Understanding the Superwinch Parts Diagram for Efficient Repairs

In the realm of heavy-duty equipment, the intricate interplay of various elements is crucial for optimal functionality. Each component plays a vital role, contributing to the overall performance and reliability of the system.

To fully appreciate the mechanics at work, one must delve into the individual sections that compose these machines. Grasping the structure allows users to make informed decisions regarding maintenance and upgrades, ensuring longevity and efficiency.

Ultimately, a clear visualization of these mechanisms empowers operators to troubleshoot effectively and enhances their operational expertise. A comprehensive grasp of each segment not only improves performance but also fosters confidence in handling equipment.

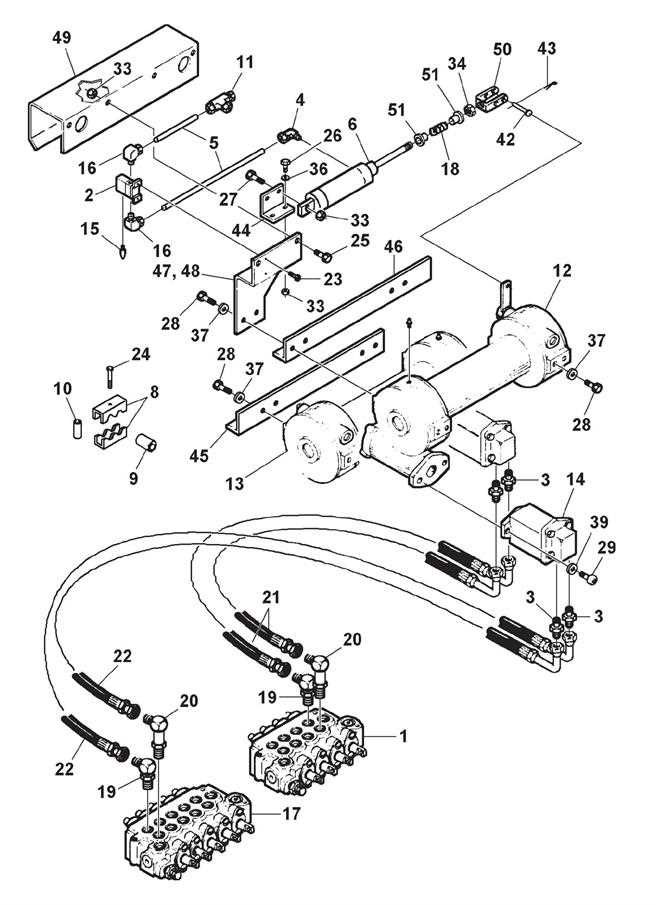

Understanding Superwinch Components

When delving into the intricacies of a winching system, it’s essential to comprehend the various elements that work harmoniously to ensure optimal performance. Each component plays a crucial role in the overall functionality, contributing to efficiency, safety, and reliability during operations.

The motor serves as the powerhouse of the system, providing the necessary torque to pull heavy loads. Its power rating and design significantly influence the winch’s capabilities, making it a fundamental part of the setup.

The drum, where the cable is wound, is engineered to manage the length and tension of the line effectively. The material and dimensions of the drum are critical for maintaining durability and reducing wear over time.

