Comprehensive Guide to Husqvarna Z254F Parts Diagram

In the realm of lawn maintenance, comprehending the various elements that contribute to a machine’s functionality is essential for optimal performance. Every piece plays a crucial role, ensuring that the equipment operates smoothly and efficiently. A thorough examination of these components can empower users to make informed decisions regarding maintenance and repairs.

Visual representation of these intricate systems offers a clear overview, allowing enthusiasts and professionals alike to delve into the workings of their machinery. By familiarizing oneself with the layout and connections, one can appreciate the ultimate design that supports effective grass management.

Moreover, understanding the relationships between different parts can lead to improved troubleshooting skills. Whether it’s addressing a malfunction or simply performing routine upkeep, knowledge of each component fosters a proactive approach to maintenance.

Understanding the Husqvarna Z254F

This section delves into the intricacies of a popular lawn maintenance machine, focusing on its components and overall functionality. Recognizing how each element interacts can enhance your ability to operate and maintain this equipment efficiently.

Key Features

This model boasts a range of features designed for optimal performance and user convenience. Key highlights include an efficient engine, robust construction, and innovative steering mechanisms. These attributes not only ensure smooth operation but also contribute to durability over time.

Component Overview

To better understand the machine’s mechanics, it’s important to familiarize yourself with its essential components. Below is a table summarizing the critical parts and their functions:

| Component | Function |

|---|---|

| Engine | Powers the mower and drives the cutting blades. |

| Cutting Deck | Houses the blades for efficient grass cutting. |

| Transmission | Transfers power from the engine to the wheels. |

| Steering System | Enables precise control and maneuverability. |

| Fuel System | Stores and delivers fuel to the engine. |

Understanding these elements will not only help in regular maintenance but also improve the overall user experience with the machine.

Key Features of the Z254F

This model offers a range of innovative characteristics that enhance performance and usability, making it an ideal choice for various lawn care tasks.

- Powerful engine for efficient cutting.

- Robust build for durability and longevity.

- Easy-to-use controls for seamless operation.

- Superior maneuverability in tight spaces.

- Enhanced cutting deck for a cleaner finish.

Overall, these attributes contribute to its reputation as a reliable and effective machine for maintaining your lawn.

Importance of Replacement Parts

Maintaining the efficiency and longevity of any machinery relies heavily on the availability of quality components. Over time, wear and tear can lead to decreased performance, making it essential to address these issues promptly. By replacing worn or damaged elements, one ensures optimal functionality and reduces the risk of further complications.

Utilizing high-quality substitutes not only enhances performance but also contributes to safety. Malfunctioning equipment can pose hazards, both to the operator and the surrounding environment. Therefore, regular inspection and timely updates of critical components are vital practices in any maintenance routine.

Moreover, investing in reliable replacements can lead to cost savings in the long run. Preventative measures, such as early replacement, often mitigate the need for more extensive repairs down the line. This proactive approach not only keeps machinery in peak condition but also supports efficient operation, ultimately benefiting productivity.

