Kawasaki Parts Diagram Overview

The intricate arrangement of elements in mechanical systems is essential for ensuring optimal performance and longevity. By examining these layouts, one can gain insights into how different components interact and function together effectively. This knowledge is invaluable for both enthusiasts and professionals who wish to maintain and enhance the efficiency of their machinery.

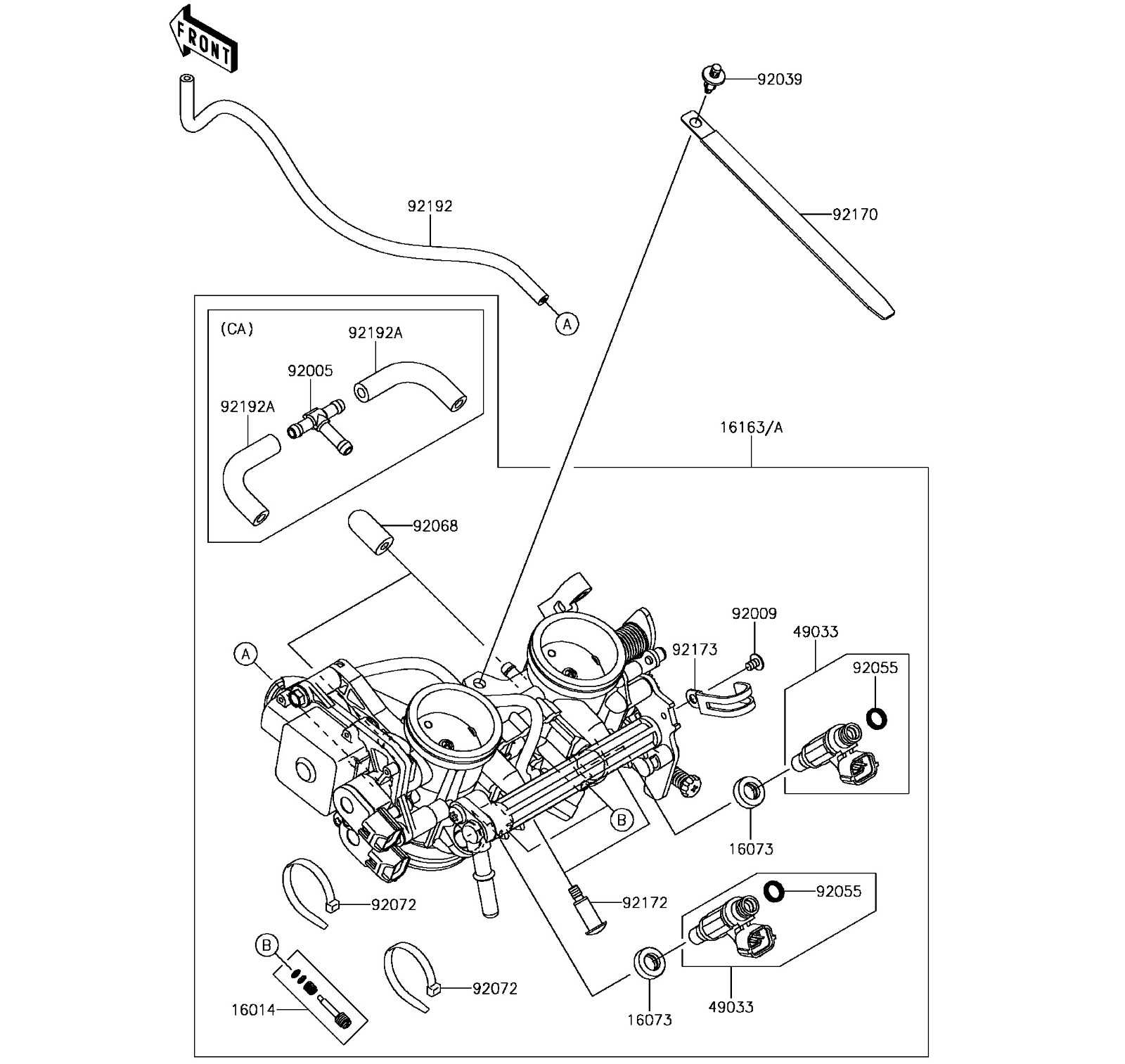

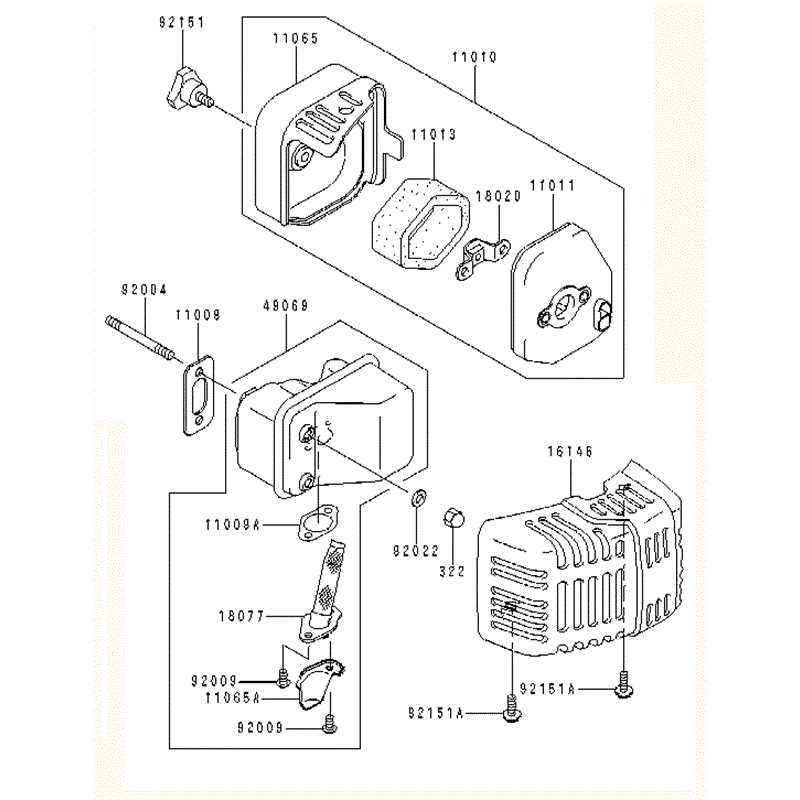

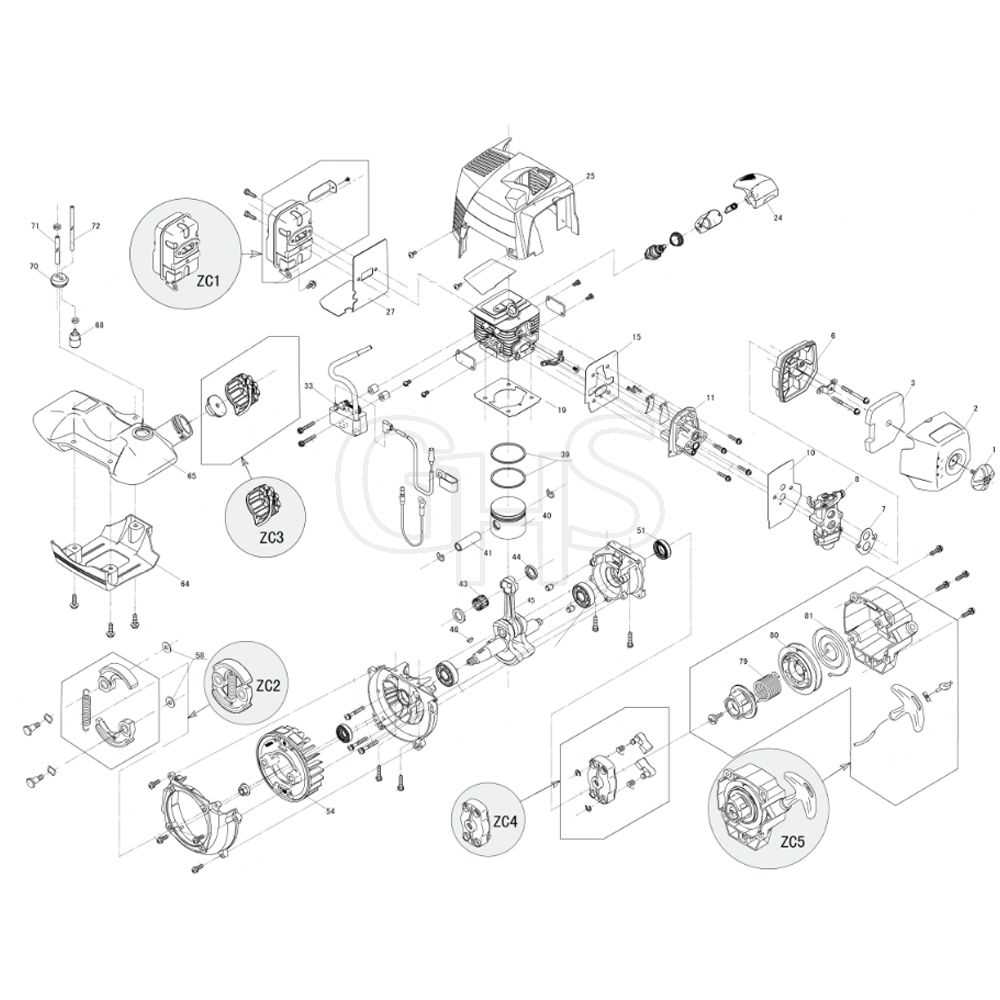

Visual aids play a crucial role in this exploration, providing a clear representation of how various components are organized within a larger framework. These illustrations serve as a guide, helping users identify specific parts and understand their roles within the assembly. Whether for repair, maintenance, or upgrades, a detailed overview is key to making informed decisions.

Additionally, familiarity with these layouts can simplify troubleshooting processes. Recognizing the placement and function of each element allows for quicker identification of issues, ultimately saving time and resources. Embracing this knowledge empowers individuals to engage more confidently with their mechanical systems, fostering a deeper appreciation for the technology at hand.

This section aims to provide a comprehensive overview of the structural elements and components that make up various models of a renowned motorcycle manufacturer. Understanding these components is crucial for enthusiasts and mechanics alike, as it enables effective maintenance, repair, and modification of the vehicles.

Understanding the Components

The first step in comprehending the layout of a motorcycle is to identify its major elements. This includes the engine, chassis, transmission, and suspension. Each component plays a pivotal role in the vehicle’s performance and overall functionality.

