Understanding the 9.9 Johnson Outboard Parts Diagram

In the world of marine mechanics, comprehending the intricate elements that contribute to engine performance is essential for both enthusiasts and professionals. Navigating through the various components not only enhances operational efficiency but also aids in troubleshooting and maintenance. This knowledge empowers users to make informed decisions about repairs and upgrades.

When dealing with specific engine models, visual aids become invaluable. These representations highlight the relationships and functionalities of each component, making it easier to identify issues and understand assembly. By familiarizing oneself with these illustrations, users can enhance their technical expertise and gain confidence in their mechanical capabilities.

In this section, we will delve into a detailed exploration of the critical elements that constitute a small marine engine. Each part plays a significant role, and recognizing their functions will help in maximizing performance and ensuring longevity. Whether you are a novice or a seasoned mechanic, grasping this information is vital for effective maintenance and operation.

Understanding Johnson Outboard Motors

Exploring the intricacies of marine propulsion systems unveils a world of engineering excellence and reliability. These engines have long been a staple for recreational and commercial watercraft, embodying innovation and durability. A comprehensive understanding of their components is essential for maintenance and optimization, ensuring smooth performance on the water.

These propulsion systems are characterized by various critical elements that work in harmony to deliver efficient power. Familiarity with the key components aids in troubleshooting and repairs, enhancing the overall lifespan and functionality of the motor.

| Component | Description |

|---|---|

| Powerhead | The main unit housing the engine and essential components for combustion. |

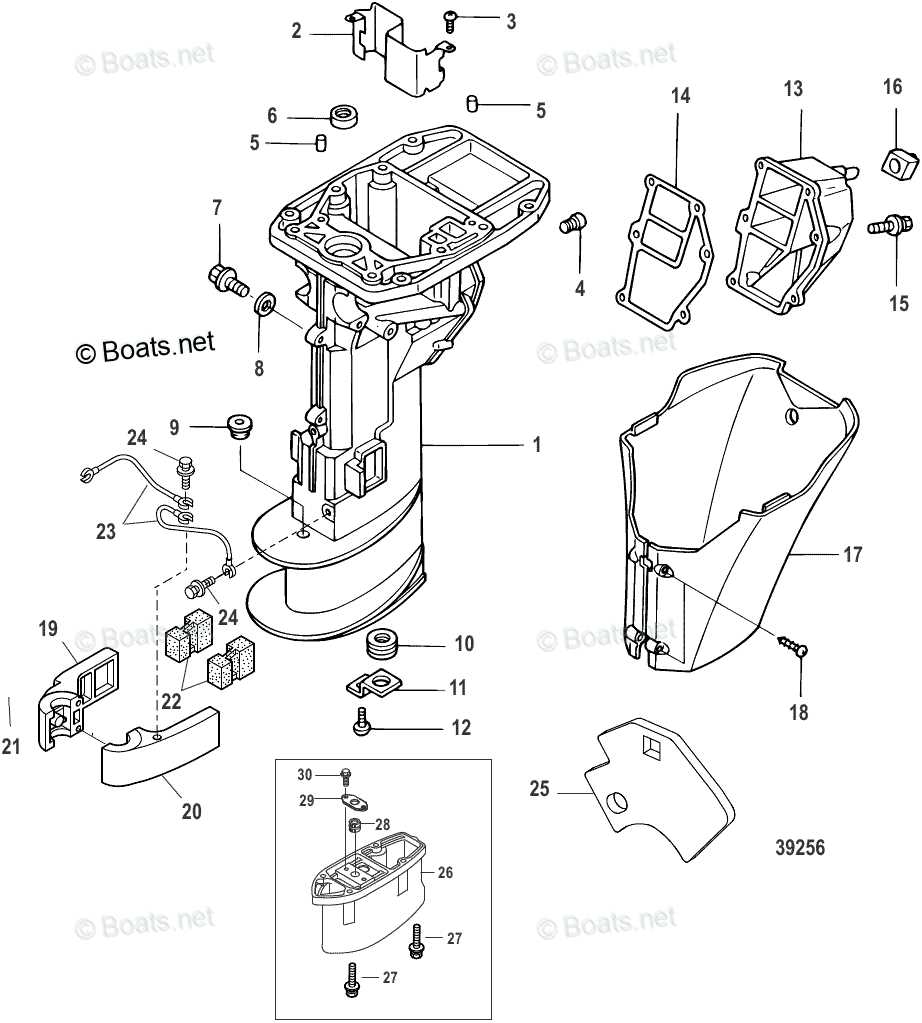

| Lower Unit | Contains the gearbox and propeller, responsible for thrust and maneuverability. |

| Fuel System | Includes the tank, lines, and carburetor, ensuring proper fuel delivery. |

