Understanding the Polaris Winch Parts Diagram for Ultimate Performance

In the realm of outdoor machinery, having a clear grasp of each essential element is crucial for optimal functionality. Whether you’re tackling rugged terrains or engaging in heavy-duty tasks, the intricate interplay of various components plays a significant role in achieving desired results. A comprehensive overview of these vital elements can empower users to maintain, troubleshoot, and enhance their equipment effectively.

As you delve into the specifics of each element, it becomes evident that understanding their arrangement and interaction is key. A well-structured visual representation can illuminate the relationships between different sections, enabling enthusiasts and professionals alike to navigate maintenance or upgrades with confidence. This clarity not only aids in efficient repairs but also contributes to extending the lifespan of the machinery.

By familiarizing yourself with the configuration and function of each integral part, you lay the groundwork for informed decisions. Armed with this knowledge, you can optimize performance and ensure your equipment is always ready for the next adventure. Join us as we explore the essential features that make outdoor tools reliable and efficient.

Understanding Polaris Winch Functionality

The mechanism in question plays a crucial role in enhancing the versatility of off-road vehicles, enabling them to overcome challenging terrains and obstacles with ease. By harnessing mechanical advantage, this device aids in towing, lifting, and maneuvering heavy loads, making it indispensable for adventurers and professionals alike.

Core Components: The system is comprised of several essential elements that work in harmony to provide effective performance. Each component, from the motor to the spool, contributes to the overall efficiency and reliability of the mechanism.

Operation: When activated, the device employs a cable that winds around a drum, allowing for controlled movement of the load. The power source drives the motor, which ultimately dictates the speed and strength of the pull.

Versatility: Whether it’s for recreational use or industrial applications, the functionality of this tool can be tailored to meet various demands, showcasing its adaptability across different scenarios.