Utilizing Visual Representations

Visual aids are invaluable when it comes to grasping the intricate relationships between different parts. Diagrams can simplify complex systems and provide clear guidance for assembly or disassembly. They often include detailed labels that specify the function and location of each component.

Benefits of Familiarity with the Layout

Having a clear understanding of the arrangement of elements allows for more efficient troubleshooting and repair processes. It also aids in recognizing potential issues before they escalate into major problems, thereby enhancing the longevity of the vehicle.

| Component | Description |

|---|---|

| Engine | The heart of the motorcycle, responsible for power generation. |

| Chassis | The framework that supports the entire structure. |

| Transmission | System that transmits power from the engine to the wheels. |

| Suspension | Components that absorb shocks and enhance ride comfort. |

Importance of Accurate Parts Diagrams

Precise representations of components are essential for effective maintenance and repair of machinery. These visual aids serve as a crucial reference, enabling users to identify and understand each element’s function and interrelation. Accurate illustrations facilitate a smoother workflow, ensuring that technicians can quickly locate necessary items and comprehend their assembly or disassembly procedures.

Having a reliable visual reference reduces the likelihood of errors during repairs, as users can follow detailed depictions to avoid misplacing or misidentifying crucial components. Furthermore, precise representations contribute to better inventory management, allowing for efficient tracking of parts and preventing unnecessary delays in service. Overall, clear and detailed visuals enhance the overall efficiency and effectiveness of maintenance tasks.

Understanding Kawasaki Model Variations

When exploring the range of motorbike models from this manufacturer, it is essential to recognize the distinctions among various versions. Each variant offers unique characteristics, catering to diverse riding preferences and requirements. Understanding these differences enhances the experience for both enthusiasts and potential buyers, ensuring the selection of the most suitable model for individual needs.

Factors Influencing Variants

The variations in design often stem from factors such as engine size, frame construction, and intended use. For example, some models are engineered for high-speed performance, while others prioritize comfort for longer rides. By identifying the specific traits of each model, riders can better appreciate the engineering decisions that shape their motorbikes.

Benefits of Knowing the Variants

Familiarity with the different models aids in making informed decisions regarding maintenance and modifications. Understanding the specific components and configurations allows for more effective troubleshooting and enhancement of the riding experience. Ultimately, recognizing these variations empowers riders to maximize their machines’ potential and longevity.

Common Components in Kawasaki Diagrams

When exploring the illustrations used in the assembly and maintenance of motorcycles, several key elements frequently emerge. These components serve crucial functions, ensuring the proper operation and safety of the vehicle. Understanding their roles is essential for anyone involved in servicing or customizing their ride.

