Comprehensive Guide to Warn Winch Parts Diagram

When it comes to robust machinery designed for challenging terrains, knowing the intricate layout of essential components is crucial for optimal performance and maintenance. Each element plays a vital role, ensuring the entire system operates smoothly and efficiently. A thorough comprehension of these arrangements not only aids in troubleshooting but also enhances the longevity of the equipment.

In this section, we will explore the various segments that make up this powerful apparatus. By delving into their functions and interconnections, users can better appreciate how these components interact with one another. Such insights can prove invaluable for operators looking to improve their skills or for enthusiasts eager to deepen their knowledge.

Furthermore, understanding these configurations is key to effective repairs and upgrades. With clear illustrations and detailed descriptions, this guide aims to provide clarity on how each piece fits into the larger puzzle. Whether you’re a seasoned professional or a newcomer, mastering these layouts will empower you to tackle challenges with confidence.

Understanding Warn Winch Components

Exploring the intricate elements of a recovery system reveals how each component plays a vital role in ensuring functionality and reliability. A comprehensive grasp of these mechanisms not only enhances efficiency but also aids in troubleshooting and maintenance. This section delves into the essential features that comprise this powerful tool, emphasizing their significance in various applications.

Key Elements of the Recovery System

The heart of the operation lies in the motor, which provides the necessary power to initiate movement. Coupled with a robust spool, this assembly allows for the effective winding and unwinding of the cable. Additionally, the control unit serves as the interface, granting the user command over the entire setup. Understanding these core elements is crucial for maximizing performance.

Additional Components and Their Functions

Beyond the primary features, various auxiliary components contribute to overall efficiency. Clutches play a significant role in engaging and disengaging the mechanism, while gear systems facilitate the translation of power into motion. Furthermore, the mounting hardware ensures stability and security during operation. A well-rounded knowledge of these parts enables users to optimize their equipment for diverse challenges.

