Husqvarna T540XP Components Overview

The efficient functioning of any machinery relies on the intricate design and arrangement of its elements. A thorough comprehension of these configurations is essential for users and technicians alike. This section aims to explore the significance of component layouts in enhancing performance and facilitating maintenance.

By examining the arrangement of individual elements, one can gain valuable insights into how each piece contributes to the overall operation. Understanding these schematics not only aids in identifying potential issues but also empowers users to perform effective repairs and upgrades. This knowledge is crucial for anyone looking to maintain their equipment in optimal condition.

Whether you are a seasoned professional or a novice, familiarizing yourself with these configurations will enhance your capability to troubleshoot and optimize machinery. The ability to interpret these layouts can significantly reduce downtime and improve the longevity of your equipment.

Key Components of the T540XP

The effective operation of any high-performance equipment relies on its essential elements, each designed to perform specific functions. Understanding these components is crucial for maintaining optimal performance and longevity of the machine. In this section, we will explore the primary parts that contribute to the efficiency and reliability of this particular model.

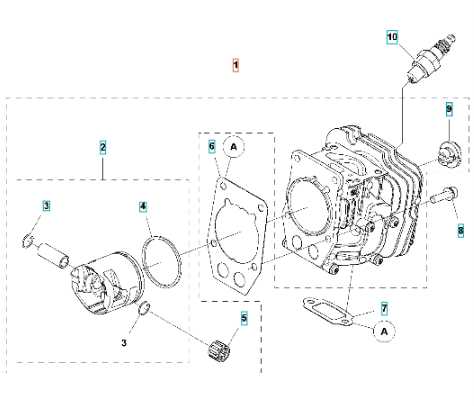

Engine Assembly: The heart of the unit, the engine assembly, drives the entire system, providing the necessary power for operation. Its design is optimized for both performance and fuel efficiency, ensuring that users can accomplish their tasks without frequent interruptions.

Guide Bar and Chain: This system is critical for cutting tasks. The guide bar provides stability and support, while the chain is engineered for precision cutting. Together, they enhance the effectiveness of the tool, making it suitable for various applications.

Air Filtration System: An efficient air filtration system ensures that the engine receives clean air, preventing debris and contaminants from causing damage. This component is vital for maintaining the machine’s performance over time, especially in challenging environments.

