Understanding Husqvarna Part Diagrams for Easy Repairs

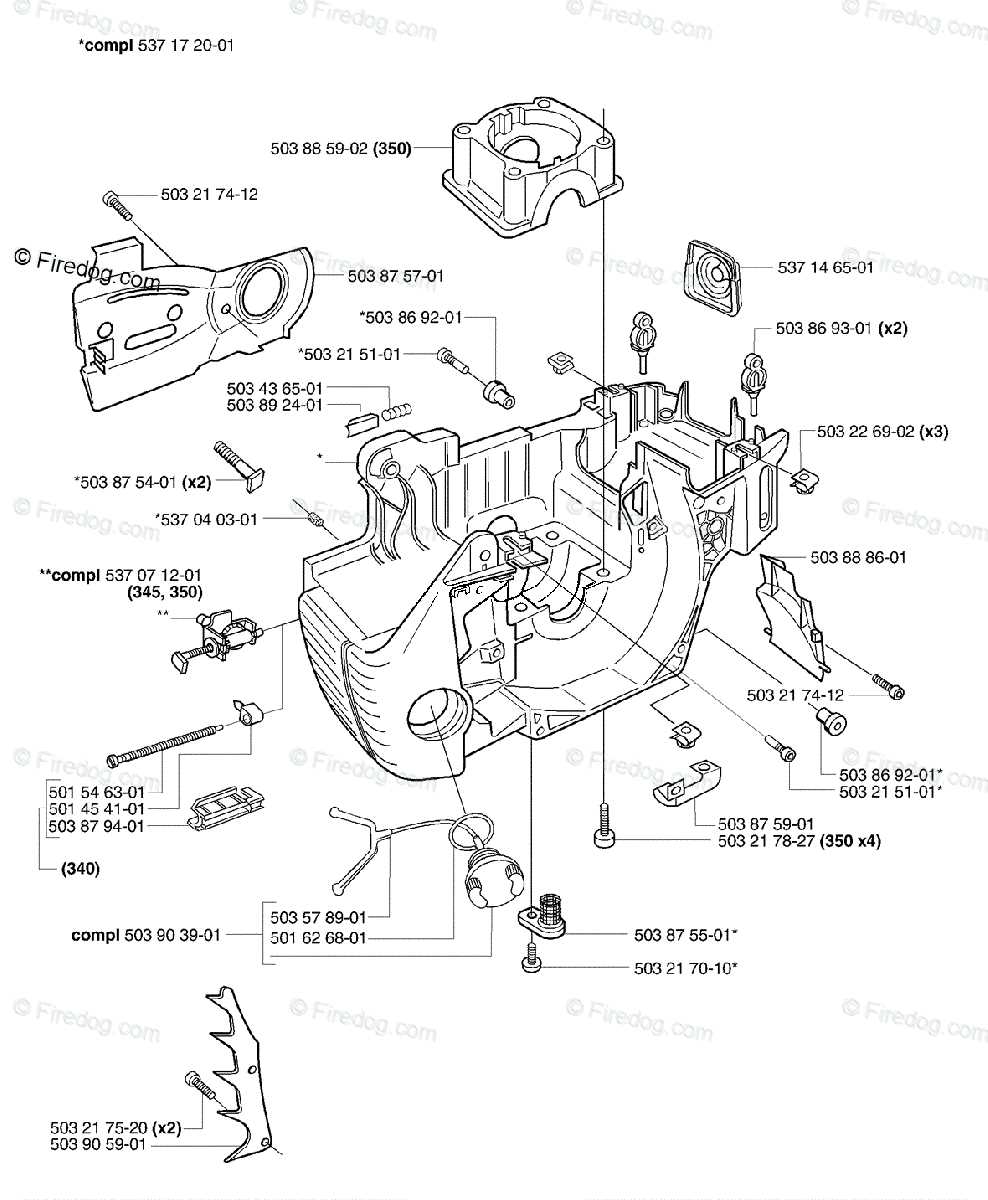

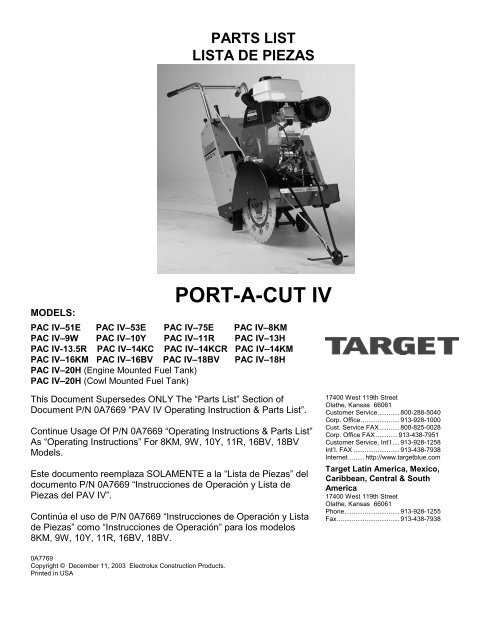

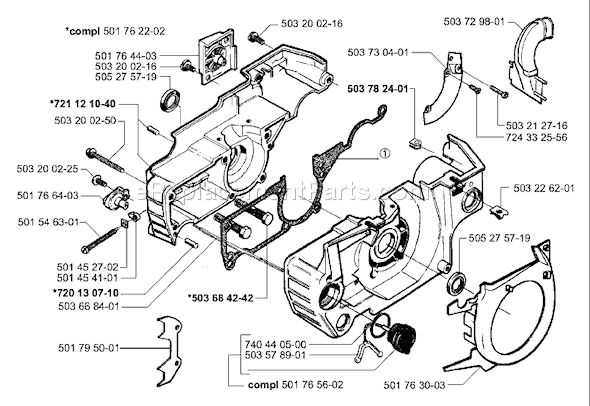

In the realm of machinery and outdoor equipment, having a clear visual representation of individual elements is essential for optimal upkeep and repair. This section delves into the significance of detailed schematics that outline the various components of a device, enabling users to better grasp its assembly and functionality. Such visual aids serve as indispensable tools for both novice and experienced technicians alike.

By exploring these comprehensive layouts, one can gain insights into the intricate relationships between different parts, ensuring that any maintenance or troubleshooting efforts are conducted with precision. With a thorough understanding of the arrangement and interaction of these elements, operators can effectively address issues that may arise, thereby enhancing the longevity and performance of their equipment.

Furthermore, recognizing the specific roles and positions of each component empowers users to source replacements or upgrades with confidence. This knowledge fosters not only skill development but also a deeper appreciation for the craftsmanship involved in the design of these machines. Ultimately, the ability to visualize and understand the intricate details of a device’s structure paves the way for informed decision-making and successful operation.

Understanding Husqvarna Part Diagrams

Comprehending the layout of components for outdoor machinery is essential for efficient maintenance and repair. These visual representations provide a clear insight into how different elements fit together, making it easier for users to identify and troubleshoot issues. Grasping the structure not only aids in proper assembly but also enhances the overall understanding of the equipment’s functionality.