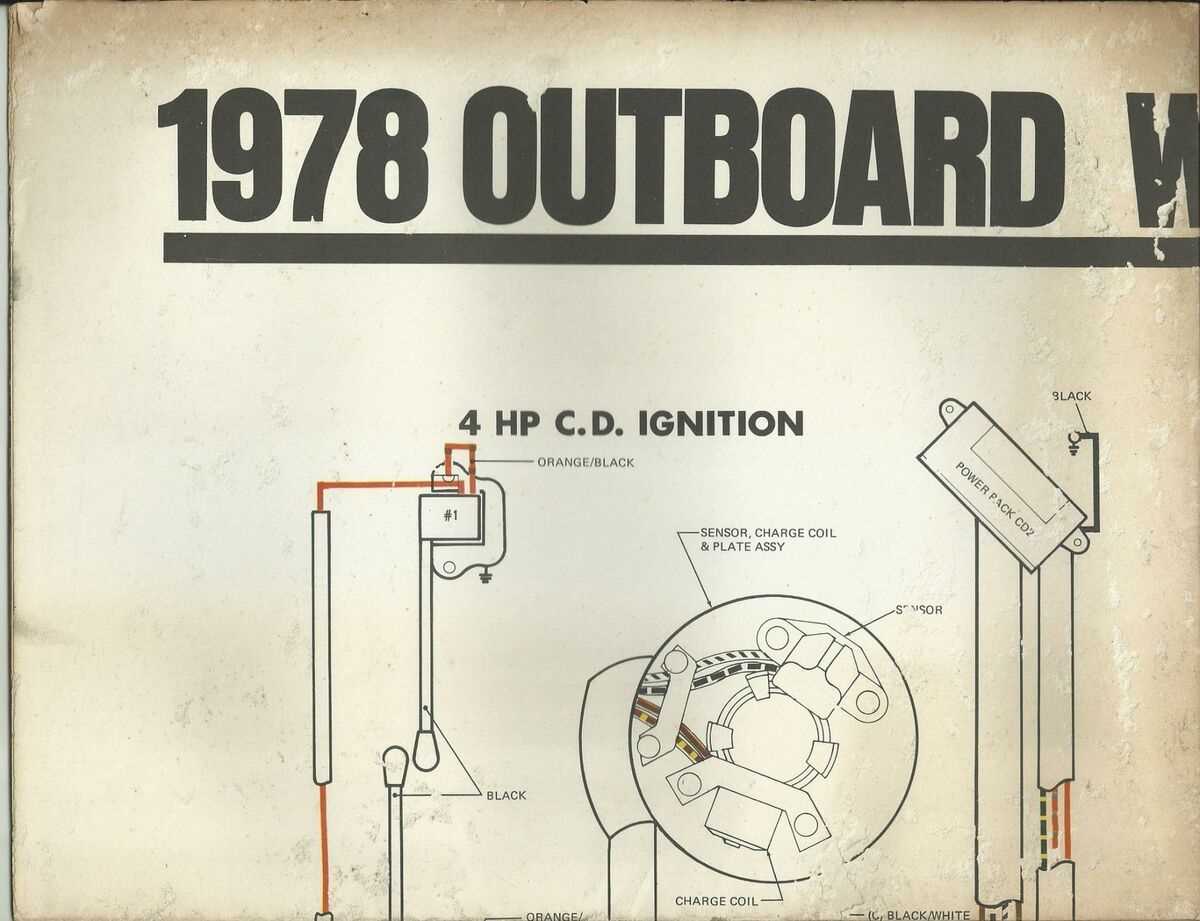

| Ignition System | Generates the spark necessary for ignition, crucial for engine operation. |

| Cooling System | Prevents overheating by circulating water through the engine. |

Understanding these essential components not only enhances repair skills but also deepens appreciation for the engineering marvels that power our marine adventures.

