Understanding the Husqvarna LTH1742 Parts Diagram for Easy Maintenance

In the realm of gardening and lawn maintenance, the efficiency of a mowing machine hinges on its intricate assembly. A thorough comprehension of the various elements that constitute these machines is essential for effective operation and maintenance. Knowing how each part interacts can significantly enhance performance and longevity.

Visual representations serve as invaluable tools for users seeking to navigate the complexities of their machinery. These illustrations break down the numerous components into easily digestible sections, allowing for better identification and understanding. From the engine to the cutting deck, each segment plays a vital role in the overall functionality of the equipment.

Additionally, having access to a clear and detailed layout aids in troubleshooting issues and facilitates informed decision-making when it comes to repairs or replacements. By grasping the relationships between various sections, operators can ensure their machines remain in peak condition, ready to tackle any landscaping challenge that arises.

Understanding Husqvarna LTH1742 Overview

This section provides a comprehensive overview of a specific lawn care machine designed for efficiency and ease of use. With its robust design and advanced features, this model caters to the needs of both casual gardeners and professionals. The combination of power and functionality ensures optimal performance for maintaining lawns of various sizes.

Key Features

One of the standout attributes of this model is its powerful engine, which allows for effective grass cutting and maneuverability. Additionally, the ergonomic seating and controls enhance user comfort during operation. The cutting deck is designed for precision, ensuring an even finish and reducing the number of passes required for a well-manicured lawn.

Maintenance and Care

Proper upkeep is essential to maximize the lifespan of this equipment. Regular checks on the blades, engine, and other components can prevent potential issues and maintain optimal performance. Utilizing quality fuel and adhering to manufacturer recommendations for maintenance schedules are crucial for ensuring longevity and reliability.

Key Components of the LTH1742

Understanding the essential elements of this lawn tractor model is crucial for effective maintenance and repair. Each part plays a vital role in ensuring the machine operates smoothly and efficiently, contributing to overall performance and longevity.

| Component | Function |

|---|---|

| Engine | Provides the necessary power to operate the machine, driving the blades and wheels. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed adjustments and maneuverability. |

| Cutting Deck | Houses the blades that cut the grass, ensuring an even and efficient mowing process. |

| Fuel System | Stores and delivers fuel to the engine, critical for operation. |

| Wheels and Tires | Facilitate movement across various terrains, providing stability and traction. |

| Steering Mechanism | Allows the operator to guide the tractor easily, enhancing control and precision. |

| Battery | Powers the electrical components and starts the engine. |

Importance of Accurate Parts Diagrams

Detailed illustrations of components play a crucial role in maintenance and repair processes. They serve as visual guides that enable users to understand the intricate relationships between various elements within a system. This clarity is essential for both novices and experienced technicians alike, ensuring efficient and effective work.

Key benefits of having precise component illustrations include:

- Enhanced Understanding: Clear visuals help in grasping complex assemblies, making it easier to identify each part’s function.

- Efficient Repairs: Knowing exactly which elements are involved accelerates troubleshooting and reduces the risk of errors.

- Time Savings: Accurate visuals streamline the process, minimizing downtime and increasing productivity.

- Prevention of Miscommunication: Clear representations reduce the chances of misunderstandings between team members regarding repairs or replacements.

- Support for Ordering: Knowing the exact specifications and part numbers aids in procuring the correct items without delay.

In summary, reliable representations of components are invaluable tools that enhance operational efficiency, reduce errors, and ultimately contribute to the longevity and performance of the equipment.

Common Issues with Husqvarna Lawnmowers

When it comes to lawn maintenance equipment, users often encounter various challenges that can hinder performance. Understanding these typical problems is essential for effective troubleshooting and ensuring smooth operation throughout the mowing season.

One prevalent issue is engine starting difficulties. Owners may find that their machine struggles to start or fails to ignite altogether. This can stem from issues such as stale fuel, clogged air filters, or faulty spark plugs. Regular maintenance and prompt attention to these components can often resolve these issues.

Another common concern is uneven cutting. This can lead to an unsightly lawn and may be caused by dull blades, improper cutting height adjustments, or even an unevenly leveled mower deck. Ensuring blades are sharp and correctly aligned can significantly improve cutting performance.

Overheating is also frequently reported, particularly during hot weather or extended use. Insufficient oil levels or blocked cooling fins can contribute to this problem. Regular checks and maintenance of oil levels and air intakes can help prevent overheating.

Lastly, poor traction can be an issue, especially in wet or uneven terrain. Worn tires or inadequate tire pressure can affect the machine’s ability to maneuver effectively. Inspecting tires regularly and replacing them when necessary can enhance overall stability and performance.