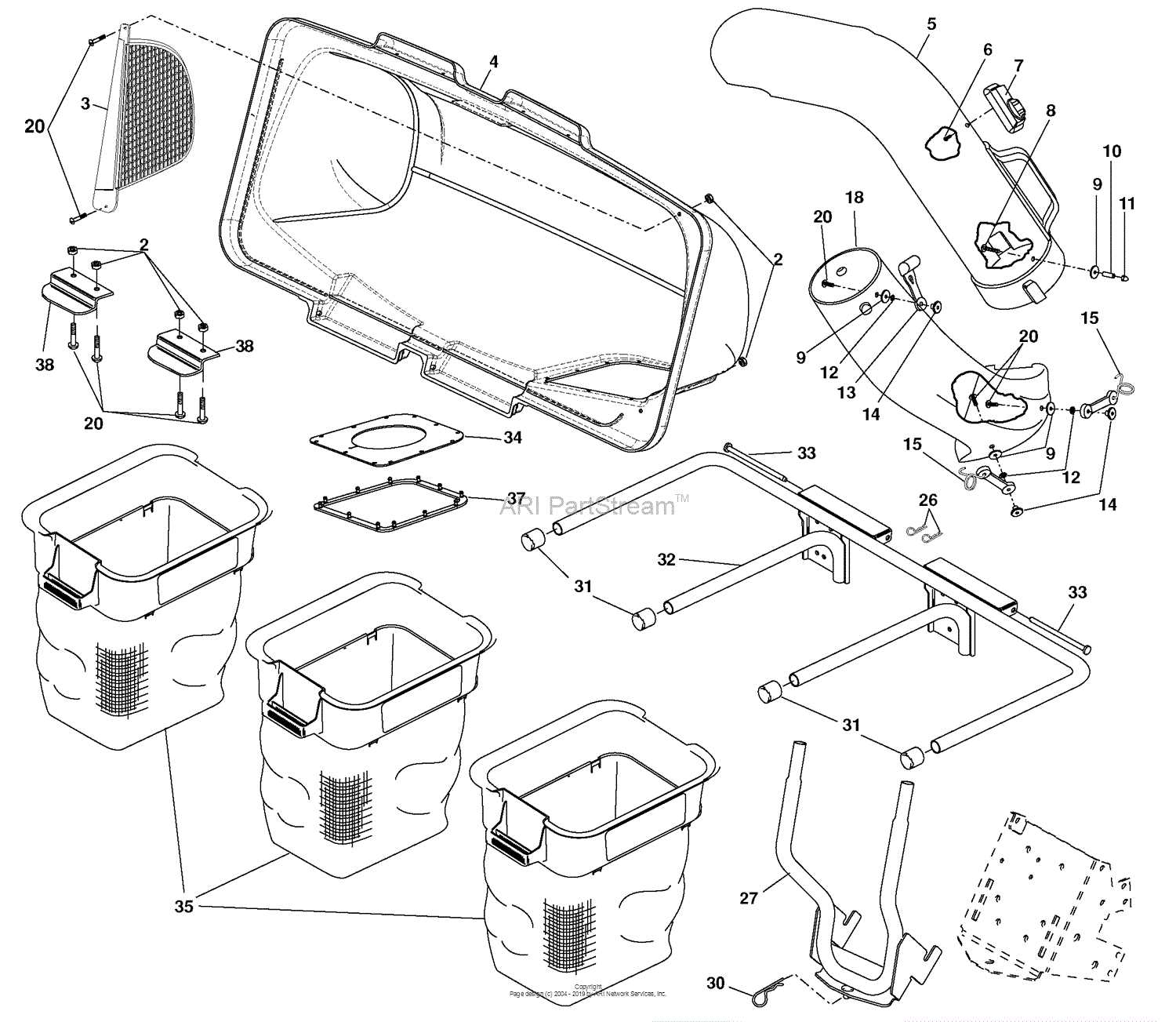

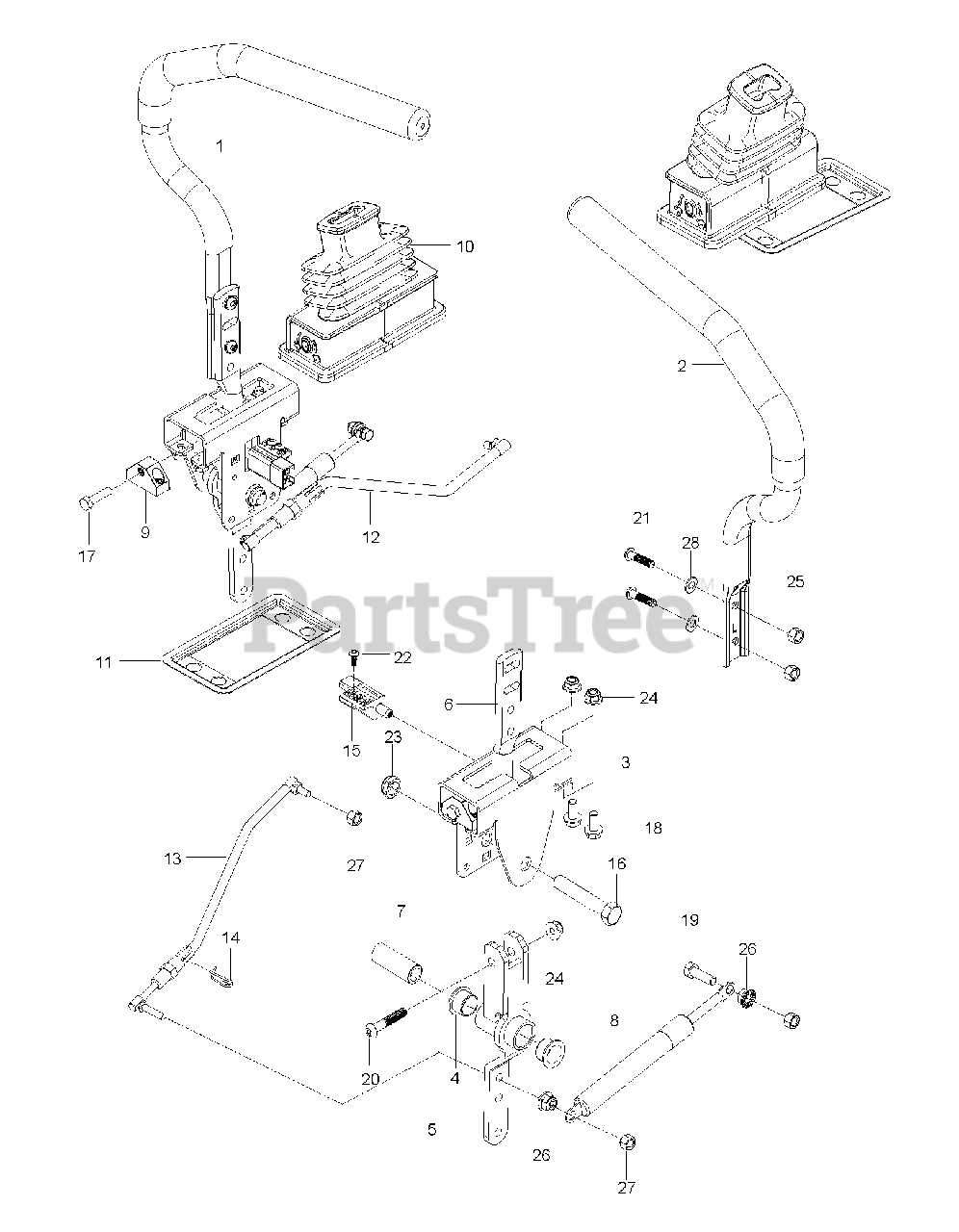

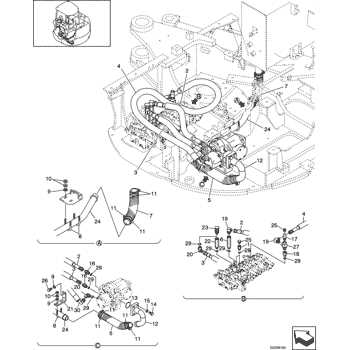

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for anyone looking to maintain or repair machinery. These visual aids provide a detailed view of the various elements involved, enabling users to identify, locate, and comprehend the relationship between parts. Mastering how to interpret these illustrations can save time and enhance the efficiency of maintenance tasks.

Key Components to Focus On

When analyzing a visual representation of components, pay attention to labels and numbers associated with each item. Typically, each part will have a corresponding identifier that allows you to cross-reference it with a list of available components. Familiarize yourself with common symbols used to represent different elements, such as bolts, belts, and housing units. This knowledge will facilitate a smoother identification process.

Understanding Layout and Organization

Most schematics are arranged in a logical manner, grouping related parts together. Look for sections that may represent specific assemblies or functional areas within the machinery. Recognizing these groupings can help you understand how parts interact and contribute to the overall operation. Additionally, pay attention to any directional arrows or notes that indicate the flow of operation or assembly order.

Common Issues and Solutions

Many users encounter typical problems with their lawn care equipment, which can often lead to frustration. Understanding these issues and their remedies can enhance performance and longevity.