Key Components of Outboard Engines

The functionality and performance of marine propulsion systems hinge on several essential elements. Understanding these critical components allows for better maintenance and optimization of the equipment, ensuring reliable operation on the water.

Powerhead is the heart of the engine, where the combustion process occurs. It houses the cylinders, pistons, and crankshaft, converting fuel into mechanical energy.

Lower unit plays a vital role in transferring power to the propeller. This section includes the gear case and driveshaft, facilitating the necessary torque for propulsion.

Fuel system is responsible for delivering the right mixture of air and fuel to the combustion chamber. This system includes the carburetor or fuel injectors, which regulate the intake to optimize performance and efficiency.

Cooling system prevents overheating, circulating water to absorb excess heat generated during operation. This component is crucial for maintaining optimal engine temperature and prolonging lifespan.

Ignition system initiates the combustion process. It comprises components such as spark plugs and ignition coils, ensuring timely firing and efficient engine operation.

Each of these elements plays a crucial role in the overall functionality of marine engines, and understanding them can significantly enhance maintenance practices and performance management.

Importance of Parts Diagrams

Understanding the intricacies of mechanical systems is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to navigate complex assemblies with ease. They provide clarity, ensuring that every component’s function and relationship within the system are easily comprehensible.

Enhanced Troubleshooting

When issues arise, visual aids can significantly streamline the diagnostic process. By clearly illustrating each component’s placement and interaction, these illustrations allow technicians to identify malfunctions quickly. Accurate identification of problematic areas leads to more efficient repairs and less downtime.

Facilitated Ordering of Components

Utilizing visual references simplifies the process of acquiring replacement items. Knowing the exact part needed becomes straightforward, minimizing the risk of errors during procurement. Clarity in these visuals not only saves time but also ensures that repairs are performed with the correct materials, enhancing overall reliability.

Common Issues with Johnson Outboards

Many enthusiasts encounter several recurring problems when operating and maintaining their marine engines. Understanding these challenges can help in troubleshooting and prolonging the lifespan of these machines.

Frequent Problems

- Fuel Delivery Issues

- Overheating

- Electrical Failures

- Starting Difficulties

- Propeller Performance Issues

Troubleshooting Tips

- Regularly check fuel lines for blockages or leaks.

- Inspect the cooling system and clean any debris.

- Test electrical connections and replace corroded components.

- Ensure proper maintenance of the starting mechanism.

- Examine the propeller for damage or improper attachment.