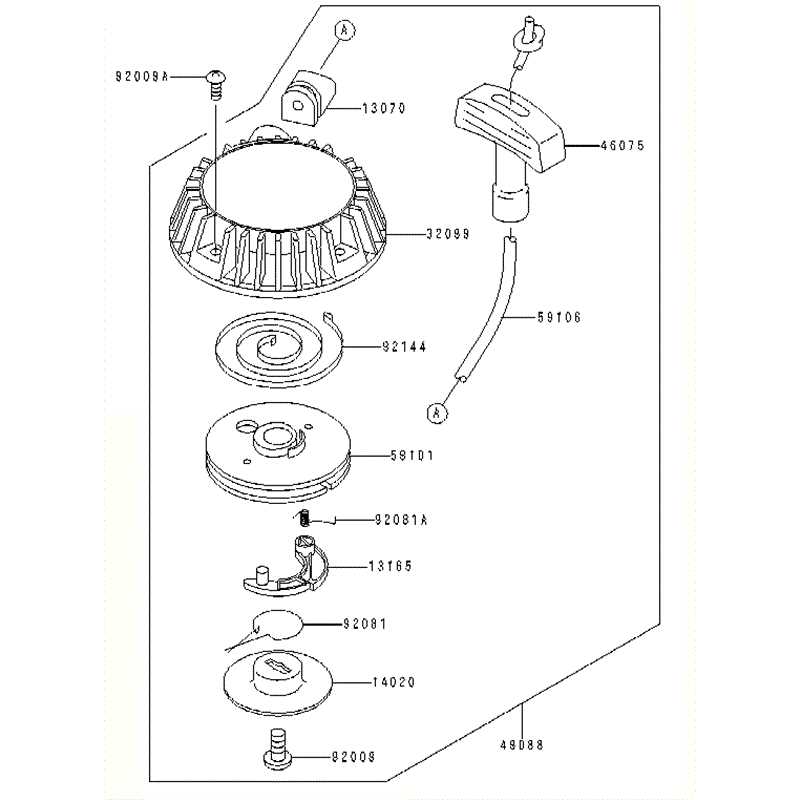

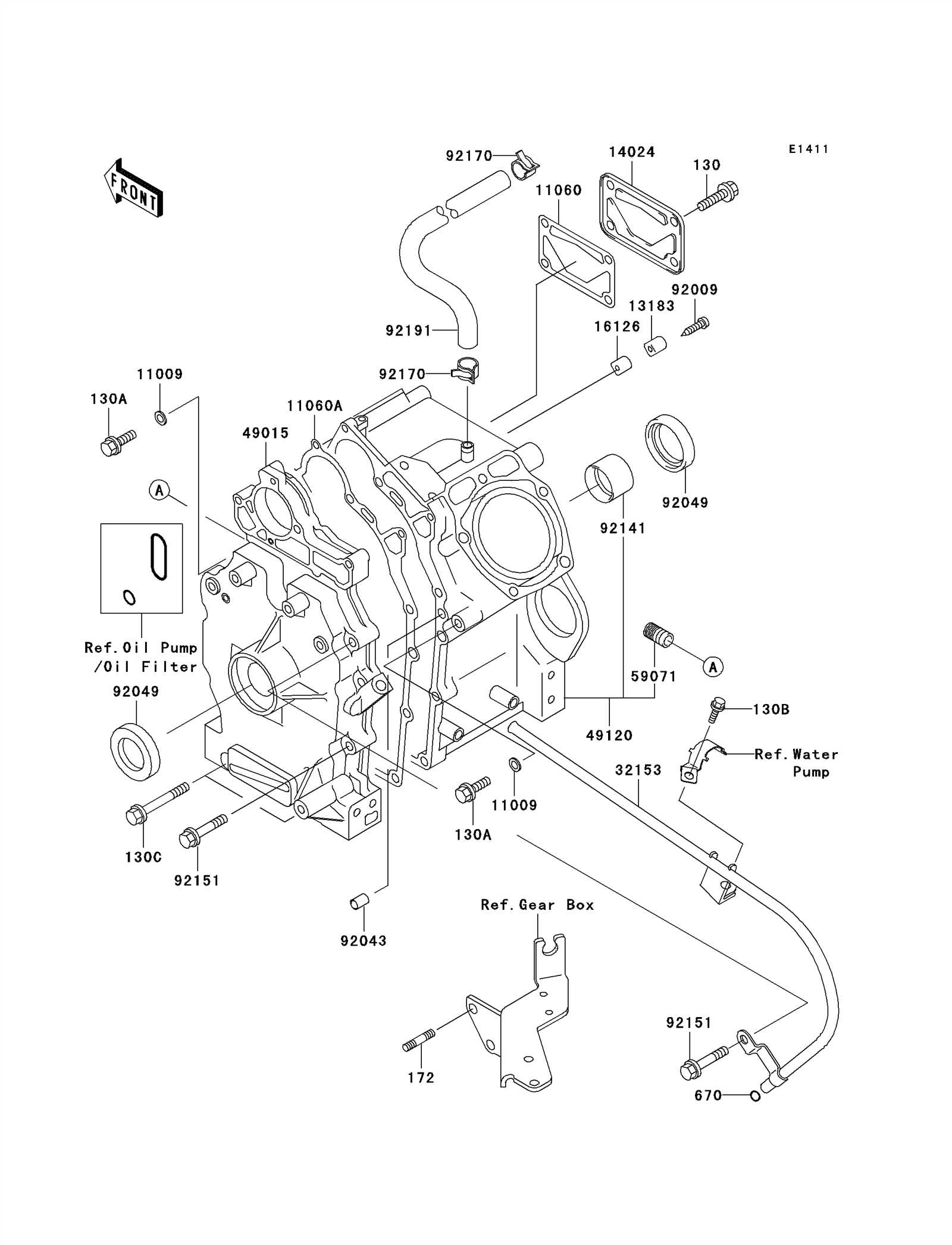

1. Engine Assembly: This is a fundamental part of any motorcycle, comprising various sections that work together to provide power. The engine’s layout includes the cylinder head, crankshaft, and piston, all of which play vital roles in the combustion process.

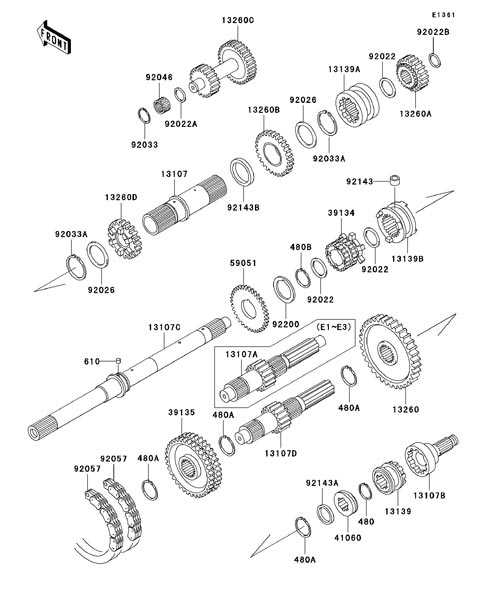

2. Transmission System: Essential for transferring power from the engine to the wheels, this system includes gears, shafts, and clutches. Understanding the configuration of these elements helps in troubleshooting performance issues.

3. Suspension Setup: The suspension system is critical for maintaining stability and comfort. It consists of components such as forks, shock absorbers, and swingarms, which work in unison to absorb bumps and enhance ride quality.

4. Electrical System: This encompasses the wiring, battery, and lighting components. A clear understanding of this network is vital for diagnosing electrical failures and ensuring all systems function harmoniously.

