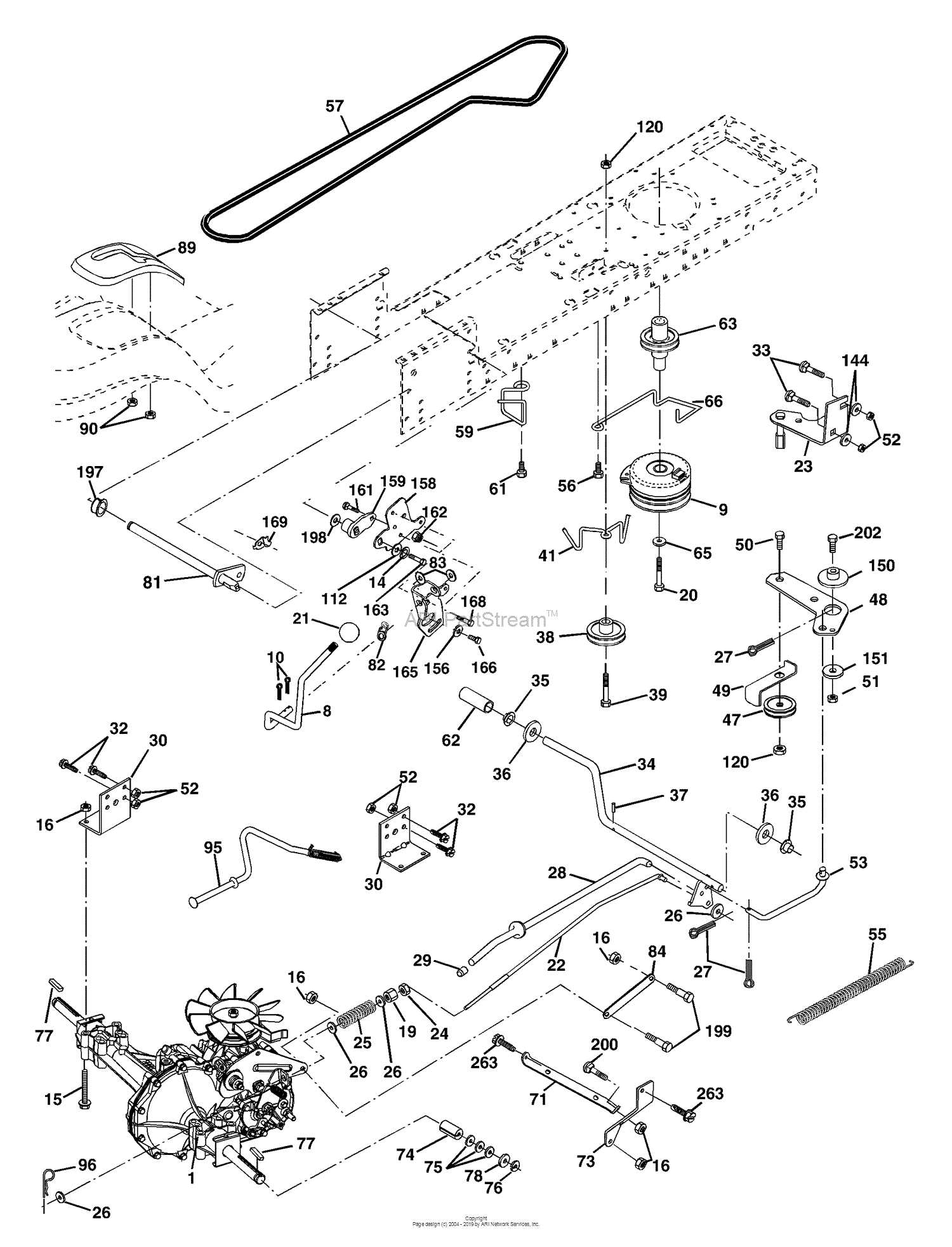

Comprehensive Parts Diagram for Husqvarna YTH1542XP

Maintaining a lawn mower requires a solid grasp of its various elements and how they work together. By familiarizing yourself with the inner workings of your machine, you can ensure optimal performance and longevity.

