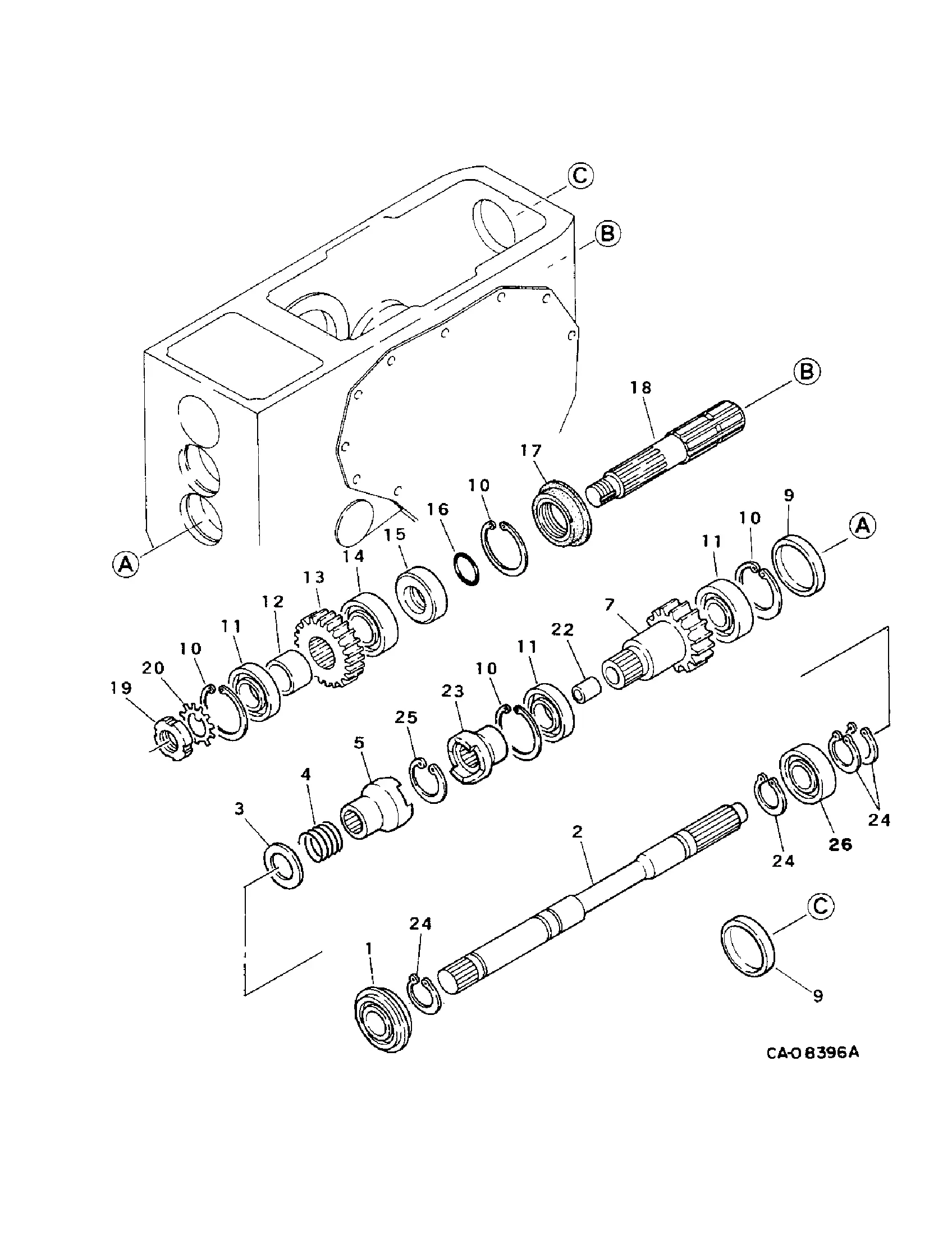

Understanding the International 244 Parts Diagram

In the realm of machinery, a thorough comprehension of the various elements that constitute a vehicle is essential for effective maintenance and operation. Each unit comprises an array of interconnected parts that work harmoniously to achieve optimal performance. Familiarity with these components not only aids in troubleshooting but also enhances the overall longevity of the equipment.

Visual representations of these assemblies serve as invaluable resources for technicians and enthusiasts alike. They provide clarity, illustrating how individual sections relate to one another and facilitating a better grasp of their functions. By analyzing these visual guides, users can gain insights into the intricate workings of their machines.

