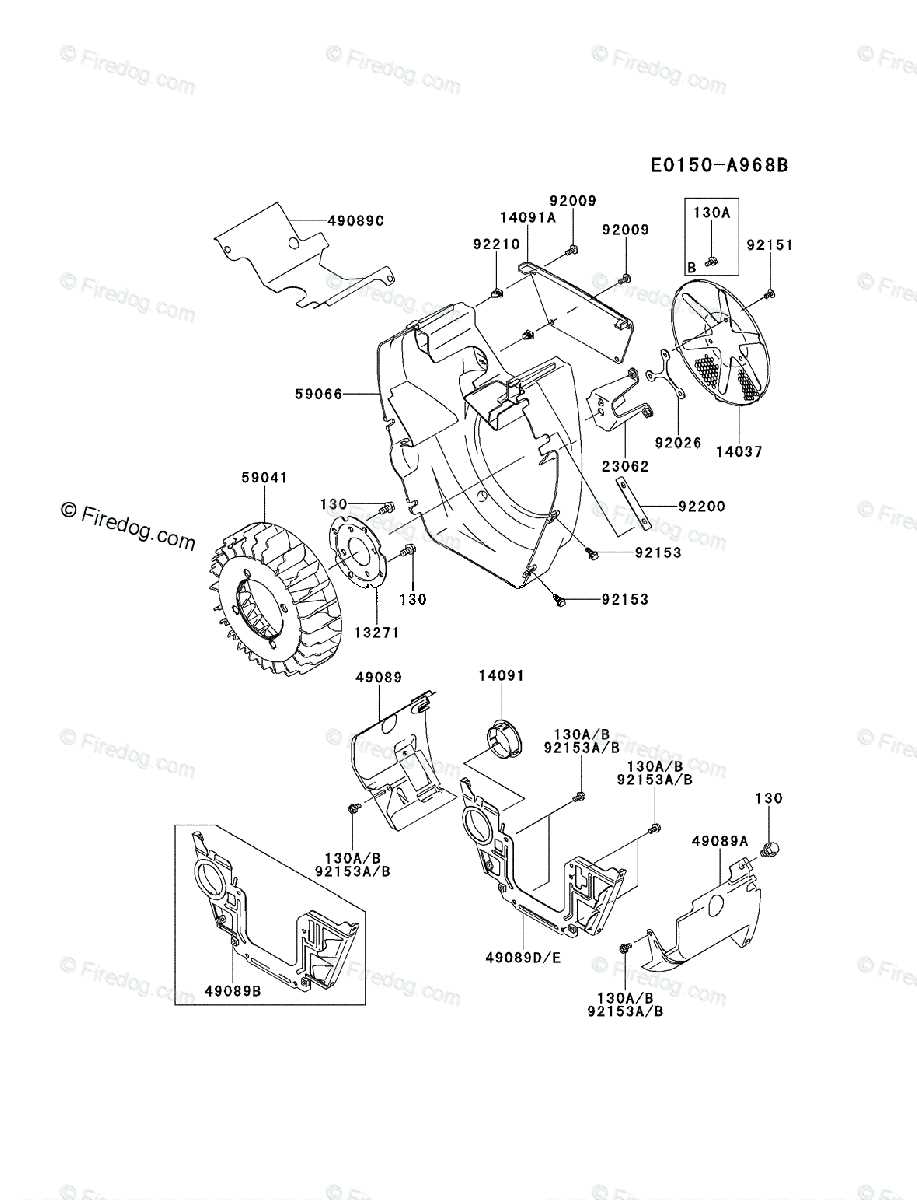

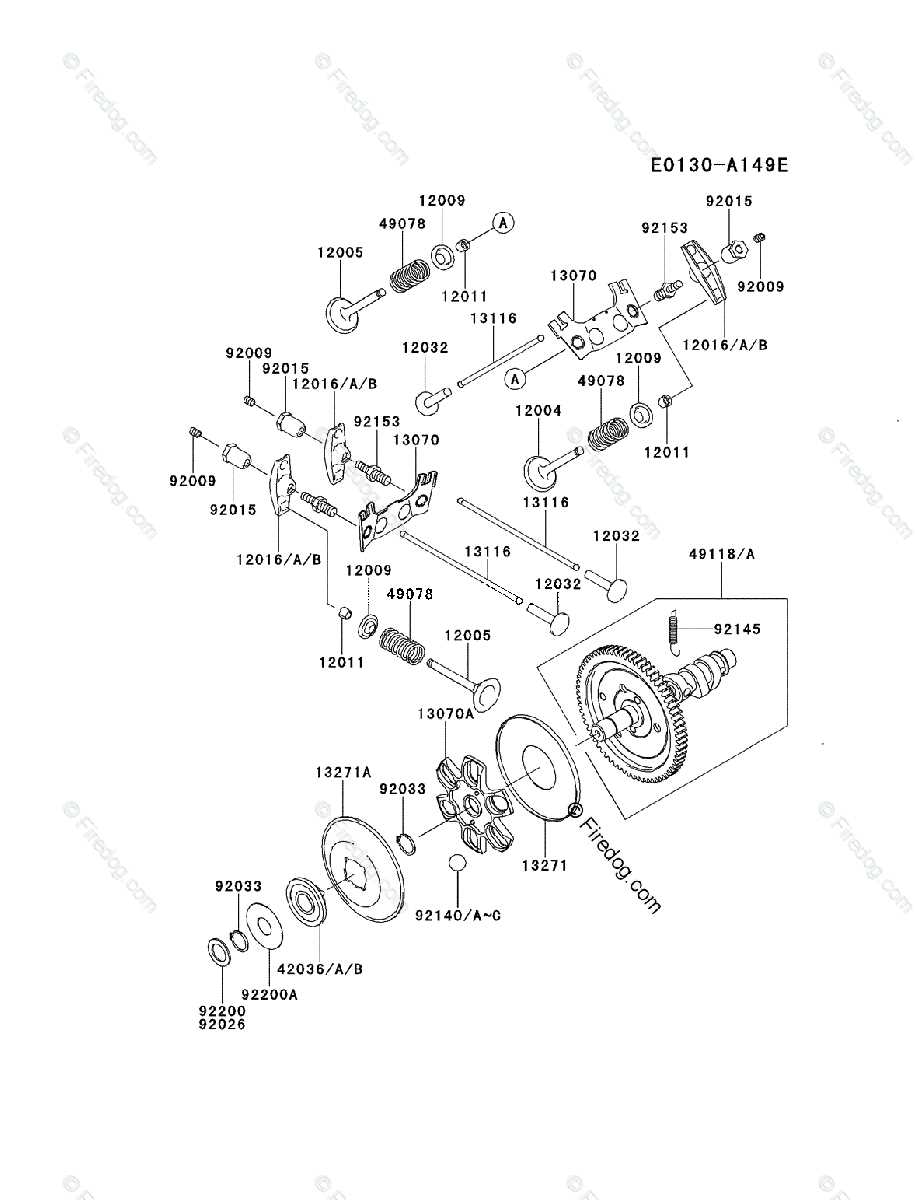

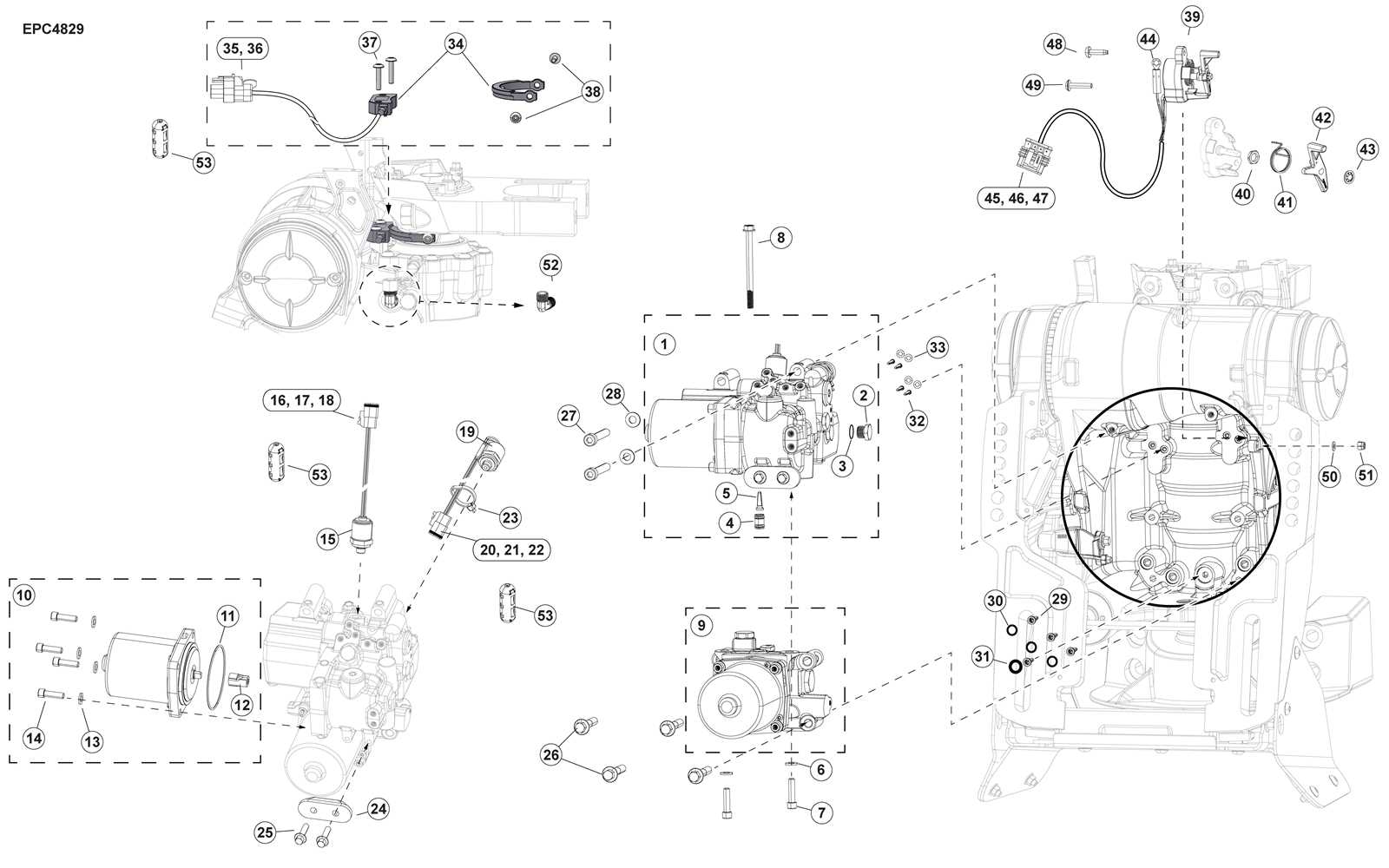

Kawasaki FH680D Parts Diagram Breakdown

In the realm of small engine maintenance and repair, having a clear visual representation of the internal components is essential for efficient troubleshooting and assembly. An accurate layout serves as a valuable reference for both seasoned mechanics and enthusiasts alike, ensuring that each piece fits seamlessly within the overall structure.

Comprehending the intricacies of engine assemblies can significantly reduce downtime during repairs. Familiarity with various sections and their interconnections not only enhances the understanding of functionality but also aids in identifying potential issues before they escalate. A well-organized layout can streamline the maintenance process, making it more accessible and less daunting.

For those diving into the world of engine servicing, leveraging a detailed schematic can elevate the repair experience. By visualizing the arrangement and purpose of each component, one can develop a deeper appreciation for the machinery and improve their ability to diagnose problems efficiently. Engaging with these resources empowers individuals to tackle repairs with confidence.

Kawasaki FH680D Engine Overview

This section provides a comprehensive understanding of a robust power unit designed for various outdoor equipment. Renowned for its efficiency and reliability, this engine type is widely utilized in residential and commercial applications.

Key features of this engine include:

- High Performance: Delivers impressive horsepower suitable for demanding tasks.

- Durability: Engineered with high-quality materials to withstand rigorous use.