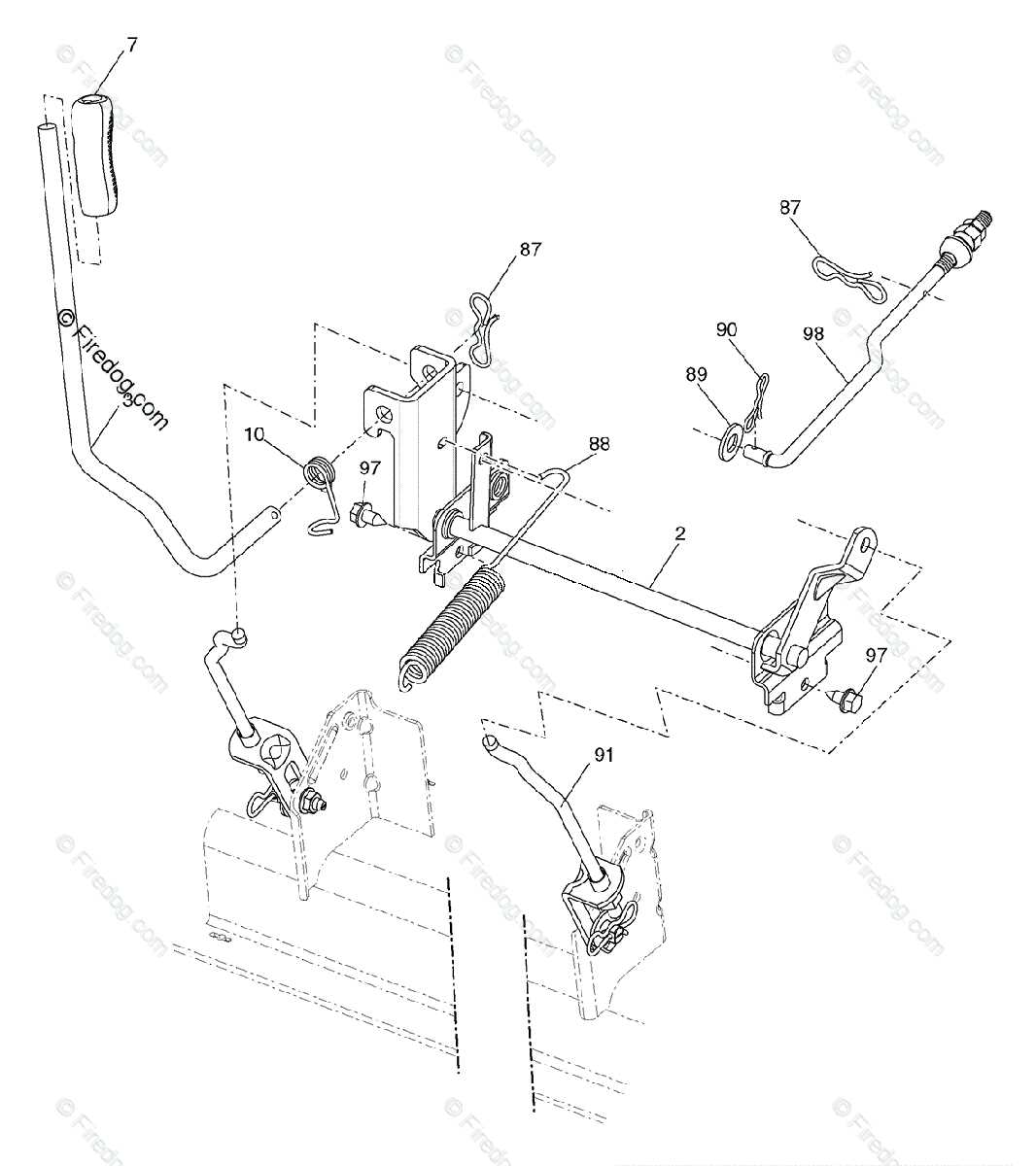

Identifying each component is crucial for effective repairs and maintenance. A comprehensive visual representation can simplify the process of recognizing parts, allowing for a quicker diagnosis of any issues that may arise.

Furthermore, having access to detailed schematics can significantly enhance your understanding. This knowledge empowers you to make informed decisions when purchasing replacements, ultimately contributing to a more efficient and reliable machine.