Equipping oneself with knowledge about specific components and their arrangements empowers operators to tackle repairs and upgrades with confidence. This understanding is critical for anyone looking to maximize the efficiency and reliability of their machinery, ensuring it operates smoothly for years to come.

Understanding the International 244 Tractor

The agricultural machine in question represents a significant achievement in engineering, designed for versatility and efficiency on the farm. Its robust construction and reliable performance have made it a favorite among farmers and machinery enthusiasts alike. This section aims to explore its key features, operational mechanics, and overall impact on agricultural practices.

Key Features and Specifications

This model is equipped with a powerful engine that ensures optimal performance in various field conditions. The design incorporates an ergonomic layout, facilitating ease of use and maintenance. Additionally, it boasts a variety of attachments, enhancing its functionality across diverse tasks, from plowing to harvesting.

Operational Mechanics

Understanding the operational mechanics of this machine is crucial for effective usage. The transmission system allows for smooth gear shifts, which is vital for maintaining traction and control during operation. Moreover, the hydraulic system plays a significant role in powering attachments, contributing to the overall efficiency and productivity of farming activities.

In summary, this agricultural powerhouse is not just a tool but a vital asset that has transformed farming methods. By delving into its characteristics and functionalities, users can maximize their productivity and ensure long-term reliability.

Key Components of the International 244

The functionality and efficiency of agricultural machinery largely depend on their essential elements. Understanding these vital components can enhance performance and facilitate maintenance. Each part plays a significant role in ensuring the overall effectiveness of the machine.

Engine: The heart of the equipment, it provides the necessary power for various operations. Its performance directly impacts productivity.

Transmission: This mechanism transfers power from the engine to the wheels, allowing for smooth movement and control.

Hydraulic System: Essential for powering attachments and performing tasks, this system allows for increased versatility in operations.

Chassis: The framework supports all other components and contributes to the stability and durability of the equipment.

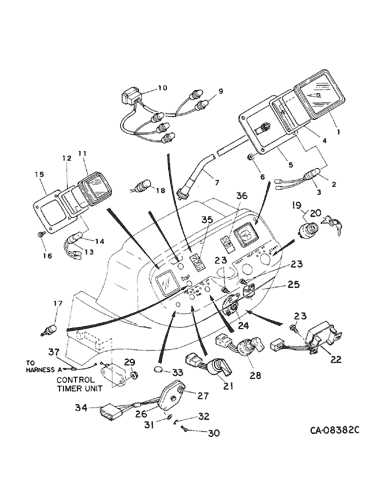

Electrical System: This part ensures proper functioning of lights, ignition, and other electronic features critical for operation.

By delving into these key elements, users can maximize the effectiveness and longevity of their machinery, ultimately leading to better agricultural outcomes.

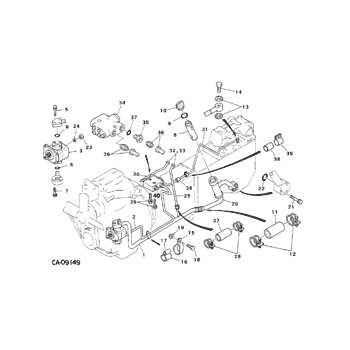

Importance of Accurate Parts Diagrams

Precise visual representations of components play a crucial role in maintaining the functionality and efficiency of machinery. They serve as essential tools for technicians and engineers, ensuring that every element is understood and correctly implemented during repairs or assembly.

Enhanced Understanding

Clear and detailed visuals aid in comprehending complex systems, making it easier for professionals to identify and locate individual elements. This clarity minimizes the risk of errors during maintenance tasks.

Streamlined Maintenance

Accurate illustrations facilitate quicker repairs and replacements, as they provide a reliable reference. This efficiency ultimately leads to reduced downtime and enhanced productivity in operations.

Common Issues with International 244 Parts

When it comes to machinery components, various challenges can arise, impacting performance and reliability. Understanding these common problems is crucial for maintenance and efficient operation. This section highlights typical concerns that users encounter with specific machinery elements, providing insights into their causes and potential solutions.

