Comprehensive Guide to Husqvarna 394xp Parts Diagram

In the realm of mechanical devices designed for cutting and shaping, understanding the intricate arrangement of their internal components is crucial. This article delves into the detailed anatomy of a high-performance saw, shedding light on the spatial relationships and functional interplay among its various parts. Each element plays a pivotal role in the seamless operation of the equipment, ensuring optimal efficiency and durability.

Unveiling the Structural Blueprint

At the core of this exploration lies the structural blueprint that dictates how each piece fits into the larger mechanism. Components are meticulously arranged to facilitate a harmonious workflow, emphasizing both precision and robustness. From the foundational framework that supports the entire assembly to the smallest gears and bearings that enable smooth movement, every detail contributes to the overarching performance of the device.

Key Functional Units

Zooming in on the functional units, one encounters a network of gears, shafts, and cylinders, intricately connected to translate power from motor to blade. The arrangement is designed with a keen eye on optimizing torque transmission while minimizing energy loss. These units are not merely static parts but dynamic contributors to the tool’s ability to handle diverse cutting tasks with finesse and reliability.

Understanding Components of the 394XP Chainsaw

In this section, we delve into the intricate makeup of the 394XP chainsaw, exploring its various essential elements that contribute to its functionality and performance. The 394XP is a complex assembly of parts, each playing a crucial role in the overall operation and durability of the tool.

Engine and Powertrain

At the heart of the 394XP lies its robust engine and powertrain system. These components are responsible for generating the necessary horsepower and torque to drive the chain, enabling efficient cutting through wood of varying densities. The engine assembly includes components such as the piston, crankshaft, and cylinder, meticulously engineered to deliver optimal power output and endurance.

Cutting and Safety Mechanisms

Beyond the engine, the 394XP features sophisticated cutting and safety mechanisms that ensure both precision and user protection during operation. Components like the chain brake, throttle control, and bar ensure safe handling and prevent accidental kickbacks, enhancing overall usability and safety in challenging cutting environments.

Key Features of the 394XP Model

The 394XP stands out due to its advanced engineering and robust design, making it a preferred choice for professionals in various industries. This model integrates cutting-edge technology to enhance performance and reliability, ensuring efficient operation in demanding environments.

Performance and Power

Equipped with a high-performance engine, the 394XP delivers impressive power and torque, enabling swift and precise cutting through dense materials. Its dynamic capabilities cater to intensive tasks, ensuring consistent performance over extended periods.

Durability and Construction

The construction of the 394XP emphasizes durability and longevity, utilizing premium materials and precision craftsmanship. Components are engineered to withstand rigorous use, providing resilience against wear and tear, thereby extending the operational lifespan of the equipment.