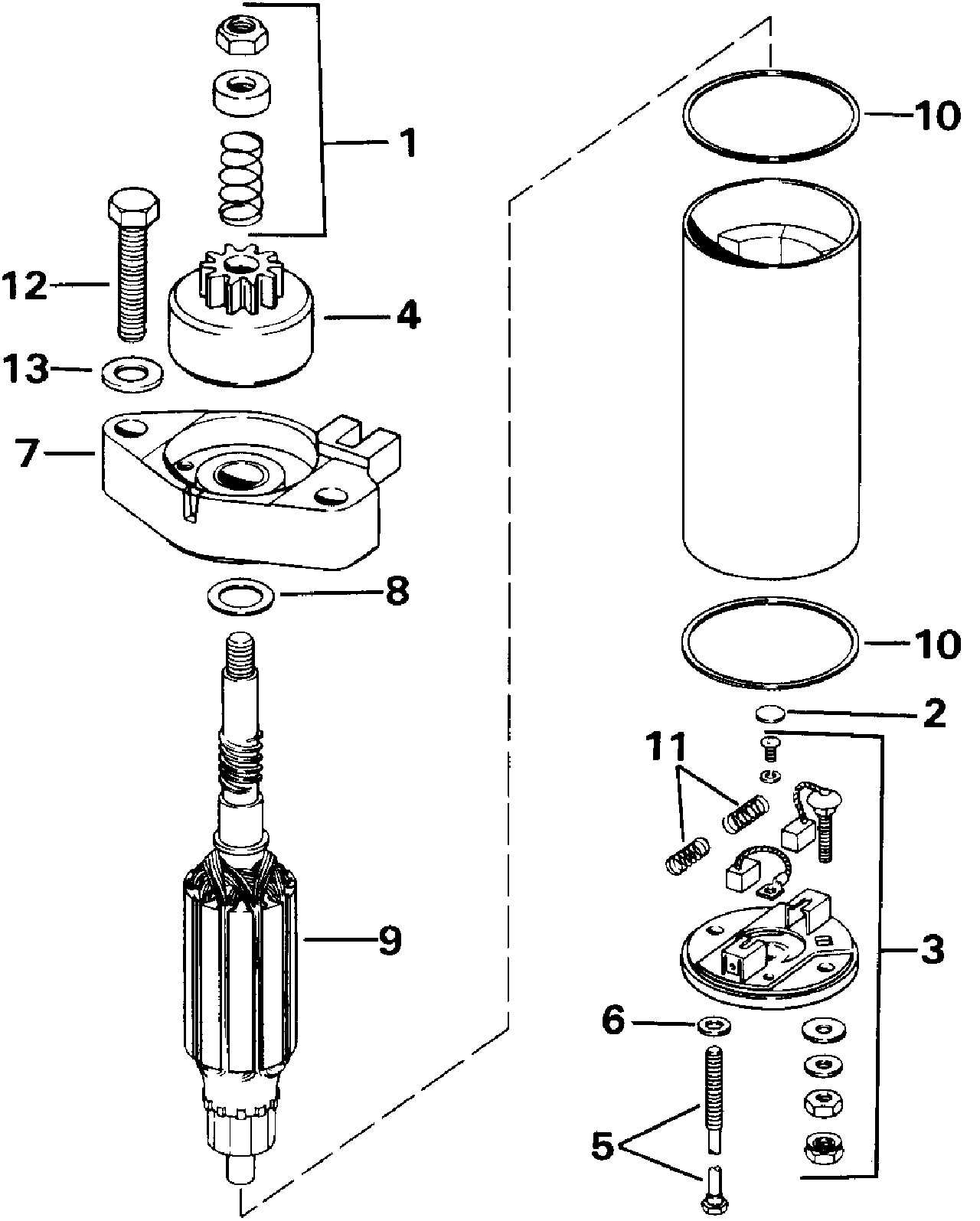

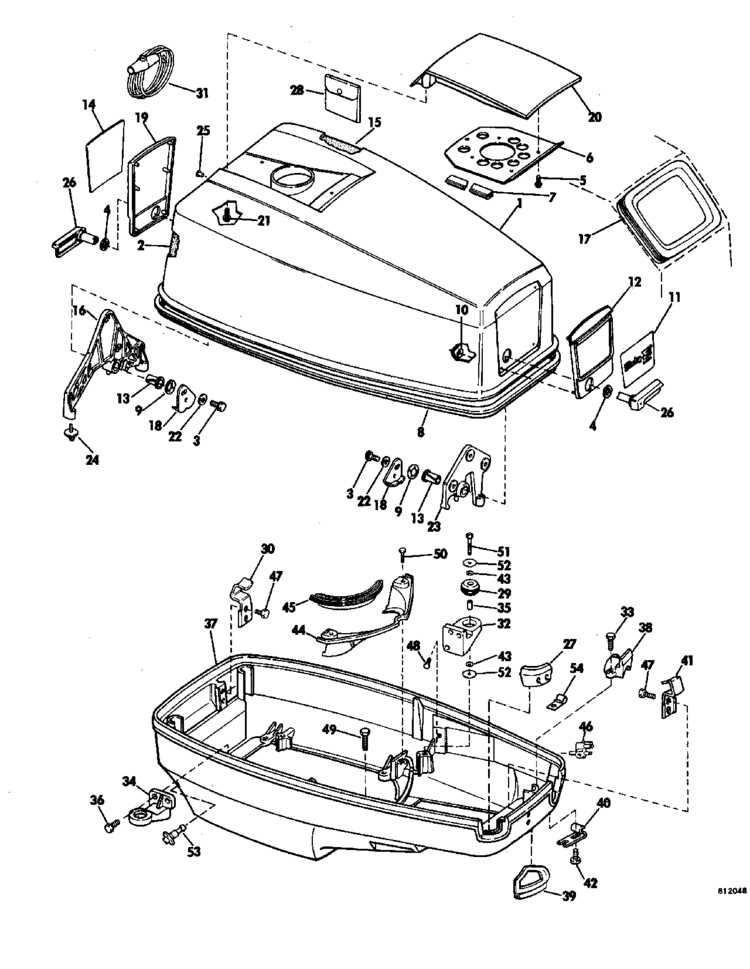

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone involved in mechanical maintenance or repair. These illustrations provide a comprehensive overview of components and their relationships within a system. By grasping the layout and terminology used, you can enhance your troubleshooting and assembly skills effectively.

Identifying Components

Each symbol or image represents a specific item, often labeled with numbers or letters. Familiarize yourself with these identifiers, as they are crucial for locating replacement items. Typically, a corresponding list details these references, allowing you to cross-reference parts with ease.

Understanding Relationships

Pay attention to how elements are connected or grouped. Lines and arrows often indicate relationships or functions, guiding you through assembly sequences or operational flow. Recognizing these connections can simplify complex tasks, making it easier to understand how each piece contributes to the overall functionality.

Finding Replacement Parts Online

Locating suitable components for your marine engine has become increasingly straightforward with the rise of online resources. This digital approach offers a wealth of options, enabling enthusiasts and professionals to secure the necessary items efficiently. Understanding where to look and how to navigate these platforms can significantly enhance your experience.

Key Online Resources

- Specialty Retailers: Websites that focus on marine supplies often have extensive inventories, allowing users to search by make and model.

- Marketplaces: Platforms like eBay or Amazon can provide a variety of new and used components, catering to different budgets.

- Manufacturer Websites: Directly visiting the official sites can yield accurate specifications and authorized sellers.

- Forums and Communities: Engaging with online groups can lead to valuable recommendations and sometimes even sources for hard-to-find items.

Tips for Successful Searches

- Use specific keywords related to your engine’s model to refine search results.

- Check for compatibility information to ensure that the item fits your requirements.

- Read customer reviews to gauge the quality and reliability of the component.