Frequent Challenges

Users often report several recurring issues, which can lead to decreased functionality. These challenges may stem from wear and tear, improper installation, or inadequate maintenance practices.

| Issue | Description | Possible Solutions |

|---|---|---|

| Leakage | Seals or gaskets may degrade, causing fluid loss. | Regular inspection and timely replacement of worn components. |

| Overheating | Inadequate cooling can lead to excessive heat buildup. | Ensure proper coolant levels and check for airflow obstructions. |

| Noise | Unusual sounds may indicate misalignment or wear. | Conduct alignment checks and replace worn bearings as needed. |

Preventive Measures

To mitigate these issues, regular maintenance is essential. Establishing a routine that includes inspections, lubrication, and part replacements can significantly enhance longevity and performance. Being proactive rather than reactive often saves time and costs in the long run.

Where to Find Parts Diagrams Online

Finding detailed illustrations for machinery components is essential for repairs and maintenance. Online resources provide a wealth of information, allowing users to access comprehensive visual guides that facilitate understanding and part identification. Whether you’re a seasoned technician or a DIY enthusiast, these platforms can greatly enhance your repair experience.

Online Platforms

Several websites specialize in providing valuable resources for machinery maintenance. These platforms often include a mix of official manufacturer sites and user-driven forums where enthusiasts share their knowledge.

Recommended Sources

| Website | Description |

|---|---|

| Manufacturer’s Official Site | Offers official resources and accurate diagrams for specific models. |

| Online Forums | Community-driven spaces where users exchange information and diagrams. |

| Parts Retailers | Retail websites often provide schematic views along with the parts they sell. |

| YouTube Tutorials | Visual guides often include references to specific illustrations. |

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to maintain and repair machinery. This skill involves recognizing symbols, annotations, and layouts that convey vital information about the various elements within a system. By mastering this art, you can streamline your troubleshooting and parts replacement processes.

Identify Key Elements

Start by examining the overall layout. Each section often correlates with specific functional groups. Annotations next to each symbol provide essential details, such as part numbers and descriptions, which are crucial for accurate identification. Pay attention to color codes or unique shapes that might indicate different categories of components.

Follow the Flow

Understanding the flow of the system is essential. Look for directional arrows or lines that indicate connections and interactions among components. This can help you visualize how each element works together, ultimately aiding in effective maintenance and repair strategies.

Maintenance Tips for International 244

Proper upkeep of your machinery is crucial for ensuring longevity and optimal performance. Regular maintenance helps to prevent breakdowns and costly repairs, allowing for smooth operation throughout its lifespan.

1. Regular Fluid Checks: Ensure that all essential fluids, such as engine oil, coolant, and hydraulic fluid, are at appropriate levels. Change these fluids according to the manufacturer’s recommendations to prevent wear and tear.

2. Air Filter Maintenance: Clean or replace the air filter regularly to ensure that the engine receives a clean air supply. A clogged filter can lead to decreased efficiency and increased fuel consumption.

3. Tire Inspection: Check the condition and pressure of the tires frequently. Properly inflated tires contribute to better fuel efficiency and handling, while worn-out tires can pose safety risks.

4. Battery Care: Inspect the battery terminals for corrosion and ensure connections are tight. Regularly check the battery charge to avoid unexpected failures.

5. Belts and Hoses: Examine belts and hoses for any signs of wear, cracking, or fraying. Replace them as necessary to prevent potential breakdowns and to maintain efficiency.

6. Cleaning: Keep the exterior clean and free from debris. This not only improves aesthetics but also helps prevent rust and other damage.

7. Scheduled Professional Inspections: Consider scheduling periodic professional inspections to catch any underlying issues early. Experienced technicians can provide insights that may not be obvious to the owner.

Implementing these maintenance strategies will significantly enhance the functionality and reliability of your equipment, ensuring it remains a valuable asset for years to come.

Aftermarket Parts vs. OEM Parts

The choice between alternative components and original manufacturer products can significantly impact the performance and longevity of machinery. Understanding the differences between these options helps users make informed decisions that align with their needs and budget.

When considering the two categories, here are some key aspects to evaluate:

- Quality: Original components are designed to meet specific standards set by the manufacturer, ensuring compatibility and reliability. Alternative options can vary widely in quality, with some matching or even exceeding OEM standards, while others may fall short.

- Cost: Generally, alternative components tend to be more budget-friendly. However, lower prices can sometimes correlate with reduced durability or performance.

- Availability: Alternative options are often more readily available, especially for older models where original components might be scarce. This can be crucial for minimizing downtime in operations.

- Warranty: Products from the original manufacturer typically come with a warranty, providing assurance against defects. In contrast, warranties for alternative options can be limited or nonexistent.