| Engine Type | High-output, fuel-efficient |

| Bar Length Options | Available in various sizes |

| Weight | Optimized for balance and maneuverability |

| Starting System | Effortless start-up for quick deployment |

| Handling | Ergonomic design for comfort during prolonged use |

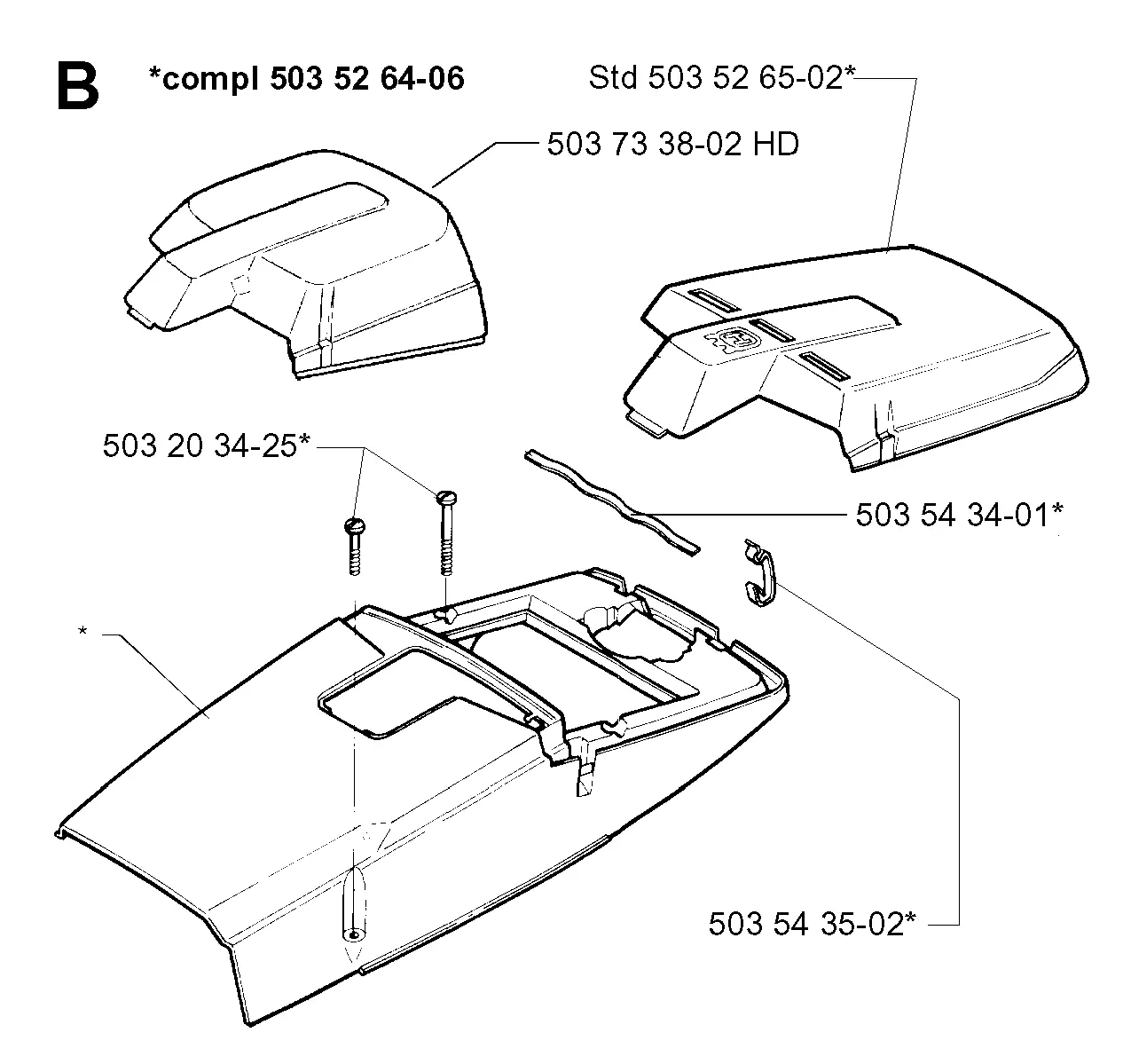

Importance of Parts Diagrams

Understanding the layout and composition of components within a machine is crucial for effective maintenance and repair. These visual representations provide a comprehensive view of the internal structure and interconnections of mechanical assemblies. By deciphering these diagrams, technicians gain insights into the intricate relationships between parts, facilitating precise identification and troubleshooting of issues.

Enhancing Maintenance Precision

Accurate maintenance hinges on the ability to pinpoint specific parts swiftly and accurately. Parts diagrams serve as navigational aids, guiding technicians through the labyrinth of components. This precision minimizes downtime and ensures that repairs are conducted with the correct components, fostering operational reliability and longevity.

Furthermore, these diagrams foster a deeper understanding of the machinery’s functionality, empowering users to anticipate potential areas of wear or failure. In essence, they act as blueprints, decoding the mechanical puzzle and transforming complex assemblies into manageable tasks.

Identifying Common Replacement Parts

When maintaining outdoor power equipment, understanding the components that may require replacement is essential for optimal performance. Regular use can lead to wear and tear, making it important to recognize which elements are most susceptible to damage. Here, we will explore key components that often need to be replaced, ensuring your equipment continues to function efficiently.

- Fuel System Components

- Fuel filters

- Carburetors

- Fuel lines

- Ignition System Parts

- Spark plugs

- Ignition coils

- Wiring harnesses

- Cutting Mechanism Elements

- Chains

- Bars

- Chain tensioners

- Body and Chassis Components

- Handles

- Protective covers

- Housing sections

By familiarizing yourself with these critical elements, you can ensure that you have the necessary replacements on hand, thereby prolonging the life of your equipment and maintaining its efficiency.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your outdoor equipment requires regular upkeep. Proper maintenance not only enhances performance but also minimizes the risk of breakdowns. Adopting a systematic approach to care can significantly extend the lifespan of your machinery and maintain its functionality.

