Understanding the Parts Diagram for Husqvarna YTH24V48

Maintaining your lawn machinery can be a daunting task, especially when it comes to understanding its intricate elements. Each component plays a crucial role in ensuring optimal performance and longevity. By exploring the specifics of these parts, users can enhance their maintenance practices and ensure a smoother operation.

Having a comprehensive visual guide can greatly assist in identifying each piece and its function. Such resources enable enthusiasts and professionals alike to pinpoint issues quickly, making repairs and replacements far more efficient. Understanding the layout of these elements ultimately leads to a better overall experience.

In this section, we will delve into the essential components of your equipment, highlighting their significance and how they interact with one another. Grasping this knowledge not only fosters better upkeep but also empowers users to tackle challenges confidently.

Understanding Husqvarna YTH24V48

This section explores a specific model of riding mower, focusing on its essential components and functionalities. Recognizing how each part contributes to overall performance is crucial for maintenance and optimal operation.

Key Features

This mower boasts a robust engine and an efficient cutting system, designed to provide a smooth and effective mowing experience. With user-friendly controls, it ensures ease of use, making lawn care accessible to a broader audience.

Maintenance Tips

Regular upkeep is vital for longevity. Ensuring that filters are clean and blades are sharp will ultimately enhance performance. Additionally, familiarizing oneself with the layout of the machine can help identify areas that may need attention.

Key Features of the Lawn Mower

A well-designed mower offers a variety of attributes that enhance its performance and user experience. Understanding these features is crucial for selecting the right machine for your landscaping needs.

Engine Performance

The heart of any mower is its engine, which determines the cutting power and efficiency. A robust engine ensures that the machine can tackle thick grass and uneven terrain with ease. Look for models with high horsepower ratings for the ultimate cutting experience.

Cutting Deck Versatility

A versatile cutting deck allows for different mowing heights and patterns, adapting to various grass types and conditions. Features like mulching and bagging capabilities can enhance lawn care, providing flexibility in maintenance approaches. The ease of adjusting the cutting height is also a significant advantage.

