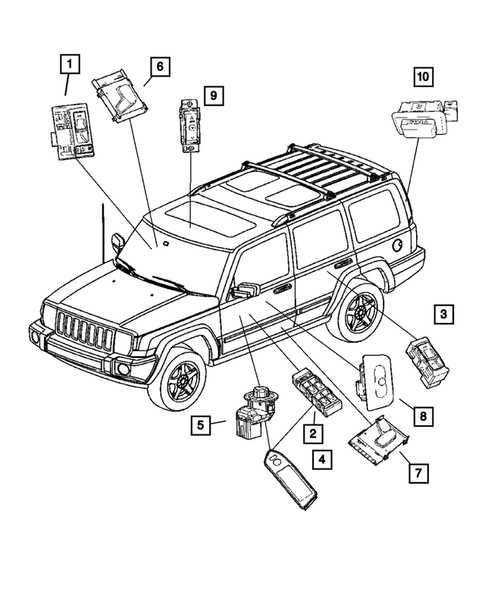

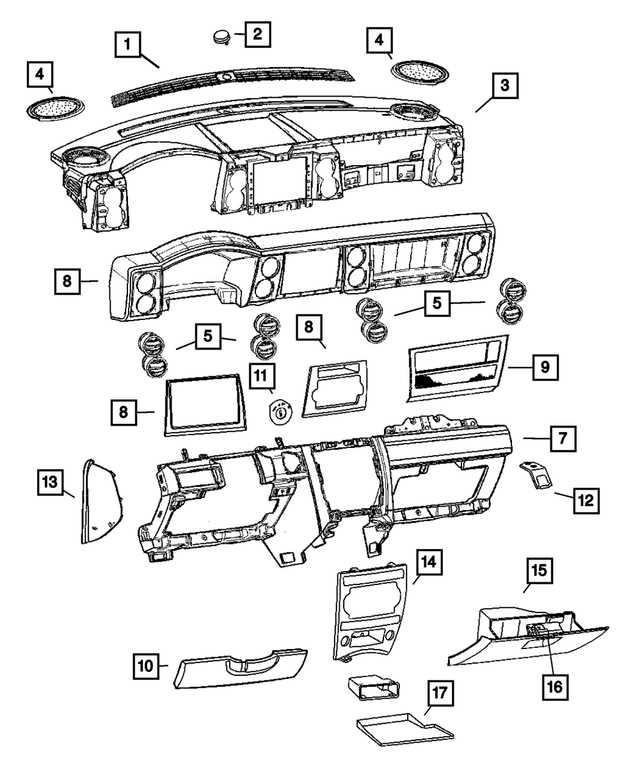

Essential Jeep Commander Parts Diagram for Every Enthusiast

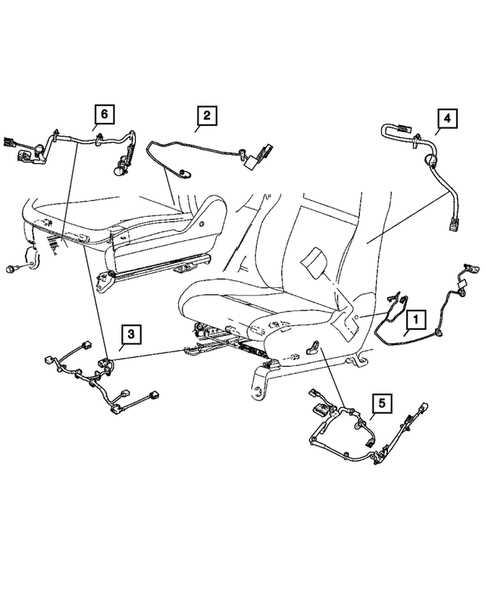

When exploring the intricacies of a rugged utility vehicle, one must appreciate the complexity of its construction. This comprehensive guide aims to illuminate the various sections and elements that comprise such a model, providing clarity for both enthusiasts and mechanics alike.

By examining the interconnected systems, we can gain insights into the functionality and design choices that define the driving experience. The visual representation of these components serves as an invaluable resource for maintenance, repairs, and upgrades, ultimately enhancing performance.

Whether you are a seasoned professional or a newcomer to the world of automotive care, delving into these layouts can empower you with the knowledge needed to tackle any project confidently. Join us as we navigate the essential features and attributes that make this vehicle a standout in its class.