- Engine Starting Difficulties:

- Check fuel levels and quality.

- Inspect spark plug condition.

- Ensure the choke is functioning properly.

- Uneven Cutting:

- Examine blade sharpness and alignment.

- Adjust cutting height settings.

- Inspect tire pressure for uniformity.

- Overheating:

- Ensure adequate airflow around the engine.

- Clean the air filter regularly.

- Check for oil levels and quality.

By addressing these common issues promptly, users can maintain optimal functionality and prevent more serious complications.

Essential Components of the Z254F

The functionality of a high-performing mower relies on a variety of critical elements that work harmoniously together. Each component plays a pivotal role in ensuring efficiency, durability, and ease of use, ultimately enhancing the mowing experience.

The engine serves as the powerhouse, providing the necessary energy to drive the machine. The cutting deck is engineered for optimal grass management, ensuring a clean and precise cut. Additionally, the transmission system facilitates smooth movement, while the wheels offer stability on diverse terrains. Other essential features include the control panel, which allows for user-friendly operation, and the safety mechanisms that protect the operator during use.

Understanding these integral parts can significantly improve maintenance practices, ensuring longevity and peak performance for every mowing session.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the life of your equipment. By implementing a few simple practices, you can ensure optimal performance and durability over time. A proactive approach not only enhances functionality but also saves costs in the long run.

1. Routine Cleaning: Regularly clean your machine to prevent the buildup of dirt and debris. This helps maintain airflow and prevents overheating.

2. Check and Replace Fluids: Keep an eye on oil and fuel levels, replacing them as needed. Fresh fluids reduce wear and improve efficiency.

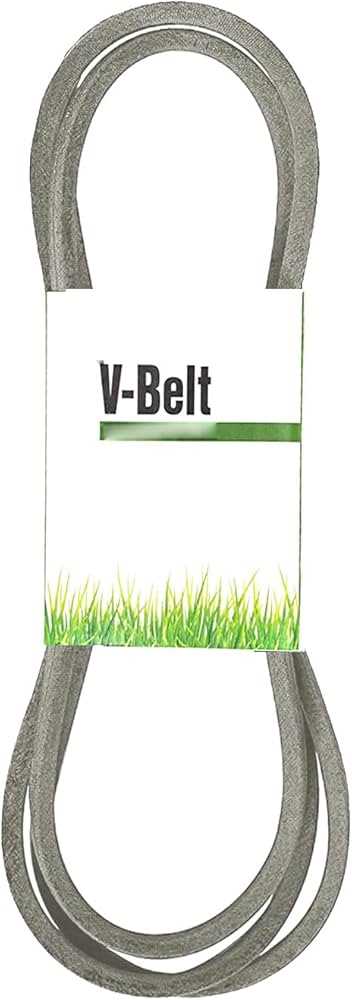

3. Inspect Belts and Blades: Frequently examine these components for signs of wear. Timely replacements can prevent further damage and ensure a smooth operation.

4. Store Properly: When not in use, store your equipment in a dry, sheltered area. This protects it from the elements and prolongs its lifespan.

5. Follow the Manufacturer’s Guidelines: Always refer to the maintenance manual for specific recommendations and schedules. Adhering to these guidelines is key for long-term reliability.

Where to Find Parts Diagrams

Locating visual representations of components for machinery can greatly enhance the repair and maintenance process. These resources provide essential information for identifying and sourcing the necessary pieces for efficient functionality.

Online Resources: Numerous websites specialize in offering detailed illustrations for various models. Searching through manufacturer websites or authorized dealers often yields reliable results.

Manuals and Guides: User manuals typically contain comprehensive breakdowns of machine parts. Consulting these documents can provide valuable insights into assembly and disassembly.

Forums and Community Groups: Engaging with online communities dedicated to machinery can be beneficial. Enthusiasts and experts often share helpful links and personal experiences regarding component identification.

Local Dealers: Visiting a nearby dealer or repair shop can also be advantageous. Professionals often have access to proprietary resources and can assist in finding specific information.

By utilizing these avenues, one can delve into a wealth of information, ultimately ensuring better maintenance and repairs of machinery.

