Exploring the Husqvarna 576XP Parts Diagram for Ultimate Maintenance

Maintaining complex machinery requires a clear understanding of its various components. For anyone involved in outdoor power tools, familiarity with individual parts can significantly enhance both maintenance and repair efforts. Having access to a visual representation of these elements can streamline troubleshooting processes and improve efficiency.

Comprehending the layout of your device is crucial for ensuring optimal performance. Each section plays a vital role, and knowing how they interact can prevent costly mistakes during repairs. Whether you’re a seasoned technician or a novice, an organized overview can provide valuable insights into your equipment’s functionality.

By exploring the intricate relationships between components, users can identify wear and tear, pinpoint malfunctions, and optimize their tool’s lifespan. This knowledge empowers you to make informed decisions regarding replacements and upgrades, enhancing your overall experience with your machinery.

Understanding Husqvarna 576xp Components

Exploring the intricacies of a high-performance machine involves examining its various essential elements. Each component plays a critical role in ensuring optimal functionality and efficiency. A comprehensive grasp of these parts enhances maintenance, repair, and overall user experience.

Key Elements of the Equipment

Understanding the core elements is vital for troubleshooting and upgrades. Here are some important components:

| Component | Function |

|---|---|

| Engine | Drives the machine and powers various functions. |

| Bar | Enables cutting through various materials. |

| Chain | Provides movement and engagement for effective cutting. |

Maintenance and Care

Regular maintenance of these components ensures longevity and peak performance. Knowledge of each part’s role aids in identifying wear and addressing potential issues promptly.