Understanding Husqvarna YTH1542XP Components

This section aims to provide a comprehensive overview of the essential elements that contribute to the overall functionality and performance of the machine. By exploring each component’s role and interconnections, users can gain valuable insights into maintenance and repair processes.

| Component | Description |

|---|---|

| Engine | Powers the unit and drives the cutting mechanism. |

| Transmission | Transfers power from the engine to the wheels. |

| Cutting Deck | Houses the blades and determines the cutting height. |

| Blades | Responsible for trimming grass and vegetation. |

| Wheels | Facilitate movement and maneuverability on various terrains. |

| Steering System | Enables control and navigation of the machine. |

Key Parts Overview

This section provides a comprehensive look at the essential components of the lawn care equipment model in question. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity of the machine.

Engine: The heart of the equipment, it delivers the necessary power to operate various functions. Regular checks and maintenance can prevent issues and enhance efficiency.

Transmission: This component is responsible for transferring power from the engine to the wheels, allowing for smooth movement. Proper lubrication and adjustments can significantly improve functionality.

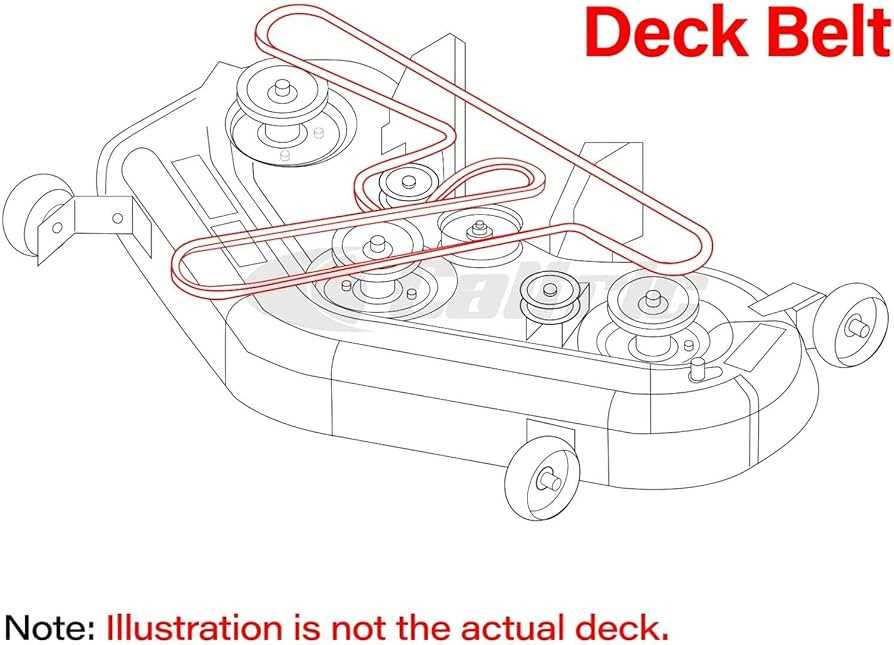

Deck: The cutting platform is vital for achieving a clean and even cut. Inspecting the blades and deck for wear and tear is essential for maintaining cutting performance.

Wheels: These parts provide mobility and stability. Ensuring they are in good condition and properly inflated can greatly affect maneuverability and traction.

Controls: The user interface, including levers and pedals, allows for precise operation. Regular cleaning and inspection help ensure responsive performance.

By focusing on these critical components, users can enhance their understanding and management of the equipment, leading to better results in lawn care activities.

Benefits of Regular Maintenance

Regular upkeep of machinery not only enhances performance but also extends the lifespan of the equipment. By adhering to a consistent maintenance schedule, users can prevent minor issues from escalating into major problems, ensuring smooth operation over time.

Improved Efficiency: Routine checks and servicing can significantly boost the efficiency of the equipment. Well-maintained machines operate at optimal levels, reducing energy consumption and enhancing productivity.

Cost Savings: Investing in regular maintenance can save money in the long run. Preventative care minimizes the risk of costly repairs and replacements, allowing users to allocate resources more effectively.

Enhanced Safety: Properly maintained equipment is safer to operate. Regular inspections can identify potential hazards, reducing the likelihood of accidents and ensuring a secure working environment.

Increased Resale Value: A well-documented maintenance history can improve the resale value of machinery. Prospective buyers are often willing to pay more for equipment that has been cared for diligently.

Peace of Mind: Knowing that the equipment is regularly serviced instills confidence in its reliability. Users can focus on their tasks without the constant worry of unexpected breakdowns or malfunctions.