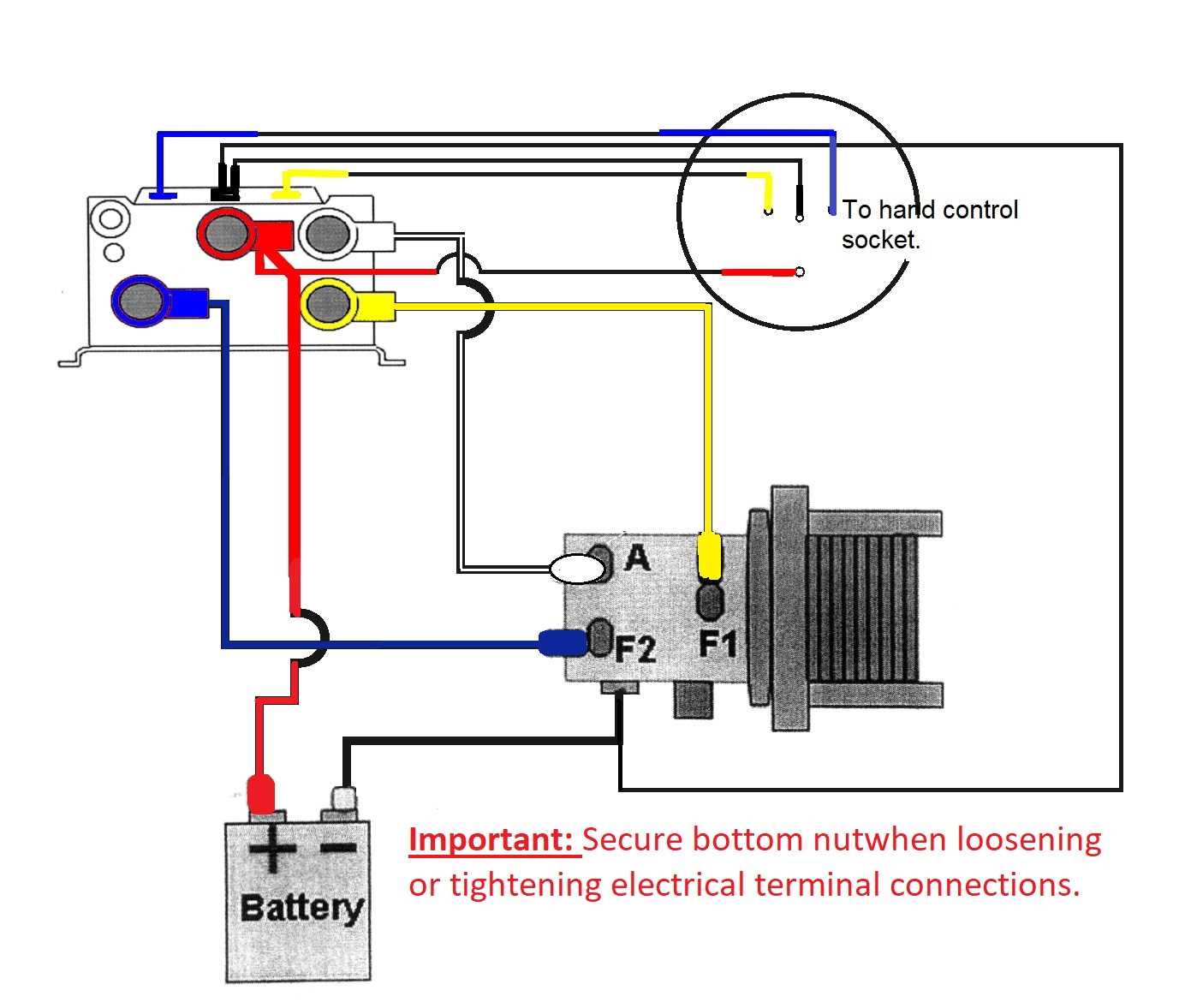

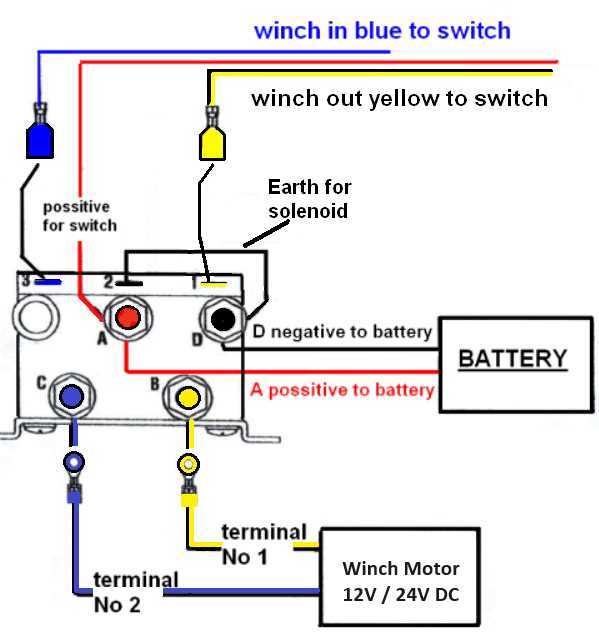

Control mechanisms, whether manual or remote, allow for precise operation. Understanding how these controls interact with the motor and other components is vital for ensuring safe and efficient use.