- Fuel Efficiency: Optimized design that promotes better fuel consumption rates.

- Easy Maintenance: Components designed for straightforward access, facilitating routine checks and repairs.

In addition to these features, the power unit boasts advanced engineering that ensures smooth operation and minimal vibration. This results in enhanced comfort for users during extended periods of operation.

Understanding the components and systems within this engine can significantly aid in its maintenance and performance optimization. The following elements are critical:

- Air Intake System: Ensures proper airflow for combustion.

- Fuel Delivery Mechanism: Efficiently supplies fuel to the combustion chamber.

- Ignition System: Provides reliable starting and stable engine performance.

- Cooling System: Prevents overheating, maintaining optimal operating temperatures.

Overall, this engine type is designed to meet the demands of various outdoor tasks while offering reliability and efficiency, making it a preferred choice among professionals and enthusiasts alike.

Understanding Parts and Their Functions

Every engine consists of various components that work together to ensure optimal performance. Understanding these elements and their specific roles is essential for maintenance and troubleshooting.

Key Components

- Engine Block: The core structure housing the cylinders and other critical elements.

- Piston: Moves up and down within the cylinder, creating power.

- Cylinder Head: Covers the cylinders, facilitating combustion.

- Crankshaft: Converts linear motion of the pistons into rotational motion.

Functions of Each Component

- Ensure proper air and fuel mixture for efficient combustion.

- Facilitate smooth movement of mechanical parts.

- Maintain optimal temperature through cooling systems.

- Support overall stability and reduce vibrations during operation.

