Understanding the John Bean Tire Changer Parts Diagram

The efficient functioning of automotive machinery relies heavily on a thorough grasp of its essential components. This section aims to explore the intricate structure and various elements that contribute to the overall performance of equipment designed for managing wheels. By breaking down the intricate systems, users can enhance their operational expertise and troubleshooting skills.

As technology advances, the importance of knowing how each component interacts cannot be overstated. A detailed examination of these elements not only aids in effective maintenance but also empowers operators to make informed decisions regarding repairs and replacements. Mastering the layout of these crucial mechanisms ensures the longevity and reliability of the machinery.

In this exploration, we will delve into the various sections, highlighting their roles and functionalities. Understanding these interconnected parts will provide the ultimate insight necessary for achieving optimal results in wheel service and repair.

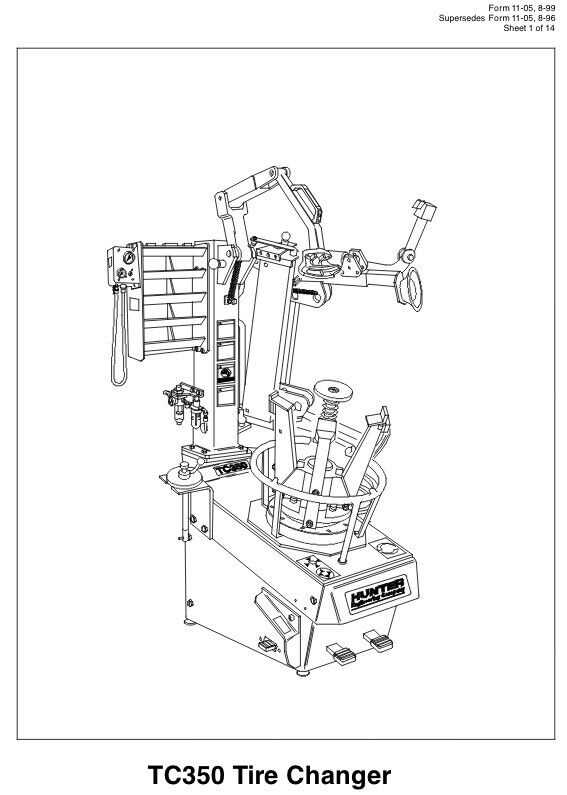

Overview of John Bean Tire Changer

This section provides a comprehensive understanding of a renowned equipment brand specializing in wheel servicing machinery. The focus is on the innovative solutions designed to enhance efficiency and precision in the automotive repair industry.

Key Features

The equipment is equipped with advanced technology that facilitates seamless operation, reducing time and effort during the wheel servicing process. Users benefit from features such as user-friendly controls and robust construction, ensuring longevity and reliability.

Applications

This machinery is widely utilized in various settings, including professional garages and service centers. Its versatility allows for the handling of diverse wheel types, catering to both passenger vehicles and commercial fleets, ultimately meeting the demands of a dynamic market.

Importance of Tire Changer Components

The various elements involved in the process of wheel maintenance play a crucial role in ensuring efficiency and safety. Each component is designed to contribute to the overall functionality, allowing for seamless operation and minimizing the risk of errors. Understanding these individual elements is essential for optimal performance and longevity of the equipment.

Key components work together to facilitate smooth operations. Their quality and maintenance directly impact the effectiveness of the entire system. A thorough comprehension of these parts not only aids in troubleshooting but also enhances the ability to perform routine upkeep, ensuring that the machinery operates at peak efficiency.

