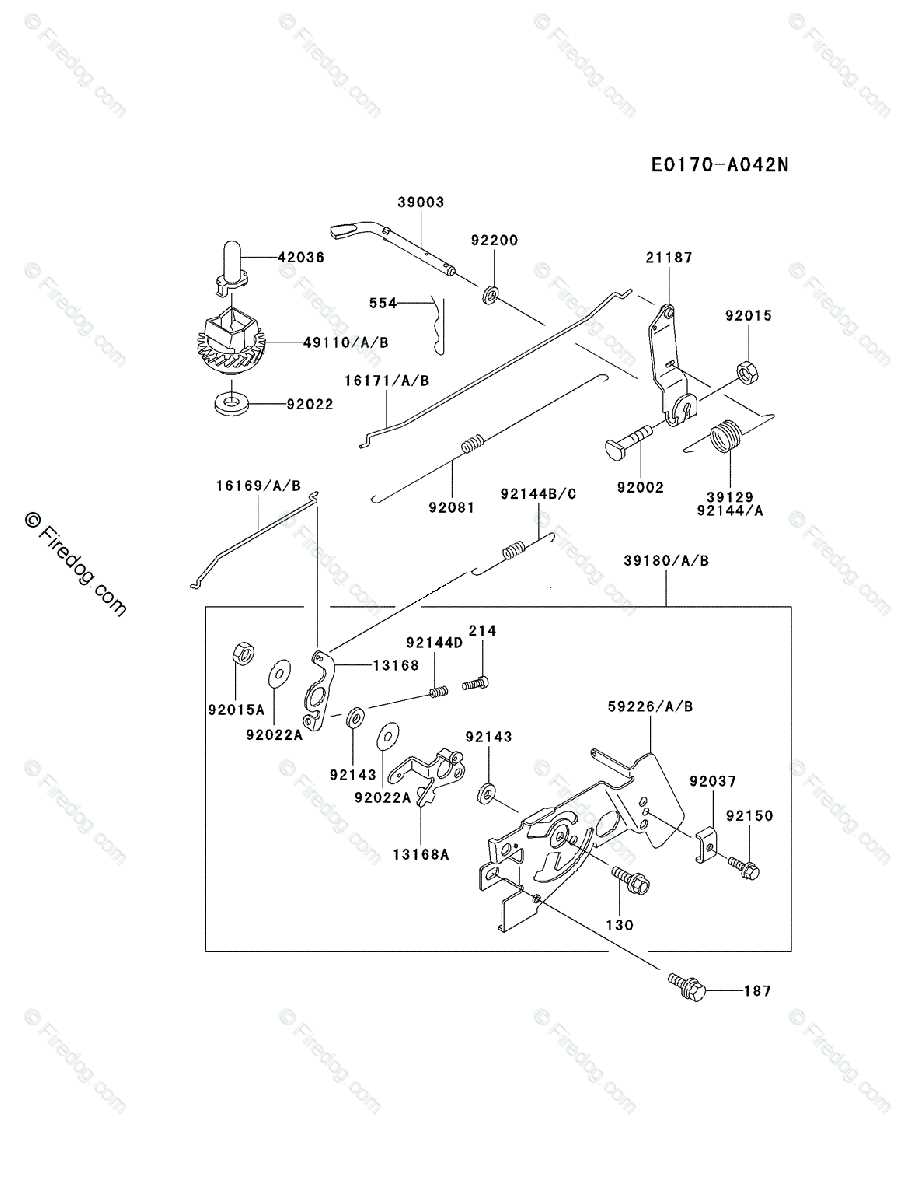

Kawasaki FC150V Parts Diagram Overview

In the realm of small machinery, the intricate assembly of various elements plays a crucial role in ensuring optimal performance. Grasping the configuration of these components allows users to maintain their equipment effectively and troubleshoot potential issues. An organized visual representation serves as a valuable resource, providing insight into how each part interacts within the overall system.

By familiarizing oneself with the structure of these mechanical units, operators can enhance their understanding of functionality and efficiency. This knowledge empowers users to identify specific sections quickly, whether for repair or routine maintenance. A clear schematic not only illustrates the arrangement but also highlights the significance of each element, making it easier to comprehend the operational dynamics.

In addition, having access to a detailed visual guide aids in the selection of replacement elements, ensuring compatibility and quality. This resource proves indispensable for those looking to extend the life of their equipment, reduce downtime, and optimize performance. Ultimately, an effective grasp of the layout fosters greater confidence in handling machinery, leading to improved operational success.