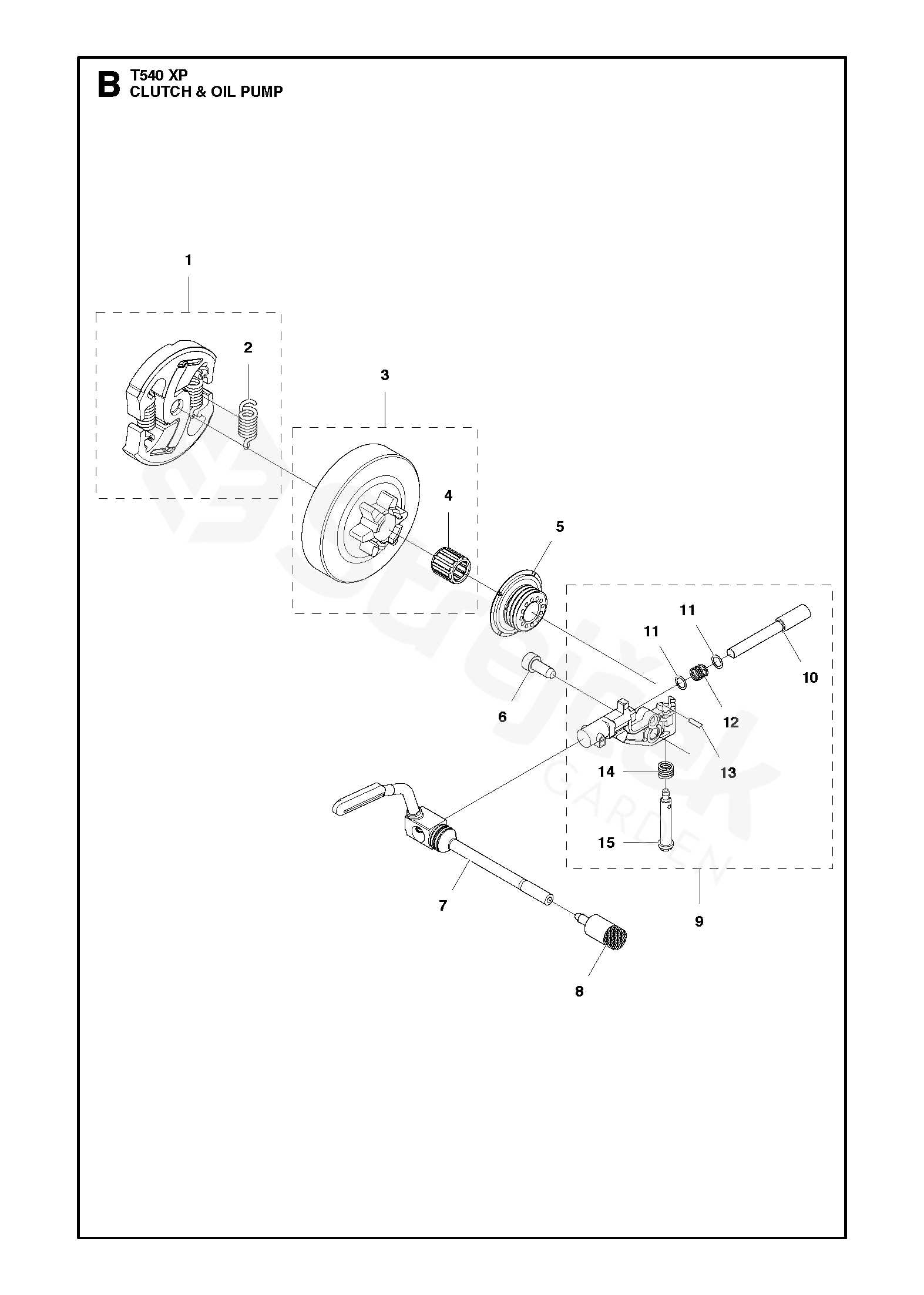

Detailed Parts Breakdown

This section offers an in-depth exploration of the various components that make up a specific model of a high-performance machine. Understanding the individual elements is essential for effective maintenance, repairs, and overall performance enhancement. Each component plays a critical role, contributing to the machine’s efficiency and reliability.

Key Components Overview

The essential parts include the engine assembly, fuel system, and cutting mechanism. Each of these components must be well understood to ensure optimal operation. The engine assembly provides the necessary power, while the fuel system ensures that the engine receives the correct mixture for combustion. The cutting mechanism is crucial for achieving precise results in its intended applications.

Maintenance Considerations

Regular inspection of these components can prevent unexpected failures and prolong the lifespan of the equipment. Proper maintenance involves checking for wear and tear, cleaning, and timely replacement of any worn-out elements. By adhering to these practices, users can maintain the effectiveness and efficiency of their machinery over time.

Maintenance Essentials for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By adhering to maintenance routines, operators can enhance performance, reduce downtime, and extend the lifespan of their machinery. This section outlines key practices and components that contribute to optimal functionality.

Regularly checking and replacing essential elements plays a crucial role in maintaining peak operation. Below is a table that highlights vital components along with recommended maintenance actions and intervals.

| Component | Maintenance Action | Recommended Interval |

|---|---|---|

| Air Filter | Clean or replace | Every 25 hours of use |

| Spark Plug | Inspect and replace if necessary | Every 50 hours of use |

| Chain Oil | Check and refill | Before each use |

| Bar and Chain | Inspect for wear and tension | Every 10 hours of use |

Following these maintenance essentials will help ensure your equipment operates efficiently and reliably, providing optimal results for your tasks.

Common Replacement Parts for T540XP

Maintaining optimal performance in a power tool requires the timely replacement of various components. Understanding which elements may need to be swapped out can help ensure longevity and efficiency in operation. Here are some frequently replaced items that users should be aware of.

- Chainsaw Bar: The bar may wear out over time, impacting cutting efficiency.

- Chain: A dull or damaged chain can hinder performance, making regular checks essential.

- Air Filter: A clean filter is crucial for optimal airflow and engine performance.

- Fuel Filter: Ensuring a clean fuel filter helps maintain engine health and efficiency.

- Spark Plug: Regularly replacing the spark plug can improve starting and overall engine function.

- Oil Pump: A functioning oil pump is vital for lubrication and cooling of the chain.

By being proactive about these components, users can enhance the reliability and lifespan of their equipment.