| Component | Function |

|---|---|

| Motor | Provides the necessary power for operation. |

| Arm | Holds and positions the wheel securely. |

| Clamp | Grips the wheel to prevent movement during the process. |

| Bead Breaker | Separates the tire from the rim for removal. |

| Control Panel | Allows the operator to manage settings and monitor progress. |

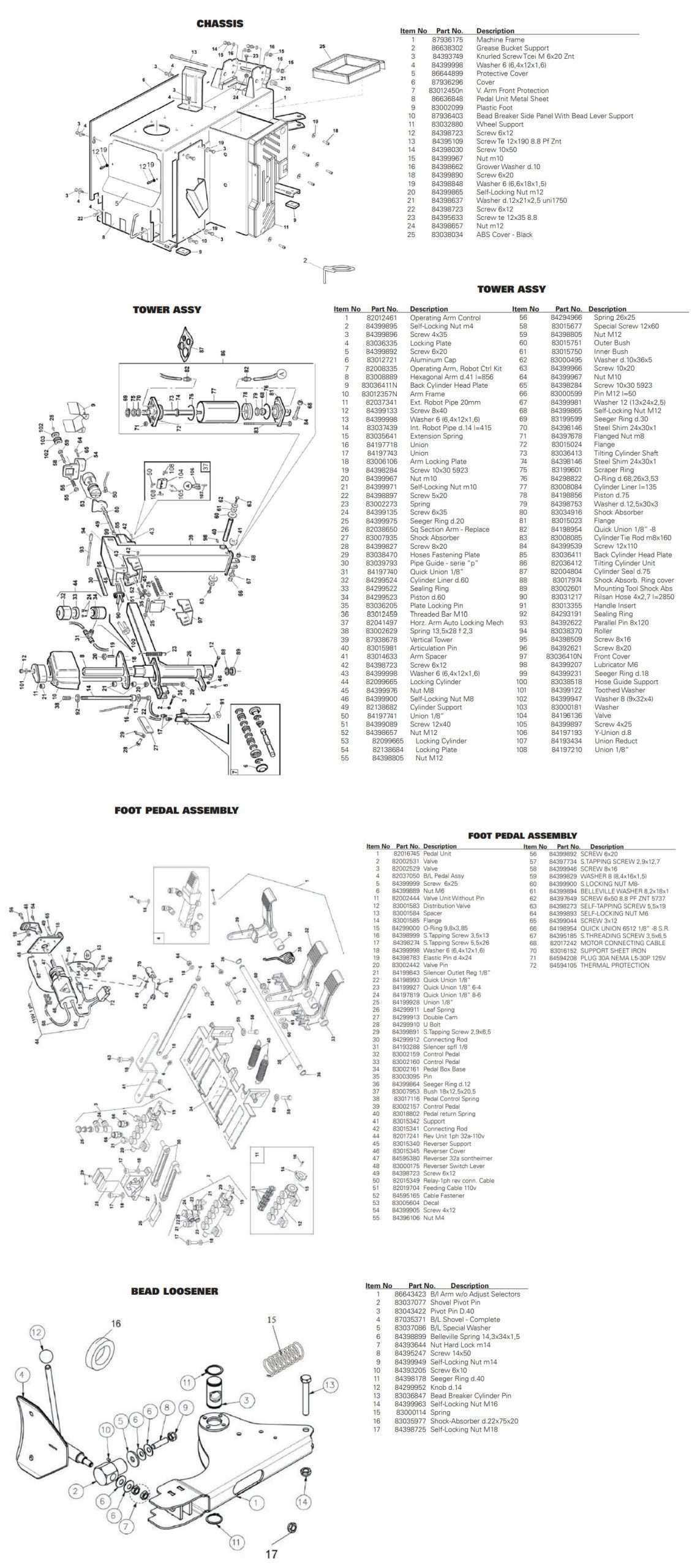

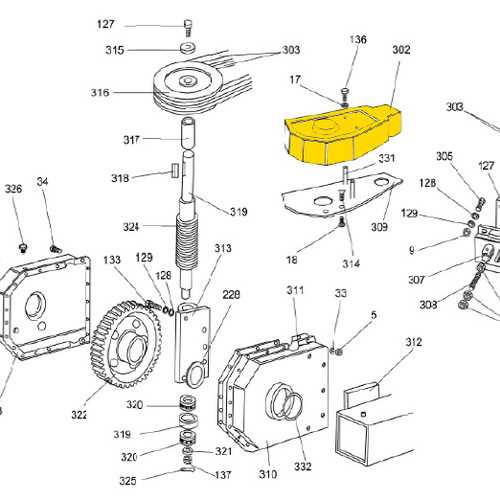

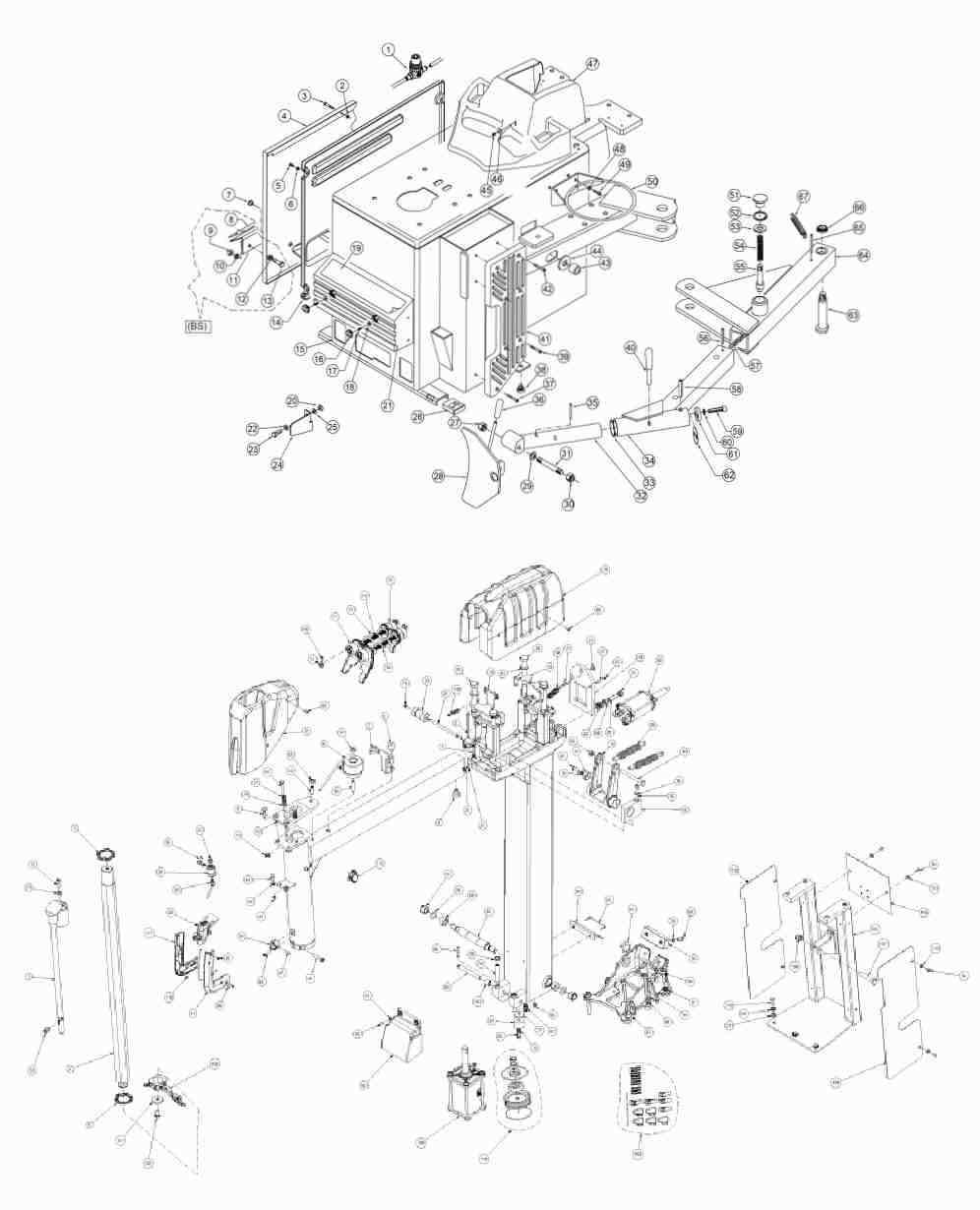

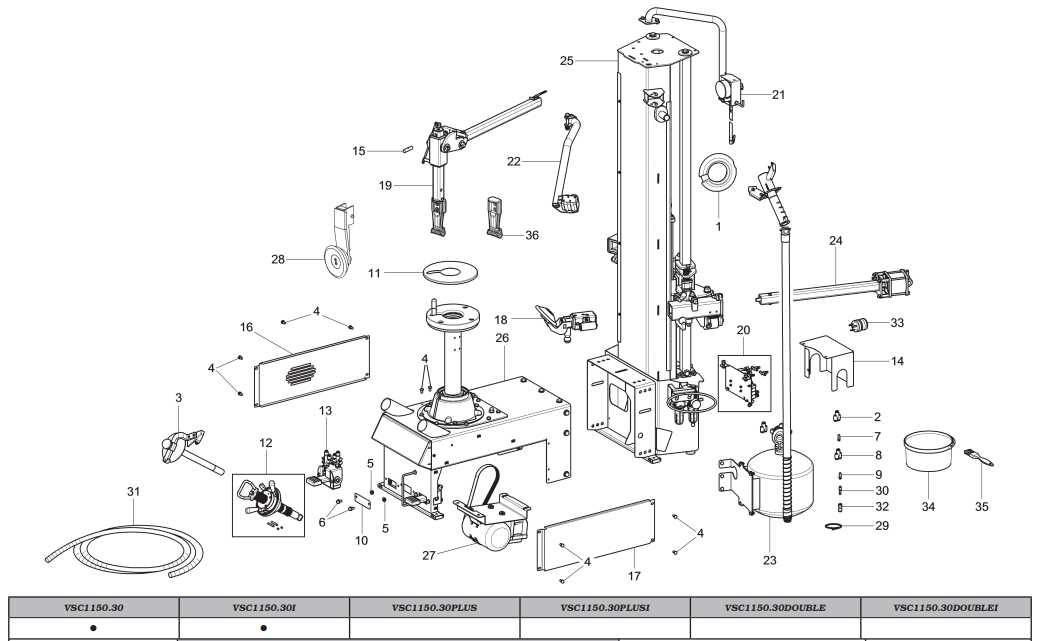