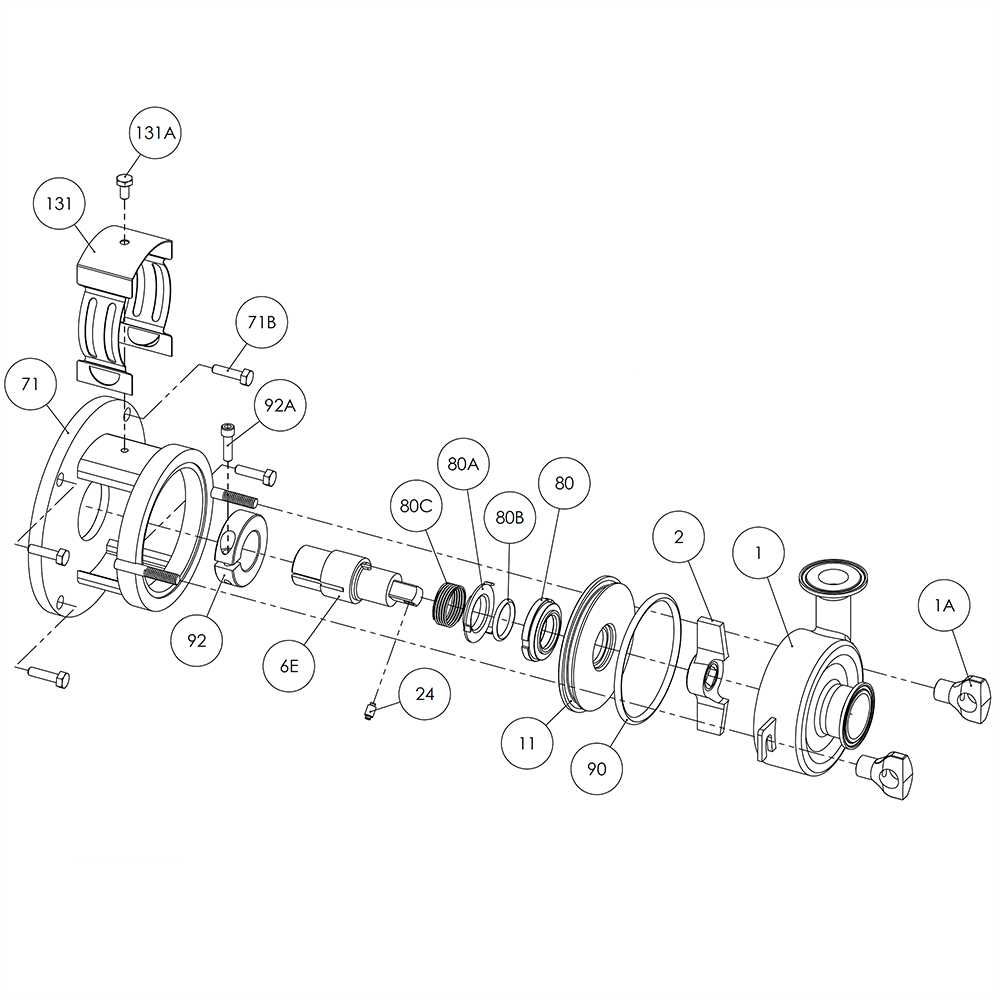

Key Components of a Winch

The functionality of a pulling mechanism relies on several essential elements that work in harmony to ensure efficiency and reliability. Understanding these crucial components is fundamental for optimal performance and maintenance.

Drum: The central cylinder where the cable is wound, allowing for smooth extension and retraction. Its design is critical for load management.

Motor: This powerhouse drives the mechanism, providing the necessary torque to handle heavy loads. Various types exist, including electric and hydraulic options, each suited for specific tasks.

Gear System: This assembly regulates the speed and strength of the pulling action. A well-designed gear ratio can enhance performance significantly.

Control Switch: This device enables the operator to manage the pulling action safely and efficiently, providing convenience during operation.

Cable or Strap: The crucial link that connects the mechanism to the load. It must be strong and durable, designed to withstand substantial forces.

Brake System: A vital safety feature that ensures the load remains secure when not in motion. Proper functionality of this component is essential to prevent accidents.

Each of these elements plays a pivotal role in the overall functionality of the pulling apparatus, making their understanding imperative for users and technicians alike.

Importance of Winch Maintenance

Common Issues with Winch Parts

Understanding the frequent challenges that arise with these essential tools is crucial for maintaining their functionality. Many users encounter similar problems that can hinder performance and safety.

Wear and Tear

One of the most prevalent issues is the gradual deterioration of components due to heavy usage. Friction can lead to damaged gears and reduced efficiency, making it vital to regularly inspect and replace worn elements.

Electrical Failures

Another common concern is related to electrical systems. Short circuits or battery issues can prevent proper operation, necessitating thorough checks of wiring and connections to ensure reliability during use.