Understanding Jeep Commander Parts

Gaining insight into the various components of your vehicle is essential for optimal performance and longevity. Each element plays a crucial role in ensuring smooth operation and safety on the road. By familiarizing yourself with these individual elements, you can better appreciate how they work together to enhance your driving experience.

Identification of key components allows for informed decisions regarding maintenance and upgrades. Whether it’s the engine, transmission, or suspension, understanding each unit’s function can significantly impact your vehicle’s efficiency.

Moreover, familiarity with these features can help in troubleshooting issues, making it easier to spot potential problems before they escalate. Regularly reviewing these components ensures that you maintain a high standard of care, ultimately leading to a more enjoyable journey.

Importance of Accurate Parts Diagrams

Precision in visual representations of components is crucial for effective maintenance and repairs. Accurate illustrations not only facilitate identification but also enhance understanding of the overall structure. This clarity is essential for both novice and experienced individuals working on complex machinery.

Efficiency is significantly improved when technicians can easily reference detailed visual aids. These resources minimize the risk of errors during assembly or disassembly, ensuring that each piece fits correctly. This attention to detail ultimately saves time and resources, allowing for smoother operations.

Furthermore, comprehensive visual guides foster better communication among team members. When everyone is on the same page regarding component layouts, collaboration becomes more effective, leading to quicker resolutions and improved teamwork.

In addition, reliable illustrations contribute to enhanced safety. By providing a clear understanding of where each element resides, they help prevent accidents that may arise from incorrect handling or misplacement of components. Therefore, investing in high-quality visual references is vital for promoting both operational efficiency and workplace safety.

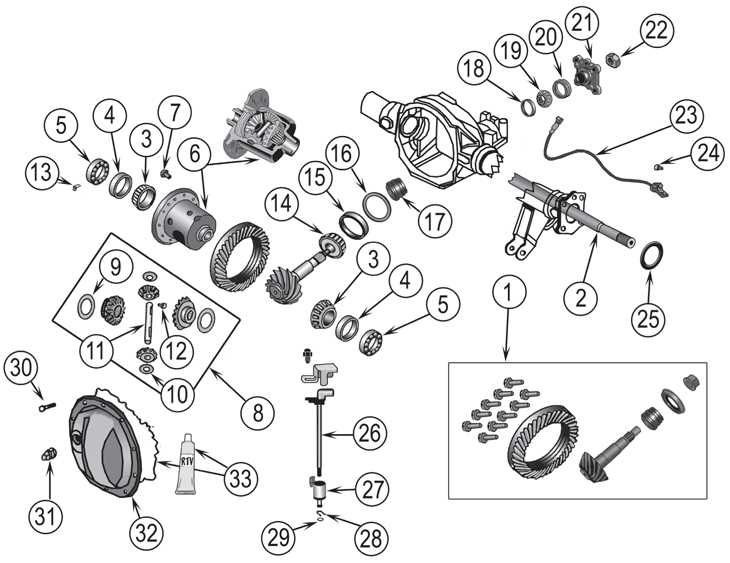

Common Components in Jeep Commanders

This section explores the essential elements that make up a rugged off-road vehicle, highlighting their functions and significance in ensuring optimal performance and reliability.

Key Functional Parts

The vehicle comprises several critical components that work in harmony to provide stability, control, and comfort. Each part plays a vital role in the overall operation.

| Component | Function |

|---|---|

| Engine | Powers the vehicle and provides torque for acceleration. |

| Transmission | Facilitates gear shifts for improved performance and fuel efficiency. |

| Suspension | Absorbs shocks and provides stability on uneven terrain. |

Additional Important Elements

Beyond the key parts, several auxiliary systems enhance the driving experience, ensuring safety and convenience for passengers.

| System | Purpose |

|---|---|

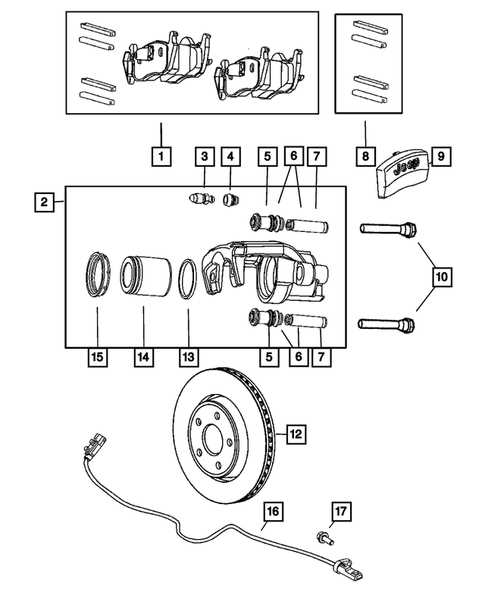

| Braking System | Ensures effective stopping power in various conditions. |

| Fuel System | Delivers the necessary fuel for engine operation. |

| Electrical System | Powers accessories and essential functions like lighting. |