How to Access the Parts Diagram

Finding the right visual guide for your machinery can streamline repairs and maintenance. This section provides a straightforward approach to accessing the necessary illustrations and information for your equipment.

- Visit the manufacturer’s official website.

- Navigate to the support or resources section.

- Search for your specific model using the provided tools.

- Locate the relevant visuals, often listed under manuals or schematics.

Utilizing these resources will ultimately enhance your understanding and ability to service your machine effectively.

Common Issues with YTH1542XP

When operating a residential riding mower, several challenges may arise that can affect its performance and efficiency. Identifying these common problems early can help in maintaining optimal functionality and prolonging the lifespan of the machine.

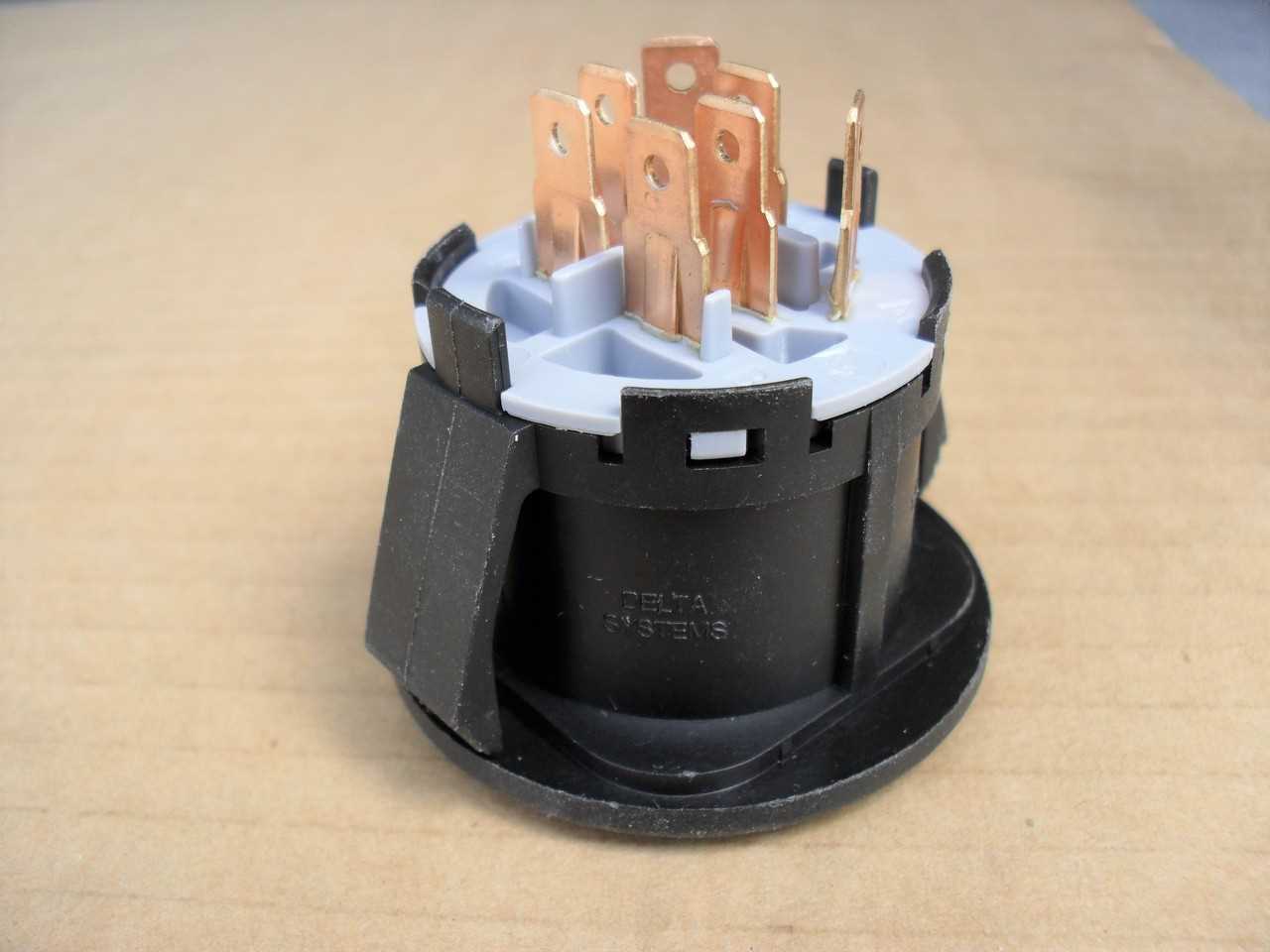

Starting Difficulties: One frequent concern is trouble starting the engine. This can be caused by a drained battery, faulty ignition components, or issues with the fuel system. Ensuring that the battery is charged and the fuel is fresh can often resolve this problem.