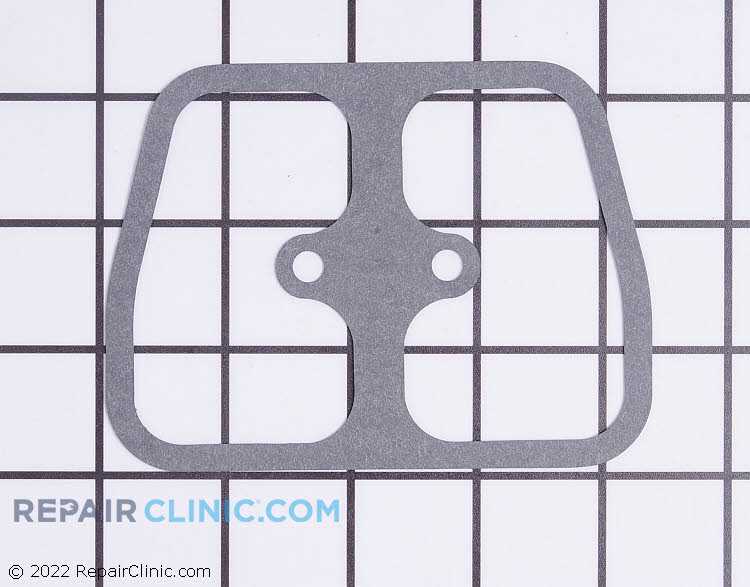

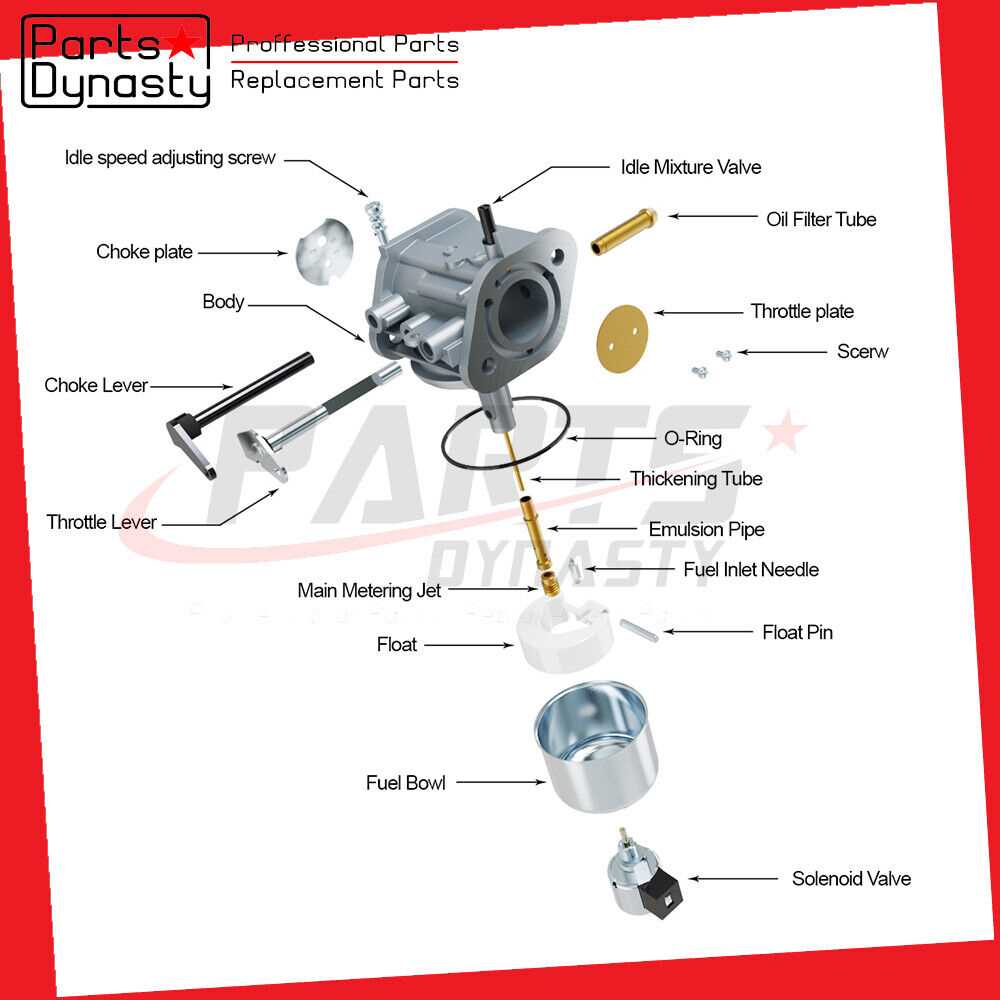

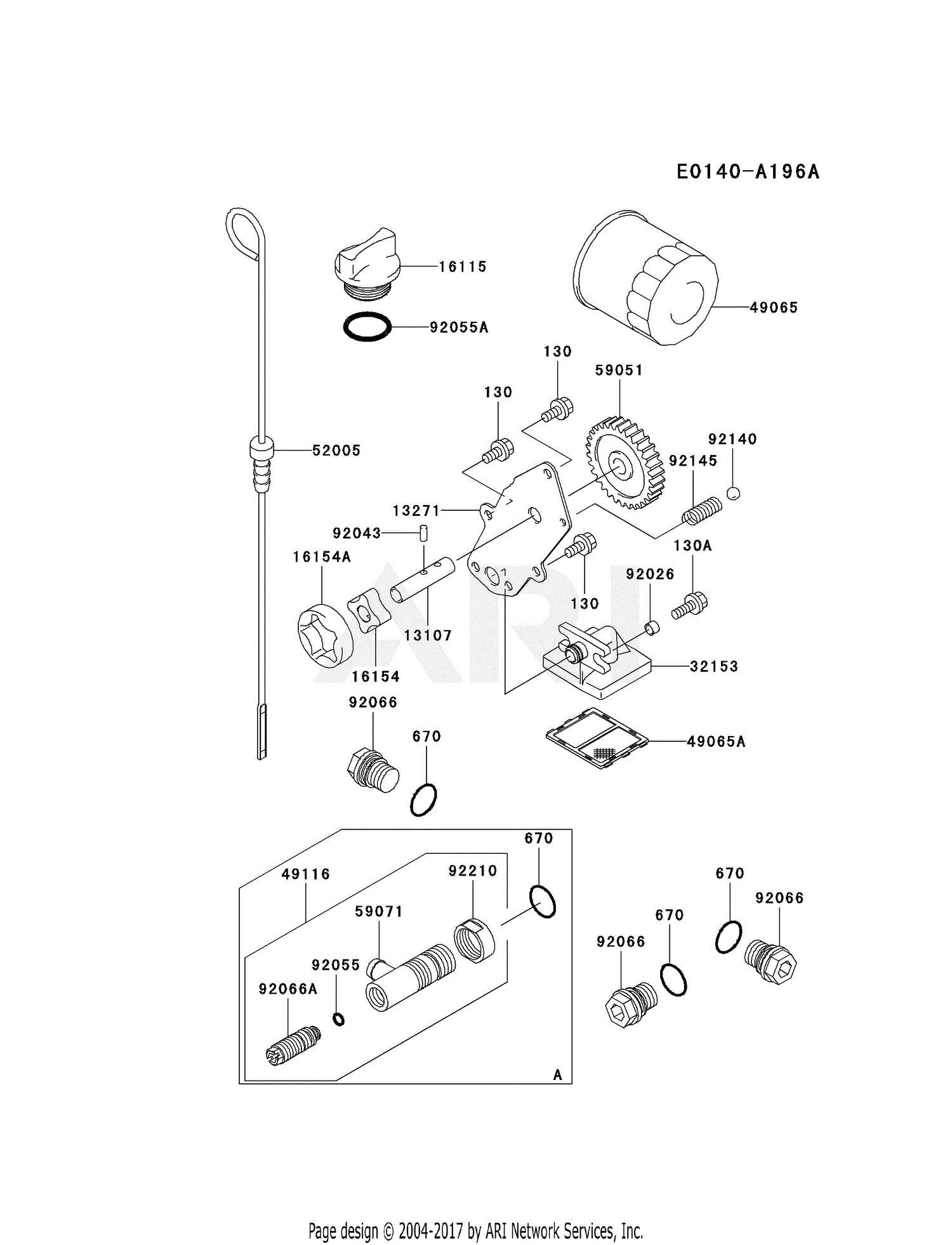

Importance of Accurate Parts Diagrams

Precise illustrations are essential for effective maintenance and repair processes. They serve as crucial references, allowing users to identify components accurately and understand their relationships within a system. Without these visual aids, confusion can lead to errors that may compromise performance and safety.

Clear visual representations facilitate the identification of necessary components and their specific functions. This clarity is vital for both novices and experienced technicians, ensuring that repairs are conducted efficiently. Moreover, accurate schematics minimize downtime by streamlining the sourcing of the correct elements, ultimately enhancing productivity.

Additionally, reliable representations foster a better understanding of the overall system design. By delving into these detailed illustrations, individuals can grasp how each piece contributes to the functionality of the entire apparatus. This knowledge not only aids in immediate tasks but also promotes long-term maintenance strategies.

Common Issues with Kawasaki FH680D

Engines in this category often encounter various challenges that can affect performance and reliability. Understanding these common problems is crucial for effective maintenance and troubleshooting.

Frequent Problems

- Overheating due to inadequate cooling.

- Fuel system blockages affecting power delivery.

- Starting difficulties linked to battery issues.

Troubleshooting Tips

- Regularly check and clean the air filter to ensure proper airflow.

- Inspect fuel lines and filters for any signs of obstruction.

- Test the battery voltage and connections to ensure reliable starts.

Where to Find Replacement Parts

Locating suitable components for your machinery can be crucial for maintaining optimal performance and extending its lifespan. Various sources offer quality replacements, ensuring that you can keep your equipment running smoothly without interruptions.

One reliable option is authorized dealers, who provide original components tailored for specific models. This guarantees compatibility and performance. Additionally, many online retailers specialize in aftermarket alternatives, often at competitive prices. Exploring these platforms can yield a range of options to suit different budgets and preferences.

For those who prefer a hands-on approach, local repair shops can be invaluable. These establishments not only stock various items but also offer expert advice on the best choices for your needs. Furthermore, community forums and discussion groups can be excellent resources for recommendations and insights from fellow users.

Finally, consider checking auction sites and marketplaces. Many individuals sell surplus or unused items, which can lead to significant savings. Always ensure to verify the condition and compatibility before making a purchase.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. By implementing a few essential practices, you can extend the lifespan of your equipment, reduce the likelihood of breakdowns, and maintain optimal performance. Regular maintenance is not just about fixing issues when they arise; it’s about proactive measures that keep everything running smoothly.