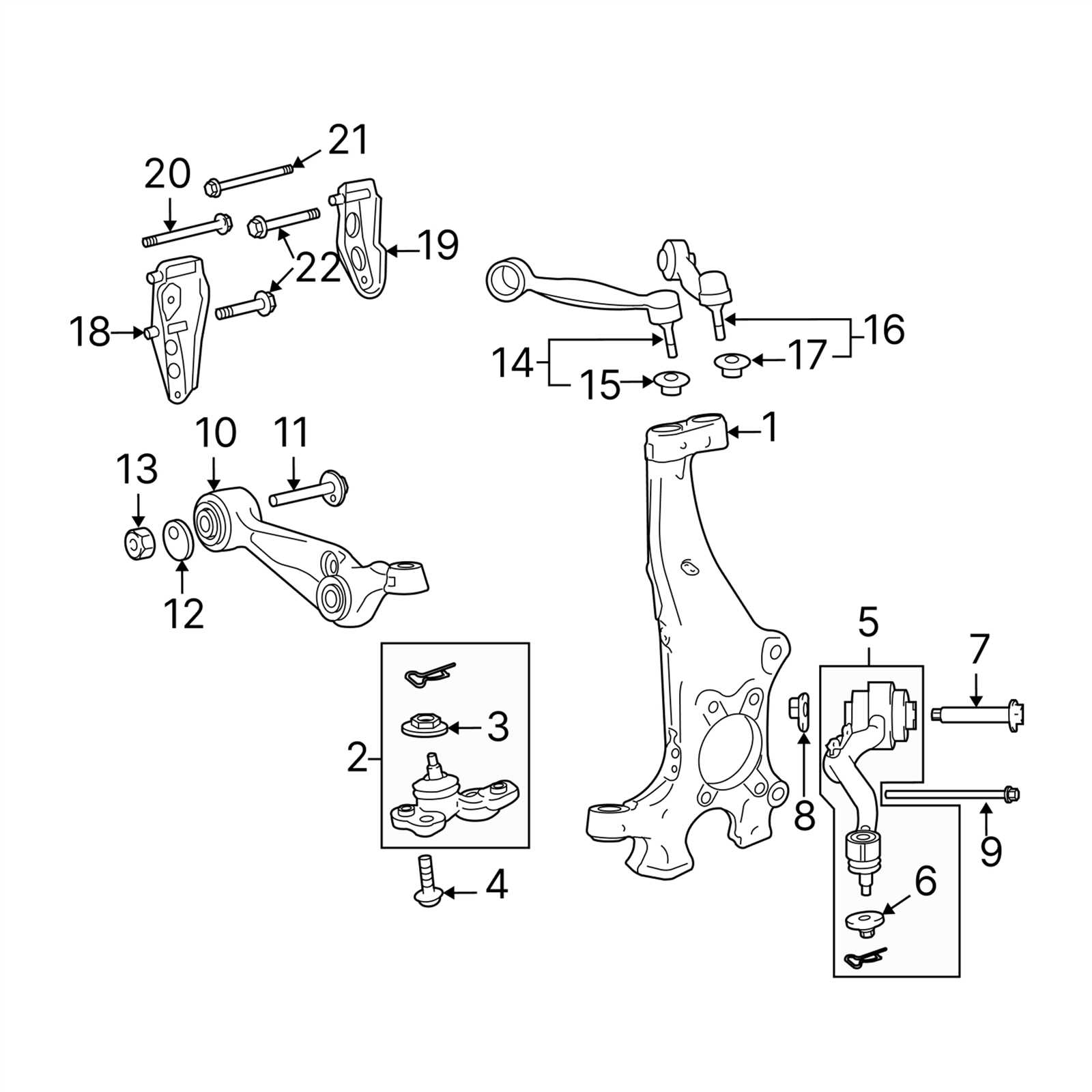

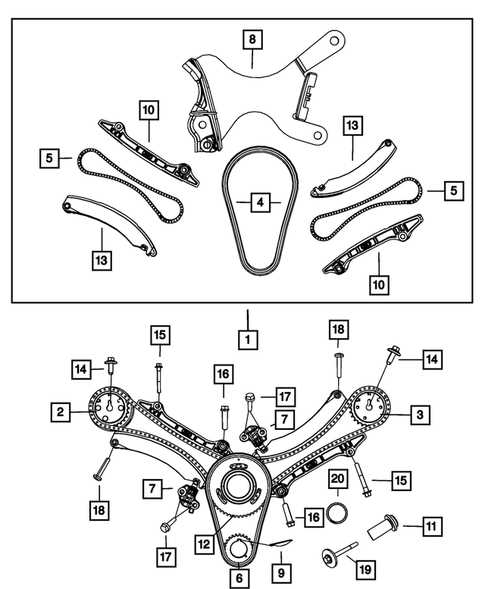

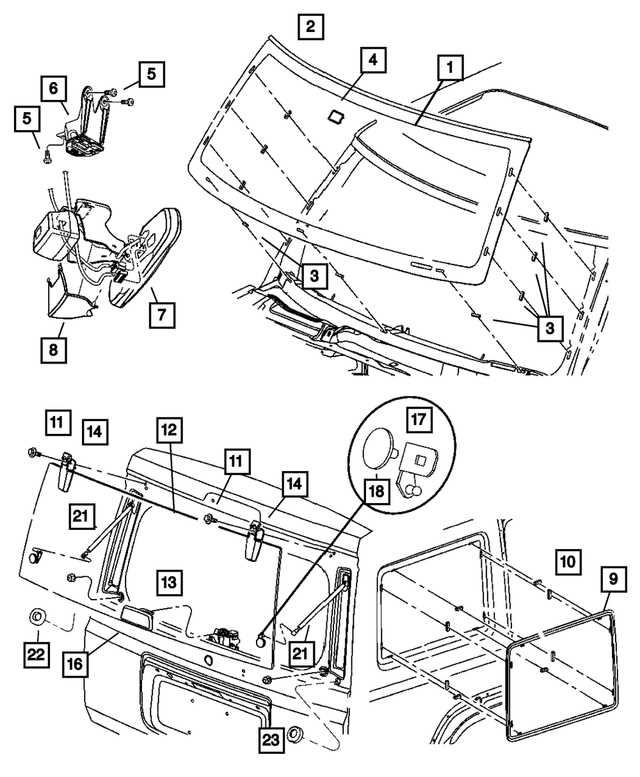

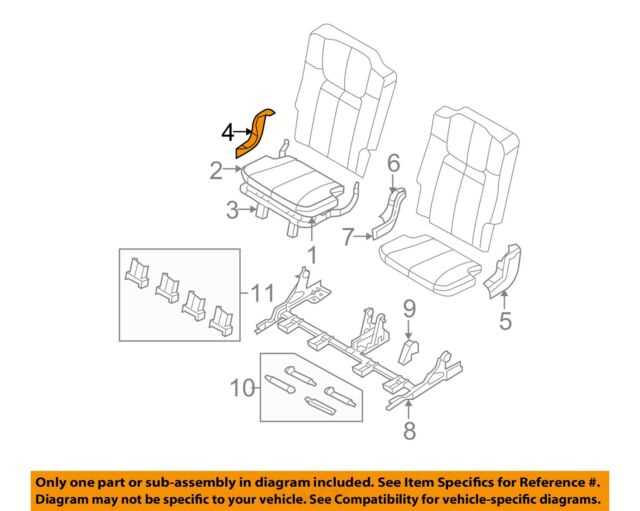

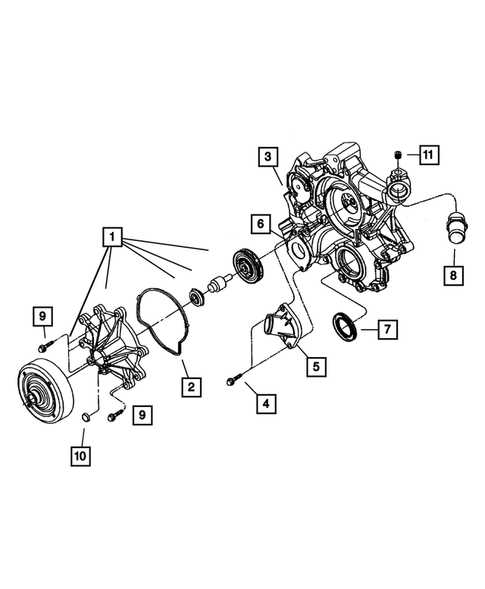

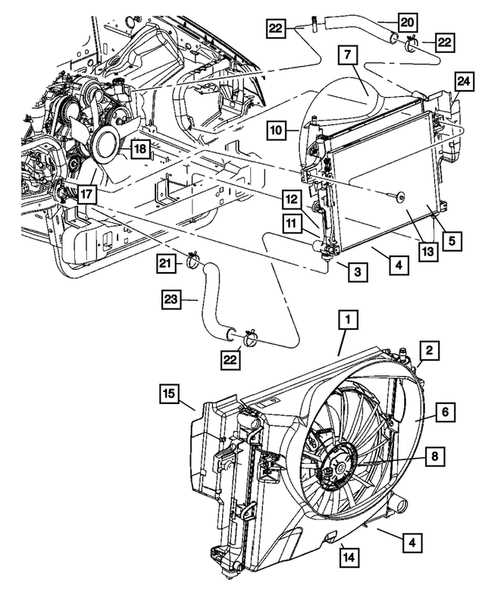

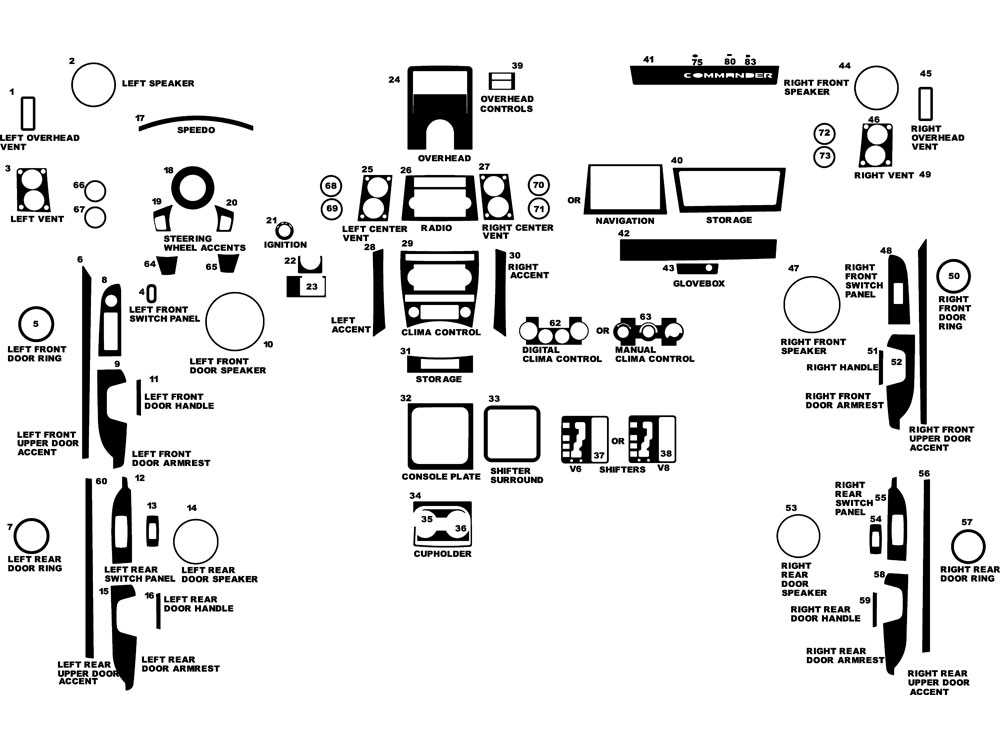

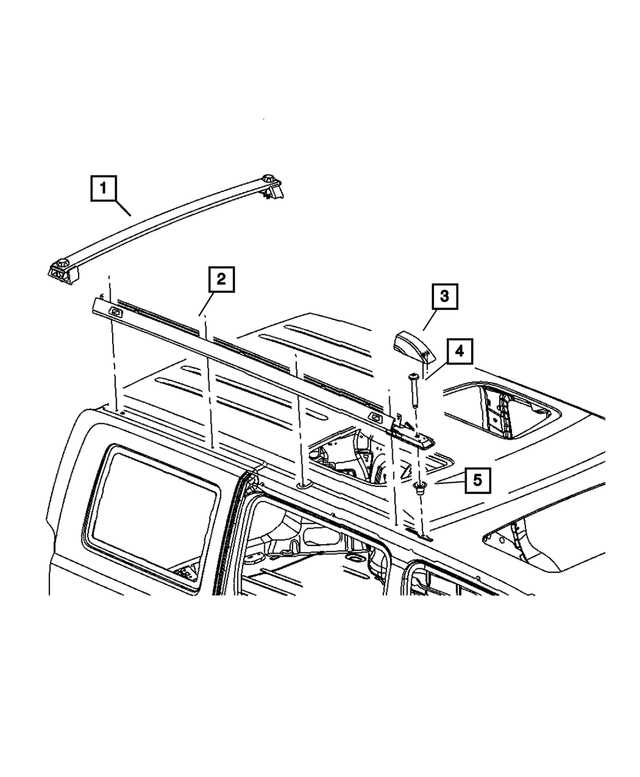

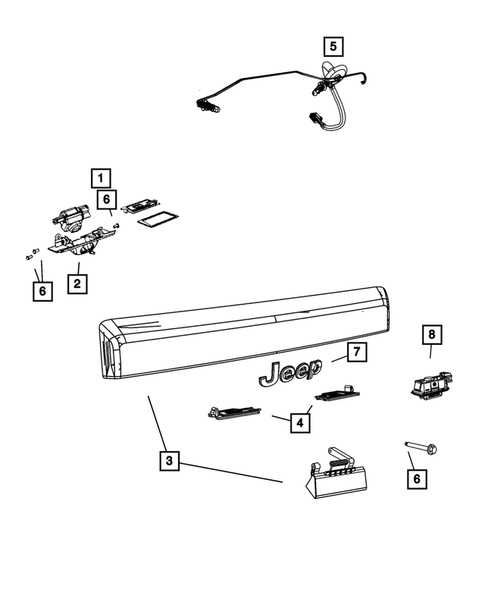