Additional elements, such as the cable or synthetic line, play a significant role in load management. Choosing the right type and size is essential for maximizing performance while minimizing risks during heavy lifting.

Grasping the functionalities of each component provides insight into how they contribute to the system’s overall effectiveness, enabling users to make informed decisions for maintenance and upgrades.

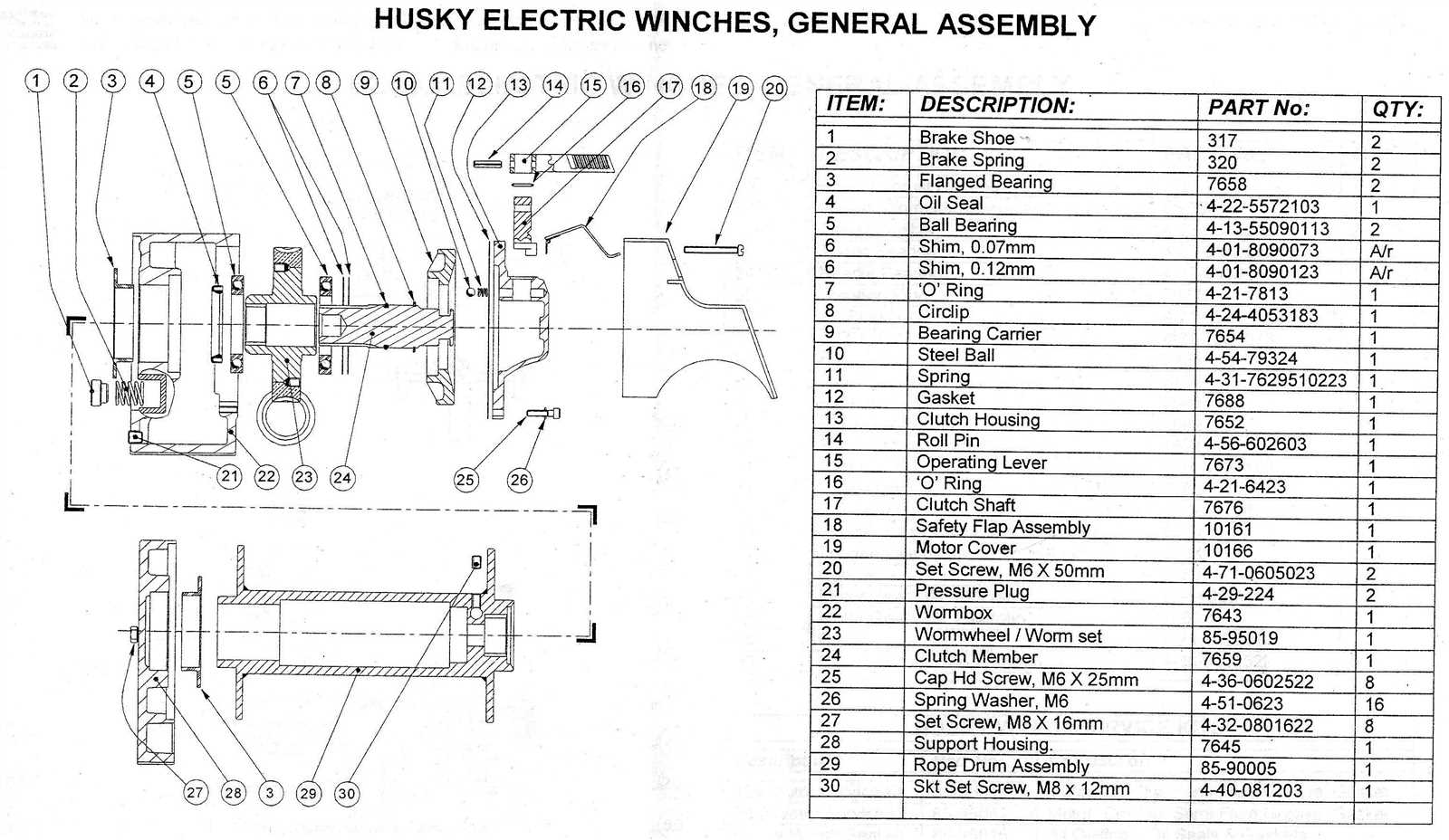

Importance of a Parts Diagram

Understanding the layout of components within a mechanical system is crucial for effective maintenance and repair. A clear representation enables users to quickly identify and locate each element, ensuring efficiency during troubleshooting and assembly.