Importance of Visual Representations

- Facilitates easier identification of individual components.

- Assists in understanding the assembly process.

- Improves troubleshooting efficiency by showcasing connections.

- Guides users in ordering the correct replacements.

How to Use Component Layouts Effectively

- Familiarize yourself with the overall structure before diving into details.

- Locate the specific section related to your issue or repair needs.

- Match the parts to your equipment to ensure compatibility.

- Refer to annotations for guidance on assembly and disassembly.

Importance of Accurate Parts Identification

Identifying components with precision is crucial for ensuring the optimal functioning of any machinery. When each element is recognized correctly, it facilitates efficient repairs, minimizes downtime, and enhances the longevity of the equipment. Accurate identification helps users understand the specific requirements for maintenance and replacement, ultimately leading to better performance and reliability.

Furthermore, the availability of precise information allows technicians and operators to avoid errors that could result in costly repairs or operational failures. It fosters a deeper understanding of the machinery, empowering individuals to make informed decisions regarding upkeep and troubleshooting. This level of awareness is essential in maintaining operational efficiency and preventing disruptions in workflow.

In industries where performance and safety are paramount, having the right knowledge about each component is indispensable. It not only streamlines the repair process but also contributes to the overall safety of the equipment. Misidentification can lead to improper installations or use of incompatible elements, posing risks to both the machinery and the personnel operating it.