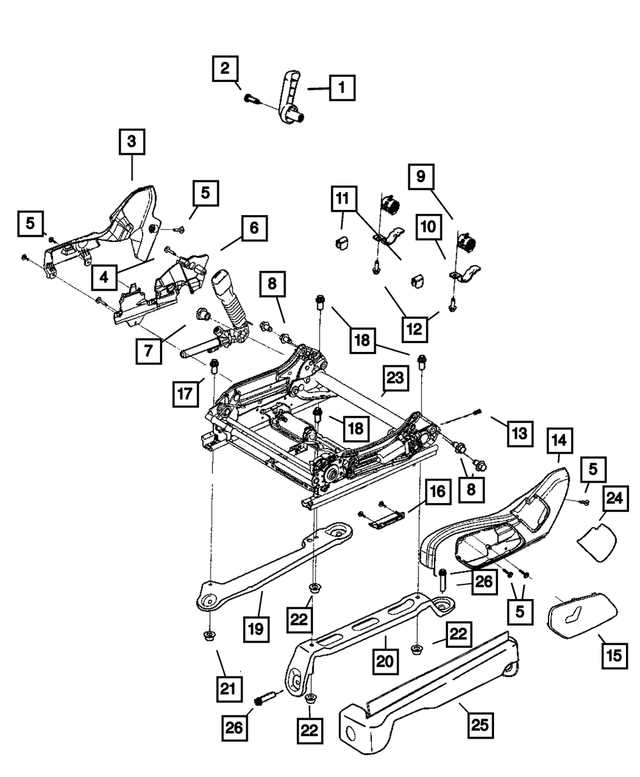

How to Read Parts Diagrams

Understanding visual representations of components is essential for anyone looking to maintain or repair vehicles. These illustrations serve as guides, showcasing how various elements fit together and function within the overall system. Learning to interpret these images can streamline the process of identifying and ordering necessary items for repairs.

When analyzing these visual guides, pay attention to several key aspects:

| Aspect | Description |

|---|---|

| Labels | Look for clearly marked identifiers that correspond to specific components. These often include part numbers or names. |

| Connections | Observe how different pieces are linked. Arrows or lines may indicate where connections occur. |

| Orientation | Note the perspective from which the assembly is viewed. This can influence how components are installed. |

| Sections | Many illustrations are divided into sections for clarity. Familiarize yourself with each part of the layout. |

By focusing on these elements, you can efficiently decode the information presented and ensure successful repairs or maintenance on your vehicle.