Here are essential maintenance practices to keep your equipment running smoothly:

| Task | Frequency | Description |

|---|---|---|

| Air Filter Cleaning | Every 10 hours | Remove the air filter and clean it to ensure proper airflow and prevent debris buildup. |

| Spark Plug Inspection | Every 25 hours | Check for wear and replace if necessary to maintain optimal ignition performance. |

| Chain Tension Adjustment | Before each use | Ensure the cutting chain is properly tensioned to prevent accidents and improve cutting efficiency. |

| Fuel System Maintenance | Every 3 months | Inspect fuel lines for leaks and clean the fuel filter to ensure a clean fuel supply. |

| Lubrication | After every use | Apply lubricant to moving parts to reduce friction and wear. |

Following these guidelines will help you maintain peak performance and reliability, allowing you to tackle your tasks with confidence. Regular maintenance is an investment in your equipment’s future and efficiency.

Where to Find Official Schematics

When seeking detailed visual representations for mechanical assemblies, locating authoritative illustrations can significantly aid in understanding intricate components and their interconnections. These diagrams serve as visual blueprints, offering clarity on the spatial relationships and functionalities of various parts within a machinery structure.

Manufacturer’s Official Resources

One primary source for these essential visuals is directly from the manufacturer’s official channels. These resources provide meticulously crafted depictions that adhere to industry standards, ensuring accuracy and reliability in depicting each element’s placement and purpose.

Authorized Service Centers often possess comprehensive documentation that includes these detailed visuals. These centers serve as crucial repositories of knowledge, equipped with diagrams that assist in both repair and maintenance tasks.

How to Interpret Parts Diagrams

Understanding the layout and components of a machine can significantly enhance your ability to maintain and repair it effectively. A visual representation of these elements provides a roadmap for identifying individual pieces, their functions, and how they fit together. By grasping the structure of these illustrations, you can streamline the repair process and ensure that you are using the correct items for replacements.

Here are some key steps to help you decipher these visual aids:

- Familiarize Yourself with the Legend: Most diagrams include a legend that explains the symbols and lines used. Review this section carefully to understand what each symbol represents.

- Identify Major Components: Begin by locating the primary elements of the machine. These often include the engine, housing, and any attachments.

- Look for Numbering: Many illustrations will number components sequentially. This numbering often corresponds to a list of items, making it easier to identify specific parts.

- Note Connections and Assemblies: Pay attention to how components are linked. Understanding these connections can aid in disassembly and reassembly.

- Use Supplementary Resources: Sometimes, additional documentation such as manuals or online tutorials can provide context that is not immediately clear from the visuals.

By following these steps, you can enhance your comprehension of mechanical layouts, making repairs more efficient and less daunting.

Top Accessories for the 394XP

Enhancing the performance and versatility of your cutting tool can greatly improve your experience and efficiency. Various supplementary items can significantly boost functionality, making tasks easier and safer. Whether you are a professional or a hobbyist, investing in quality accessories can make a notable difference in your operations.

Essential Safety Gear

When working with powerful cutting machines, safety should always be a priority. High-quality protective apparel, such as chaps, gloves, and helmets, is crucial for preventing injuries. Additionally, ear protection and eye gear will safeguard against noise and debris, ensuring a secure working environment.

Performance Enhancements

To maximize the output of your equipment, consider upgrading with specialized chains, guide bars, and fuel additives. These enhancements not only improve cutting efficiency but also prolong the life of the tool. Regular maintenance items, like air filters and spark plugs, are also essential for optimal performance, keeping your machine running smoothly.

Common Issues and Solutions

When operating high-performance outdoor machinery, users may encounter several typical challenges that can affect performance and efficiency. Understanding these common problems and their respective solutions can enhance the longevity of the equipment and ensure smooth operation.

Engine Starting Problems

One frequent issue is difficulty in starting the engine. This can arise from several factors, including fuel quality, spark plug condition, or air filter blockage. To resolve this, ensure that the fuel is fresh and of high quality. Check and replace the spark plug if it shows signs of wear or fouling. Additionally, inspect the air filter for dirt and debris, cleaning or replacing it as necessary.

Overheating and Stalling

Another concern is overheating, which can lead to stalling. This problem often results from insufficient lubrication or debris obstructing airflow. Regularly check the oil levels and replace the oil at recommended intervals. Clear any debris from cooling fins and ensure that the cooling system is functioning properly. If overheating persists, further inspection of the internal components may be required to identify any underlying issues.