In conclusion, accurate recognition of individual elements is vital for successful maintenance and operational effectiveness. By prioritizing this aspect, users can ensure that their equipment runs smoothly and efficiently, ultimately enhancing productivity and safety in their respective fields.

Navigating the Husqvarna Online Resources

In today’s digital age, accessing information about machinery and tools has become more straightforward. Users can find detailed resources online that facilitate understanding and maintenance of their equipment. This section aims to guide you through effective strategies for locating and utilizing these invaluable resources, ensuring you get the most out of your tools.

Explore Official Websites: The primary step is to visit the manufacturer’s official website. Here, you’ll find comprehensive guides, manuals, and support sections dedicated to various models. Look for sections labeled “Support” or “Resources” to access a wealth of information tailored to your specific needs.

Utilize Search Functions: Most websites offer search functionalities that allow you to input model numbers or keywords. This feature can streamline your search, directing you to the most relevant information quickly. Make sure to use precise terms to enhance your results.

Engage with Online Communities: Forums and discussion groups dedicated to equipment enthusiasts can provide practical advice and insights. Users often share experiences, tips, and tricks that can help you troubleshoot common issues or optimize the use of your machinery.

Downloadable Resources: Many official sites offer downloadable manuals and guides. These documents can be invaluable for on-the-go reference. Ensure you have the latest versions to access the most current information about your equipment.

Video Tutorials: Visual learners may benefit from video content available on various platforms. Tutorials can walk you through specific processes, providing a step-by-step guide that is often easier to follow than written instructions.

By leveraging these online resources, you can enhance your knowledge and skills, ensuring your equipment remains in optimal condition and performs effectively for years to come.

Common Components in Husqvarna Equipment

Understanding the essential elements of outdoor machinery is crucial for maintenance and performance optimization. Various models feature specific parts that contribute to their overall functionality. Familiarity with these components aids in troubleshooting and enhances the longevity of the equipment.

| Component | Description | Function |

|---|---|---|

| Engine | A power unit that converts fuel into mechanical energy. | Drives the entire system, providing necessary force for operation. |

| Blade | A sharp cutting element, often made from high-strength steel. | Cuts grass, shrubs, or other vegetation efficiently. |

| Fuel Tank | A reservoir designed to hold fuel for combustion. | Supplies energy to the engine for prolonged use. |

| Air Filter | A filter that prevents dirt and debris from entering the engine. | Ensures optimal air flow, enhancing engine performance and longevity. |

| Handlebar | The control interface for maneuvering the device. | Allows the operator to guide the equipment safely and effectively. |