Enhanced Clarity

Having a visual reference offers several advantages:

- Facilitates quick identification of components

- Reduces the likelihood of errors during assembly

- Aids in understanding the relationship between different parts

Streamlined Maintenance

Utilizing a comprehensive visual guide can significantly improve maintenance processes:

- Helps in pinpointing wear or damage

- Guides users in ordering the correct replacements

- Enhances overall system reliability and performance

Common Issues with Winch Parts

Winching systems can encounter various challenges that may hinder their performance and reliability. Understanding these common problems is essential for maintenance and ensuring optimal functionality.

- Wear and Tear: Over time, components can degrade due to constant use, leading to reduced efficiency.

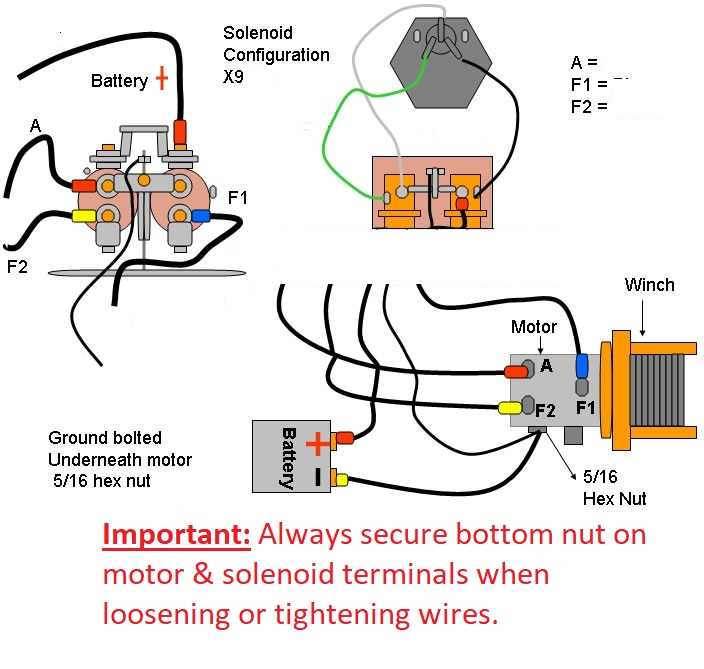

- Electrical Failures: Issues with wiring or connections can disrupt power supply, affecting operation.

- Mechanical Malfunctions: Gears and drums may become misaligned or damaged, resulting in ineffective winching.

- Corrosion: Exposure to elements can lead to rust and deterioration, especially in outdoor environments.

- Overheating: Continuous operation without breaks may cause overheating, risking permanent damage.

Regular inspection and maintenance can help mitigate these issues, ensuring that the system remains reliable and efficient for any task.

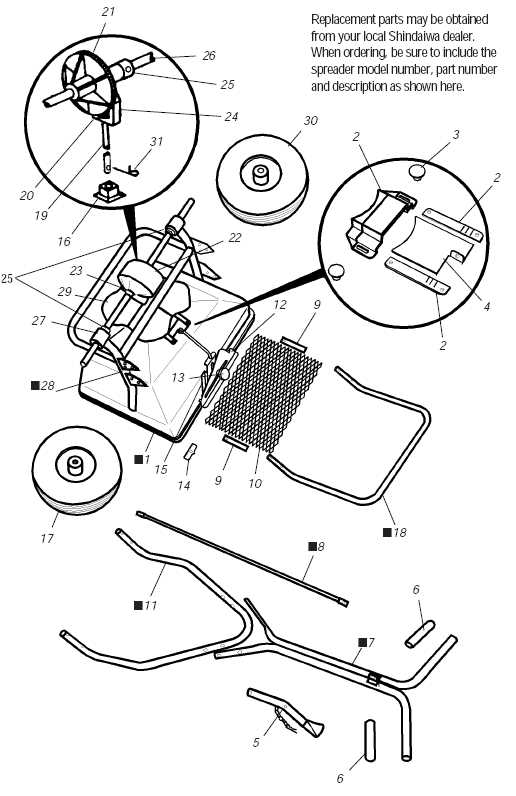

How to Read a Parts Diagram

Understanding a technical illustration is crucial for effective assembly and maintenance of machinery. This guide will provide insights into interpreting these visual guides, enhancing your ability to identify components and their functions within a system.