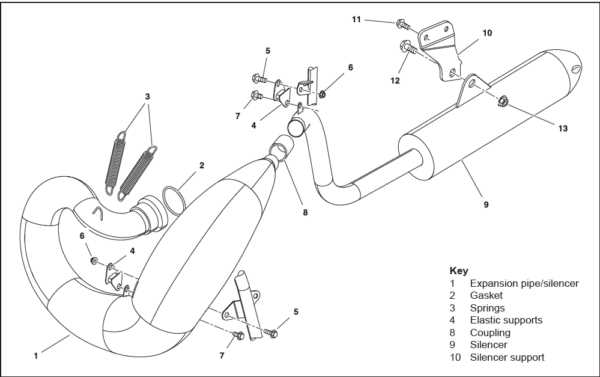

How to Interpret Parts Diagrams

Understanding technical illustrations is crucial for maintaining and repairing machinery. These visual guides provide essential information about components and their arrangements. By mastering how to read these illustrations, users can efficiently identify parts and their functions, leading to more effective maintenance practices.

Here are some key tips for interpreting these visuals:

- Familiarize Yourself with Symbols: Different illustrations use specific symbols to represent various components. Learning these symbols is the first step in understanding the overall layout.

- Follow the Numbering System: Most guides include a numbering or lettering system that correlates with a list of parts. This helps in locating and identifying each item accurately.

- Examine the Orientation: The perspective shown can affect how components fit together. Pay attention to the view (top, side, etc.) to understand spatial relationships.

To ensure successful interpretation, consider the following steps:

- Review the Legend: Most illustrations come with a legend explaining the symbols and lines used. This is an invaluable resource.

- Identify Major Components First: Start by locating the primary elements before delving into the details. This will provide context for smaller parts.

- Take Notes: As you analyze the visual, jot down any observations or questions you may have. This will aid in further research or discussions.

By following these guidelines, you can enhance your ability to navigate technical illustrations, making maintenance and repair tasks more manageable and efficient.

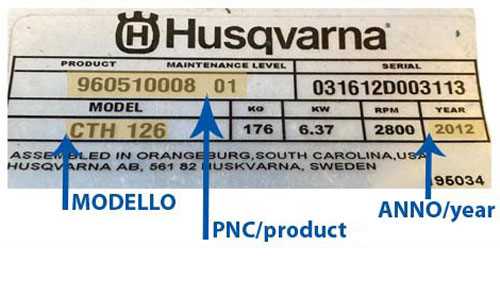

Replacing Parts on Your LTH1742

Maintaining the performance of your mower is essential for ensuring its longevity and efficiency. Over time, certain components may wear out or become damaged, necessitating their replacement. Understanding how to identify and replace these elements can greatly enhance the functionality of your machine and improve your overall mowing experience.

Identifying Worn Components

Regular inspection is key to catching issues early. Look for signs of wear such as unusual noises, vibrations, or decreased performance. Commonly affected areas include the cutting blades, belts, and filters. Keeping an eye on these parts can help you determine when it’s time for a change.

Steps for Replacement

Once you’ve identified the components that need replacing, gather the necessary tools and a suitable replacement. First, ensure the mower is powered off and safely secured. Next, follow the manufacturer’s guidelines for disassembling the relevant sections. Always consult a reference guide if you are unsure about the process. After removing the old component, install the new one carefully, ensuring everything is aligned correctly. Finally, test the equipment to confirm it operates smoothly.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-lasting performance of your equipment. By following a structured maintenance routine, you can enhance efficiency, prevent breakdowns, and extend the lifespan of your machine. Below are some key practices to help you maintain optimal functionality.

1. Clean Regularly: Dust, debris, and grass clippings can accumulate over time, affecting performance. Make it a habit to clean your equipment after each use, focusing on air filters and cutting decks to prevent clogging.

2. Check Fluids: Regularly inspect and replace engine oil, fuel, and other vital fluids. Fresh fluids ensure smooth operation and reduce wear and tear on engine components.

3. Inspect Blades: Dull or damaged blades can hinder performance and affect the quality of your work. Sharpen or replace blades as needed to maintain efficiency and ensure a clean cut.

4. Tighten Bolts and Screws: Vibration during operation can loosen fasteners. Periodically check and tighten all bolts and screws to maintain structural integrity and prevent accidents.

5. Store Properly: When not in use, store your equipment in a dry, sheltered location. Protect it from the elements to prevent rust and damage, ensuring it’s ready for use when needed.

6. Follow the Manufacturer’s Guidelines: Always refer to the user manual for specific maintenance schedules and recommendations. Adhering to these guidelines will help you keep your machine in optimal condition.

Implementing these maintenance strategies will not only enhance the performance of your equipment but also save you time and money on repairs in the long run.