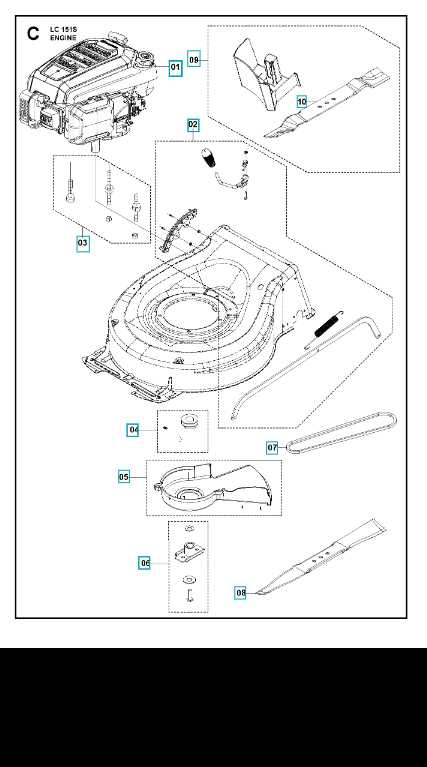

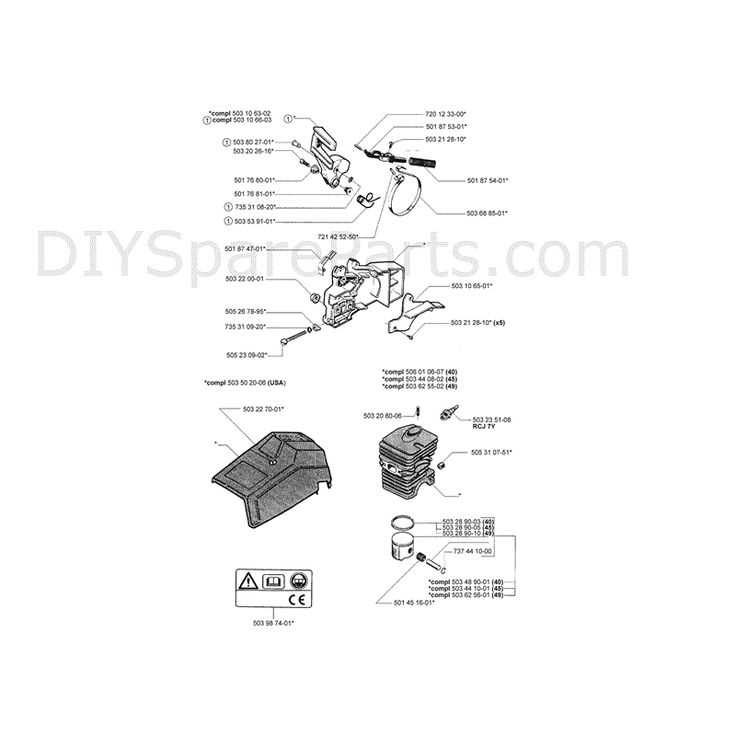

How to Use Part Diagrams Effectively

Understanding and utilizing technical illustrations can significantly enhance your ability to maintain and repair machinery. These visual aids provide a detailed representation of components, enabling users to identify parts and comprehend their interrelationships. Effectively leveraging these resources can streamline repairs and improve overall efficiency in handling equipment.