- Performance: Original products are tested to ensure they perform optimally with specific machinery. Some aftermarket choices may improve performance or offer enhanced features, but this is not universally guaranteed.

Ultimately, the decision hinges on the specific needs of the user, including budget constraints, performance requirements, and maintenance strategies. Evaluating these factors will aid in making the right choice for sustaining operational efficiency.

Repair Procedures for Common Problems

Addressing frequent issues with machinery can significantly enhance performance and longevity. By understanding the typical challenges that arise, operators can effectively troubleshoot and implement appropriate solutions, ensuring smoother operation and reduced downtime.

Engine Overheating: If the engine experiences excessive heat, check the coolant levels and inspect for leaks. Cleaning the radiator and ensuring the fan operates correctly are vital steps.

Starting Difficulties: For machines that struggle to start, begin by examining the battery condition and connections. Clean terminals and replace the battery if necessary. Additionally, inspect the fuel system for blockages.

Transmission Issues: When faced with shifting problems, verify the fluid levels and quality. Replace any contaminated fluid and check for leaks in the system.

Hydraulic Failures: In case of inadequate hydraulic performance, inspect the fluid levels and look for leaks in hoses. Replace any damaged components and ensure filters are clean.

Electrical Failures: For electrical malfunctions, check the wiring for damage or corrosion. Testing fuses and relays can also help identify issues, allowing for timely replacements.

Benefits of Using Official Manuals

Utilizing authorized guides provides numerous advantages for users seeking accurate information and efficient solutions. These resources are specifically designed to offer comprehensive insights into machinery and equipment, ensuring optimal performance and longevity. Relying on official documentation enhances reliability and minimizes the risk of errors that could arise from unofficial sources.

One of the primary benefits of accessing these manuals is clarity. They present detailed instructions and illustrations that simplify complex procedures. This clarity allows users to perform maintenance and repairs with confidence, reducing the likelihood of misunderstandings that can lead to costly mistakes.

Additionally, official guides are often updated regularly, reflecting the latest advancements and best practices. This ensures that users are informed about any modifications or improvements, which can enhance operational efficiency. The inclusion of safety protocols is another critical aspect, as these documents emphasize best practices to prevent accidents and injuries during use.

Finally, having a legitimate reference source can greatly improve troubleshooting efforts. When faced with an issue, users can quickly consult these manuals for specific solutions, saving time and resources. Overall, investing in official documentation is a wise choice for anyone looking to maintain their equipment effectively and safely.

Case Studies of Successful Repairs

This section explores various instances where effective restoration techniques were applied to machinery, showcasing practical solutions and the expertise involved. By examining these case studies, readers can gain valuable insights into troubleshooting and repair methodologies that yield positive outcomes.

Restoration of a Vintage Model

In one notable case, a classic agricultural machine was brought back to life after years of neglect. The technician meticulously assessed the engine and identified critical wear in several components. Through careful sourcing of replacements and dedicated effort, the machinery was fully operational, demonstrating the importance of expertise in maintaining vintage equipment.

Modern Upgrades for Enhanced Performance

Another example involved upgrading a well-used unit with contemporary enhancements. By integrating advanced technology and modern materials, the repair team significantly improved efficiency and reliability. This case illustrates how embracing innovation can breathe new life into older systems, ultimately leading to greater productivity and reduced downtime.

Community Resources for Support and Advice

In any field, having access to a network of knowledgeable individuals can significantly enhance problem-solving capabilities and foster innovation. Communities built around shared interests provide valuable insights, experiences, and practical advice, making them essential for anyone looking to navigate challenges effectively.

Online Forums and Discussion Groups

Participating in online platforms allows enthusiasts and professionals to exchange ideas, seek assistance, and share their experiences. These virtual spaces often host discussions that can clarify complex topics and offer support when faced with difficulties.

Local Clubs and Meetups

Joining local organizations or attending gatherings can strengthen connections with others in the same field. These face-to-face interactions not only facilitate learning but also create a supportive environment where members can collaborate on projects and share resources.

| Resource Type | Description | Benefits |

|---|---|---|

| Online Forums | Websites where users can post questions and share knowledge. | Immediate assistance, diverse perspectives. |

| Local Clubs | Groups that meet regularly to discuss topics and share expertise. | Networking opportunities, hands-on learning. |

| Social Media Groups | Communities on platforms like Facebook or Reddit focused on specific interests. | Wide reach, easy access to information. |