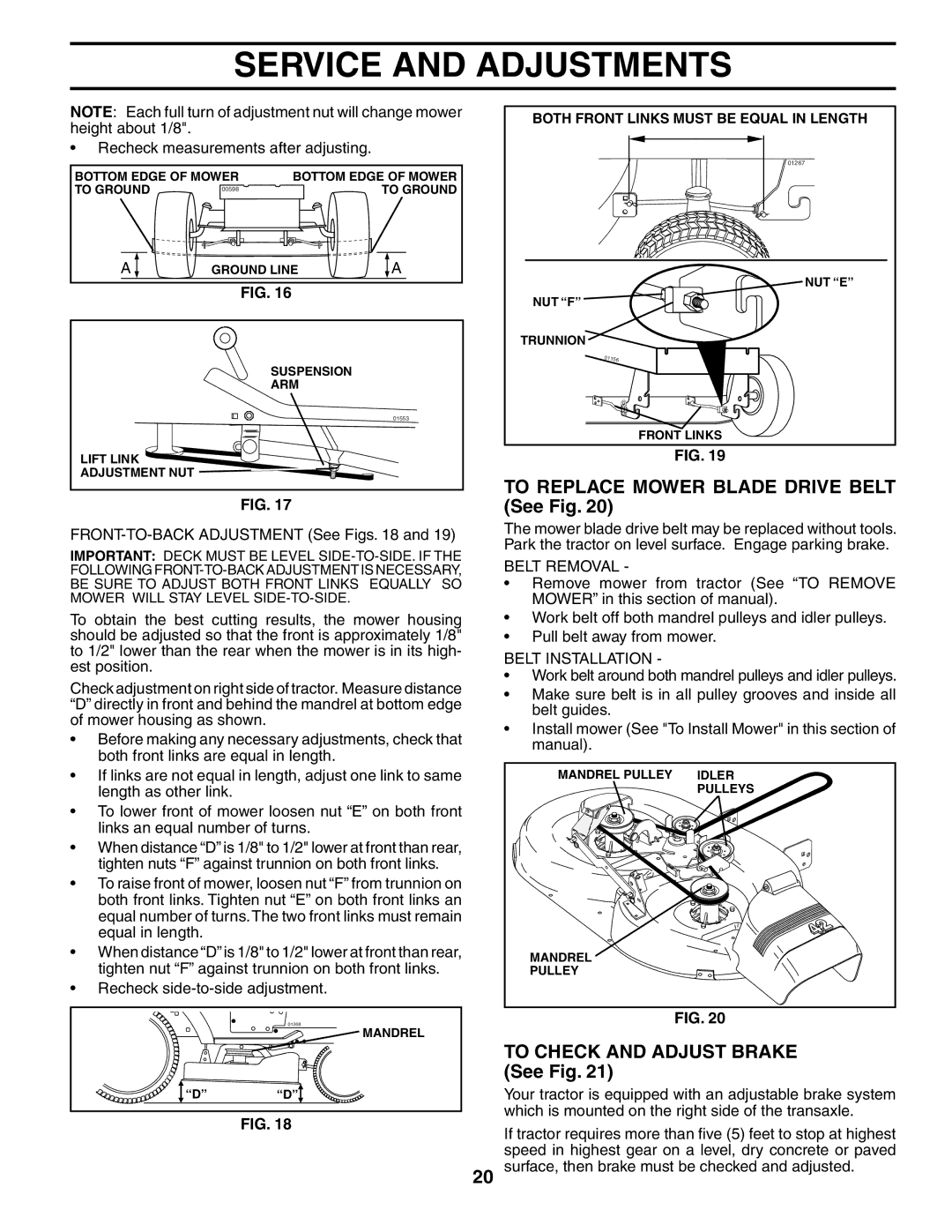

Cutting Quality: Uneven cutting or poor grass discharge can also occur. This might be due to dull blades, incorrect deck height settings, or clogged discharge chutes. Regular maintenance, including blade sharpening and deck cleaning, can help maintain a clean cut.