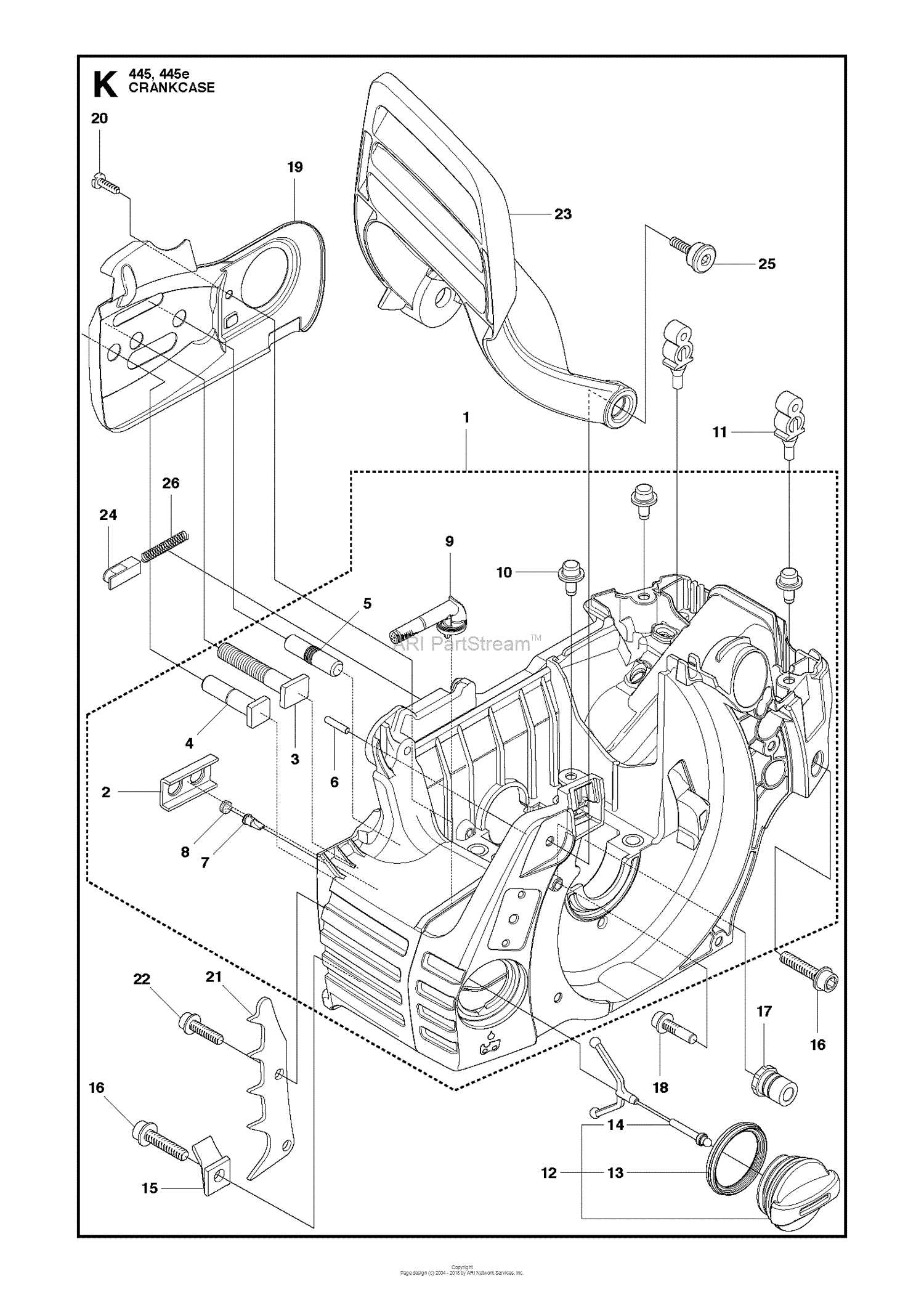

Familiarize Yourself with the Layout

Before diving into repairs, take time to study the layout of the illustration. Each section typically corresponds to specific areas of the machinery, often organized in a logical sequence. Recognizing how different elements are grouped allows for quicker reference when troubleshooting or ordering replacements. Pay attention to notations that indicate part numbers and descriptions, as they are crucial for accurate identification.

Utilize the Information for Efficient Repairs

When performing maintenance tasks, refer back to the visual representation regularly. Cross-referencing the image with your actual equipment can help you pinpoint issues more effectively. If a component appears damaged or worn, consult the illustration to confirm its specifications and locate compatible replacements. This method minimizes errors and ensures you have the correct items before starting repairs, ultimately saving time and resources.

Identifying Replacement Parts Quickly

Efficiently locating the necessary components for your equipment can significantly reduce downtime and enhance productivity. Understanding how to navigate through various resources is essential for quick identification. By leveraging visual aids and comprehensive guides, users can streamline the process of finding the correct items without unnecessary delays.