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality of the equipment. Familiarity with the arrangement can lead to more efficient repairs and a deeper comprehension of the machine’s operation.

Key Components and Their Functions

Identifying the main elements within the visual representation allows users to understand their specific functions. For instance, some parts are responsible for movement, while others provide stability. Recognizing these roles helps in diagnosing issues and performing necessary adjustments.

Maintenance and Repair Insights

Utilizing the visual guide can significantly enhance one’s ability to maintain the equipment. By knowing where each part is located and how they interconnect, operators can more easily pinpoint problems and execute repairs. This not only saves time but also improves the longevity of the machinery.

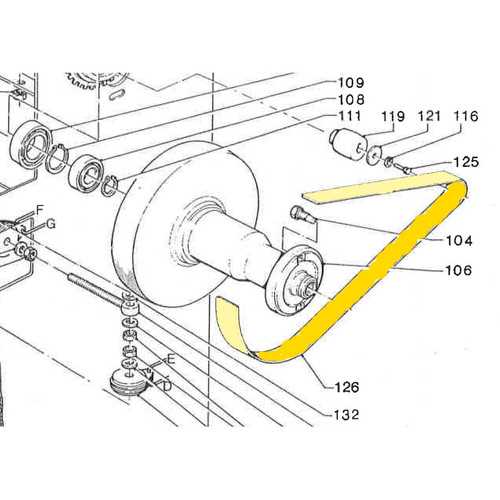

Key Components Explained

This section will explore the essential elements that play a crucial role in the operation of equipment used for wheel servicing. Understanding these components is vital for effective maintenance and efficient functionality.