Transmission Issues: Problems with the transmission can manifest as unusual noises or difficulty changing speeds. Checking the fluid levels and inspecting for leaks can assist in addressing these concerns. It’s essential to ensure that the drive belt is in good condition as well.

Electrical Problems: Electrical malfunctions may lead to lights not functioning or accessories failing to operate. This can often be traced back to blown fuses or loose connections. Regularly inspecting wiring and connections can help prevent these issues.

By being aware of these potential issues and conducting routine maintenance, owners can ensure a smoother experience with their mower and reduce the likelihood of unexpected breakdowns.

Replacement Parts: What You Need

Maintaining your equipment in optimal condition often requires sourcing the right components. Understanding which items to replace can significantly enhance performance and longevity. Below is a guide to assist you in identifying essential replacements.

When considering replacements, it’s important to focus on the following categories:

- Engine Components: Ensure your engine runs smoothly by checking filters, spark plugs, and belts.

- Cutting Mechanisms: Blades, spindles, and deck parts are crucial for effective operation. Regular checks can prevent wear and tear.

- Drive System: Look into wheels, axles, and transmission parts to maintain mobility and control.

- Electrical Systems: Batteries, switches, and wiring should be examined for any signs of damage or wear.

When sourcing replacements, consider the following tips:

- Always refer to the manufacturer’s specifications for compatibility.

- Purchase from reputable suppliers to ensure quality and authenticity.

- Keep an inventory of commonly used components for quick access during maintenance.

By prioritizing these factors, you can ensure that your machinery remains reliable and efficient throughout its lifespan.

Tools for DIY Repairs

When tackling home repair projects, having the right tools is essential for success. A well-equipped workspace not only boosts efficiency but also enhances safety. From basic hand tools to specialized equipment, each plays a vital role in ensuring tasks are completed effectively.

Essential Hand Tools

Every DIY enthusiast should start with a solid collection of hand tools. Screwdrivers, wrenches, and hammers are fundamental for most tasks. Investing in a quality toolkit allows for quick fixes and adjustments without the hassle of searching for the right implement.

Power Tools for Efficiency

To delve deeper into repairs, consider incorporating power tools into your arsenal. Drills, saws, and sanders can significantly reduce the time and effort needed for various projects. Choosing the right power tool for specific jobs can make a world of difference in achieving ultimate results.

Comparing OEM vs Aftermarket Parts

The choice between original equipment manufacturer components and their alternative counterparts can significantly impact the performance and longevity of machinery. Each option presents unique advantages and disadvantages that cater to different user preferences and budget considerations.

Original equipment manufacturer (OEM) components are crafted by the same company that produced the original device. These parts are designed to match the specifications of the initial assembly, ensuring a perfect fit and optimal functionality. Users often appreciate the reliability and warranty coverage that accompany these components, providing peace of mind regarding their investment.

On the other hand, aftermarket alternatives are produced by third-party manufacturers. These options can often be more affordable and may offer enhancements not found in the original versions. However, the quality and compatibility of aftermarket components can vary significantly, necessitating thorough research to ensure satisfactory performance and durability.

Ultimately, the decision hinges on the specific needs of the user, weighing factors such as cost, quality, and intended use. A well-informed choice can lead to improved efficiency and satisfaction with the overall operation of the equipment.

Step-by-Step Repair Guide

This guide aims to provide a clear and concise approach to repairing your lawn equipment. By following each step carefully, you can ensure that your machine is restored to optimal working condition.

Step 1: Identify the Issue

Begin by assessing the equipment to determine the problem. Listen for unusual sounds, check for leaks, and inspect any visible components for wear or damage. This initial evaluation is crucial for effective troubleshooting.

Step 2: Gather Necessary Tools

Collect all required tools and replacement parts before starting the repair. This may include wrenches, screwdrivers, and any specific components identified during your assessment. Having everything at hand will streamline the process.

Step 3: Disconnect Power Sources

Ensure that the machine is turned off and disconnected from any power sources. This step is vital for your safety, preventing accidental starts while you work on the equipment.