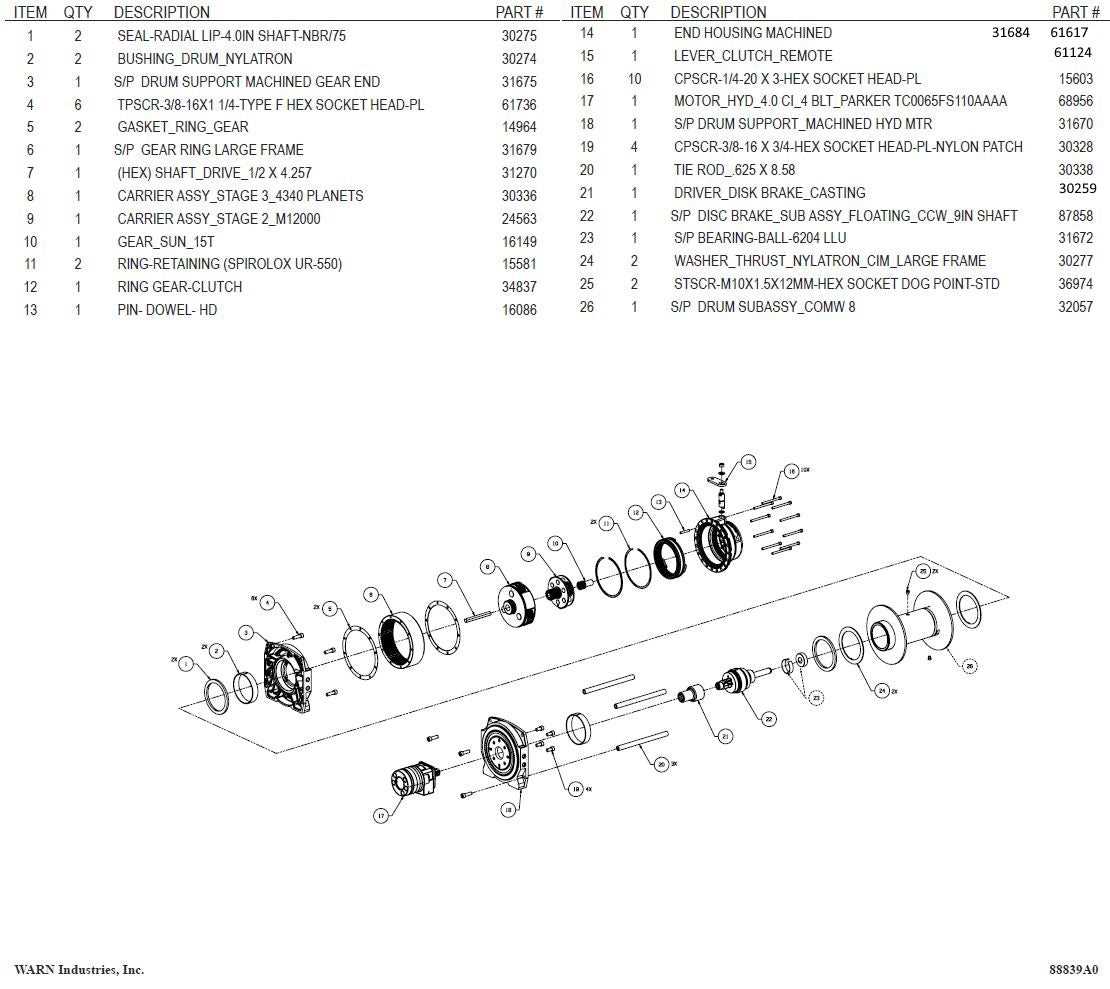

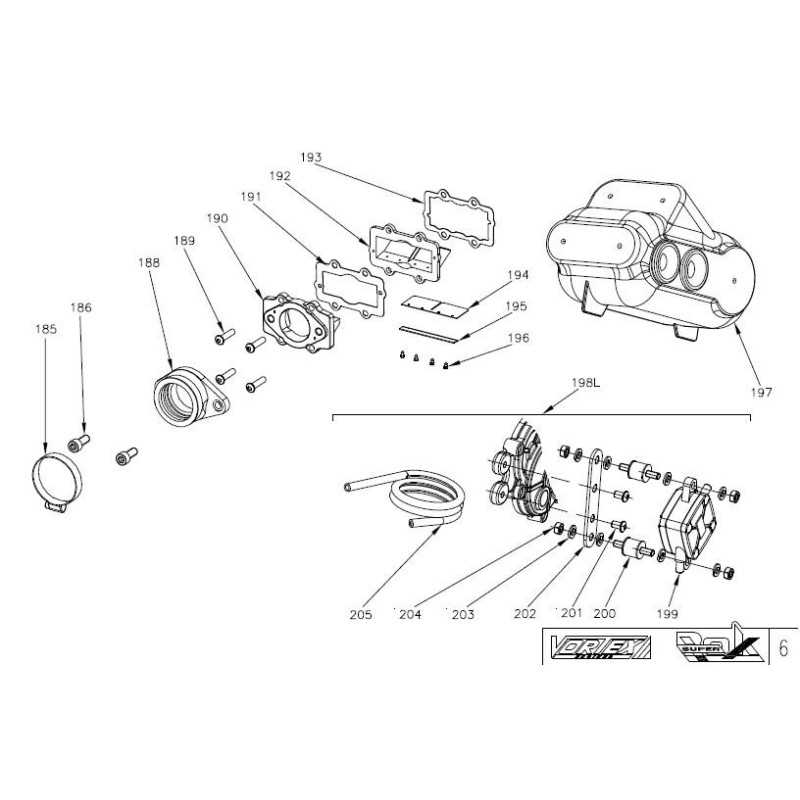

Types of Warn Winches Available

When it comes to recovery equipment, various models cater to different needs and preferences, ensuring that every user finds a suitable solution for their specific requirements. Understanding the distinctions among these options can significantly enhance performance and safety during demanding tasks.

Electric Models

Electric systems are known for their convenience and ease of use. They operate smoothly, relying on battery power, making them ideal for quick setups and on-the-go applications. These units are popular among off-road enthusiasts for their reliability and efficient operation.

Pneumatic Options

Pneumatic alternatives utilize air pressure for functionality, which can be advantageous in certain environments. These systems often provide robust power and are favored for industrial applications where electric power may not be available. Their versatility makes them a compelling choice for heavy-duty tasks.

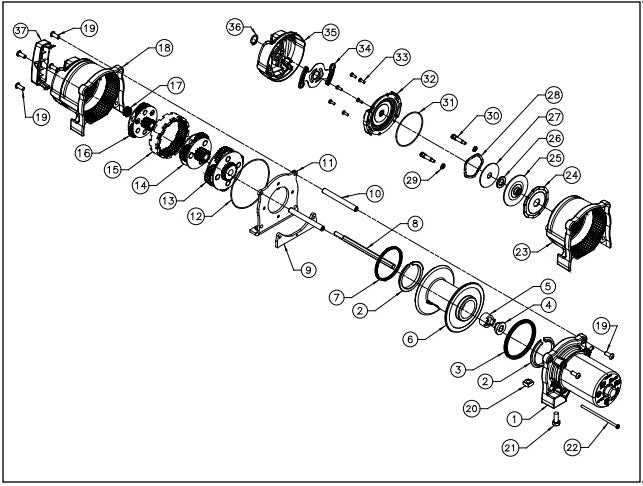

Key Parts of a Winch System

The functionality of a pulling mechanism relies on several crucial components that work in harmony to ensure efficiency and reliability. Understanding these elements is essential for optimal operation and maintenance.