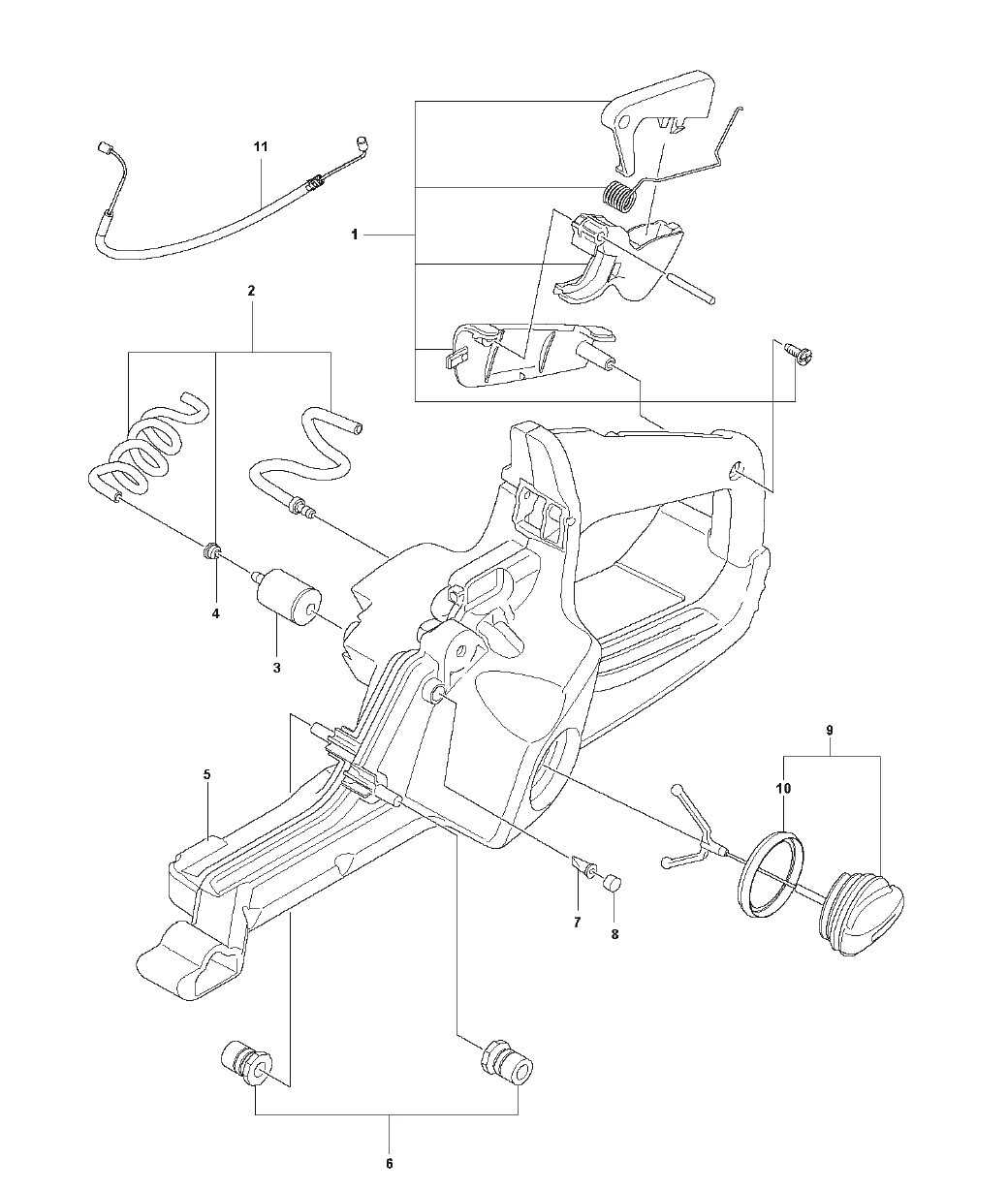

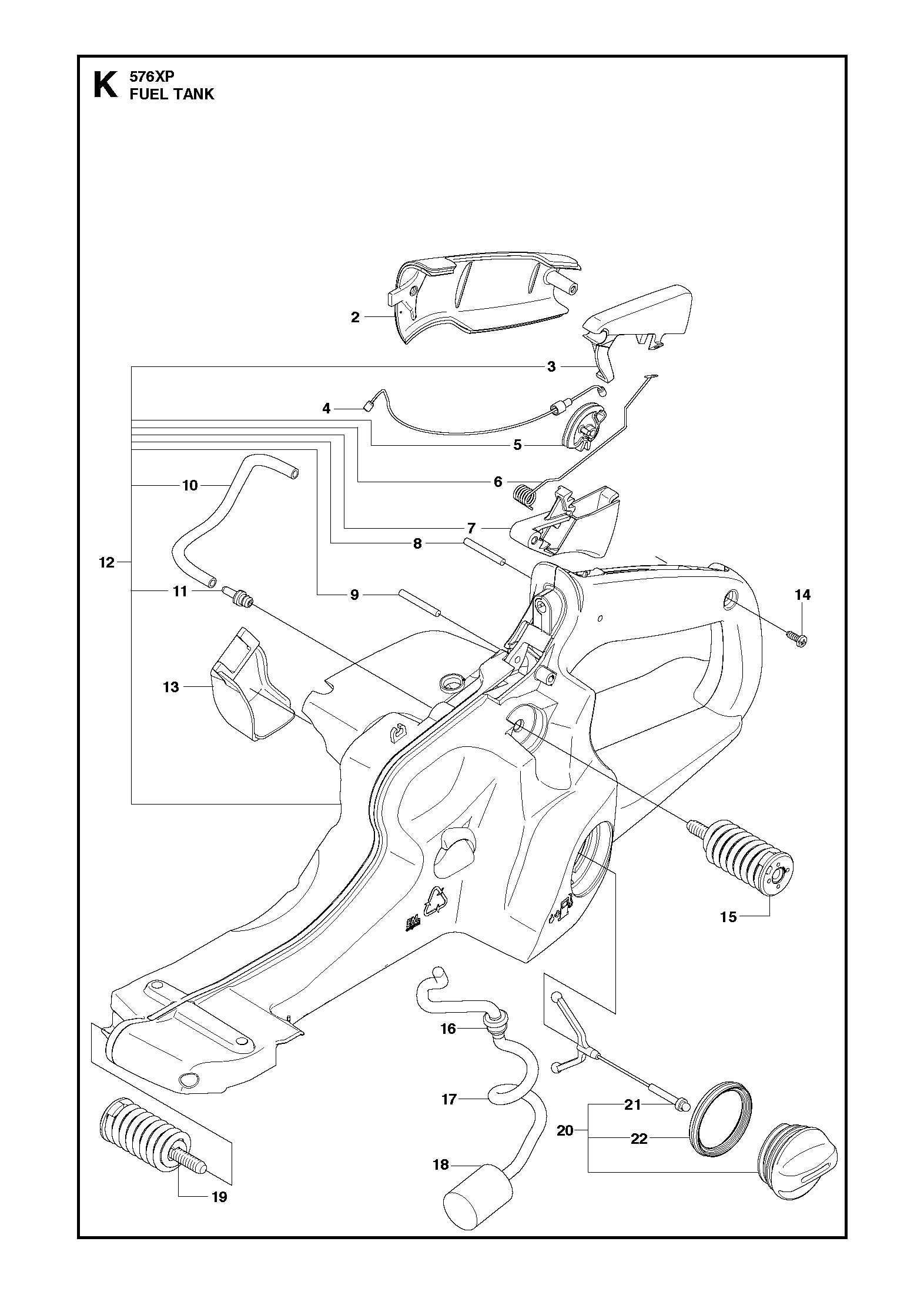

Importance of Parts Diagrams

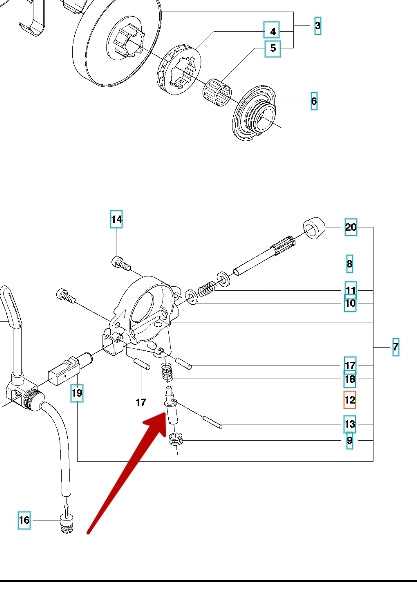

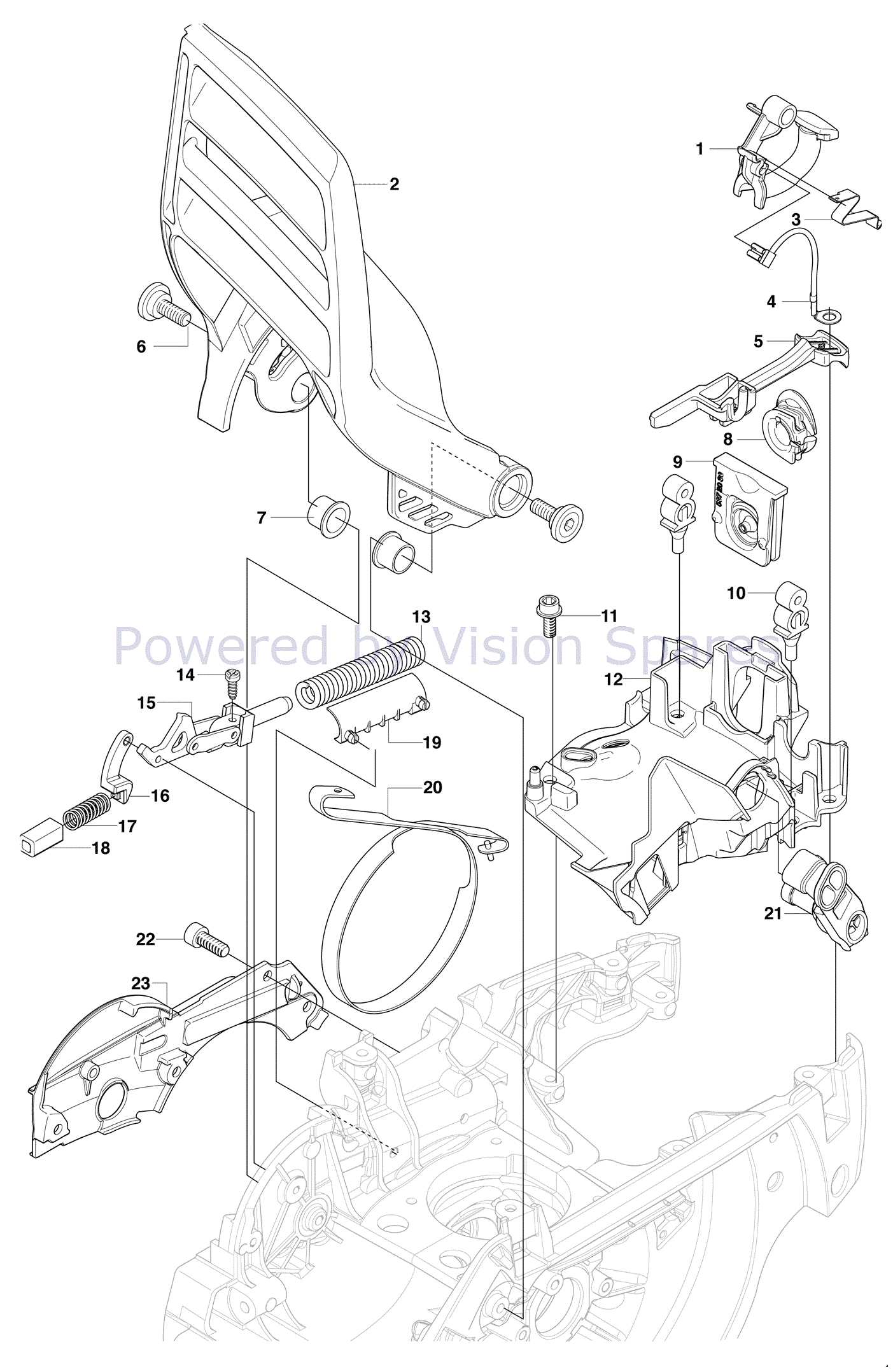

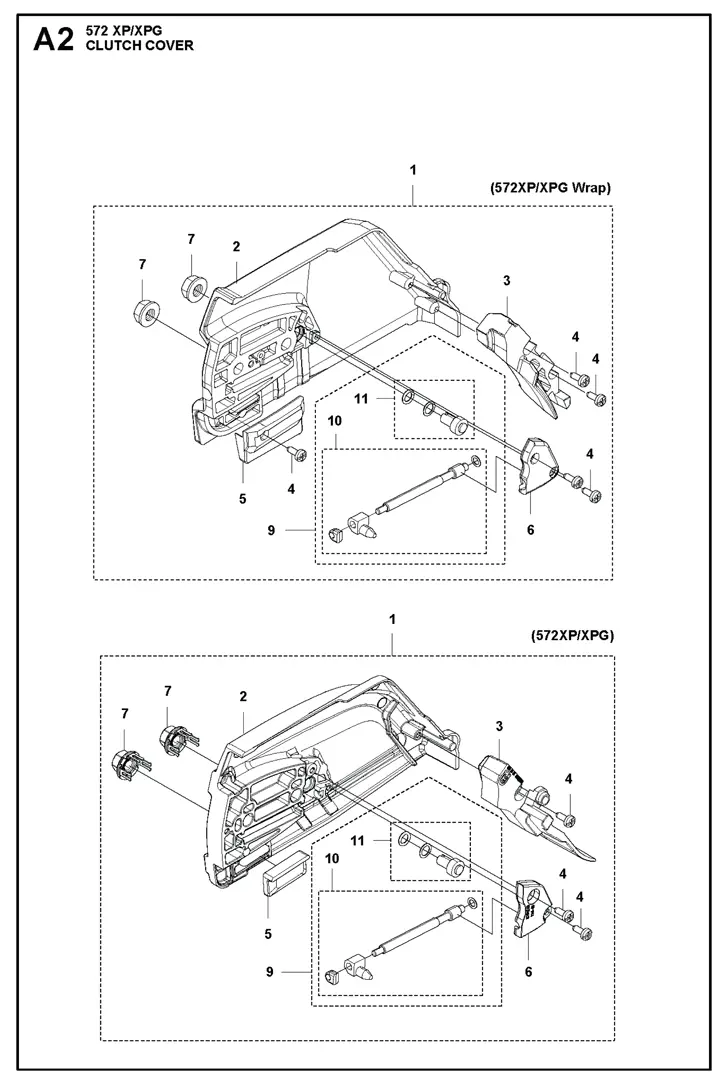

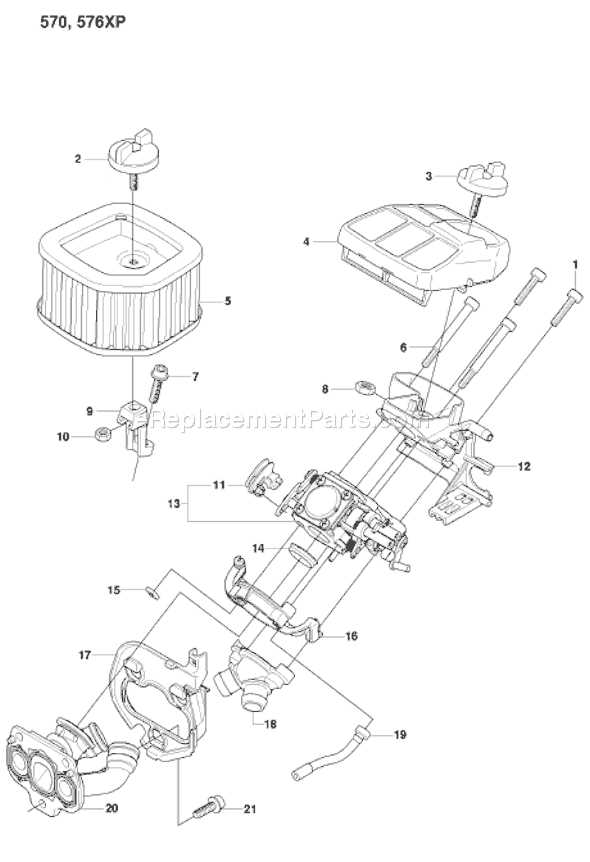

Visual representations of components play a crucial role in the maintenance and repair of machinery. These illustrations offer a clear overview of individual elements, their functions, and their interconnections within the system. This understanding is essential for both novice users and seasoned technicians, as it simplifies the identification of specific items and enhances the efficiency of repair tasks.

Moreover, having access to these visual guides significantly reduces the chances of errors during assembly or disassembly. By providing detailed information about each component, users can ensure that everything is correctly aligned and fitted, which ultimately prolongs the lifespan of the equipment. Clarity in these illustrations fosters confidence, empowering users to tackle repairs with greater assurance.

Additionally, such references are invaluable when sourcing replacements. Knowing the exact specifications of the required items enables individuals to make informed purchasing decisions, avoiding the pitfalls of incorrect parts that could compromise performance. Overall, these visual tools enhance the overall experience of maintaining equipment, making the process more accessible and reliable.

Key Features of Husqvarna 576xp

This model is designed to excel in performance and durability, making it a top choice for professionals and enthusiasts alike. With advanced engineering, it combines power and efficiency, ensuring that users can tackle demanding tasks with ease.