Step 4: Disassemble the Affected Area

Carefully remove any panels or covers to access the parts needing attention. Take note of the order in which components are removed, as this will help you reassemble everything correctly later.

Step 5: Replace or Repair Components

Once you have access to the necessary parts, proceed with repairs or replacements as needed. Follow manufacturer guidelines for any components to ensure proper installation and functionality.

Step 6: Reassemble the Equipment

After making the necessary repairs, reassemble the machine in the reverse order of disassembly. Double-check that all screws and fittings are secure to avoid any issues during operation.

Step 7: Test the Equipment

Reconnect any power sources and conduct a thorough test of the equipment. Monitor its performance and listen for any irregularities. This final step ensures that your repair was successful and that the machine is ready for use.

By following this structured approach, you can effectively manage repairs and maintain the longevity of your lawn equipment.

Understanding the Engine Assembly

The engine assembly serves as the heart of any machinery, playing a crucial role in its overall performance and efficiency. This complex system comprises various components that work together seamlessly to convert fuel into mechanical energy. Understanding how each part contributes to the assembly can enhance maintenance practices and improve operational longevity.

Key Components: The assembly typically includes the cylinder, crankshaft, piston, and various valves. Each of these elements has a specific function, such as regulating air and fuel intake or facilitating exhaust expulsion. Recognizing the role of each part helps in troubleshooting issues and optimizing functionality.

Maintenance and Care: Regular inspection and maintenance of the engine assembly are vital to prevent wear and tear. Components like filters and spark plugs require periodic replacement to ensure optimal performance. Proper care can extend the life of the engine and maintain its efficiency over time.

In summary, a thorough understanding of the engine assembly is essential for anyone looking to ensure their equipment operates smoothly and reliably. Familiarity with its components and maintenance needs can lead to better performance and reduced downtime.

Electrical System Components Explained

The electrical system in outdoor machinery plays a crucial role in its overall functionality. Understanding the various components can enhance maintenance and troubleshooting efforts.

- Battery: Provides the necessary power to start the engine and operate electrical systems.

- Alternator: Charges the battery while the engine runs, ensuring a steady power supply.

- Starter Motor: Engages the engine to initiate operation, drawing power from the battery.

- Ignition System: Responsible for igniting the fuel-air mixture for engine combustion.

- Wiring Harness: Connects all electrical components, facilitating communication and power distribution.

By delving into each of these components, users can better appreciate their function and importance in maintaining peak performance.

Tips for Effective Troubleshooting

Effective problem-solving is crucial for maintaining the longevity and performance of your equipment. Understanding common issues and their symptoms can significantly streamline the repair process. Here are some strategies to enhance your troubleshooting skills.

1. Start with the Basics: Always check the simplest factors first. Ensure that the device is properly connected and powered on before moving to more complex diagnostics.

2. Gather Information: Take note of any unusual sounds, smells, or behaviors. Documenting these details can help pinpoint the issue more accurately.

3. Consult the Manual: Referring to the user guide can provide valuable insights into common problems and recommended solutions specific to your equipment.

4. Systematic Approach: Tackle one problem at a time. Isolate variables to determine the root cause, rather than addressing multiple issues simultaneously.

5. Use Resources Wisely: Online forums, videos, and repair guides can offer additional perspectives and solutions that may not be covered in the manual.

6. Don’t Hesitate to Ask for Help: If troubleshooting becomes overwhelming, seeking assistance from professionals can save time and prevent further damage.

Where to Buy Replacement Parts

Finding the right components for your outdoor equipment can be a straightforward process if you know where to look. There are several reliable sources that offer a variety of options for maintaining your machinery, ensuring optimal performance and longevity.

- Authorized Dealers: Visiting a licensed retailer is a great option. They usually carry a comprehensive selection of genuine components and can provide expert advice on installation and maintenance.

- Online Retailers: Many e-commerce platforms specialize in outdoor machinery parts. They often provide detailed descriptions, customer reviews, and competitive pricing, making it easy to compare options.

- Local Hardware Stores: Many community hardware shops stock a range of items for various brands. This option allows for quick purchases and the benefit of in-person assistance.

- Manufacturer’s Website: Directly purchasing from the official site guarantees authenticity. You can often find a catalog of components, along with specifications and compatibility information.

By exploring these sources, you can confidently acquire the necessary items to keep your equipment running smoothly and efficiently.