Key Elements to Look For

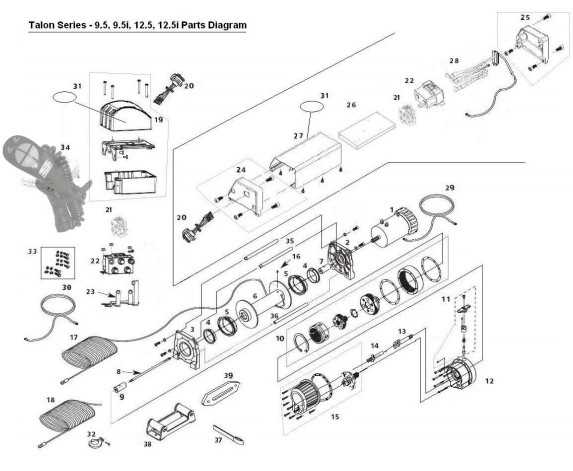

When examining a visual representation, focus on symbols and labels. Each component will usually be numbered or marked with letters, corresponding to a legend or list that details their specifications. Familiarizing yourself with these markers can significantly streamline the identification process.

Tips for Effective Interpretation

To effectively analyze the visual guide, first, familiarize yourself with the overall layout and structure. Start from the top left corner and work your way down, ensuring you understand the relationships between different components. This methodical approach will help you build a comprehensive understanding of the assembly as a whole.

Essential Tools for Maintenance

Proper upkeep of equipment requires a selection of fundamental instruments to ensure efficiency and longevity. Having the right tools at hand not only facilitates routine checks but also enables swift repairs when needed.

Basic Tool Requirements

Every maintenance kit should include various essential items. These tools assist in both preventive measures and emergency fixes, allowing for seamless operation.

| Tool | Function |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Fastening or removing screws |

| Pliers | Gripping and twisting wires |

| Socket Set | Efficiently handling nuts and bolts |

| Torque Wrench | Ensuring proper tightness |

Additional Recommendations

In addition to the basics, consider investing in specialized tools tailored for specific tasks. This approach not only enhances productivity but also promotes safe and effective maintenance practices.

Upgrading Your Superwinch System

Enhancing your winching setup can significantly improve performance and reliability in challenging situations. Upgrades may involve incorporating advanced components or modifying existing equipment to meet specific needs. This section explores various strategies to elevate your winching experience.

Choosing the Right Accessories

Selecting appropriate accessories can make a considerable difference in functionality. Consider the following options:

| Accessory | Benefits |

|---|---|

| Remote Control | Offers convenience and safety by allowing operation from a distance. |

| Snatch Block | Increases pulling power and reduces strain on the cable. |

| Heavy-Duty Cable | Enhances durability and load capacity, reducing the risk of breakage. |

Installing Upgraded Components

Investing in superior components can elevate the performance of your system. Focus on the following key elements:

- Motor: A more powerful motor can provide increased torque for demanding tasks.

- Gear Ratio: Opting for a better gear ratio can improve speed and efficiency.

- Control System: Upgrading to a more advanced control unit can enhance responsiveness and features.

Safety Tips for Winch Operation

Operating a winching device requires careful attention to safety protocols to prevent accidents and ensure efficient performance. By adhering to specific guidelines, users can enhance their safety and that of those around them while utilizing this powerful tool.

Pre-Operation Checks

Before initiating any winching activity, conduct a thorough inspection of the equipment. Check for wear and tear on cables, connectors, and the winching mechanism. Ensure that all components are securely attached and functioning properly to avoid unexpected failures during operation.

Proper Usage Techniques

When in use, maintain a safe distance from the winch and the load being moved. Always use appropriate protective gear, including gloves and safety glasses. Be aware of your surroundings and ensure that bystanders are at a safe distance to minimize risks during operation.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and reliability. Whether you’re dealing with wear and tear or upgrading for enhanced functionality, knowing where to seek these items can save you time and ensure you find the right fit.

