Comprehensive Guide to Winchester SX4 Parts Diagram

The intricate design of modern shooting instruments combines advanced engineering with user-friendly features. For enthusiasts and professionals alike, gaining a comprehensive understanding of these mechanisms is essential for optimal performance and maintenance. This section will explore the critical elements that contribute to the overall functionality and reliability of your equipment.

Identifying the various elements within your firearm not only enhances your knowledge but also ensures that you can troubleshoot issues effectively. Each component plays a vital role, and familiarity with their arrangement and function can significantly impact your shooting experience. With the right information at hand, you can delve into the specifics and appreciate the craftsmanship involved.

Whether you are looking to enhance your skills or simply maintain your equipment, knowing the layout of these crucial parts is the ultimate key to success. Engaging with this information empowers you to make informed decisions regarding upgrades, repairs, or adjustments, ensuring that your shooting experience remains exceptional.

Understanding the Winchester SX4

This segment delves into the intricacies of a widely recognized shotgun, exploring its design, functionality, and the essential components that contribute to its performance. Whether for sport shooting or hunting, this firearm has garnered attention for its reliability and efficiency.

Key Features

- Ergonomic design for comfortable handling

- Gas-operated system for reduced recoil

- Interchangeable chokes for versatility in various environments

- Lightweight construction for ease of use

Maintenance Tips

- Regularly clean the barrel and action to prevent buildup.

- Inspect all moving parts for wear and tear.

- Store in a dry, cool place to avoid rust.

- Lubricate components as needed to ensure smooth operation.

Key Features of the SX4 Shotgun

This firearm is designed with a range of characteristics that enhance its performance and user experience. With innovative engineering and thoughtful design elements, it stands out in the world of shotguns.

Performance Enhancements

- Gas-operated action for reliable cycling.

- Adjustable stock for a customized fit.

- Enhanced recoil management for improved comfort.

Versatile Usability

- Interchangeable chokes for various shooting scenarios.

- Lightweight construction for ease of handling.

- Durable materials ensuring longevity in tough conditions.

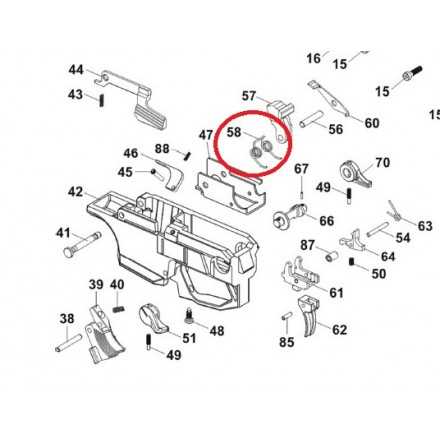

Importance of a Parts Diagram

A comprehensive visual representation of components is essential for anyone involved in maintenance or assembly tasks. Such illustrations provide clarity, ensuring that users can easily identify each element’s role and placement within a system.

Enhancing Understanding

Detailed visuals significantly improve comprehension of complex mechanisms. They serve several purposes:

- Facilitate quick identification of components.

- Clarify the relationships between various parts.

- Assist in troubleshooting by pinpointing areas of concern.

Streamlining Maintenance

Utilizing a visual guide not only speeds up repairs but also minimizes the risk of errors. Benefits include:

- Reducing assembly time with clear instructions.

- Providing a reference for ordering replacements.

- Improving overall efficiency during upkeep tasks.

Common Components of the SX4

Understanding the essential elements of this firearm can enhance the user’s experience and maintenance knowledge. Each component plays a crucial role in the overall functionality, ensuring reliability and performance during use.

Key Mechanisms

The primary mechanisms include the trigger assembly, which facilitates firing, and the gas system that ensures smooth cycling. These parts work in unison to provide a seamless shooting experience.

Safety Features

Important safety elements, such as the safety catch and the ejector, contribute significantly to user protection. Ensuring these components are in optimal condition is vital for safe operation and longevity of the firearm.

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repair tasks. These visual representations provide an organized view of various components, helping users identify each piece’s role within the overall system.

Start by Familiarizing Yourself with the layout. Typically, these illustrations are arranged in a way that mirrors the actual assembly process. Take time to observe how components interact and their placement.

Next, Pay Attention to Labels. Most diagrams include annotations or numbers that correlate with a legend. This reference guide often explains the function and specifications of each item, making it easier to comprehend their purpose.

Lastly, Practice Patience. Initially, these visuals can seem overwhelming. Delve into each section step by step to build a comprehensive understanding, ultimately enhancing your ability to troubleshoot and repair effectively.

Identifying Replacement Parts Easily

Understanding how to locate and identify components is essential for maintaining your equipment effectively. Whether you’re performing routine maintenance or making necessary repairs, having a clear approach to recognizing and sourcing the right elements can save time and effort.

Utilizing Resources for Identification

There are several resources available to assist you in pinpointing the correct components. Online manuals, user guides, and dedicated websites provide valuable information that can help you determine what you need. Additionally, visual aids can be especially useful in clarifying which parts correspond to your requirements.

Table of Common Components

| Component Name | Description | Common Issues |

|---|---|---|

| Trigger Assembly | Mechanism that activates the firing process. | Sticking or misfiring. |

| Gas System | Controls the operation of the firing mechanism. | Inconsistent cycling or failure to operate. |

| Stock | The handle that provides support and stability. | Cracks or loose fittings. |

| Barrel | The tube through which the projectile is fired. | Obstructions or misalignment. |

By using these strategies and resources, you can enhance your ability to identify and obtain the necessary components, ensuring your equipment remains in optimal condition.

Maintenance Tips for the SX4

Regular upkeep is essential for ensuring optimal performance and longevity of your firearm. By adhering to a systematic maintenance routine, you can prevent issues and enhance reliability, allowing for a seamless shooting experience.