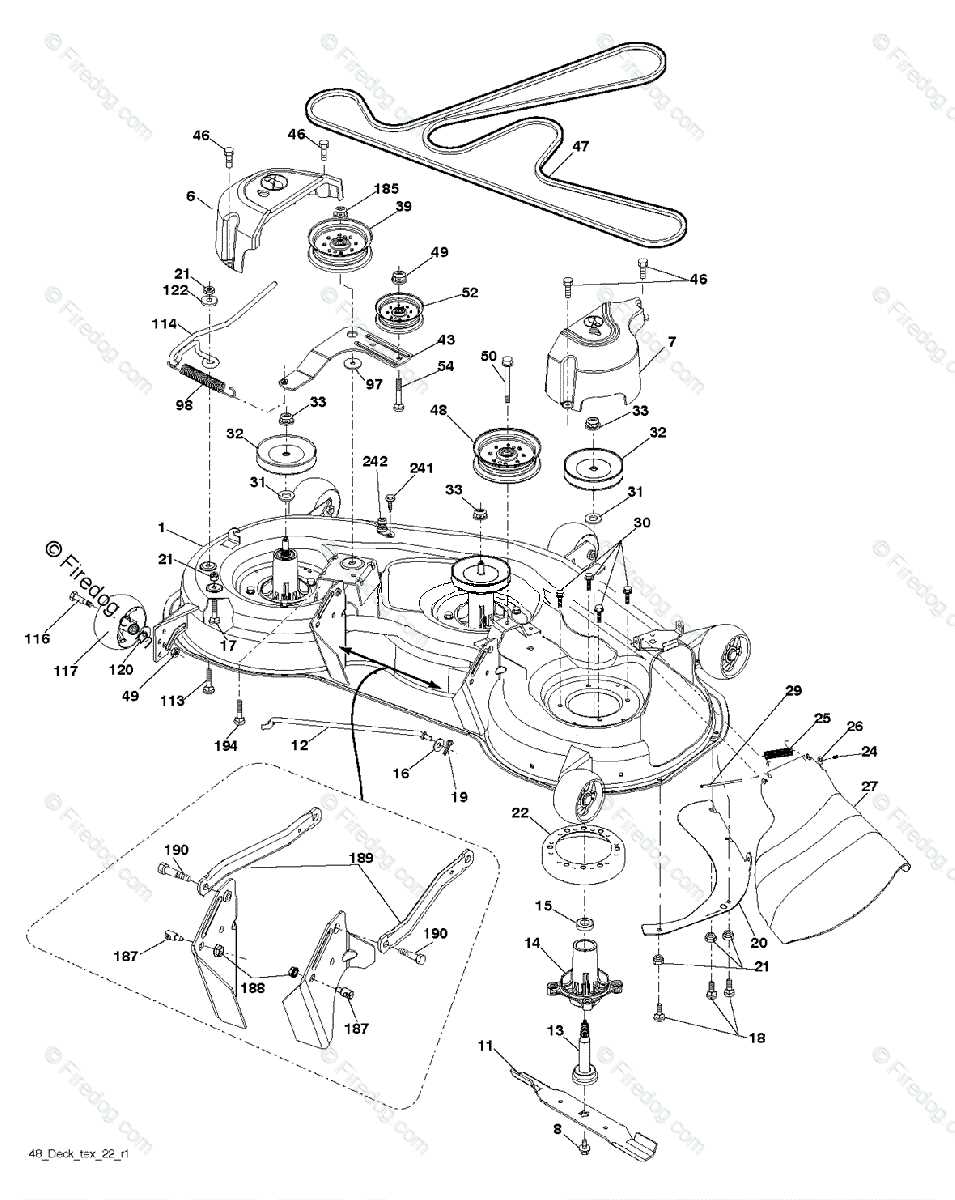

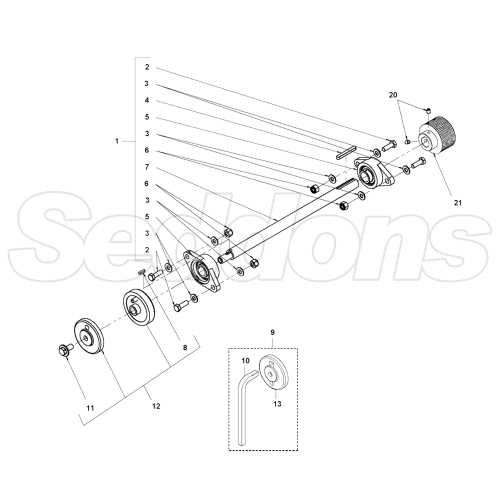

Utilizing exploded views and labeled illustrations allows for a clearer understanding of the assembly and relationship between different elements. When faced with a malfunction or the need for an upgrade, these resources become invaluable. Familiarizing oneself with the terminology and layout of these guides facilitates rapid recognition of required components.

Moreover, cross-referencing model numbers and specifications can aid in verifying compatibility and ensuring the right selection. Maintaining a systematic approach to categorizing and storing these resources can further enhance efficiency. With the right tools and knowledge, anyone can quickly pinpoint what is needed for their machinery, ensuring seamless operation.

Maintenance Tips for Husqvarna Products

Ensuring the longevity and optimal performance of outdoor equipment requires regular upkeep and attention. Implementing a systematic maintenance routine can prevent potential issues and enhance efficiency.

Here are some essential maintenance suggestions:

- Regular Cleaning: Keep the exterior and interior components free from debris and dirt. This prevents wear and tear and allows for better performance.

- Inspect the Blades: Check cutting tools for damage or dullness. Sharpen or replace them as needed to ensure clean cuts.

- Check Fluid Levels: Regularly monitor oil and fuel levels. Ensure they meet the manufacturer’s specifications for optimal operation.

- Air Filter Maintenance: Clean or replace air filters to maintain airflow and engine efficiency, particularly in dusty environments.

- Battery Care: For battery-operated models, ensure the battery is charged and stored properly to extend its lifespan.

By following these guidelines, users can enhance the functionality and durability of their equipment, ensuring it remains in top condition for years to come.