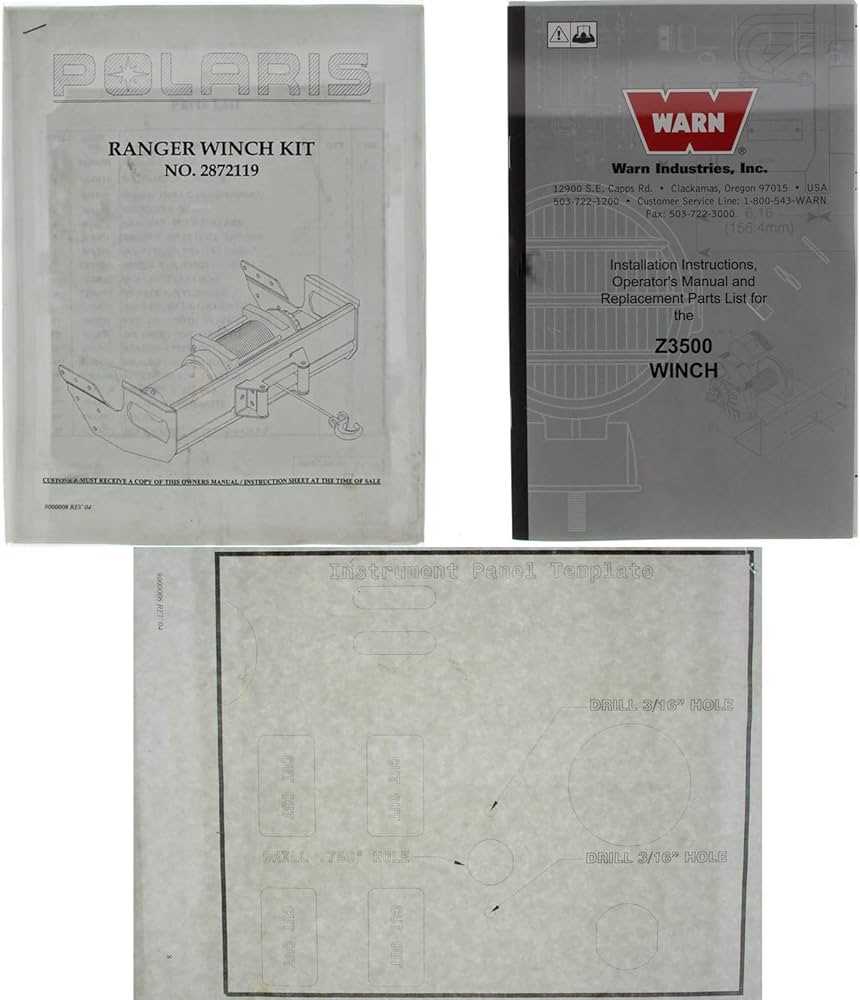

Step-by-Step Repair Guide

This guide provides a comprehensive approach to troubleshooting and restoring your equipment. Whether you’re addressing minor issues or conducting a thorough overhaul, following a structured method will help ensure successful repairs.

Preparation

Before starting any repair process, gather the necessary tools and materials. Make sure to have a clean workspace and wear appropriate safety gear. Assess the condition of your machinery and identify any visible problems. Taking detailed notes and photographs can be beneficial for reference during reassembly.

Disassembly and Inspection

Begin by carefully disassembling the unit, ensuring that you keep track of all components. As you remove each part, inspect for wear or damage. Pay particular attention to critical areas that may affect performance. If you notice any broken or worn elements, plan to replace them with quality replacements to restore functionality.

Once disassembled, clean all components thoroughly. Removing dirt and debris will not only improve performance but also help you identify any hidden issues. After cleaning, re-evaluate each part before moving forward with repairs.

By following these steps methodically, you can enhance the reliability and longevity of your equipment.

Choosing the Right Winch Accessories

Selecting the appropriate tools and enhancements for your recovery system is crucial for ensuring efficiency and safety during use. The right accessories not only optimize performance but also provide additional security and versatility in various situations. Understanding the types available and their respective functions can significantly improve your overall experience.

Essential Components

Among the key items to consider are straps, shackles, and rollers. Straps are vital for connecting your recovery device to an anchor point or vehicle, while shackles facilitate secure connections between various components. Rollers help manage the cable’s direction and reduce wear, ensuring longevity and reliability during operations.

Safety and Maintenance

Always prioritize safety features when selecting accessories. Look for high-quality materials and construction that can withstand significant forces. Regular inspection and maintenance of your tools will enhance their performance and extend their lifespan, ultimately ensuring you are prepared for any challenge.

Safety Tips for Winch Use

Using a hoisting device can be incredibly useful for various tasks, but it also comes with its own set of risks. To ensure safe operation, it’s essential to follow specific guidelines and practices that minimize hazards. Being aware of these precautions can help prevent accidents and injuries while maximizing efficiency.

1. Read the Manual

Before operating any equipment, familiarize yourself with the manufacturer’s instructions. Understanding the specifications and limitations is crucial for safe usage.

2. Inspect Regularly

Conduct routine checks on your equipment. Look for signs of wear or damage, including frayed cables or malfunctioning components. Address any issues immediately to maintain optimal performance.

3. Use Protective Gear

Always wear appropriate safety equipment, such as gloves, goggles, and steel-toed boots. This protective gear can significantly reduce the risk of injury during operation.

4. Maintain a Safe Distance

When the device is in use, ensure that bystanders maintain a safe distance. Establish a designated area to keep others clear from potential hazards, such as falling objects or sudden releases.