Drum: This cylindrical component serves as the core around which the cable winds. Its design influences the pulling capacity and overall strength of the system.

Motor: A powerful engine drives the mechanism, converting electrical or hydraulic energy into the motion needed to reel in or let out the cable.

Gear Train: This system of gears amplifies the motor’s power, enabling greater torque and enhancing the pulling ability, especially under heavy loads.

Cable: Made from robust materials, this element is essential for strength and durability, ensuring it can withstand significant tension without snapping.

Control System: The interface allows the operator to manage the movement of the cable, providing safety and precision during operation.

Fairlead: This guide helps to direct the cable, minimizing wear and preventing tangles, ensuring smooth operation as it unwinds and winds.

Importance of Winch Maintenance

Regular upkeep of mechanical lifting devices is crucial for ensuring their longevity and optimal performance. Proper maintenance not only enhances reliability but also minimizes the risk of malfunctions during critical operations. Neglecting these essential tasks can lead to unexpected breakdowns and safety hazards, making it imperative to establish a consistent maintenance routine.

Benefits of Regular Care

Consistent attention to mechanical systems provides numerous advantages, including improved efficiency, extended lifespan, and enhanced safety for users. By addressing wear and tear early on, operators can prevent costly repairs and ensure the equipment functions correctly under demanding conditions.

Key Maintenance Tasks

| Task | Description | Frequency |

|---|---|---|

| Inspection | Check for signs of wear, corrosion, and damage. | Monthly |

| Lubrication | Apply appropriate lubricants to moving parts. | Every 3 months |

| Functional Testing | Test the device under load to ensure proper operation. | Quarterly |

| Cleaning | Remove dirt and debris from components. | Monthly |

| Replacement of Worn Parts | Replace components that show significant wear. | As needed |

In conclusion, maintaining these essential mechanical devices is not just about performance; it is a critical aspect of ensuring user safety and operational reliability. Establishing a comprehensive maintenance plan will contribute to the efficiency and effectiveness of the equipment in the long run.