Essential Tools for Repairs

Having the right equipment is crucial when it comes to maintaining and fixing vehicles. A well-equipped workshop not only makes the repair process more efficient but also enhances safety and precision. From basic hand tools to specialized instruments, understanding which tools are necessary can make a significant difference in any repair task.

Basic Hand Tools

At the core of any repair kit are the basic hand tools. These include items such as wrenches, screwdrivers, and pliers. A good set of wrenches, both standard and metric, is essential for loosening and tightening bolts. Screwdrivers of various sizes and types (flathead and Phillips) will help tackle numerous fasteners. Pliers, including needle-nose and locking types, provide additional grip and leverage for handling difficult components.

Specialized Equipment

Beyond the basics, some specialized equipment can greatly aid in more complex repairs. Torque wrenches are vital for ensuring that bolts are tightened to the manufacturer’s specifications, preventing potential damage. Diagnostic scanners can provide valuable insights into electronic systems, helping to identify issues that might not be visible to the naked eye. Additionally, having a reliable jack and jack stands is essential for safely lifting the vehicle, allowing for easier access to the undercarriage.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment and third-party components is crucial for making informed choices. Each type comes with its own set of advantages and considerations, impacting performance and longevity.

| Aspect | OEM Components | Aftermarket Components |

|---|---|---|

| Quality | Typically higher, designed to meet manufacturer standards. | Varies widely; can be equal or inferior in quality. |

| Price | Generally more expensive due to brand and warranty. | Often more affordable, offering budget-friendly options. |

| Availability | Limited to manufacturer distributors or authorized dealers. | Widely available from various retailers and online platforms. |

| Warranty | Usually comes with a manufacturer’s warranty. | May have limited or no warranty, depending on the supplier. |

Maintenance Tips for Jeep Commanders

Proper upkeep is essential for ensuring the longevity and performance of your vehicle. Regular checks and timely interventions can prevent costly repairs and enhance your driving experience. Here are some key strategies to maintain your automobile effectively.

| Task | Frequency | Details |

|---|---|---|

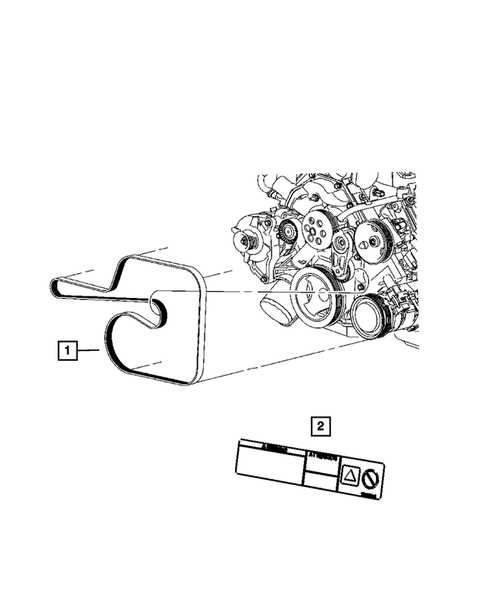

| Oil Change | Every 5,000 miles | Use high-quality oil and filters to keep the engine running smoothly. |

| Tire Rotation | Every 6,000 miles | Ensure even wear by rotating tires regularly. |

| Brake Inspection | Every 10,000 miles | Check pads and rotors for wear to maintain safety. |

| Fluid Levels Check | Monthly | Monitor coolant, brake fluid, and transmission fluid levels. |

| Belt and Hose Inspection | Every 30,000 miles | Look for cracks or fraying to avoid breakdowns. |

Where to Find Parts Diagrams

Accessing detailed schematics for vehicles is crucial for maintenance and repair. Various resources can provide these invaluable visuals, ensuring that every component is correctly identified and understood.

- Manufacturer Websites: Many brands offer comprehensive resources directly on their official sites.

- Online Forums: Enthusiast communities often share diagrams and tips for locating them.

- Repair Manuals: These can be purchased or found at libraries, offering detailed visuals and instructions.

- Parts Retailers: Websites specializing in automotive components usually provide schematics as part of their product listings.

- YouTube Tutorials: Video guides often include references to diagrams, enhancing understanding through visual aids.