Cleaning Routine

Establish a cleaning schedule based on usage frequency. After each outing, thoroughly clean the bore and chamber to remove residue and prevent corrosion. Utilize appropriate solvents and brushes, ensuring that all components are free from debris.

Inspection and Lubrication

Regularly inspect moving parts for wear and tear. Apply lubricant to key areas to facilitate smooth operation, but avoid over-lubrication, as excess oil can attract dirt and grime. Pay special attention to the trigger assembly and bolt mechanisms.

Where to Find Quality Parts

When seeking reliable components for your firearm, it’s essential to know where to look. Quality materials not only enhance performance but also ensure longevity and safety. Here are some recommended avenues to explore:

- Authorized Retailers: Visit shops that are certified to sell genuine items. They often have a wide selection and knowledgeable staff.

- Online Marketplaces: Websites dedicated to firearm accessories can offer convenience and competitive pricing. Ensure they have good reviews.

- Gun Shows: Local events provide opportunities to connect with vendors who specialize in quality goods.

- Manufacturer Websites: Directly purchasing from the source can guarantee authenticity and reliability.

- Forums and Communities: Engaging with fellow enthusiasts can lead to valuable recommendations and insights on where to find superior items.

By utilizing these resources, you can confidently acquire the necessary components for your equipment.

Common Repairs and Upgrades

Maintaining and enhancing your firearm can significantly improve its performance and longevity. This section explores the typical repairs that enthusiasts often undertake, as well as popular modifications that elevate functionality. From addressing minor issues to implementing upgrades, each adjustment can lead to a more reliable and enjoyable experience.

One frequent repair involves the examination and replacement of worn components, such as springs and extractors, which can affect the reliability of operation. Regular cleaning and maintenance are essential to prevent malfunctions caused by debris or corrosion.

For those looking to enhance their shooting experience, options like improved recoil pads, upgraded sights, and custom stocks are popular choices. These modifications not only boost comfort but can also increase accuracy and reduce fatigue during extended use.

Ultimately, understanding the common issues and potential enhancements available allows firearm owners to make informed decisions that best suit their needs. Regular attention to repairs and upgrades ensures a top-notch experience every time you take to the range or field.

Compatibility with Other Winchester Models

Understanding the interchangeability of components across different firearms can enhance the shooting experience and maintenance options. This section explores how certain elements from various models may be utilized interchangeably, providing users with greater flexibility and choice.

Similar Design Features: Many models share fundamental design characteristics, allowing for the use of specific components from one firearm in another. These similarities often stem from a common lineage or design philosophy, facilitating compatibility in certain areas, such as trigger assemblies or gas systems.

Customization Options: Shooters looking to personalize their experience may find that parts from other models can enhance functionality and aesthetics. Custom stocks, for instance, can sometimes fit multiple designs, offering users an opportunity to create a more tailored firearm.

Manufacturer Guidelines: It’s crucial to consult manufacturer specifications before attempting to mix and match components. While some elements may appear compatible, subtle differences in design or function can lead to performance issues or safety concerns.

In summary, exploring compatibility across various models can provide significant advantages for enthusiasts, but it requires careful consideration and adherence to guidelines to ensure optimal performance and safety.

Visual Guide to SX4 Components

This section provides a comprehensive overview of the various elements that make up the firearm, offering insights into their functions and interrelationships. Understanding these components is crucial for enthusiasts and users who seek to enhance their knowledge and maintenance skills.

Key Elements of the mechanism include the trigger assembly, bolt, and barrel. Each part plays a vital role in ensuring smooth operation and reliability during use. For instance, the trigger assembly is responsible for initiating the firing sequence, while the bolt securely chambers each round.

Maintenance is an essential aspect of ownership, and familiarity with these components can aid in troubleshooting and repairs. Regular inspection and proper care can prevent issues and extend the lifespan of the firearm. Whether you are a seasoned user or a newcomer, having a visual reference can greatly enhance your understanding of how each element contributes to overall performance.

Best Practices for Assembly and Disassembly

Efficient assembly and disassembly of complex mechanisms require a systematic approach and attention to detail. By adhering to established techniques, you can ensure that each component is handled with care, promoting both safety and longevity. Understanding the nuances of each step will facilitate smoother operations and reduce the likelihood of errors.

1. Prepare Your Workspace: Before starting, organize your tools and components in a clean, well-lit area. Having everything at hand will minimize distractions and streamline the process.

2. Follow Manufacturer Guidelines: Always refer to the official documentation or manuals provided. These resources offer essential instructions specific to the model, ensuring proper handling and assembly.

3. Use the Right Tools: Employing appropriate tools not only makes the job easier but also prevents damage to delicate parts. Invest in quality equipment that suits your needs.

4. Keep Track of Components: As you disassemble, keep parts organized. Use containers or labeled bags to avoid confusion during reassembly. This practice is particularly helpful for small or similar-looking items.

5. Take Notes or Photos: Documenting each step can serve as a valuable reference. Photographs can help you remember the order of assembly, while notes can highlight any challenges encountered.

6. Handle with Care: Always treat components gently, especially those that are fragile or sensitive. Avoid applying excessive force, as this can lead to damage.

7. Inspect for Wear: While handling each piece, check for signs of wear or damage. Addressing these issues promptly can prevent problems during operation.

8. Reassemble Methodically: When putting everything back together, work systematically. Begin with the foundational components and build upon them, ensuring each piece fits snugly before proceeding.

9. Test Functionality: Once reassembly is complete, conduct a thorough check to ensure everything operates as intended. This step is crucial to identify any overlooked issues.

By implementing these practices, you can achieve a successful assembly and disassembly experience, enhancing both efficiency and reliability.