Regular Inspections

Conducting frequent checks on your equipment is vital. Look for signs of wear and tear, leaks, or any irregularities in performance. Early detection of potential problems can save time and resources in the long run. Be thorough in your inspections, paying close attention to critical components that are prone to failure.

Proper Lubrication

Ensuring all moving parts are adequately lubricated is crucial for preventing friction and overheating. Use the recommended lubricants for your specific model and follow the manufacturer’s guidelines. Regularly clean the components before applying new grease or oil to avoid the buildup of dirt and debris, which can cause further damage.

Tools Required for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for achieving effective results. Proper tools not only facilitate the repair process but also enhance safety and efficiency. This section outlines essential instruments needed to perform various repairs effectively.

Basic Hand Tools

Starting with the fundamentals, a set of wrenches and screwdrivers is indispensable. These tools allow for the loosening and tightening of various components. Additionally, pliers are useful for gripping and manipulating small parts, ensuring precision in your work.

Specialized Equipment

In some cases, specialized tools may be necessary to address specific issues. A socket set is highly recommended for tasks that involve bolts and nuts in tight spaces. Furthermore, having a reliable torque wrench ensures that components are tightened to the correct specifications, preventing future complications.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repairs. These illustrations provide a clear overview of various elements and their arrangements, enabling users to identify what is needed for restoration or replacement. Mastering this skill can significantly enhance the efficiency of any mechanical project.

To begin, familiarize yourself with the legend or key, which often explains symbols and color coding used throughout the representation. This section serves as a guide to deciphering the various parts depicted. Next, pay attention to the layout; components are usually arranged logically, reflecting their physical relationships. This can help in visualizing how pieces fit together.

Additionally, take note of the numbering system. Each item is typically assigned a unique identifier, simplifying communication when ordering replacements. By following these steps and practicing with various visual aids, you can develop a strong proficiency in interpreting these essential tools for mechanical work.

Cost Analysis of Replacement Parts

The assessment of expenses associated with component replacements is crucial for effective maintenance planning. Understanding the financial implications can aid in budgeting and decision-making processes for repairs and upgrades.

Initial Investment: The upfront costs of acquiring new components can vary significantly based on quality and brand. Opting for high-quality items may lead to higher initial expenditures but could result in enhanced longevity and performance.

Long-Term Savings: Evaluating the long-term benefits is essential. Investing in durable components often reduces the frequency of replacements, ultimately saving money over time.

Labor Costs: It’s important to factor in labor expenses related to installation. The complexity of the replacement process can influence these costs, making professional assistance a consideration for certain components.

Market Trends: Staying informed about market fluctuations can provide insights into potential savings. Prices may vary due to demand and availability, allowing for strategic purchasing opportunities.

In conclusion, a thorough cost analysis of replacement components not only aids in immediate decision-making but also fosters long-term financial efficiency.

Aftermarket vs. OEM Parts Comparison

When it comes to sourcing replacement components for machinery, the choice often narrows down to two primary categories: original and alternative suppliers. Each option presents distinct advantages and potential drawbacks that can influence decision-making.

Benefits of Original Equipment Manufacturer (OEM) Components

- Quality Assurance: OEM items are typically designed to meet strict performance and durability standards set by the manufacturer.

- Exact Fit: These components are made to precisely match the specifications of the original unit, ensuring seamless integration.

- Warranty Protection: Utilizing OEM components often means maintaining the warranty on the equipment, safeguarding against future issues.

Advantages of Aftermarket Alternatives

- Cost-Effectiveness: Aftermarket options can often be more affordable than their original counterparts, making them a budget-friendly choice.

- Variety: A wide range of aftermarket suppliers may offer different designs or enhancements that can improve performance or aesthetics.

- Availability: Alternative options are frequently more accessible, especially for older models where OEM items might be scarce.

Ultimately, the decision between these two types hinges on individual priorities, including budget constraints, performance needs, and long-term goals for the machinery in question.