Powerful Engine: The robust motor delivers exceptional torque, allowing for efficient cutting and a quick response time.

Lightweight Design: Its ergonomic structure minimizes fatigue, enabling extended use without discomfort.

Enhanced Filtration System: The superior air filtration mechanism extends service intervals and maintains performance even in dusty conditions.

Vibration Reduction: Innovative technology reduces vibrations, providing a smoother operation and increasing comfort during prolonged usage.

Easy Starting Mechanism: The simplified starting system ensures reliable ignition, allowing users to get to work without delay.

Overall, this model stands out for its combination of efficiency, comfort, and cutting-edge features, making it an ideal companion for any heavy-duty task.

Common Replacement Parts Overview

Maintaining the efficiency and longevity of outdoor power equipment often requires the timely replacement of certain components. Understanding which elements are prone to wear can help users ensure optimal performance and prevent unexpected breakdowns.

Key Components to Monitor

- Chains: Essential for cutting, chains may become dull or damaged over time.

- Filters: Air and fuel filters play a crucial role in engine performance; they should be checked regularly.

- Spark Plugs: These are vital for ignition and should be replaced periodically to ensure smooth operation.

- Fuel Lines: Inspect for cracks or wear, as damaged lines can lead to fuel leaks.

- Guide Bars: Over time, these may bend or wear out, impacting cutting efficiency.

Signs of Wear and When to Replace

- Diminished Cutting Performance: If cutting becomes less efficient, inspect the chain and guide bar.

- Starting Issues: Frequent problems starting the engine may indicate the need for a new spark plug or filter.

- Fuel Smell: An unusual smell could signal leaking fuel lines that require immediate attention.

- Visible Damage: Cracks, bends, or other visible damage on any component should prompt a replacement.

By regularly monitoring these crucial elements and addressing wear promptly, users can significantly enhance the reliability and performance of their equipment.

Where to Find Diagrams Online

Locating technical illustrations for machinery can significantly aid in maintenance and repairs. Various online resources provide access to these visual guides, making it easier for users to identify components and understand assembly processes.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Websites | Official sites often have downloadable manuals and illustrations. | Visit Manufacturer |

| Online Forums | Community discussions frequently share links and resources. | Join Forum |

| Repair Websites | Specialized sites offer guides and breakdowns for various models. | Explore Repair Sites |

| YouTube | Video tutorials often include detailed visuals and explanations. | Watch Videos |

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repair tasks. These visual aids offer a comprehensive overview of components, making it easier to identify and source the necessary elements for repairs. By grasping the layout and notation used in these images, users can streamline their approach to fixing machinery.

| Element | Description |

|---|---|

| Legend | A guide that explains symbols and notations used in the illustration. |

| Labels | Specific names or numbers assigned to each component for easy identification. |

| Connections | Lines that show how different parts are linked or interact with each other. |

| Views | Different angles or perspectives to provide a complete understanding of the assembly. |

By familiarizing yourself with these aspects, you can efficiently navigate through the visuals, ensuring you find the ultimate solutions for your maintenance needs.

Essential Tools for Repairs

When it comes to maintaining and fixing equipment, having the right instruments is crucial. The correct tools not only facilitate efficient repairs but also ensure that the job is done safely and effectively. Familiarity with these essential instruments can greatly enhance the repair process and extend the life of your machinery.

Basic Tool Set

A well-rounded collection of tools should include items such as wrenches, screwdrivers, and pliers. These fundamental tools serve various purposes and can handle most routine maintenance tasks. Investing in high-quality versions will ensure durability and reliability over time.

Specialized Instruments

For more complex repairs, specific tools like torque wrenches and diagnostic kits may be necessary. Using these specialized instruments allows for precise adjustments and accurate troubleshooting, ultimately leading to more successful outcomes. Delving into the specifics of your machinery will help you determine which specialized tools are essential for your repair needs.