5. Avoid Overloading

Be mindful of the weight limits specified by the manufacturer. Overloading can lead to equipment failure and serious accidents. Always calculate the weight of the load before attempting to lift or pull.

6. Stay Alert

Maintain focus while operating the device. Distractions can lead to mistakes. Ensure you are fully aware of your surroundings and any potential risks.

7. Practice Proper Techniques

Use correct lifting and pulling techniques to enhance safety. Always ensure that the load is balanced and secure before moving it.

8. Know Emergency Procedures

Be prepared for unexpected situations. Familiarize yourself with emergency protocols and ensure that all operators know how to respond to potential emergencies.

By following these safety recommendations, you can greatly reduce risks associated with using a hoisting device, ensuring a more secure and efficient experience.

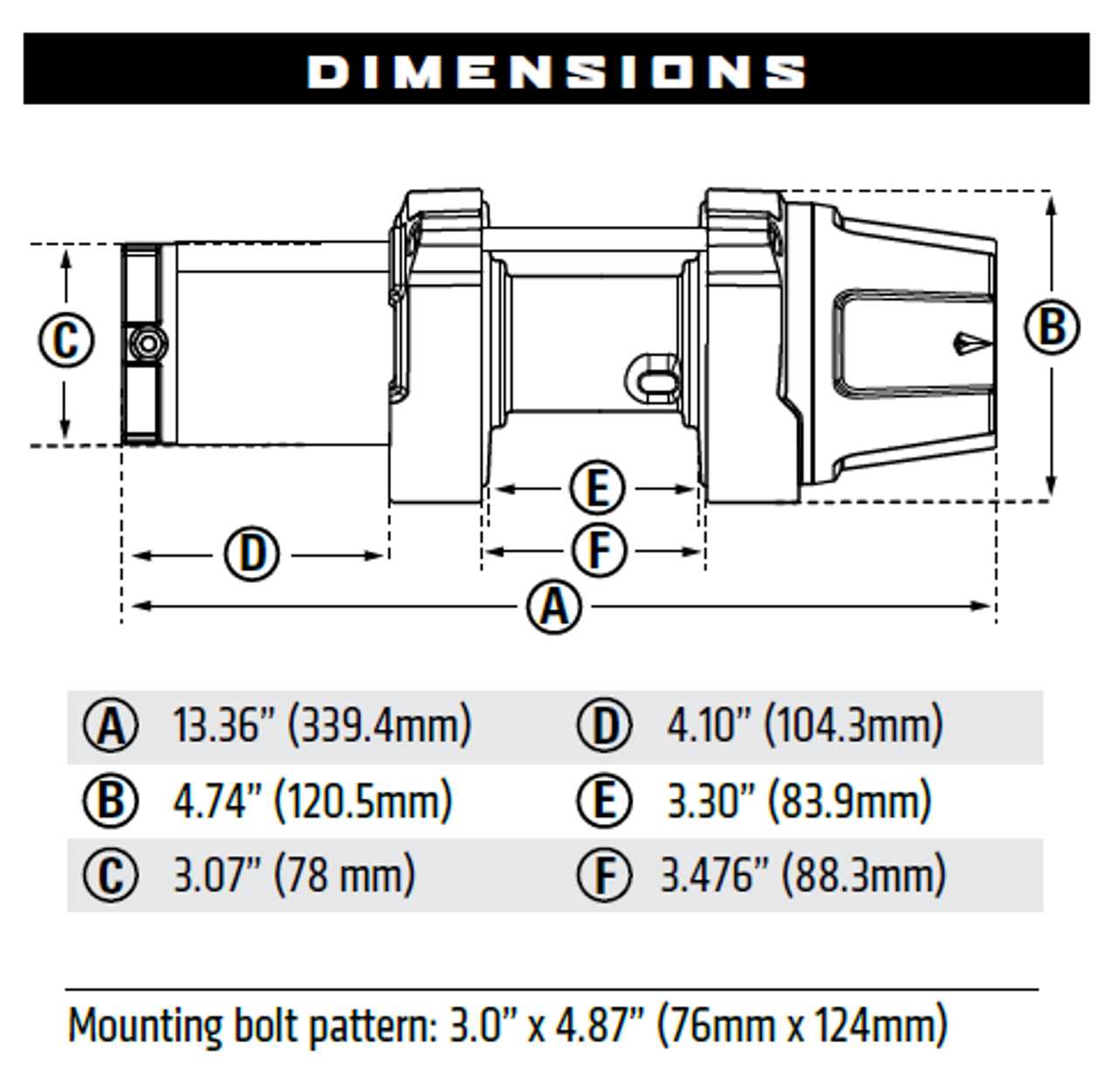

How to Install Winch Components

Proper assembly of your device is crucial for optimal performance and safety. This section provides a step-by-step guide to help you seamlessly integrate various elements, ensuring everything functions harmoniously. Understanding the components and their roles will facilitate a smoother installation process.

Step 1: Gather Tools and Components

Step 2: Prepare the Mounting Surface

Ensure the area where you plan to install is clean and free of debris. A stable and level surface will help secure components more effectively and prevent issues down the line.

Step 3: Secure the Main Unit

Attach the primary mechanism to the prepared area using appropriate fasteners. Ensure that it is tightly fixed to prevent any movement during operation. Double-check alignment for optimal functionality.

Step 4: Connect the Auxiliary Parts

Next, carefully connect additional elements, such as the control system and power supply. Follow the provided guidelines to ensure proper connections. Pay attention to polarity and wiring to avoid potential malfunctions.

Step 5: Test the Setup

After installation, conduct a thorough check of the entire setup. Test each component individually to ensure they operate as expected. Look for any irregular sounds or movements that could indicate misalignment.

Step 6: Final Adjustments

If necessary, make adjustments to improve performance or ease of use. Regular maintenance checks can help sustain functionality and extend the lifespan of your assembly.

Upgrading Your Winch System

Enhancing your towing mechanism can significantly improve its performance and reliability. By focusing on various components, you can create a more efficient setup that meets your specific needs.

- Evaluate the existing components to identify areas for improvement.

- Consider upgrading the motor for increased power and speed.

- Replace the cable with a more durable and lightweight alternative.

- Invest in advanced control systems for better precision and ease of use.

By systematically addressing each element, you can achieve the ultimate enhancement to your equipment, ensuring it performs optimally in any situation.