Online Retailers

Many online platforms specialize in offering a wide array of components for various machinery. Websites like Amazon and eBay feature numerous listings, allowing you to compare prices and reviews easily. Additionally, manufacturer websites often provide direct options for ordering authentic items.

Local Dealers and Repair Shops

Visiting local dealers or specialized repair shops can be beneficial for those who prefer hands-on assistance. These establishments not only carry stock but also possess valuable knowledge about compatibility and installation, ensuring you receive tailored advice and support.

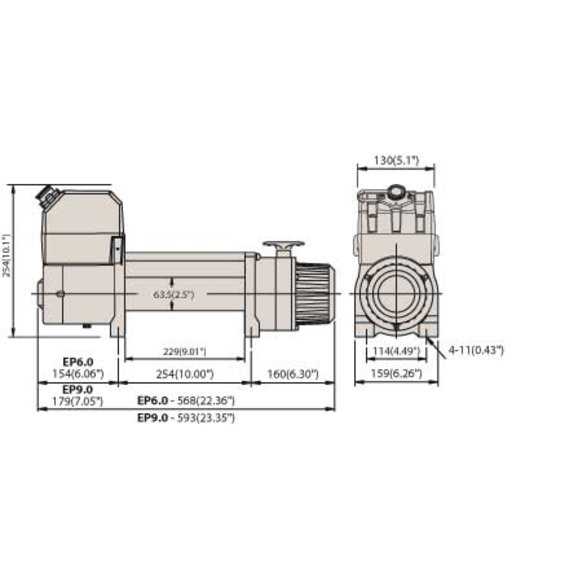

Comparing Different Superwinch Models

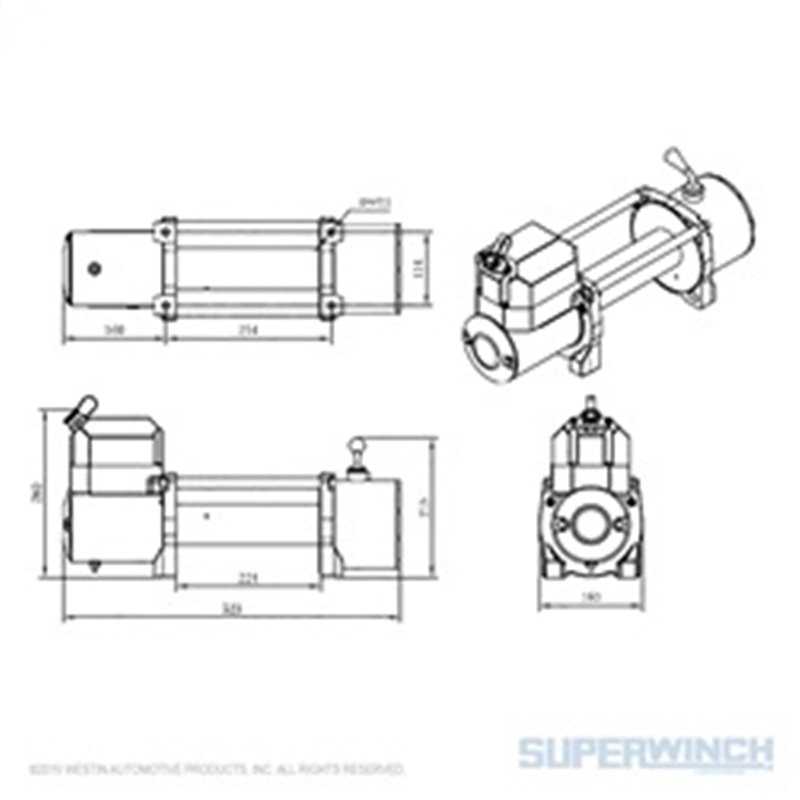

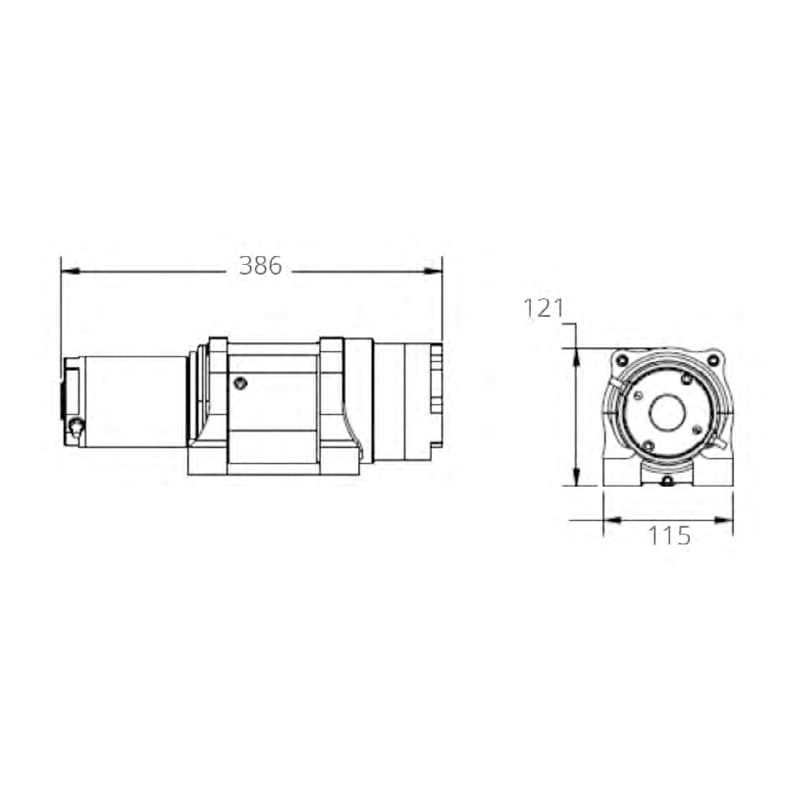

When evaluating various models of cable pulling devices, it’s essential to consider their unique features, capabilities, and applications. Each variant is designed with specific tasks in mind, catering to diverse user needs, whether for off-road adventures, industrial uses, or rescue operations. Understanding these differences helps in selecting the right equipment for optimal performance.

Power and Capacity

One of the primary distinctions among these devices is their power output and load capacity. Some models are engineered for lighter tasks, making them ideal for smaller vehicles or recreational use. In contrast, others offer robust performance, capable of handling heavier loads in challenging conditions. This range of specifications allows users to choose the most suitable option based on their intended application.

Durability and Features

Another crucial factor is the durability and additional features offered by each model. Many devices come equipped with advanced technology, such as wireless controls or enhanced braking systems, providing added convenience and safety. Additionally, the materials used in construction play a significant role in longevity, ensuring reliable operation even in demanding environments. Comparing these aspects can significantly influence the decision-making process.