Utilizing these avenues can greatly assist in the repair and restoration process, enabling a thorough understanding of vehicle construction.

Popular Upgrades for Jeep Commanders

Enhancing your vehicle can significantly improve its performance, aesthetics, and overall driving experience. Many enthusiasts explore various modifications that cater to personal preferences and functional needs.

Suspension Lift Kits: Elevating the suspension allows for increased ground clearance, enabling better off-road capabilities and a more aggressive stance.

Performance Exhaust Systems: Upgrading to a high-flow exhaust can enhance engine efficiency, resulting in improved power and a more aggressive sound.

Cold Air Intakes: These systems facilitate better airflow to the engine, which can boost horsepower and fuel efficiency.

All-Terrain Tires: Opting for rugged tires designed for varied conditions can greatly improve traction and handling in off-road scenarios.

LED Lighting Kits: Upgrading to modern lighting solutions not only enhances visibility but also adds a stylish touch to your vehicle.

Upgraded Infotainment Systems: Incorporating advanced audio and navigation options can elevate the in-cabin experience, making journeys more enjoyable.

Each upgrade presents an opportunity to tailor your ride to better suit your lifestyle and preferences, ensuring it meets your ultimate expectations.

Common Issues and Solutions

When it comes to maintaining a robust vehicle, several challenges may arise over time. Understanding these frequent problems can significantly enhance the longevity and performance of the automobile. Addressing these issues promptly and effectively is essential for any owner looking to ensure smooth operation.

Electrical System Failures

One of the prevalent challenges faced is related to the electrical components. Symptoms often include dimming lights, erratic instrument panel readings, or complete power loss. Solution: Start by checking the battery connections for corrosion and ensuring they are tight. If the battery is in good condition, inspect the fuses and relays for any signs of damage. A multimeter can be handy for diagnosing voltage levels and identifying faulty wiring.

Transmission Troubles

Transmission issues can manifest through unusual noises, slipping gears, or delayed shifting. These symptoms can lead to significant performance concerns if not addressed quickly. Solution: Regular fluid checks are crucial; ensure the transmission fluid is at the appropriate level and in good condition. If problems persist, consider a professional inspection to diagnose deeper mechanical issues.

Benefits of Using Quality Parts

Choosing high-quality components for your vehicle is essential for ensuring optimal performance and longevity. These premium materials often offer superior durability and reliability, leading to fewer breakdowns and a smoother driving experience.

Enhanced Performance

When you invest in top-notch materials, you can expect improved functionality. Quality components are designed to fit perfectly, minimizing wear and tear and enhancing the overall efficiency of your vehicle.

Cost-Effectiveness in the Long Run

While the initial investment may be higher, using reliable materials can save you money over time. Reduced maintenance needs and longer lifespans mean fewer replacements and repairs, making it a smart choice for any vehicle owner.

Comparing Prices: OEM and Aftermarket

When considering vehicle components, consumers often face a choice between original equipment manufacturer options and alternatives produced by third-party vendors. Each category presents distinct advantages and price points that can influence purchasing decisions.

OEM products typically come with a guarantee of quality and compatibility, reflecting the manufacturer’s standards. This reliability often justifies their higher cost. Conversely, aftermarket options can offer significant savings and a broader range of choices, appealing to budget-conscious buyers looking for functionality without the premium price tag.

Ultimately, the decision hinges on balancing quality and cost. While OEM components may provide peace of mind, aftermarket parts could deliver comparable performance at a fraction of the price, making it essential to evaluate individual needs and preferences.

Safety Considerations When Replacing Parts

When undertaking the task of component replacement in vehicles, it is crucial to prioritize safety to prevent accidents and ensure optimal performance. Understanding the potential risks involved in the process can significantly reduce the likelihood of injury and damage to the vehicle. Adopting proper practices not only safeguards the individual performing the work but also protects the integrity of the vehicle itself.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential when working on any mechanical tasks. Items such as gloves, safety goggles, and steel-toed boots should be utilized to minimize the risk of injury from sharp objects, chemicals, or heavy components. Ensuring that clothing is not loose or dangling can further reduce the chances of accidents.

Proper Tools and Techniques

Using the right tools and following recommended techniques is vital for safe component replacement. Ensure that all tools are in good condition and suitable for the task at hand. Familiarize yourself with the installation procedures and follow manufacturer guidelines closely. This practice not only enhances safety but also ensures the longevity and reliability of the new components.