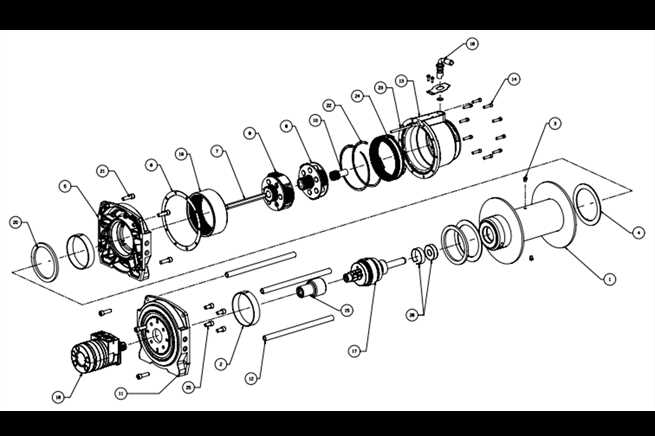

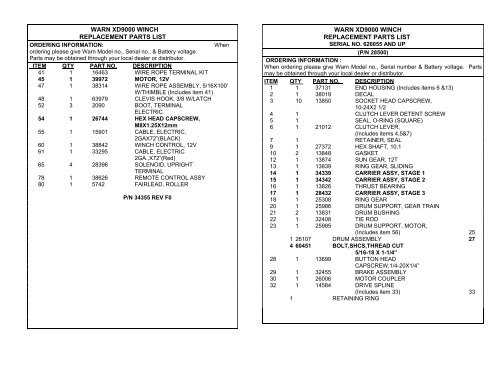

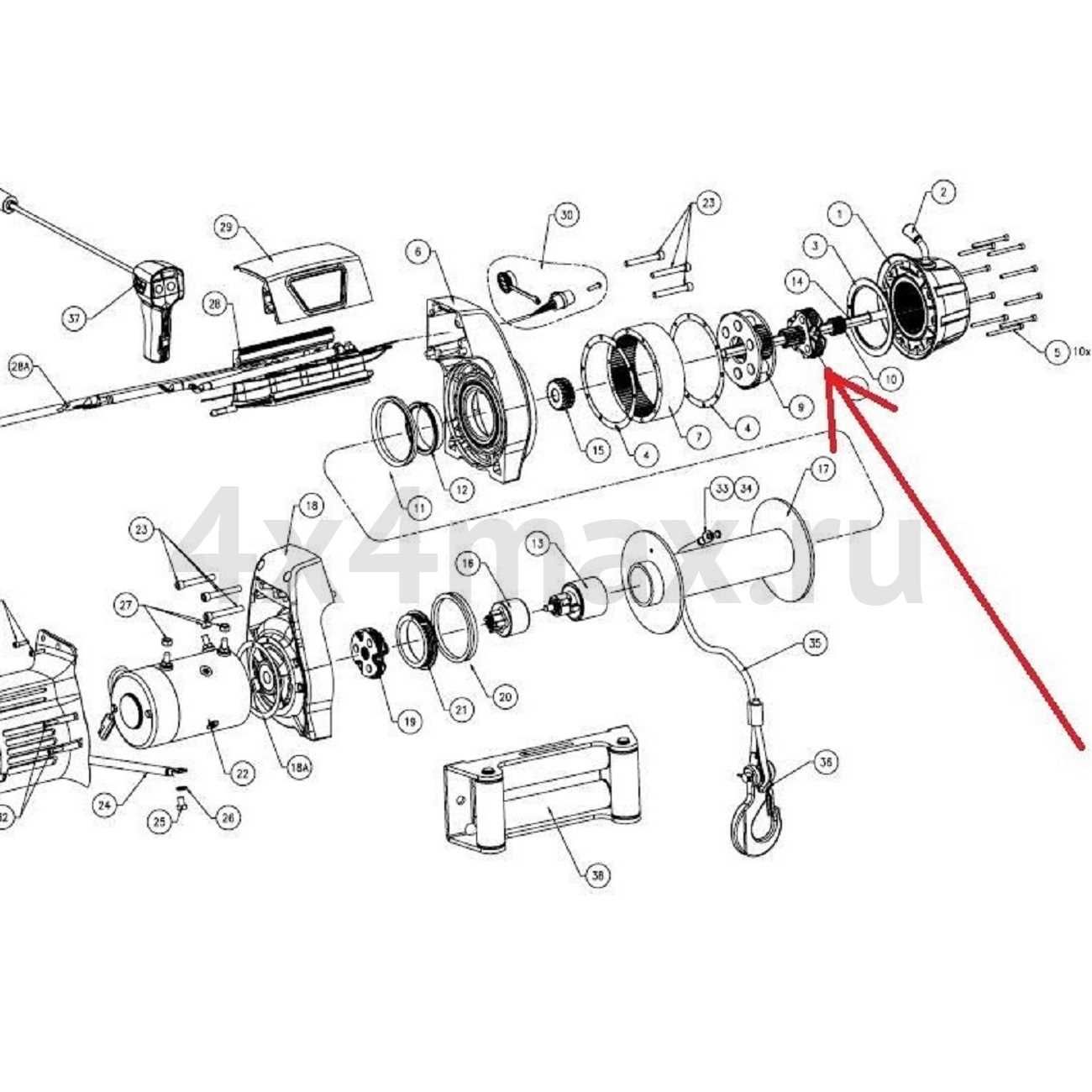

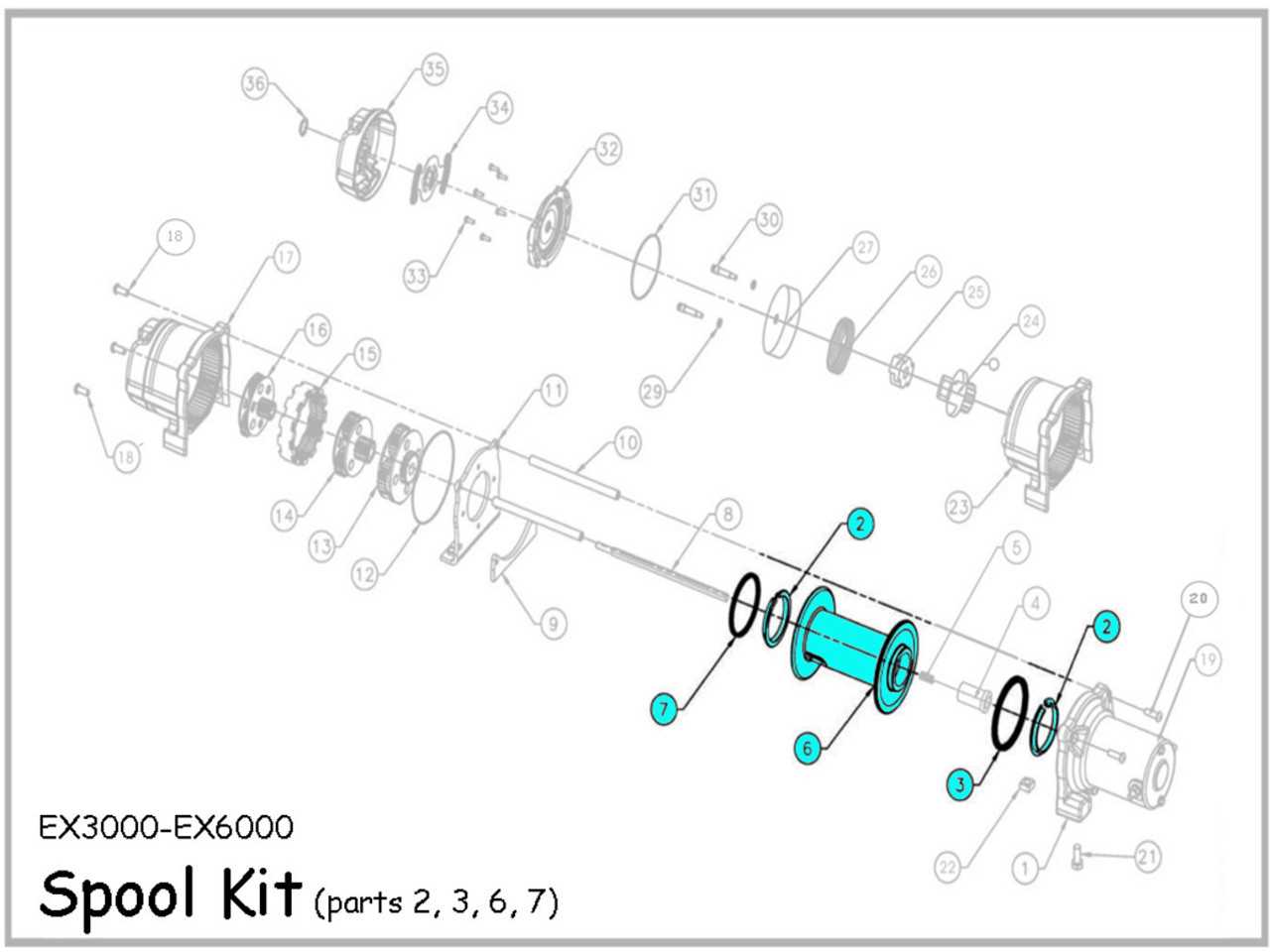

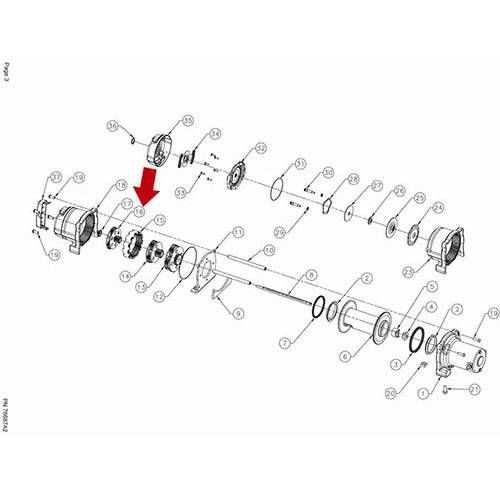

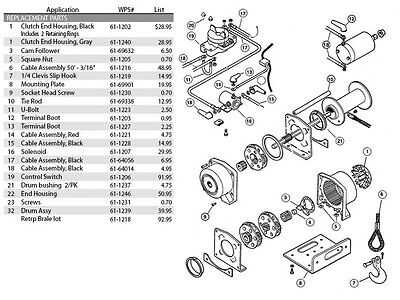

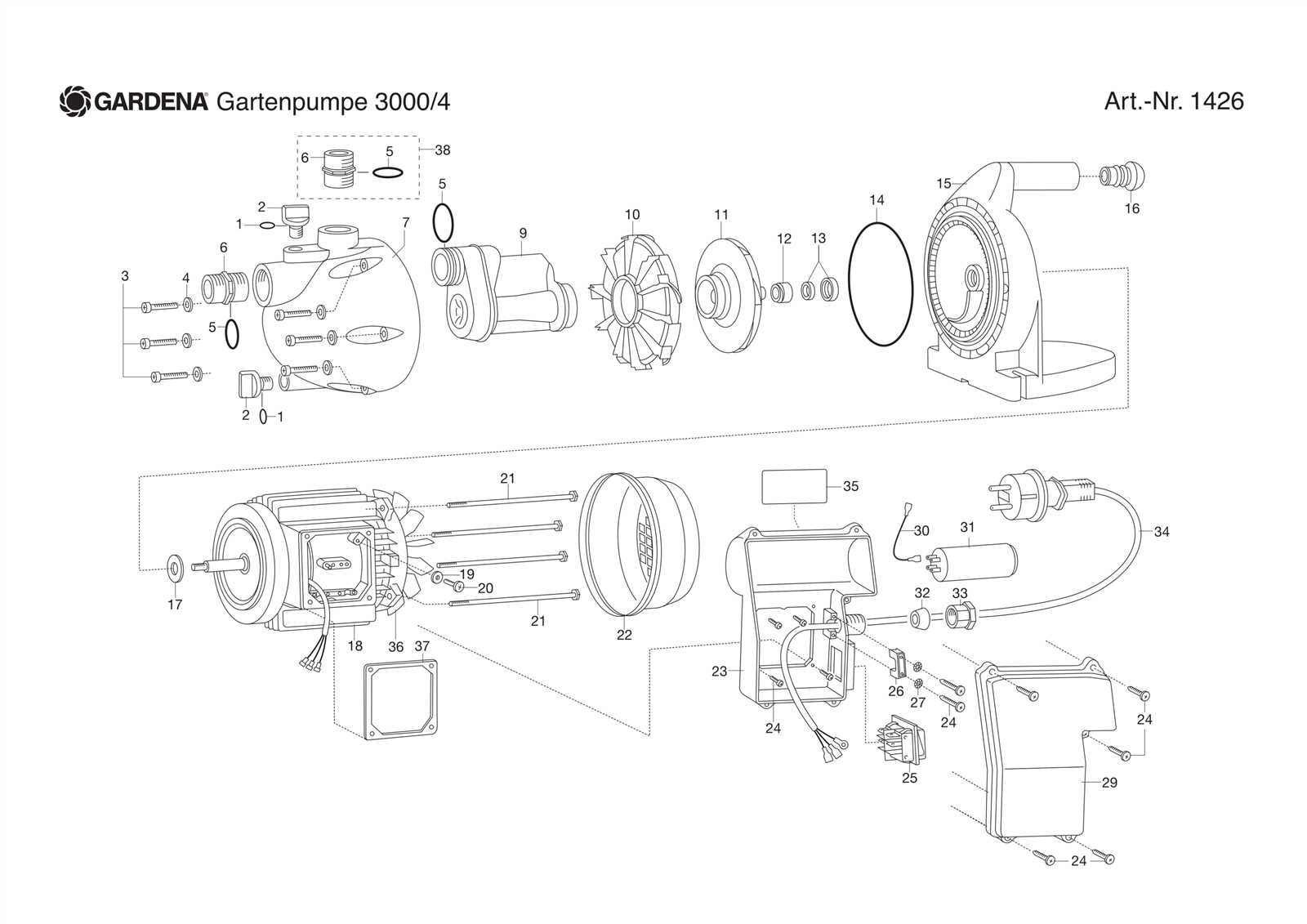

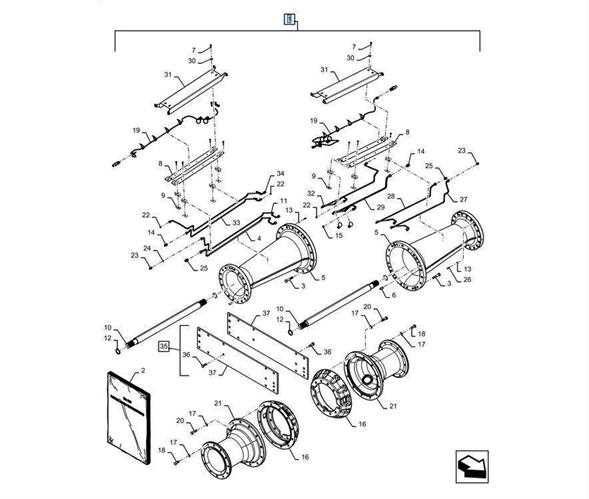

Identifying Winch Part Diagrams

Understanding the components of a pulling mechanism is essential for effective maintenance and operation. Recognizing these elements can enhance performance and prolong the lifespan of the equipment. Familiarity with the various sections of the assembly allows users to troubleshoot issues efficiently.

Key Components to Recognize

When examining the blueprint, focus on the drive system, which often includes the motor and gear assembly. Additionally, the spool and rope guide are crucial for ensuring smooth operation during use. Each part plays a significant role in the overall functionality.