DIY Repairs: What You Need

When tackling maintenance tasks on your equipment, having the right tools and components at your disposal is essential. Whether you’re fixing a mechanical issue or upgrading features, understanding what you require can make the process smoother and more efficient.

Essential Tools

Before diving into any repair, ensure you have a solid toolkit. Basic items include:

- Wrenches: Various sizes for loosening and tightening.

- Screwdrivers: Both flathead and Phillips for different types of screws.

- Pliers: For gripping and manipulating small parts.

- Socket Set: Essential for larger bolts and nuts.

Replacement Components

Identifying and acquiring the correct replacement items is crucial. Pay attention to:

- Compatibility: Ensure parts fit your specific model.

- Quality: Choose durable materials for long-lasting repairs.

- Manufacturer Recommendations: Follow guidelines for optimal performance.

By being well-prepared with the right tools and components, you can confidently handle any repair job that comes your way.

Enhancing Performance with Upgrades

Improving the efficiency and capability of your equipment can lead to significant advantages in various applications. By focusing on specific enhancements, users can experience better functionality, durability, and overall satisfaction.

Key Areas for Improvement

- Power Supply: Upgrading to a more robust power source can enhance performance.

- Mechanical Components: Replacing outdated elements with high-quality alternatives boosts reliability.

- Control Systems: Implementing advanced control mechanisms allows for precise operation.

Benefits of Upgrading

- Increased Efficiency: Enhanced components lead to better energy use.

- Longer Lifespan: Quality upgrades reduce wear and tear.

- Improved Safety: Modern systems often include safety features that protect users.