- Compare prices across different platforms to find the best deal.

By utilizing these strategies, you can efficiently find the components you need to keep your vessel in optimal condition.

Maintenance Tips for Outboard Engines

Proper upkeep of marine propulsion systems is essential for ensuring optimal performance and longevity. Regular attention to specific components can prevent costly repairs and enhance overall efficiency. Here are some effective strategies to maintain your engine in peak condition.

Routine Checks

- Inspect fuel levels and quality regularly to avoid engine issues.

- Examine the oil and change it according to manufacturer recommendations.

- Check the cooling system for any blockages or leaks.

- Ensure that the battery connections are clean and secure.

Seasonal Maintenance

- Flush the engine with fresh water after each use to remove salt and debris.

- Store the unit in a dry, protected area during off-seasons.

- Perform a thorough inspection of the propeller for any signs of damage.

- Replace any worn-out or corroded components before the new season begins.

By adhering to these guidelines, users can extend the lifespan of their marine engines and ensure a safe and enjoyable experience on the water.

Popular Johnson Outboard Models

When it comes to recreational boating, certain motor models stand out for their reliability and performance. These engines have gained a dedicated following among enthusiasts and casual users alike, thanks to their durability and ease of maintenance.

Here are some of the most recognized models that have made a significant impact:

- Model 1: Known for its robust construction and efficient fuel consumption, this model is ideal for both freshwater and saltwater use.

- Model 2: A favorite among fishing enthusiasts, this engine offers a perfect blend of power and quiet operation, making it suitable for long days on the water.

- Model 3: This compact option is popular for smaller boats, providing excellent maneuverability and a lightweight design.

- Model 4: With advanced technology, this model delivers superior performance and quick acceleration, appealing to speed lovers.

These motors exemplify the quality and innovation that have kept them in demand over the years. Whether you’re looking for strength, efficiency, or a lightweight solution, there’s a model to meet your needs.