Major Elements

Each element serves a unique purpose, contributing to the overall efficiency of the machinery. Familiarity with these components ensures that users can handle repairs and adjustments confidently.

| Component | Description |

|---|---|

| Motor | Drives the mechanism, providing the necessary power for operation. |

| Arm | Assists in positioning and securing the wheel during servicing. |

| Plate | Acts as a stable base for the wheel, ensuring proper alignment. |

Importance of Maintenance

Regular upkeep of these key elements is essential to prolong the lifespan and enhance the efficiency of the machinery. Neglecting any part can lead to suboptimal performance and potential breakdowns.

Common Issues with Tire Changers

In the realm of automotive maintenance, various complications can arise when utilizing equipment for wheel servicing. Understanding these frequent challenges is crucial for effective troubleshooting and ensuring optimal performance.

Mechanical Failures

One of the primary concerns involves mechanical breakdowns. Components such as the hydraulic system or rotating elements may experience wear and tear, leading to inefficient operation. Regular inspections can help identify potential issues before they escalate.

Operator Errors

Human factors also play a significant role in equipment performance. Improper usage techniques can result in damage to both the machine and the wheels. Training personnel on correct procedures is essential to minimize mistakes and enhance productivity.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of any equipment. Regular maintenance not only extends the lifespan of your machine but also enhances its performance, ultimately saving time and money. Below are some effective strategies to keep your apparatus in optimal condition.

- Regular Inspections: Conduct frequent checks for wear and tear. Look for any signs of damage or misalignment that may affect functionality.

- Cleaning: Keep the equipment clean from debris and contaminants. Use appropriate cleaning agents to prevent corrosion and buildup.

- Lubrication: Apply suitable lubricants to moving parts to minimize friction. Follow manufacturer recommendations for the type and frequency of lubrication.

- Calibration: Regularly calibrate your machine to ensure it operates within specified parameters. This helps maintain accuracy and efficiency.

- Storage: When not in use, store the equipment in a dry and protected area to prevent environmental damage.

By following these simple yet effective maintenance tips, you can significantly increase the reliability and lifespan of your machinery, ensuring it remains a valuable asset for years to come.

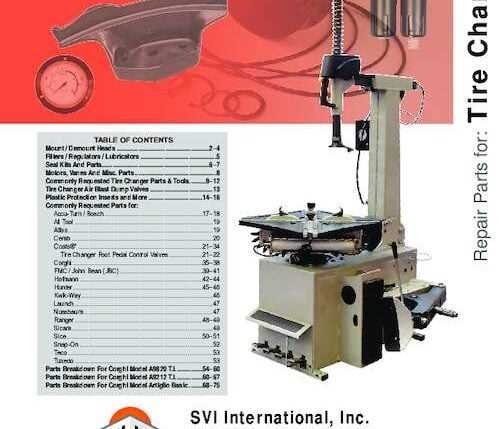

Choosing the Right Replacement Parts

When it comes to maintaining equipment, selecting the appropriate components is essential for optimal performance and longevity. Understanding the specific requirements can make all the difference in ensuring efficiency and reliability.

- Assess Compatibility: Ensure that the new elements align with the existing machinery.

- Quality Matters: Opt for high-grade materials to enhance durability.

- Manufacturer Recommendations: Follow guidelines from the original creator to avoid mismatches.

- Read Reviews: Gather feedback from other users to gauge performance and reliability.

Taking the time to research and choose wisely will lead to improved functionality and satisfaction in the long run.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to addressing common issues with equipment used for wheel maintenance. By following this structured method, users can ensure a thorough understanding of the necessary procedures and techniques required for effective restoration.

1. Identify the Problem: Begin by observing the machinery for any visible signs of malfunction or wear. This initial assessment is crucial for determining the right course of action.

2. Gather Tools: Collect all necessary tools and materials before starting the repair. Having everything at hand will streamline the process and minimize downtime.

3. Disassemble Carefully: Follow the manufacturer’s guidelines to take apart the equipment. Take note of each step and keep components organized to avoid confusion during reassembly.