Upgrading Your Z254F Parts

Enhancing your machine’s components can significantly improve performance and longevity. By selecting high-quality upgrades, you can ensure that your equipment operates at its best, making tasks easier and more efficient. It’s essential to understand which elements can be replaced for optimal results.

First, consider the engine’s efficiency. Upgrading filters or ignition systems can lead to improved power output. Additionally, the cutting deck can be optimized by using sharper blades or more durable materials, which can enhance cutting precision.

Moreover, don’t overlook the importance of the transmission. A robust upgrade here can offer smoother operation and better control. Finally, regular maintenance and timely replacements of worn-out items ensure that your machine remains reliable for years to come.

Comparing Z254F with Other Models

When evaluating a specific model within a range of lawn care equipment, it’s essential to consider various alternatives that may offer different features and performance capabilities. By examining the distinctions and similarities between models, users can make informed decisions based on their unique needs and preferences.

One significant aspect to look at is the engine power. Different models may vary in horsepower, affecting cutting efficiency and speed. A machine with a more robust engine can tackle tougher grass and larger areas with ease, while lighter options may excel in maneuverability and ease of use for smaller lawns.

Another factor to consider is the cutting deck size. Larger decks allow for broader cutting swaths, reducing mowing time, but may hinder navigation in tight spaces. Conversely, smaller decks offer enhanced control and are often better suited for intricate landscaping.

Moreover, features such as comfort and adjustability can greatly influence the user experience. Some models come equipped with ergonomic seating, adjustable steering, and intuitive controls, making them more comfortable for prolonged use. Evaluating these comfort features alongside performance can lead to a better overall mowing experience.

Finally, examining the build quality and durability across different machines is crucial. Materials and construction methods can significantly impact the longevity of the equipment, ensuring that it withstands the rigors of regular use. By carefully comparing these elements, potential buyers can select a machine that aligns with their maintenance requirements and operational expectations.

Assembly Process for Replacement Parts

The process of reassembling components is crucial for maintaining the efficiency and longevity of machinery. Proper installation ensures optimal performance and reduces the likelihood of future breakdowns. This guide outlines the essential steps to follow when integrating new elements into your equipment.

Before beginning the assembly, gather all necessary tools and new components. Having everything at hand will streamline the process and minimize interruptions. It is also advisable to consult the manual specific to your model for any unique instructions.

| Step | Description |

|---|---|

| 1 | Ensure the machine is powered off and disconnected from any energy source. |

| 2 | Remove any existing components that require replacement, taking care to note their arrangement. |

| 3 | Clean the area where the new parts will be installed to prevent debris from causing issues. |

| 4 | Carefully position the new components, ensuring they align correctly with existing structures. |

| 5 | Secure the new parts using the appropriate fasteners, ensuring they are tightened to specifications. |

| 6 | Double-check all connections and fittings before powering the machine back on. |

Following these steps will help ensure that your assembly is successful, allowing your equipment to operate at its best. Regular maintenance and timely replacements contribute significantly to the durability of your machinery.

Expert Recommendations for Parts Quality

When it comes to maintaining outdoor equipment, ensuring the integrity of components is crucial for optimal performance and longevity. Experts emphasize the importance of sourcing high-quality elements to prevent premature wear and enhance reliability. Selecting the right replacements can significantly affect the efficiency and safety of your machinery.

Here are some key recommendations to consider when evaluating the quality of components:

| Criteria | Recommendations |

|---|---|

| Material Quality | Opt for durable materials that resist corrosion and wear, such as high-grade metals and resilient plastics. |

| Manufacturer Reputation | Choose parts from reputable manufacturers known for their commitment to quality and customer satisfaction. |

| Warranty | Look for components that come with a solid warranty, indicating confidence in their durability and performance. |

| Compatibility | Ensure the replacement fits perfectly with your equipment to avoid operational issues and enhance performance. |

| Reviews and Feedback | Research user reviews and expert feedback to gain insights into the reliability and performance of specific replacements. |

By following these recommendations, you can ensure that your machinery remains efficient and reliable, ultimately saving you time and money in the long run.