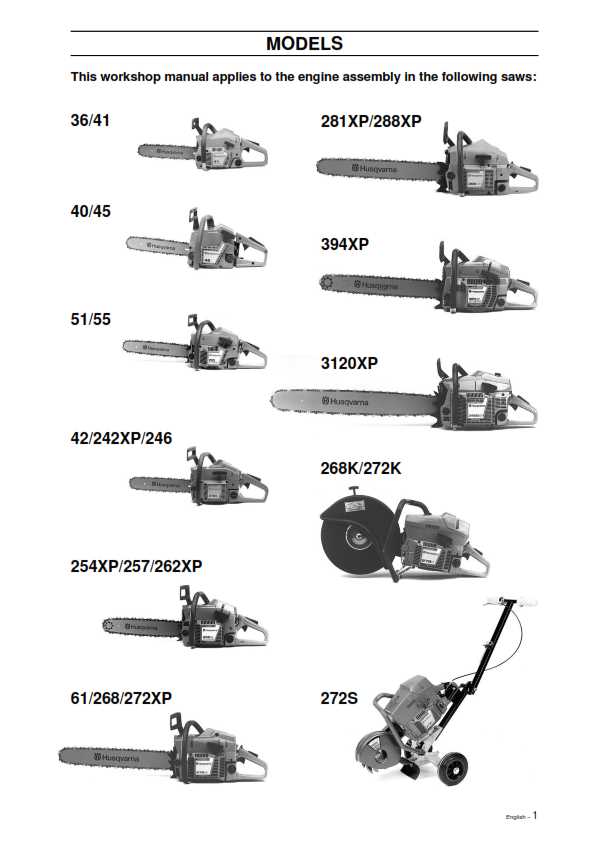

Comparing with Other Husqvarna Models

When evaluating various models within a well-known brand’s lineup, it’s essential to recognize both similarities and differences. Each machine is engineered with specific features aimed at distinct user needs, making some models better suited for certain tasks than others. Understanding these nuances can greatly enhance the selection process for potential buyers.

For instance, while one model may excel in power and durability, another might prioritize lightweight design and ease of handling. Users seeking robust performance for heavy-duty tasks might find advantages in the more powerful versions, whereas those focusing on maneuverability and convenience may prefer compact alternatives. Performance specifications such as engine size, weight, and fuel efficiency play a crucial role in this comparison.

Additionally, examining ergonomics and comfort features can provide further insights. Some designs offer advanced vibration reduction systems or better grip options, catering to users who spend extended hours operating their equipment. Ultimately, assessing these elements in relation to one another can help individuals make informed decisions tailored to their specific requirements.

Expert Recommendations for Parts Suppliers

Finding reliable vendors for replacement components can significantly impact the performance and longevity of your equipment. It’s essential to consider quality, availability, and customer support when selecting suppliers. This section provides insights into trusted sources for acquiring essential items, ensuring you make informed decisions that enhance your machinery’s efficiency.

Trusted Online Platforms

Many enthusiasts and professionals turn to reputable online marketplaces for sourcing their components. These platforms often feature user reviews, making it easier to gauge the reliability of products. eBay and Amazon are popular choices due to their extensive listings and competitive pricing. Always check seller ratings and return policies before finalizing your purchase to ensure a positive experience.

Local Specialty Stores

For those who prefer a hands-on approach, visiting local specialty shops can be invaluable. These retailers typically offer expert advice and may even have rare items in stock. Establishing a relationship with knowledgeable staff can lead to personalized recommendations and insights into maintenance best practices. Additionally, supporting local businesses contributes to the community and often results in more tailored service.

Ensuring Safety During Equipment Maintenance

When undertaking repairs or maintenance on your power equipment, prioritizing safety is paramount. This involves adhering to a series of precautionary measures to safeguard yourself and others from potential hazards. By following established safety protocols, you can mitigate risks associated with handling machinery.

First and foremost, always familiarize yourself with the operational manual provided by the manufacturer. This document contains critical information on safe handling practices and specific guidelines for maintenance procedures. Furthermore, ensure you have the appropriate personal protective equipment (PPE), such as gloves, safety goggles, and hearing protection, to shield yourself from debris, noise, and other potential dangers.

Additionally, before commencing any repair work, it is crucial to disconnect the equipment from its power source to prevent accidental activation. Moreover, inspect the work area to ensure it is well-lit and free of clutter, minimizing the risk of trips or falls during the maintenance process.

Lastly, be mindful of the tools you use, opting for those that are in good condition and suitable for the task at hand. Regularly inspect and maintain your equipment to uphold its operational efficiency and safety standards over time.