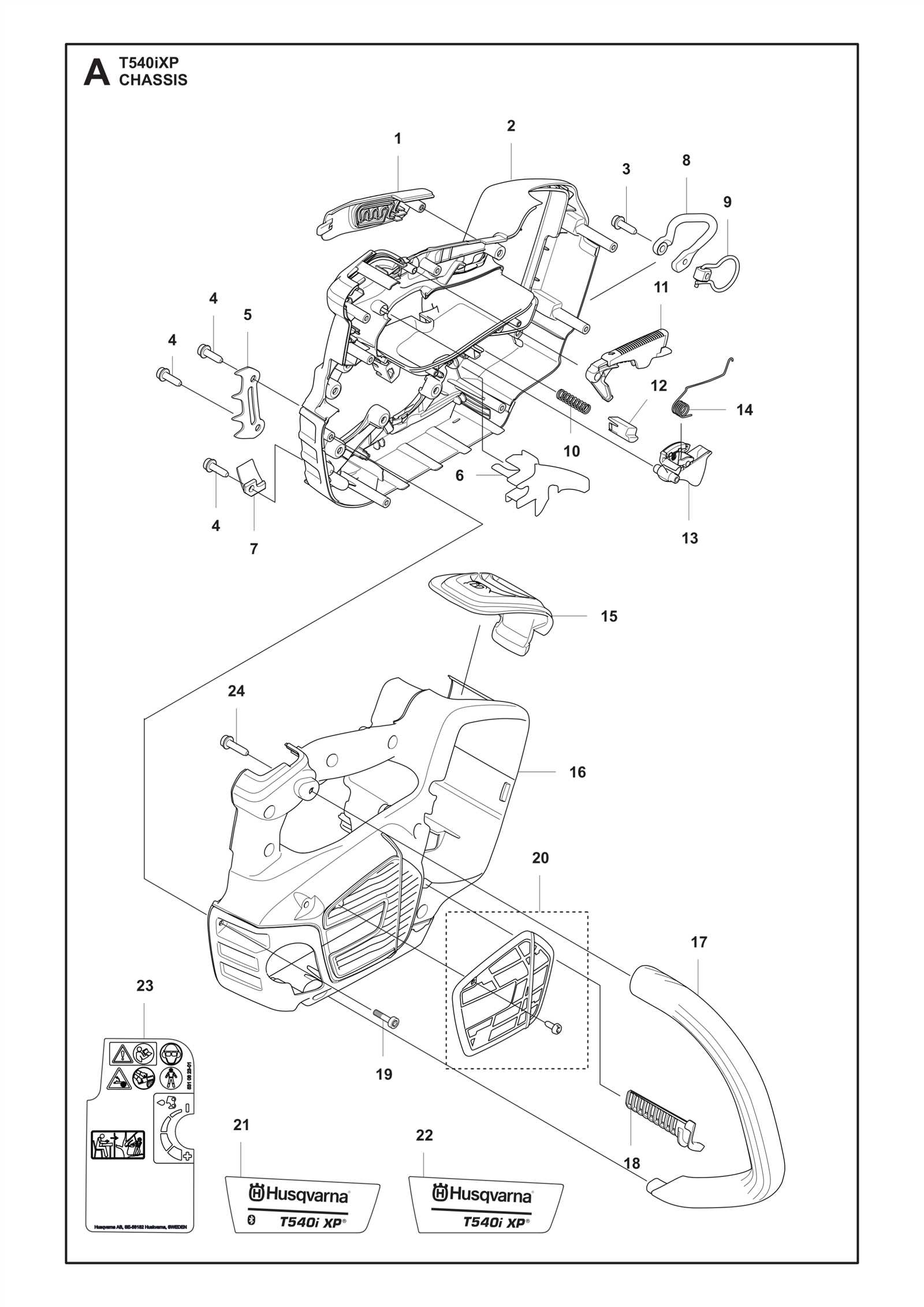

Visual Guide to Parts Diagram

This section provides an overview of a visual representation designed to assist users in identifying and understanding various components of a specific device. Such an illustration simplifies the process of locating parts, ensuring that users can effectively maintain and repair their equipment.

Understanding Component Layout

The illustration typically categorizes different elements, showcasing their arrangement and interconnections. By examining this layout, users can gain insights into how each part functions within the overall system. This knowledge is crucial for effective troubleshooting and routine maintenance.

Utilizing the Visual Representation

To make the most of this guide, users should familiarize themselves with the symbols and labels present in the visual representation. Identifying parts accurately will streamline repair processes and enhance the longevity of the equipment. Regular reference to this guide can empower users to tackle maintenance tasks confidently.

Identifying Genuine Parts vs. Counterfeits

In the world of machinery and equipment, distinguishing authentic components from imitations is crucial for ensuring optimal performance and longevity. Recognizing the signs of counterfeit items can save users from potential issues, including safety hazards and financial losses.

Key Features of Authentic Components

When evaluating components, consider the following characteristics that typically indicate genuineness:

- Brand Markings: Authentic items usually have clear, consistent branding and logos.

- Quality of Materials: Genuine components are manufactured from high-quality materials, ensuring durability.

- Packaging: Look for professional packaging with tamper-proof seals and proper labeling.

- Price Point: Extremely low prices can be a red flag for counterfeit products.

Signs of Counterfeit Components

Identifying counterfeit items involves recognizing certain warning signs, such as:

- Poor craftsmanship, including rough edges or inconsistent finishes.

- Lack of documentation or warranty information.