Utilizing Diagrams for Maintenance

Consulting detailed schematics is invaluable when performing repairs or upgrades. These illustrations provide clarity on assembly, enabling users to identify wear and potential failure points. Regularly reviewing these resources can lead to improved knowledge and better care of the machinery.

Common Issues with Winch Parts

In the realm of heavy-duty pulling devices, certain challenges frequently arise that can hinder performance and reliability. Understanding these common complications is crucial for maintaining optimal functionality and ensuring safety during operation. This section delves into typical problems encountered, as well as their potential solutions.

Mechanical Failures

One of the primary issues that can arise involves mechanical components failing due to wear and tear. These failures often manifest in the form of unusual noises or decreased efficiency during operation. Regular inspections can help identify potential concerns before they escalate.

Electrical Malfunctions

Electrical problems can also lead to significant operational disruptions. Issues such as faulty connections or worn-out wiring may result in the device not responding as expected. Ensuring that all electrical components are regularly checked can prevent these issues from occurring.

| Issue | Description | Solution |

|---|---|---|

| Mechanical Failure | Wear and tear on components can lead to reduced performance. | Conduct regular inspections and replace worn parts. |

| Electrical Malfunction | Faulty connections or wiring can disrupt operations. | Regularly check and maintain all electrical systems. |

| Overheating | Excessive heat can damage internal components. | Monitor temperature and allow for cooldown periods. |

| Corrosion | Moisture exposure can lead to rust and deterioration. | Keep components dry and apply protective coatings. |

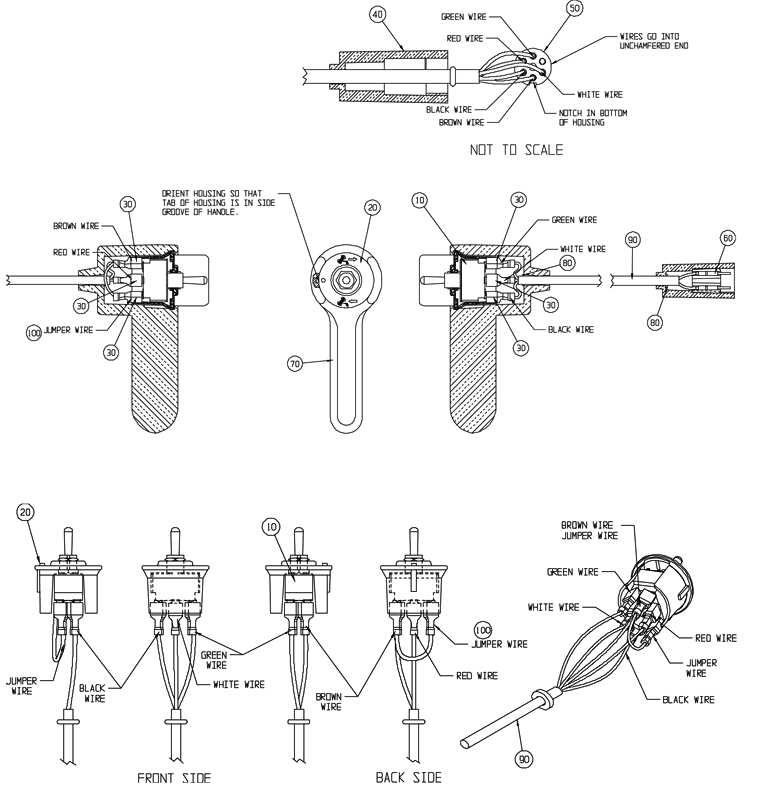

How to Read Winch Diagrams

Understanding the schematic representations of equipment can significantly enhance your ability to maintain and troubleshoot machinery. These visual guides provide crucial insights into the components and their interconnections, allowing users to identify parts and comprehend their functions more effectively.

Identifying Key Components

Begin by familiarizing yourself with the symbols and notations used in the illustrations. Each symbol typically represents a specific element, such as gears, cables, or motors. Take note of the legends provided, as they serve as a reference for decoding the imagery. Understanding these symbols is essential for grasping the overall layout and flow of operations.

Understanding Connections and Functions

Next, focus on the relationships between the components. Lines connecting symbols often indicate the flow of power or mechanical movement. Pay attention to the direction of these connections, as they are critical for understanding how energy is transferred within the system. Analyzing these relationships will help you troubleshoot issues or plan for maintenance effectively.

Replacing Damaged Winch Components

Maintaining optimal performance in heavy-duty equipment requires vigilance, especially when components show signs of wear or damage. Timely replacements can prevent further issues and ensure safety during operation. Understanding how to effectively identify and replace these essential elements is crucial for reliable functionality.