Identifying Worn Out Components

Recognizing the signs of deterioration in essential machinery parts is crucial for maintaining optimal performance and longevity. By understanding how to spot wear, users can prevent unexpected breakdowns and costly repairs.

Common Signs of Wear

Components may exhibit various indicators of fatigue, such as unusual noises, decreased efficiency, or visible damage. Cracks, chips, and excessive play in moving parts are often telltale signs that replacement is necessary.

Assessment Techniques

Regular inspections can greatly aid in identifying issues early. Utilize visual checks and functional tests to evaluate the condition of each component. This proactive approach ensures that you can address problems before they escalate, ultimately enhancing the machine’s reliability.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing a few essential practices, you can enhance performance and extend the lifespan of your machinery.

Regular Cleaning: Keep the exterior and internal components free from debris and dirt. This prevents overheating and wear, ensuring optimal functionality.

Oil Changes: Frequent oil changes are crucial for maintaining engine health. Fresh oil reduces friction and helps components operate smoothly.

Inspection of Parts: Regularly check critical components for signs of wear. Addressing minor issues promptly can prevent major breakdowns.

Proper Storage: Store equipment in a dry, sheltered area to protect it from moisture and extreme temperatures. This reduces the risk of rust and other damage.

Follow Manufacturer Guidelines: Always adhere to the maintenance schedule and recommendations provided by the manufacturer to ensure optimal performance and longevity.

OEM vs. Aftermarket Parts Comparison

When considering replacement components for your equipment, it’s crucial to evaluate the differences between original and alternative options. Each type offers distinct advantages and disadvantages that can significantly impact performance and longevity.

Advantages of OEM Components

- Designed specifically for your machine, ensuring optimal compatibility.

- Typically backed by a manufacturer’s warranty, providing peace of mind.

- High-quality materials and craftsmanship, often resulting in longer lifespan.

Benefits of Aftermarket Options

- Often more affordable, making repairs and upgrades more accessible.

- A wider variety of choices available, allowing for customization.

- Some aftermarket brands offer enhanced performance features.

Ultimately, the choice between original and alternative components will depend on your specific needs, budget, and desired performance outcomes.

Step-by-Step Repair Guide

This guide provides a structured approach to addressing common issues with outdoor power equipment. By following these detailed steps, you can ensure effective troubleshooting and repairs, enhancing the longevity and performance of your device.

Tools and Materials Needed

Before starting any repair, gather the necessary tools and materials to streamline the process. A checklist can help ensure you have everything on hand.

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws |

| Wrench | To adjust and secure bolts |

| Replacement Parts | To swap out faulty components |

| Cleaning Supplies | For maintenance and debris removal |

Repair Steps

Follow these systematic steps to ensure a thorough and effective repair process. Always consult your manual for specific instructions regarding your equipment model.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components used in outdoor power equipment. Understanding these queries can enhance your experience and help in maintaining your tools effectively.

What should I consider when selecting a component?

When choosing a replacement, it’s essential to verify compatibility with your specific model and ensure the quality meets your performance expectations.

Where can I find reliable information about replacements?

Trusted manufacturers’ websites, authorized dealers, and user manuals provide accurate and detailed information regarding available components.

| Question | Answer |

|---|---|

| How often should I replace my components? | Replacement frequency depends on usage; regular inspection is recommended to identify wear and tear. |

| Can I install replacements myself? | Yes, many components can be easily installed, but consulting the manual or a professional is advised for complex parts. |

Resources for Further Learning

This section aims to provide valuable materials for those looking to deepen their understanding of machinery components and their maintenance. Exploring these resources can enhance your knowledge and skills significantly.

Online Tutorials and Videos

- YouTube channels dedicated to machinery repair.

- Webinars on maintenance best practices.

- Instructional videos from experienced technicians.

Books and Manuals

- Comprehensive guides on engine mechanics.

- Handbooks focusing on maintenance techniques.

- Reference books covering parts identification.