Where to Find Genuine Parts

When it comes to maintaining your equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine items are designed to fit perfectly and function seamlessly, making them a smart investment for any user.

There are several reliable sources for acquiring these essential items:

| Source | Description |

|---|---|

| Authorized Dealers | These retailers offer a wide range of authentic components and often provide expert advice on installation and maintenance. |

| Official Websites | Manufacturer’s websites usually feature a dedicated section for ordering genuine items, ensuring you receive high-quality products. |

| Local Repair Shops | Many repair facilities carry authentic components and can assist with installation, ensuring that your equipment is in expert hands. |

| Online Marketplaces | Reputable e-commerce sites may offer a selection of genuine items, but it’s important to verify the seller’s credibility before making a purchase. |

By choosing the right source for your replacements, you can ensure that your machinery remains in excellent working condition for years to come.

DIY Repairs for Lawn Equipment

Maintaining your lawn machinery can be both cost-effective and rewarding. By tackling simple repairs yourself, you not only save money but also gain a deeper understanding of how your equipment operates. This section provides essential tips and techniques for handling common issues that may arise with your outdoor tools.

Identify Common Problems: The first step in any repair is recognizing the symptoms. Whether it’s a mower that won’t start or a trimmer that’s sputtering, pinpointing the issue can save you time and effort. Familiarize yourself with the usual signs of wear and tear, such as unusual noises or poor performance.

Gather Necessary Tools: Before diving into a repair, ensure you have the right tools at hand. Basic equipment like wrenches, screwdrivers, and pliers can help you tackle most tasks. Having a clean workspace and organized tools will make the process smoother and more efficient.

Follow Safety Protocols: Always prioritize safety when working on your equipment. Disconnect the power source or remove the spark plug before starting any repairs. Wear appropriate protective gear to prevent accidents, ensuring that your DIY project is both safe and successful.

Consult Manuals and Resources: Utilizing manufacturer manuals or online guides can provide valuable insights into specific repair procedures. These resources often include troubleshooting tips and step-by-step instructions that can simplify your repair process.

Practice Preventive Maintenance: Regular maintenance can help avoid major repairs down the line. Keep your equipment clean, sharpen blades regularly, and check for signs of wear. By taking these proactive steps, you can extend the life of your tools and enhance their performance.

With the right approach and knowledge, tackling repairs on your lawn equipment can be an enjoyable and educational experience. Empower yourself with these skills, and you’ll find that many repairs are well within your capabilities.

Comparing LTH1742 with Similar Models

When evaluating a particular lawn care machine, it’s essential to consider how it stands against comparable models in the market. By examining features, performance, and overall value, potential buyers can make informed decisions that best suit their needs. This analysis focuses on key characteristics that differentiate this model from its peers, highlighting strengths and weaknesses across similar offerings.

In terms of engine performance, several alternatives boast comparable horsepower, but variations in torque and fuel efficiency can influence user experience significantly. Additionally, the cutting width and deck design play crucial roles in maneuverability and effectiveness, particularly in tight spaces or uneven terrain. Some competitors may offer enhanced cutting systems, which can improve the quality of the finished lawn.

Another vital aspect to consider is the comfort and ergonomics of the operator. Features such as adjustable seats, steering ease, and vibration dampening can enhance the overall experience. While many machines provide basic comfort, a few stand out with premium features that cater to extended usage.

Durability and build quality are also critical factors. Some models are constructed with more robust materials, promising longevity and reduced maintenance needs. Analyzing user reviews and feedback can provide insight into which models consistently outperform others in this regard.

Finally, pricing and warranty options should not be overlooked. While some machines might come with a higher initial cost, their long-term reliability and service packages can make them a more economical choice over time. By thoroughly comparing these aspects, consumers can identify which lawn care solution aligns best with their expectations and requirements.

Customer Reviews and Experiences

Gathering insights from users is crucial for understanding the performance and reliability of any outdoor equipment. Feedback from customers provides a wealth of information that can help prospective buyers make informed decisions. This section explores various reviews and personal experiences, highlighting both positive aspects and areas for improvement.

Positive Feedback

Many users have praised the ease of use and efficiency of their machinery. Convenience in operation has been a recurring theme, with several reviewers noting how quickly they adapted to the controls. Additionally, the durability of the components has been highlighted, with customers expressing satisfaction over the longevity of their devices even after extended use.

Challenges Faced

While many experiences have been positive, some users reported challenges. Maintenance issues were mentioned, with a few customers finding certain parts difficult to access for regular upkeep. Moreover, there were comments about the availability of replacement components, indicating a desire for better support in sourcing necessary items. Such feedback is invaluable, as it sheds light on potential areas for enhancement in future models.