- Missing or incorrect branding.

- Suspiciously low pricing compared to market value.

Being vigilant and informed can significantly enhance the chances of acquiring reliable and effective components for your equipment.

Assembly and Disassembly Instructions

This section provides a comprehensive guide on the procedures for putting together and taking apart specific equipment components. Proper handling during these processes is crucial for maintaining optimal functionality and ensuring the longevity of the device. The following steps will outline essential techniques and precautions to follow.

Disassembly Procedure

Begin by preparing your workspace, ensuring it is clean and well-organized. Gather all necessary tools to avoid interruptions. Follow these steps to safely disassemble the unit:

- Disconnect any power source to prevent accidental activation.

- Carefully remove outer casing screws and gently lift the casing off.

- Identify and detach internal components by following the connection pathways.

Assembly Procedure

Reassembly should be approached with attention to detail. Ensure all components are clean and undamaged before proceeding. Follow these steps to correctly assemble the unit:

- Place the main components back in their original positions.

- Reconnect all wires and ensure connections are secure.

- Reattach the outer casing and fasten all screws firmly.

| Step | Description |

|---|---|

| 1 | Prepare your workspace and tools. |

| 2 | Disconnect the power source. |

| 3 | Remove screws and casing. |

| 4 | Detach components methodically. |

| 5 | Reassemble following the reverse order. |

Tools Required for Repairs

When it comes to maintaining and fixing outdoor machinery, having the right instruments is essential. A well-equipped toolbox can make the repair process more efficient and effective, ensuring that each task is completed with precision. Below are the essential tools needed for successful repairs.

Essential Hand Tools

- Screwdrivers: A set of both flathead and Phillips screwdrivers in various sizes.

- Wrenches: Open-end and socket wrenches for loosening and tightening bolts.

- Pliers: Needle-nose and standard pliers for gripping and manipulating components.

- Hex Keys: Allen wrenches for accessing screws in tight spaces.

Specialized Equipment

- Torque Wrench: To ensure fasteners are tightened to manufacturer specifications.

- Multimeter: For diagnosing electrical issues and checking voltage.

- Chain Breaker Tool: For repairing or replacing the chain on cutting equipment.

- Lubrication Tools: Oiling cans and grease guns for maintaining moving parts.

T540XP Troubleshooting Tips

When operating power equipment, encountering issues is a common occurrence. This section offers guidance to effectively identify and resolve typical problems that may arise, ensuring optimal performance and longevity of the machinery.

Common Issues and Solutions

- Starting Difficulties:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean and unobstructed.

- Unusual Noises:

- Listen for loose parts or components.

- Examine the chain and guide bar for proper alignment.

- Check the engine oil level and condition.

- Decreased Performance:

- Inspect the fuel mixture ratio.

- Ensure the carburetor is functioning correctly.

- Examine the condition of the cutting chain.

Maintenance Tips

- Regularly clean the air filter to prevent clogging.

- Change the spark plug at recommended intervals.

- Lubricate moving parts to reduce friction.

- Store the equipment in a dry, protected environment.

Upgrades and Modifications Available

Enhancing the performance and versatility of your equipment can significantly improve its efficiency and longevity. Various upgrades and modifications are accessible to users looking to optimize their tools for specific tasks or to enhance their overall functionality. These enhancements can range from simple accessory additions to comprehensive modifications that change the tool’s capabilities.

Performance Enhancements

Performance upgrades often focus on increasing power and efficiency. Options may include high-performance air filters that improve airflow, specialized spark plugs for better ignition, or upgraded fuel systems that enhance fuel delivery. Implementing these modifications can lead to smoother operation and increased cutting speed.

Ergonomic Improvements

Comfort and usability are crucial for prolonged use. Ergonomic modifications can include custom grips, improved harness systems, and vibration dampeners. These adjustments not only enhance user comfort but also reduce fatigue, enabling longer working hours without discomfort.

Where to Purchase Replacement Parts

Finding suitable components for your equipment can significantly enhance its performance and longevity. There are various avenues for acquiring high-quality replacements, ensuring your device continues to operate efficiently. This section explores different sources where you can obtain essential items for your machine.

Authorized Dealers

Authorized retailers are often the most reliable source for obtaining original components. They provide a wide range of products that are specifically designed for compatibility with your model. Additionally, these vendors may offer expert advice and support to help you select the correct items for your needs.

Online Marketplaces

The internet has made it easier to find and purchase components from various suppliers. Several online platforms specialize in selling machinery accessories, often at competitive prices. When shopping online, ensure to check customer reviews and ratings to guarantee the reliability of the seller.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine components, expert support | Higher prices, limited stock |

| Online Marketplaces | Competitive pricing, wide selection | Quality varies, potential shipping delays |