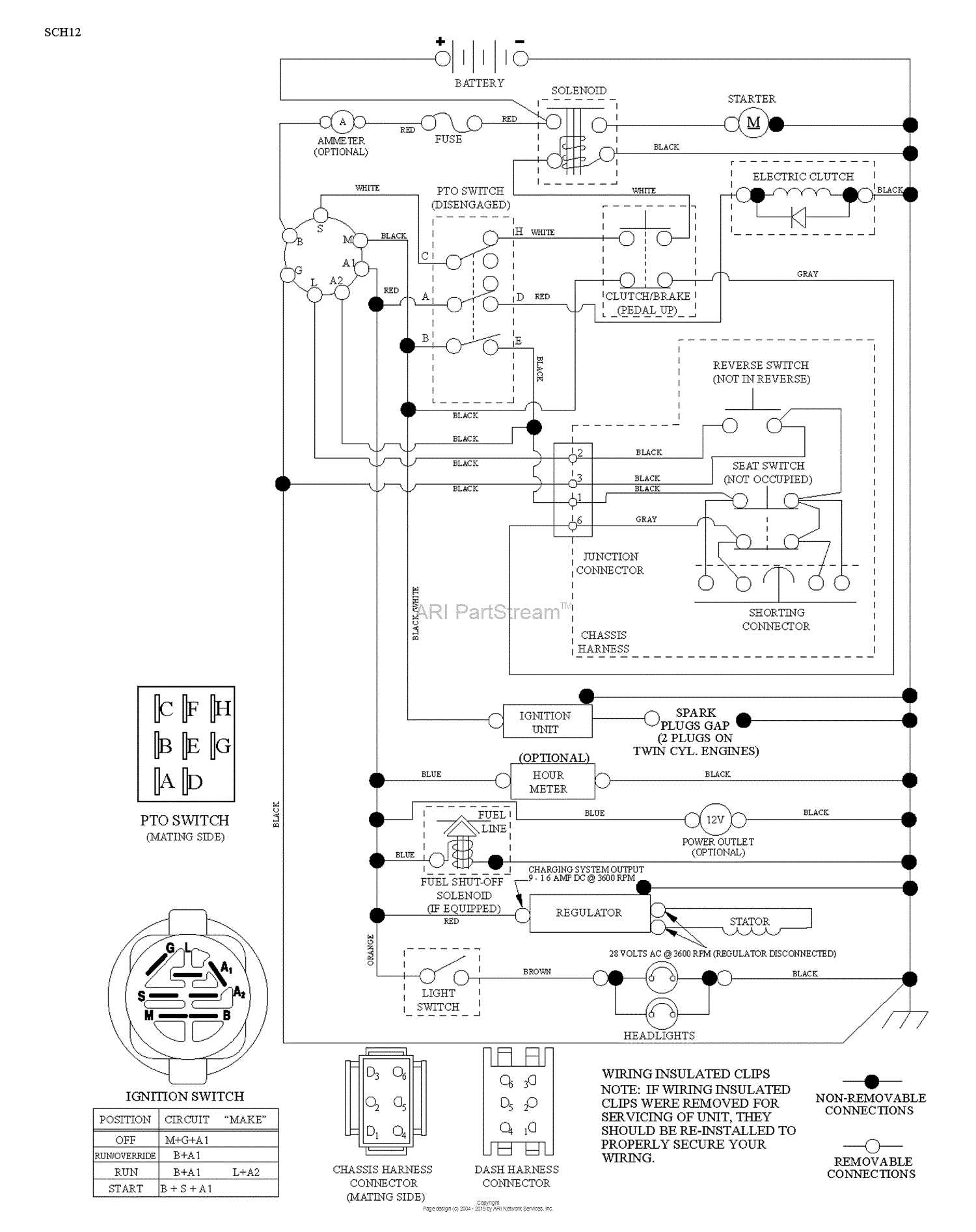

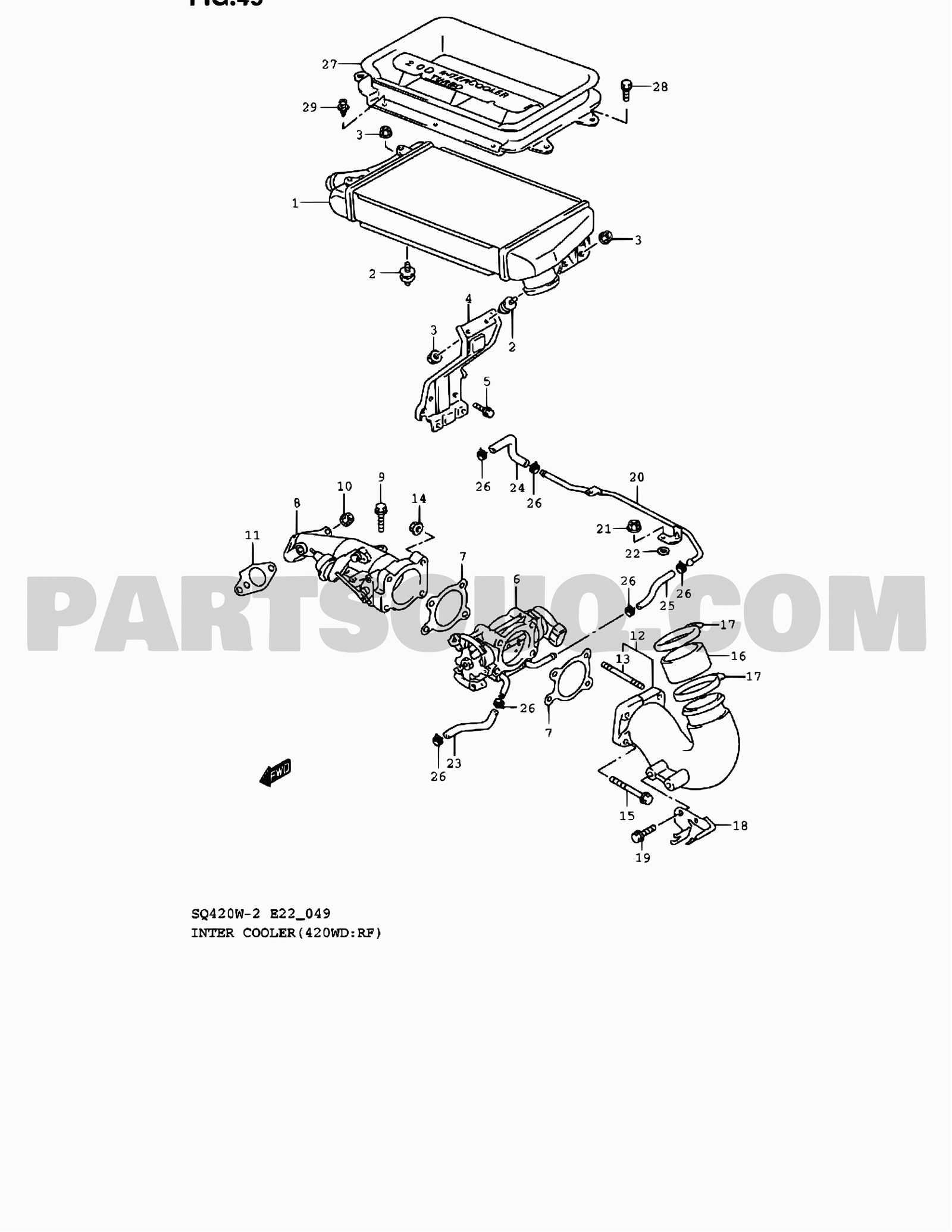

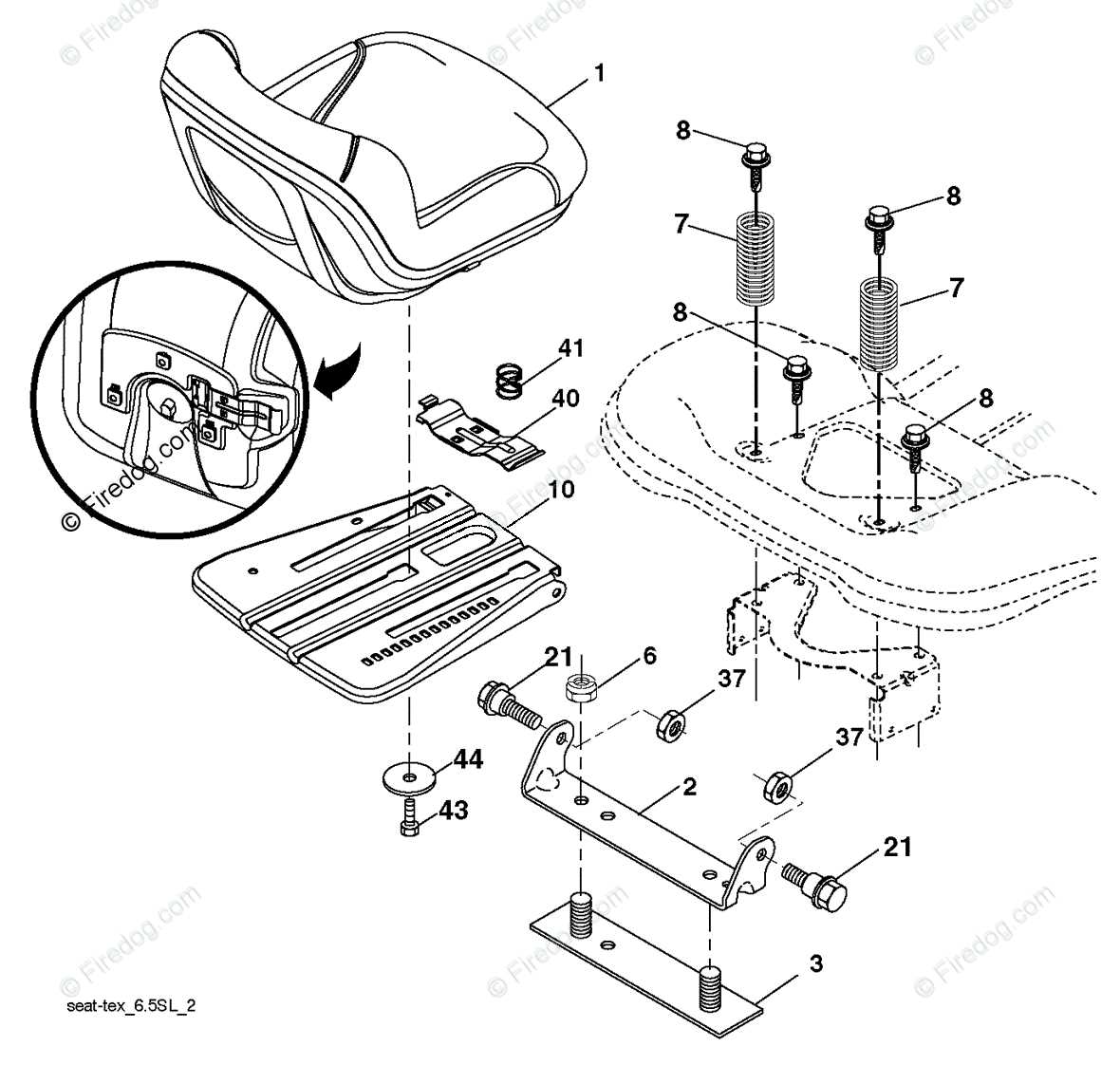

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations serve as vital tools, enabling users to identify individual elements and their functions within a larger system. This clarity helps streamline the process of troubleshooting and ensures that each part is correctly assessed.