Where to Find Official Manuals

Accessing the correct documentation is crucial for the proper maintenance and repair of equipment. Official manuals provide detailed information, including specifications, assembly instructions, and troubleshooting tips, ensuring that users can effectively handle their machinery. Finding these resources can significantly enhance the user experience and extend the lifespan of the products.

Online Resources: The primary source for official documentation is the manufacturer’s website. Many companies offer downloadable PDFs or online manuals for various models. Simply navigate to the support or resources section to find the relevant documents.

Retail Outlets: Authorized dealers and retailers often have printed manuals available. Visiting these locations can provide access to both physical copies and expert assistance in locating the appropriate documentation for specific models.

Customer Support: Reaching out to customer service can be an effective way to obtain the necessary guides. Representatives can direct you to the right resources or send the manuals directly via email or other means.

Community Forums: Engaging with online communities or forums dedicated to equipment can yield valuable insights. Users often share links to manuals or offer tips on where to find them, fostering a collaborative environment for troubleshooting and information sharing.

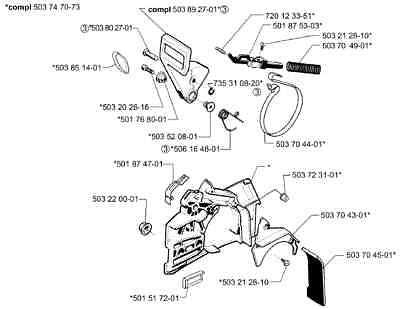

Interpreting Symbols and Notations

Understanding the visual language used in technical illustrations is essential for effective communication and accurate interpretation of information. Each symbol and notation serves a specific purpose, guiding users in identifying components and their relationships within a complex system.

Here are some common symbols and notations you might encounter:

- Circles: Often indicate connectors or junctions between various elements.

- Arrows: Show direction of movement or flow, indicating how parts interact with each other.

- Boxes: Typically represent individual components or units within the assembly.

- Lines: Can signify electrical connections or physical links between parts.

To better grasp these representations, consider the following steps:

- Familiarize yourself with the legend or key that accompanies the illustration.

- Identify the main components and how they relate to one another.

- Pay attention to annotations, which provide additional context and details.

- Practice interpreting different examples to build your understanding of the conventions used.

By mastering the symbols and notations, users can enhance their ability to troubleshoot, repair, and maintain equipment effectively.

Ordering Parts from Authorized Dealers

Acquiring components from certified retailers ensures quality and compatibility with your equipment. This section outlines the benefits and steps for sourcing items through authorized channels.

There are several advantages to choosing official distributors:

- Guaranteed authenticity of the items

- Access to expert advice and support

- Potential for warranty coverage

- Assurance of proper fitting and functionality

To effectively order components, follow these steps:

- Identify the specific item needed using the relevant reference.

- Locate a nearby certified dealer through the official website or customer service.

- Contact the dealer to confirm availability and pricing.

- Provide necessary details, such as model number and any specific requirements.

- Complete the purchase and inquire about shipping options, if applicable.

By following these guidelines, you can ensure a smooth and efficient process for obtaining necessary items for your machinery.

Benefits of Regular Equipment Maintenance

Regular upkeep of machinery is essential for ensuring optimal performance and longevity. This practice not only enhances efficiency but also minimizes the risk of unexpected breakdowns, allowing users to maintain productivity without interruption.

Improved Performance: Consistent maintenance helps to keep equipment running smoothly. By regularly checking and adjusting components, operators can ensure that machines operate at their peak efficiency, which translates to better results and lower energy consumption.

Increased Lifespan: Just like any other investment, machinery requires care to extend its useful life. Routine checks and repairs can prevent minor issues from escalating into major problems, thus safeguarding the integrity of the equipment over time.

Cost Savings: Investing in maintenance can lead to significant savings in the long run. By addressing potential issues early, operators can avoid costly repairs and replacements. Additionally, well-maintained equipment typically operates more efficiently, reducing overall operational costs.

Safety Assurance: Regular inspections play a crucial role in ensuring safety for operators and those around them. Maintaining equipment helps identify and rectify hazards, thereby minimizing the risk of accidents and injuries in the workplace.

Enhanced Resale Value: Properly maintained machinery retains its value better than neglected units. When it comes time to sell or upgrade, having a documented maintenance history can significantly enhance the resale value of the equipment.