4. Inspect Components: Examine each part for damage or wear. Replace any defective pieces with high-quality alternatives to ensure longevity.

5. Reassemble and Test: After replacing or repairing components, carefully reassemble the machinery. Conduct a thorough test to verify that everything functions correctly and efficiently.

6. Maintain Regularly: Implement a routine maintenance schedule to prevent future issues. Regular checks can extend the lifespan of the equipment significantly.

Upgrades for Enhanced Performance

Improving efficiency and effectiveness is essential for any mechanical system. Various enhancements can significantly elevate functionality and user experience, ensuring optimal operation and longevity.

Key Upgrades to Consider

- Advanced Motor Systems: Boost power and reduce energy consumption.

- Enhanced Control Interfaces: Improve user interaction and precision in adjustments.

- Durable Material Components: Increase resilience and decrease maintenance frequency.

Benefits of Upgrading

- Increased Speed: Perform tasks faster with upgraded mechanisms.

- Improved Accuracy: Enhanced precision leads to better results.

- Extended Lifespan: Quality components can reduce wear and tear.

Comparing Different Models

When it comes to selecting equipment for wheel service, understanding the variations between different models can significantly impact performance and efficiency. Each model brings unique features, capabilities, and advantages tailored to specific needs and environments. Analyzing these distinctions allows users to make informed decisions based on their operational requirements.

Key Features to Consider

One of the primary aspects to examine is the range of functionalities offered. Some models may provide advanced automation, while others emphasize manual operation for greater control. Additionally, the size and weight of the machines can influence their portability and ease of use in various settings. Durability and maintenance requirements are also critical, as they affect long-term reliability and overall costs.

Performance and Efficiency

Performance metrics, such as speed and accuracy, vary between models, impacting how quickly and effectively services can be completed. For high-volume operations, efficiency can translate into significant time savings and improved throughput. Evaluating user reviews and expert opinions can provide valuable insights into how different machines perform under real-world conditions, helping to identify the best fit for individual needs.

Professional vs. DIY Repairs

When it comes to maintenance and repairs, individuals often face the choice between relying on experts or taking matters into their own hands. Each approach has its distinct advantages and potential drawbacks, depending on the complexity of the task and the skill level of the individual.

Benefits of Professional Assistance

Engaging a skilled technician guarantees expertise and access to specialized tools, often resulting in quicker, more reliable outcomes. Professionals are also familiar with the latest techniques and safety protocols, ensuring that the work is performed to high standards.

Advantages of DIY Approaches

Opting for self-repair can be cost-effective and empowering, allowing individuals to learn and develop practical skills. This approach fosters a sense of accomplishment, and for simpler tasks, it can be a time-saving option if done correctly.

| Aspect | Professional | DIY |

|---|---|---|

| Cost | Higher | Lower |

| Skill Level Required | Advanced | Varies |

| Time Efficiency | High | Variable |

| Learning Opportunity | Minimal | Significant |

Resources for Further Learning

Expanding your knowledge in the field of equipment maintenance and repair is essential for both professionals and enthusiasts. Numerous resources are available to deepen your understanding of machinery, enhancing your skills and expertise. This section highlights valuable materials and platforms that can guide you on your learning journey.

Online Courses and Tutorials

Platforms like Coursera and Udemy offer a variety of courses that cover fundamental and advanced techniques in machinery servicing. These courses often include video lectures, interactive quizzes, and forums for discussion, providing a comprehensive learning experience. Additionally, YouTube hosts numerous channels dedicated to mechanical repair and maintenance, featuring practical demonstrations and tips.

Books and Manuals

For those who prefer traditional learning methods, consider investing in specialized books and manuals. Titles focusing on machinery mechanics and maintenance techniques can be incredibly informative. Check your local library or bookstore for texts that delve into operational principles, troubleshooting, and repair strategies. Furthermore, many manufacturers publish detailed manuals that provide insights into the specific workings of their equipment.