Understanding Kawasaki FC150V Engine Parts

Grasping the intricacies of small engine components is essential for optimal performance and maintenance. Each element plays a pivotal role in ensuring the machinery operates smoothly and efficiently. By familiarizing oneself with these elements, users can enhance longevity and functionality.

Key Components and Their Functions

Among the fundamental elements are the ignition system, fuel delivery mechanisms, and the cooling system. The ignition system initiates combustion, while the fuel delivery mechanisms ensure a steady supply of fuel to the engine. Meanwhile, the cooling system maintains optimal operating temperatures, preventing overheating and ensuring reliability.

Maintenance Tips

Regular upkeep of these components is crucial. Inspecting and cleaning parts such as air filters, spark plugs, and fuel lines can prevent common issues. Additionally, using high-quality lubricants and fuels contributes to better performance and reduced wear and tear. By prioritizing these practices, users can achieve greater efficiency and prolong the lifespan of their engine.

Importance of Parts Diagrams

Understanding the assembly and components of machinery is crucial for effective maintenance and repair. Visual representations of various elements offer clarity, aiding technicians and enthusiasts alike in identifying and sourcing the necessary items for service. The significance of these illustrations extends beyond mere convenience, providing essential support for troubleshooting and assembly tasks.

- Enhanced Understanding: Visual aids simplify complex systems, making it easier to comprehend how different components interact.

- Efficient Repairs: Quick identification of needed items streamlines the repair process, reducing downtime.

- Accurate Sourcing: Knowing specific elements helps in procuring the right replacements, ensuring compatibility and performance.

- Guided Assembly: Step-by-step visual guidance minimizes errors during reassembly, ensuring proper function.

Ultimately, utilizing these visual tools can significantly enhance the efficiency and effectiveness of maintenance efforts, leading to prolonged equipment life and optimal performance.

Key Components of the FC150V

Understanding the essential elements of a small engine is crucial for effective maintenance and operation. These components work in harmony to ensure optimal performance, longevity, and reliability. Each part plays a specific role, contributing to the overall functionality and efficiency of the machine.

Engine Assembly

The core of the system comprises the engine assembly, which includes the cylinder, crankshaft, and piston. This assembly is responsible for the combustion process that powers the engine. Proper functioning of this unit is vital, as any issues can lead to a significant decline in performance.

Fuel System

The fuel system is another critical aspect, comprising the carburetor and fuel lines. This system regulates the mixture of air and fuel, ensuring the engine receives the appropriate blend for combustion. Regular inspection and cleaning of these components can prevent clogs and ensure smooth operation.

Common Issues with Engine Parts

Engine components can experience a variety of challenges that may affect overall performance and reliability. Understanding these common issues is crucial for proper maintenance and efficient operation. Regular inspections and timely interventions can help prevent minor problems from escalating into major repairs.

Wear and Tear

Over time, mechanical elements are subjected to stress, leading to wear and tear. This can manifest as decreased efficiency, unusual noises, or even failure to start. Regular lubrication and timely replacements of worn-out parts can significantly extend the lifespan of the engine.

Fuel System Problems

Issues in the fuel delivery system can hinder performance and cause irregular operation. Clogged filters, faulty injectors, or air leaks may lead to improper fuel mixture, affecting combustion. Regular maintenance of the fuel system, including cleaning and replacing components as necessary, is essential for optimal functionality.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, helping you identify each element and its relationship to others in the assembly. Mastering this skill enables you to locate specific items, ensuring that your tasks are carried out efficiently and accurately.

Identifying Components

Start by familiarizing yourself with the various symbols and numbers used in the illustration. Each element is typically labeled for easy reference. Take note of how parts are grouped or categorized, as this can provide insights into their function within the overall system. Pay attention to any legends or keys that explain the notations, as they can clarify the meaning of each symbol.

Understanding Connections

Look for lines or arrows indicating how components connect to one another. These links show the flow of operation and highlight the interaction between different pieces. Recognizing these connections is crucial for troubleshooting and reassembly. Always consider the orientation and placement of each part to ensure a proper fit during installation or replacement.

In summary, mastering the interpretation of these visual guides enhances your ability to maintain and repair machinery effectively. With practice, you will gain confidence in navigating the complex relationships between various components.

Replacing Worn-Out Components

Over time, various elements within a mechanical system may experience degradation due to wear and tear. This can lead to decreased efficiency and potential operational failures. Identifying and replacing these damaged parts is crucial for maintaining optimal performance and prolonging the lifespan of the equipment.

Inspection is the first step in this process. Regular checks can reveal signs of wear, such as cracks, corrosion, or unusual noises during operation. Noticing these indicators early allows for timely intervention, preventing further damage and costly repairs.