Identifying Damaged Elements

Begin by conducting a thorough inspection. Look for signs of corrosion, cracks, or unusual wear patterns. Common indicators include strange noises during operation or difficulty in winding and unwinding. Early detection is key to preventing catastrophic failures.

Replacement Process

Once damaged components are identified, follow manufacturer guidelines for replacement. Gather the necessary tools and ensure you have compatible parts. Carefully remove the faulty components, taking care not to damage surrounding areas. Install the new pieces, ensuring all connections are secure and functional.

Choosing the Right Winch Parts

Selecting the appropriate components for your pulling system is crucial for optimal performance and safety. Understanding the various elements and their functions can significantly enhance your experience and efficiency.

- Capacity: Ensure the strength of the system matches the load requirements.

- Durability: Opt for materials that withstand harsh conditions and frequent use.

- Compatibility: Verify that all components fit seamlessly together for maximum efficiency.

When making your choice, consider the following factors:

- Type of application: Identify the specific tasks you will be undertaking.

- Environmental conditions: Choose elements that can endure weather exposure.

- Maintenance requirements: Look for options that minimize upkeep while ensuring reliability.

Ultimately, taking the time to evaluate your options can lead to a more effective and long-lasting setup.

Winch Accessories and Their Functions

In the realm of heavy-duty hauling equipment, various supplementary tools play crucial roles in enhancing performance and safety. These accessories are designed to complement the main apparatus, ensuring efficient operation and maximizing utility. Understanding their functions can significantly improve the overall experience and effectiveness of the equipment.

Snatch Blocks: These pulleys are essential for altering the direction of force and increasing the lifting capability. By enabling multiple configurations, they allow for smoother maneuvers and better load management.

Recovery Straps: Made from durable materials, these straps are vital for pulling vehicles out of tough situations. Their design absorbs shock loads, minimizing stress on both the equipment and the towed object.

Hooks: Sturdy and reliable, hooks are crucial for attaching the hauling line to various objects. Some models come with safety latches to prevent accidental disengagement, ensuring a secure connection.

Fairleads: These components guide the line to prevent tangling and wear. They help maintain a smooth operation and extend the lifespan of the hauling apparatus by reducing friction.

Remote Controls: Offering convenience and safety, these devices allow users to operate the system from a distance. This feature is particularly useful in hazardous environments where proximity could pose risks.

Investing in high-quality accessories not only enhances functionality but also ensures a safer and more efficient operation, making them indispensable for anyone relying on such equipment.

Safety Tips for Using Winches

When operating heavy machinery designed for pulling or lifting, prioritizing safety is essential. Proper precautions can prevent accidents and ensure smooth functioning. Adhering to recommended guidelines fosters a secure environment for both the operator and those nearby.

1. Read the Manual: Always familiarize yourself with the manufacturer’s instructions before usage. Understanding the specifications and features of the equipment enhances safety and efficiency.

2. Inspect Equipment: Conduct thorough checks on all components before starting. Look for wear and tear, frayed cables, or loose connections. Address any issues immediately to avoid malfunction during operation.

3. Use Protective Gear: Equip yourself with appropriate safety gear such as gloves, helmets, and eye protection. These items are vital for safeguarding against potential hazards associated with lifting and towing activities.

4. Establish a Safe Zone: Maintain a clear area around the machinery. Ensure that bystanders are at a safe distance to avoid injuries from sudden movements or potential equipment failures.

5. Communicate Clearly: Use hand signals or radios to coordinate with team members. Clear communication reduces the risk of misunderstandings, especially in noisy environments.

6. Avoid Overloading: Adhere to the specified load limits. Overloading not only compromises safety but can also damage the equipment and lead to accidents.

7. Stay Alert: Remain focused and attentive during operation. Avoid distractions and do not operate the machinery under the influence of alcohol or drugs.

By following these guidelines, operators can significantly reduce the risks associated with heavy lifting and towing tasks, ensuring a safer working environment for everyone involved.

Winch Repair: Tools You Need

Repairing heavy-duty pulling equipment requires a specific set of instruments to ensure effectiveness and safety. Having the right tools at hand can make the process smoother and more efficient, allowing for accurate diagnostics and repairs.

Essential tools include wrenches for loosening and tightening components, screwdrivers for accessing screws and fasteners, and pliers for gripping and bending parts. A socket set is also crucial for dealing with various bolt sizes. Additionally, a multimeter helps in diagnosing electrical issues.

Safety gear, such as gloves and goggles, is indispensable when working on mechanical equipment. A sturdy workbench and appropriate lighting will enhance your repair experience, making tasks easier and safer. With the right toolkit, you can tackle repairs with confidence and precision.