Clarity in identifying components can prevent costly mistakes and enhance the efficiency of repairs. When technicians or enthusiasts have access to detailed visuals, they can easily locate specific pieces, which ultimately reduces downtime and improves performance. Additionally, these illustrations aid in educating users about their equipment, fostering a deeper appreciation and understanding.

Moreover, accurate visuals can facilitate the procurement of necessary replacements. With a clear reference, finding the right components becomes straightforward, which minimizes the risk of ordering incorrect items. In the long run, this not only saves time but also enhances the overall functionality and longevity of the machinery.

Identifying Common Replacement Parts

Maintaining outdoor equipment often requires replacing various components to ensure optimal performance. Recognizing the key elements that may need attention can save time and enhance efficiency. This section highlights common items that might require replacement and their respective functions.

| Component | Description | Signs of Wear |

|---|---|---|

| Blades | Essential for cutting grass effectively. | Dullness, nicks, or uneven cuts. |

| Air Filter | Prevents dirt and debris from entering the engine. | Reduced engine performance or black smoke. |

| Belt | Transmits power from the engine to the cutting deck. | Cracks, fraying, or slipping noises. |

| Battery | Provides electrical power to start the engine. | Slow cranking or failure to start. |

| Spark Plug | Ignites the fuel-air mixture in the engine. | Hard starting or misfiring engine. |

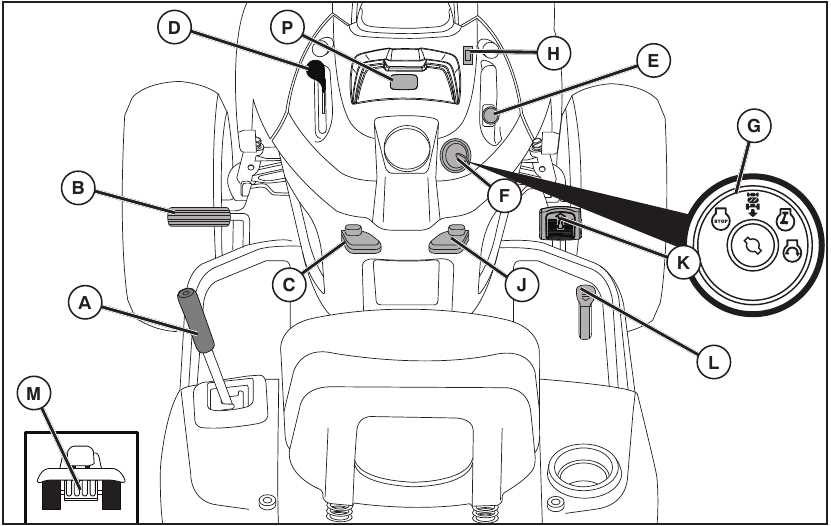

How to Use the Diagram Effectively

Understanding the visual representation of components can greatly enhance your repair and maintenance experience. This guide will provide insights into how to utilize these illustrations to streamline your workflow and ensure that you handle each part with care.

Follow these steps to make the most of the visual reference:

- Familiarize Yourself: Spend some time getting to know the layout. Identify the key sections and components relevant to your needs.

- Identify Components: Use the illustration to locate specific items you may need to replace or service. Pay attention to labels and numbering.

- Plan Your Repairs: Before starting any maintenance work, outline the steps you’ll need to take. Refer to the visual aid to ensure you don’t overlook any critical components.

- Gather Necessary Tools: With a clear understanding of what needs to be addressed, assemble all required tools and replacement items in advance to avoid interruptions.

- Follow Safety Protocols: Always keep safety in mind. Review the areas of concern highlighted in the visual and take precautions accordingly.

By using the representation effectively, you can enhance your efficiency and accuracy during maintenance tasks. A well-prepared approach will lead to better outcomes and a smoother repair process.

Maintenance Tips for Longevity

Ensuring the durability and performance of your outdoor equipment requires regular attention and care. By implementing a few essential maintenance practices, you can significantly extend the lifespan of your machinery and keep it running smoothly.

Regular Inspections

Performing routine checks on components is crucial. Look for signs of wear, loose connections, or any unusual noises during operation. Addressing minor issues promptly can prevent major breakdowns later.

Proper Cleaning

Keep your equipment clean from debris and dirt buildup. Regularly washing and clearing out grass clippings and dust helps maintain optimal performance and prevents corrosion, enhancing longevity.

Where to Find Original Parts

Locating authentic components for your equipment is essential for maintaining optimal performance and longevity. Various sources provide reliable options to ensure you receive the highest quality items tailored for your needs.

Authorized Dealers

Visiting certified retailers is one of the most dependable methods to acquire genuine components. These dealers often have extensive knowledge and can assist in identifying the exact items required for your machinery.

