential to understand how to source the most reliable alternatives that match your machine’s specifications.

Here are key steps to locate original components:

- Consult the manufacturer’s official website for verified suppliers.

- Reach out to authorized dealers who offer original replacements.

- Check detailed service manuals or online databases for correct part numbers.

- Read reviews or forums for recommendations on trustworthy sources.

Always avoid unverified sellers, as counterfeit items may compromise your machine’s efficiency and safety.

Identifying Faulty Components Quickly

Detecting malfunctioning elements in any system can be a challenge, but with the right approach, it becomes a swift process. Understanding the signs of wear or damage and knowing where to focus your attention will significantly reduce time spent on repairs. The goal is to minimize downtime by effectively pinpointing the issue.

Visual Inspection and Common Symptoms

A thorough visual inspection is often the first step in identifying problems. Look for visible signs of damage such as cracks, corrosion, or disconnection. In many cases, visual cues like these will guide you toward the root of the malfunction. Additionally, certain symptoms such as unusual sounds or performance drops can provide critical clues.

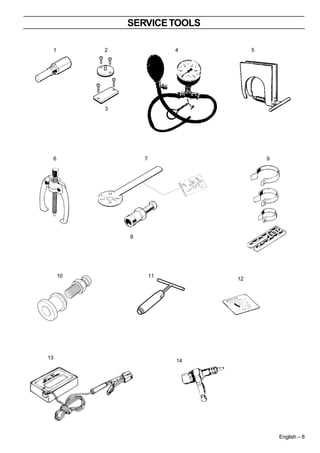

Testing and Troubleshooting

If the issue isn’t immediately obvious, using appropriate tools to test the functionality of each component is essential. Multimeters or other diagnostic tools can measure

DIY Repairs for the 385XP

Taking care of your chainsaw’s maintenance can save both time and money, ensuring long-lasting performance. By learning how to address common issues yourself, you can avoid downtime and costly professional services. In this section, we’ll walk you through essential repair techniques that can help keep your tool running smoothly.

Before starting any repairs, it’s crucial to gather the right tools and make sure you understand the problem fully. Here are some common repairs that can be done with basic knowledge and equipment:

- Replacing a worn-out chain.

- Cleaning the air filter to ensure proper airflow.

- Fixing fuel line leaks or blockages.

- Sharpening the cutting teeth for improved performance.

- Checking and adjusting the tension of the blade.

For more complex issues, such as engine troubles or malfunctioning ignition systems, it’s recommended to consult a detailed guide or seek expert advice to avoid further complications.

Resources for Parts Diagrams

Finding reliable sources for equipment schematics is crucial when dealing with repairs or maintenance. Various platforms offer detailed illustrations and technical breakdowns, helping users identify the correct components and assembly procedures.

Many websites provide access to comprehensive visual guides that cover a wide range of machines, offering easy navigation through various categories. Whether you’re looking for mechanical layouts or specific system overviews, these platforms ensure that users can efficiently pinpoint the necessary elements for repair tasks.

Additionally, specialized forums and databases often host expert advice alongside these technical drawings, allowing users to ask questions and find solutions directly from industry professionals.

Safety Considerations During Repairs

When undertaking repairs, ensuring safety is crucial. Even minor maintenance tasks can pose significant hazards if proper precautions are not taken. It is important to be mindful of potential risks and follow appropriate safety measures to protect both the individual and the equipment.

Personal Protective Equipment

Wearing the right protective gear is essential during any repair. Gloves, eye protection, and sturdy footwear should be used to minimize the risk of injury. Depending on the complexity of the work, additional safety equipment may be required, such as ear protection or a face shield.

Safe Work Environment

Maintaining a clean and organized workspace helps reduce the likelihood of accidents. Tools and equipment should be properly stored when not in use, and the area should be well-lit to avoid unnecessary hazards. Ensure that all equipment is properly secured and stable before beginning any repair work.

| Safety Measure | Purpose | |||||

|---|---|---|---|---|---|---|

| Gloves | Protect hands from sharp objects and chemicals | |||||

| Eye Protection | Prevent debris

Community Support and Forums for OwnersOnline communities provide a valuable resource for tool owners looking to exchange experiences, seek advice, and discuss maintenance challenges. These platforms bring together a wealth of knowledge shared by individuals who use similar equipment, allowing for troubleshooting, repair tips, and improvement ideas. Whether it’s addressing common problems or exploring advanced upgrades, these forums offer collaborative solutions. Popular Discussion Topics

Members often engage in conversations around best practices for tool upkeep, modifications, and long-term durability. Forums are filled with real-world insights from users who have successfully maintained their tools under various conditions. Beginners can find guidance, while more experienced individuals share in-depth technical knowledge. Finding the Right Community

When searching for the ideal community, it’s essential to choose one that aligns with your needs. Whether you’re focused on performance enhancements or general maintenance, there are platforms suited for every level of expertise. Additionally, some forums offer exclusive access to detailed resources, including manuals and user guides.

|