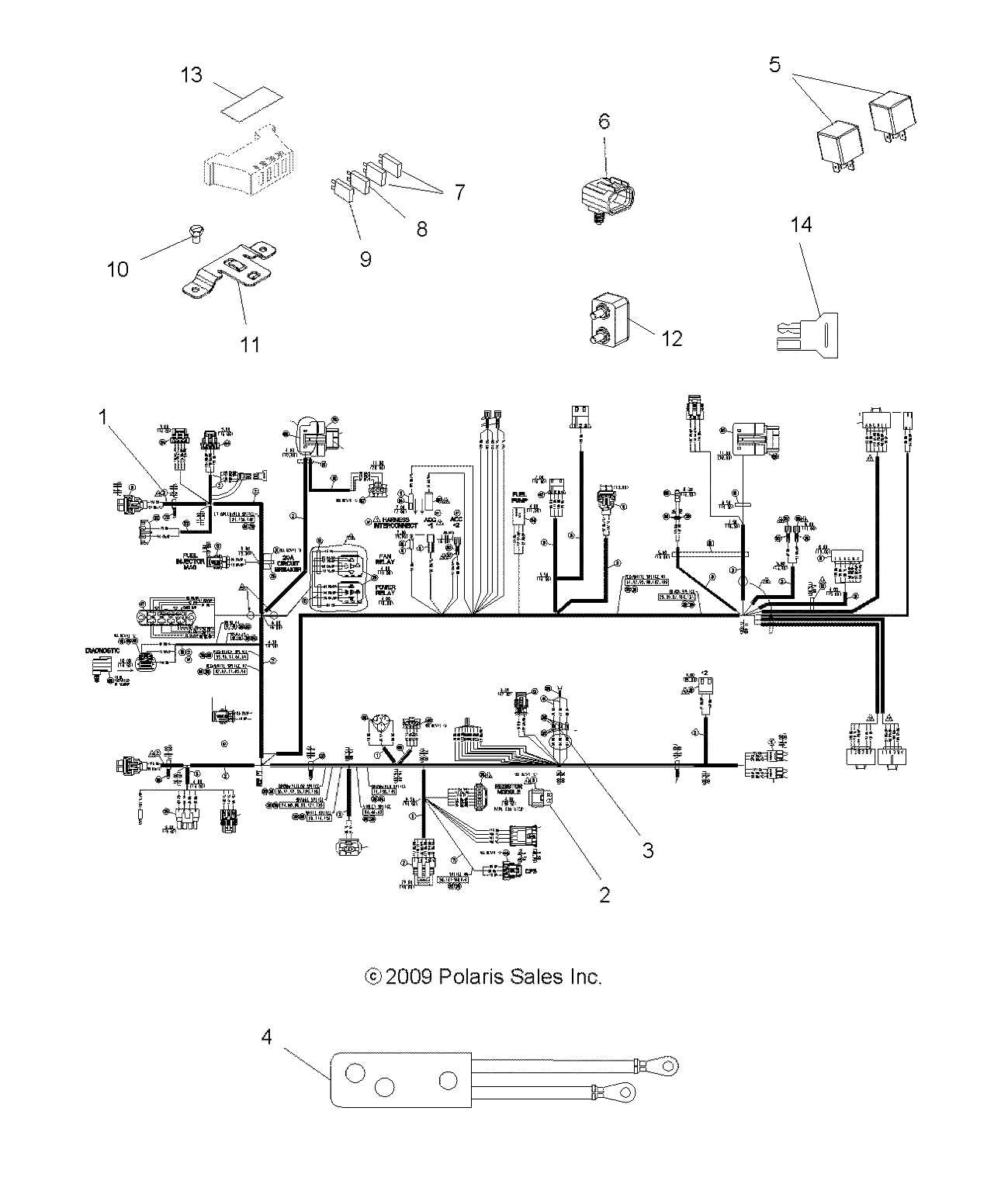

Winch Wiring and Electrical Basics

Understanding the fundamentals of wiring and electrical systems is crucial for the efficient operation of recovery tools. Proper connections and electrical components ensure reliable performance and safety during use. This section will delve into the essential concepts and components involved in setting up these systems effectively.

Key Components of the Electrical System

An effective electrical system includes several critical elements that work together seamlessly. Each component plays a vital role in ensuring the smooth operation of the device. Below are some of the primary parts you should be familiar with:

| Component | Function |

|---|---|

| Battery | Provides the necessary power to operate the system. |

| Switch | Controls the flow of electricity to the motor. |

| Motor | Converts electrical energy into mechanical energy for operation. |

| Wiring | Connects all components and facilitates the flow of electricity. |

| Fuse | Protects the system from electrical overloads. |

Basic Wiring Principles

When setting up the electrical connections, it’s essential to follow basic wiring principles to ensure safety and efficiency. Begin by using appropriately gauged wires to handle the current load. Ensure all connections are secure to prevent power loss and avoid potential hazards. Additionally, implementing proper grounding techniques is critical to minimize electrical interference and enhance the overall performance of the system.

Exploring Winch Operation Techniques

Understanding the mechanics and strategies behind pulling systems is essential for effective usage in various applications. Mastery of these techniques not only enhances performance but also ensures safety and efficiency in operations. By delving into operational methods, users can achieve optimal results in challenging environments.

One crucial aspect involves mastering the setup and alignment of the device. Ensuring that the pulling mechanism is correctly positioned can significantly impact the effectiveness of the operation. Users should familiarize themselves with various configurations to adapt to different scenarios.

Another vital technique is the proper management of tension. Maintaining the right amount of strain on the cable or line is key to preventing damage and ensuring smooth operation. Regularly checking and adjusting tension during use can make a significant difference.

Lastly, understanding the different types of control systems available can enhance user experience. Familiarity with manual and automatic options allows operators to select the most suitable method for their specific tasks, ultimately improving efficiency and reliability.