Online Marketplaces

Numerous online platforms specialize in authentic equipment supplies. When using these sites, ensure to verify the seller’s credibility and check for customer reviews to guarantee you are purchasing original merchandise.

Aftermarket vs. OEM Components

When it comes to replacement parts for machinery, users often face a choice between original and alternative options. Understanding the differences between these categories can help in making informed decisions regarding quality, cost, and performance. Each type has its advantages and disadvantages, influencing not only the longevity of the equipment but also the overall user experience.

| Feature | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Manufactured to meet specific standards | Varies widely; some high-quality, others lower |

| Cost | Generally higher due to brand reputation | Typically more affordable, offering budget options |

| Availability | May be limited to specific retailers | Often widely available through various sources |

| Warranty | Often includes manufacturer’s warranty | May have limited or no warranty |

| Compatibility | Designed specifically for the equipment | May require research to ensure fit |

Ultimately, the choice between these options hinges on individual preferences, budget constraints, and specific needs related to the equipment’s operation and maintenance. Balancing these factors can lead to a satisfactory outcome in the quest for effective machinery performance.

Step-by-Step Repair Guide

This guide provides a clear path for tackling repairs on your machine. Following these steps will ensure a systematic approach, helping you identify issues and resolve them effectively.

- Identify the Problem: Observe the machine’s performance and note any irregularities.

- Gather Necessary Tools: Ensure you have the required equipment for the repair, such as wrenches, screwdrivers, and replacement components.

- Consult the Manual: Reference the operational manual for specific instructions related to your model.

- Disassemble Carefully: Begin taking apart the relevant sections, keeping track of screws and parts.

- Inspect Components: Check for wear or damage on all pieces you have removed.

- Replace Damaged Parts: Install new or refurbished components as necessary.

- Reassemble: Put the machine back together in the reverse order of disassembly.

- Test the Machine: Once reassembled, run the machine to ensure proper functionality.

Following this structured approach will facilitate a successful repair process and prolong the life of your equipment.

Common Issues and Solutions

This section addresses frequent problems encountered with outdoor equipment and provides effective remedies to enhance performance and longevity. Understanding these issues can lead to better maintenance and user experience.

- Engine Won’t Start:

- Check fuel level and quality.

- Inspect the battery and connections.

- Examine the spark plug for wear or damage.

- Uneven Cutting:

- Ensure blades are sharp and properly aligned.

- Check tire pressure for uniform height.

- Adjust the cutting height settings as needed.

- Overheating:

- Clean air filters and cooling fins.

- Check oil levels and quality.

- Ensure proper airflow around the engine.

- Stalling Issues:

- Inspect fuel lines for blockages or leaks.

- Check for debris in the carburetor.

- Ensure the throttle linkage is functioning smoothly.

Resources for Troubleshooting

When faced with mechanical challenges, having access to reliable information is crucial. This section offers various resources that can assist in diagnosing and resolving issues effectively. From online forums to official manuals, these tools can provide invaluable insights into common problems and their solutions.

Online Communities

Joining forums and discussion boards dedicated to outdoor equipment can be a great way to gain knowledge. Experienced users often share their troubleshooting tips and personal experiences, which can help you identify problems and suggest potential fixes. Websites like Reddit and specialized groups on social media can be excellent places to seek advice.

Official Documentation

Consulting the manufacturer’s manuals and guides is essential for understanding the specifics of your equipment. These documents typically include troubleshooting sections that outline common issues and their resolutions. Additionally, videos available on platforms like YouTube can visually demonstrate repair processes, making it easier to follow along.

Benefits of Regular Inspections

Routine evaluations of equipment play a crucial role in maintaining its longevity and efficiency. By routinely checking the condition of your machinery, you can identify potential issues before they escalate into significant problems. This proactive approach not only saves time but also minimizes unexpected downtime.

Early Detection: Regular assessments allow for the early identification of wear and tear. Addressing minor repairs promptly can prevent costly failures, ensuring that your equipment operates smoothly.

Enhanced Safety: Frequent inspections contribute to a safer working environment. By ensuring that all components are functioning properly, the risk of accidents is significantly reduced, protecting both the operator and the equipment.

Cost-Effectiveness: Investing time in routine checks can lead to substantial savings in the long run. Regular maintenance helps avoid extensive repairs and extends the lifespan of your machinery, providing better value for your investment.

Optimal Performance: Consistent evaluations ensure that your equipment performs at its best. Keeping parts in good condition enhances efficiency, which can lead to improved productivity and better results.

In summary, engaging in regular inspections is a smart strategy that fosters reliability, safety, and overall effectiveness in machinery operation.