Diagnosing Engine Problems

Identifying issues within a motor can often be a complex task that requires a systematic approach. Understanding the symptoms and pinpointing their root causes is essential for effective troubleshooting. This process involves careful observation, analysis, and sometimes a bit of trial and error.

Common Symptoms to Look For

Engines may exhibit various signs of distress, such as unusual noises, diminished performance, or difficulty starting. Listen for any irregular sounds that could indicate mechanical failure. Additionally, observe any changes in acceleration or responsiveness, as these can signal underlying problems.

Steps for Troubleshooting

Begin by checking the fuel system, ensuring that there are no blockages or leaks. Next, examine the electrical components, such as the battery and ignition system, to confirm they are functioning correctly. Conducting a visual inspection can often reveal loose connections or worn parts. If issues persist, consulting the user manual can provide specific guidance tailored to the engine model.

Tools Needed for Repair

When undertaking maintenance or repairs on marine engines, having the right tools is essential for efficient and effective work. The right equipment not only facilitates the repair process but also ensures safety and accuracy, allowing for a smoother experience. Below is a list of essential tools that every technician should have at their disposal.

Basic Hand Tools

- Socket Set

- Wrenches (both standard and metric)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and adjustable)

- Hammer (rubber and metal)

Specialized Equipment

- Torque Wrench

- Multimeter

- Fuel Line Wrench

- Compression Tester

- Diagnostic Tools

Having these tools readily available will enhance the repair process, allowing for precise adjustments and thorough assessments of the engine’s condition. Proper maintenance is key to longevity and performance, so investing in quality equipment is highly recommended.

Safety Precautions During Repairs

Engaging in maintenance and repairs of marine engines requires vigilance to ensure both personal safety and the longevity of the equipment. Proper precautions can significantly reduce the risk of accidents and injuries while enhancing the efficiency of the repair process. Awareness of potential hazards and adherence to safety protocols are essential for anyone involved in these activities.

Essential Safety Gear

Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves, goggles, and ear protection to safeguard against mechanical hazards, chemicals, and excessive noise.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and chemicals |

| Goggles | Shield eyes from debris and splashes |

| Ear Protection | Minimize noise exposure during operation |

Working Environment

Ensure the workspace is well-lit and free from clutter. Proper ventilation is vital, especially when dealing with fuel or solvents. Regularly check for leaks or spills to maintain a safe environment.

Cost Considerations for Replacements

When it comes to replacing components in marine engines, understanding the financial implications is crucial. Various factors can influence the overall expenses, including the type of replacement needed, brand reputation, and the source from which parts are procured. Careful consideration can lead to informed decisions, potentially saving money in the long run.

Factors Affecting Pricing

One of the primary considerations is the quality of the replacements. OEM (Original Equipment Manufacturer) components often come at a premium price but provide reliability and compatibility. In contrast, aftermarket options may be more affordable but can vary in quality. Additionally, labor costs for installation should be factored in, especially if professional assistance is required.

Long-Term Financial Implications

Investing in high-quality replacements may seem costly initially, but it can prevent frequent repairs and replacements down the line. Evaluating the lifespan and performance of different components can help in making cost-effective choices that enhance the durability and efficiency of the engine. Planning and budgeting for these expenses are essential for maintaining optimal performance without overspending.

Where to Seek Professional Help

When encountering difficulties with your marine engine, seeking expertise can make a significant difference. Professional assistance can ensure that repairs are conducted accurately and efficiently, prolonging the lifespan of your equipment. Here are some reliable resources where you can find knowledgeable technicians and specialists.

| Resource | Description |

|---|---|

| Authorized Service Centers | These facilities are certified by manufacturers and provide specialized services tailored to specific engine models. |

| Local Marine Repair Shops | Often staffed by experienced mechanics, these shops offer a range of services, from routine maintenance to complex repairs. |

| Online Forums and Communities | Engaging with fellow enthusiasts can lead to recommendations for reputable professionals in your area. |

| Manufacturer’s Support | Contacting the manufacturer directly can provide access to trained technicians who can assist with specific issues. |

Choosing the right professional support can greatly enhance your maintenance and repair experiences, ensuring your marine equipment remains in optimal condition.