Once worn components are identified, it’s essential to choose suitable replacements. Always refer to manufacturer specifications to ensure compatibility. Utilizing high-quality substitutes can significantly enhance performance and reliability.

Installation of new parts requires careful attention to detail. Follow recommended procedures, and ensure that all fittings and connections are secure. Proper installation minimizes the risk of future issues and maximizes the effectiveness of the new components.

In conclusion, proactive maintenance through the replacement of worn-out elements is vital. Regular inspection, appropriate selection, and meticulous installation not only safeguard the equipment but also contribute to its overall efficiency and durability.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular attention and care. Implementing a systematic approach to maintenance can significantly extend the lifespan of your machinery, preventing costly repairs and downtime.

Regular Inspections

Conducting periodic inspections is crucial. Check for any signs of wear and tear, such as loose components or signs of corrosion. Addressing small issues promptly can prevent them from escalating into major problems.

Proper Lubrication

Regularly applying appropriate lubricants to moving parts is essential for reducing friction and wear. Ensure that all necessary areas are adequately serviced, as this can enhance performance and extend operational life. Always use lubricants recommended by the manufacturer for optimal results.

In summary, adopting these maintenance practices will promote the longevity of your equipment. By investing time and effort into care, you can enjoy reliable performance for years to come.

Where to Find Genuine Parts

When seeking reliable components for your outdoor power equipment, it is crucial to source them from trustworthy outlets. Genuine replacements ensure optimal performance and longevity, allowing your machinery to operate at its best. Several options are available for locating authentic supplies that meet high standards.

Authorized Dealers: Visiting an authorized retailer is one of the best ways to find legitimate replacements. These establishments are certified to sell original items and often provide expert guidance on your specific needs.

Online Marketplaces: Reputable online platforms can also be a convenient source for authentic components. Look for sellers with positive reviews and clear return policies to ensure you are purchasing quality items.

Manufacturer Websites: Many brands offer a direct purchasing option through their official sites. This method guarantees that you are getting the correct parts designed specifically for your equipment.

Local Repair Shops: Local mechanics and repair specialists often have access to genuine components and can assist in finding the right fit for your machinery. Their expertise can help you avoid common pitfalls when selecting replacements.

By utilizing these resources, you can confidently acquire the necessary components to maintain the efficiency and reliability of your equipment.

Tools Required for Repairs

To effectively perform maintenance and repairs on outdoor machinery, having the right tools is essential. Proper equipment not only facilitates the repair process but also ensures safety and efficiency. Below is a list of necessary tools that will aid in various tasks.

- Wrenches: A set of metric and standard wrenches is vital for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are needed for different types of screws.

- Socket Set: A comprehensive socket set allows for quick removal of fasteners in tight spaces.

- Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Utility Knife: Handy for cutting materials or stripping wires during repairs.

- Shop Vacuum: Ideal for cleaning debris and ensuring a tidy workspace.

By having these tools readily available, you can tackle repairs more effectively and keep your machinery in optimal condition.

Expert Recommendations for Upgrades

When enhancing the performance and reliability of your equipment, making informed upgrades can lead to significant improvements. Experts suggest focusing on key components that directly impact functionality and efficiency.

- Air Filtration: Upgrading to a high-performance air filter can enhance airflow and improve combustion efficiency.

- Fuel System: Consider replacing the fuel pump with a more robust option to ensure consistent fuel delivery.

- Exhaust System: A performance exhaust can reduce back pressure, leading to better power output.

- Ignition System: Installing an upgraded ignition coil can improve spark strength, resulting in smoother operation.

It’s also beneficial to regularly assess the condition of wear parts, such as:

- Belts and Hoses: Replace frayed or cracked belts and hoses to prevent failures.

- Seals and Gaskets: Upgrade to high-quality materials to reduce leaks and improve durability.

- Bearings: Consider high-performance bearings for smoother operation and reduced friction.

Implementing these upgrades not only boosts performance but also extends the lifespan of your machinery, ensuring reliable operation for years to come.

FAQs About FC150V Parts

This section addresses common inquiries regarding components associated with the specific engine model. Whether you are a seasoned technician or a DIY enthusiast, understanding these details can greatly enhance your maintenance and repair efforts.

What are the most commonly replaced components?

The frequently substituted items typically include filters, spark plugs, and gaskets. Regularly checking these elements can help ensure optimal performance and longevity.

How can I identify the right components for my engine?

To accurately determine the appropriate items, consult the engine’s manual or look for identification numbers on existing components. This will guide you in sourcing the correct replacements.