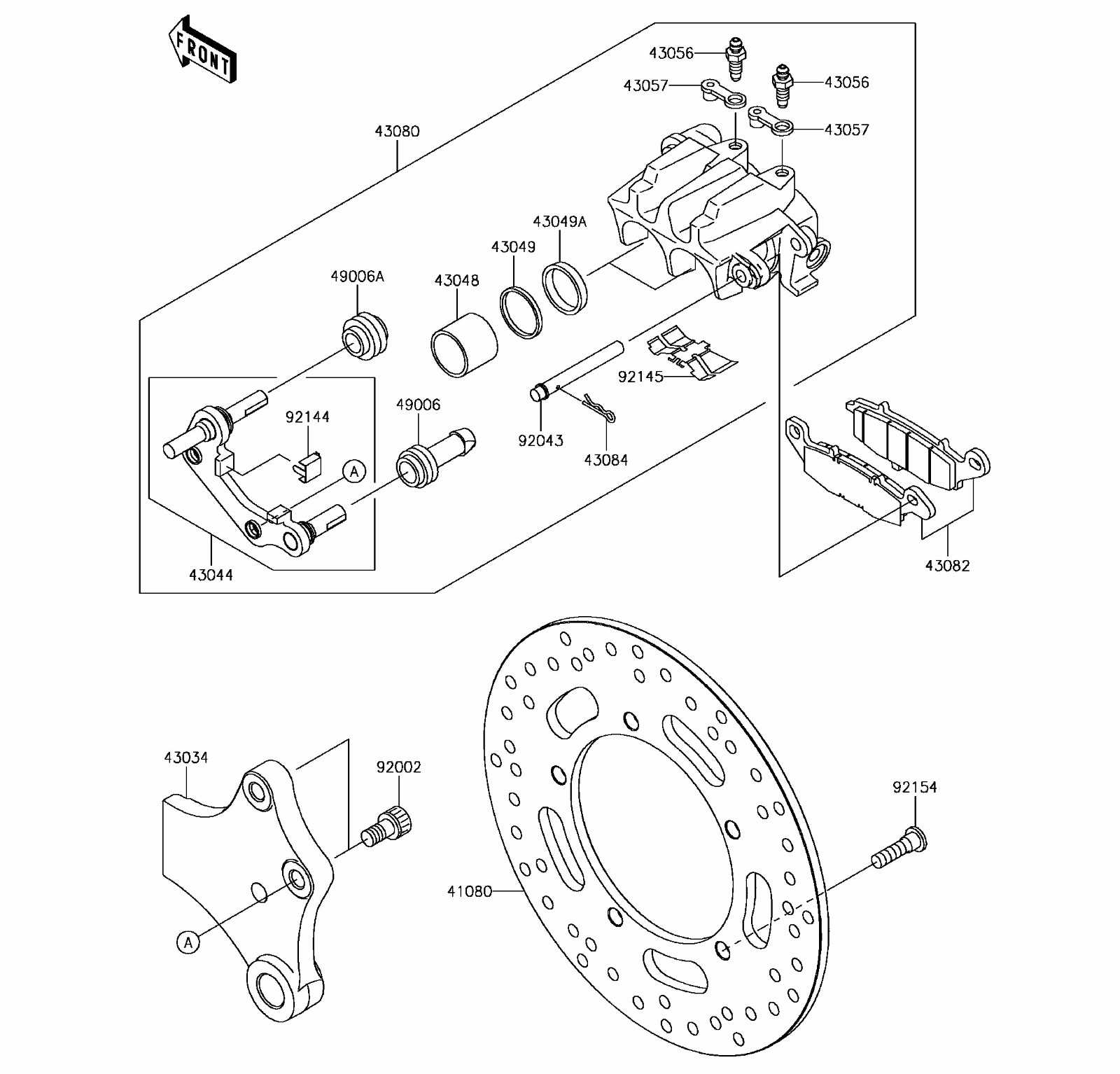

5. Brake Assembly: A well-functioning brake system is paramount for safety. The assembly includes calipers, rotors, and levers, all of which must be properly maintained and understood to ensure effective stopping power.

Familiarity with these elements enables enthusiasts and technicians alike to navigate the complexities of their vehicles more effectively. Mastery of the configurations and relationships among these components can lead to better maintenance practices and enhanced performance.

How to Read Parts Diagrams

Understanding illustrations that detail components and their relationships is essential for anyone involved in maintenance or repair tasks. These visuals provide a structured way to view how various elements fit together, facilitating easier identification and replacement when necessary. Knowing how to interpret these images can significantly enhance efficiency and accuracy in servicing equipment.

Interpreting the Visuals

Begin by familiarizing yourself with the layout of the illustration. Each section typically represents a specific area of the machinery, highlighting key components. Components are often labeled with reference numbers that correspond to lists or tables containing detailed descriptions. Understanding this relationship is crucial for locating and ordering the correct items.

Using Reference Tables

Reference tables accompany the visuals, providing essential details such as part numbers, descriptions, and sometimes pricing information. These tables serve as a guide to ensure you select the right components for your needs.

| Reference Number | Description | Part Number | Notes |

|---|---|---|---|

| 1 | Throttle Cable | 12345-67890 | Check for fraying |

| 2 | Brake Pads | 09876-54321 | Replace if worn |

| 3 | Fuel Filter | 11223-44556 | Inspect every season |

Locating OEM Parts for Your Model

Finding original equipment manufacturer (OEM) components for your vehicle is essential for maintaining its performance and longevity. With the right approach, you can ensure that your model receives the appropriate replacements, enhancing its reliability and functionality.

Researching Authorized Dealers

One of the most effective methods to locate genuine components is through authorized dealerships. These establishments provide a wide range of advantages:

- Access to a comprehensive inventory of original items.

- Knowledgeable staff who can assist in identifying the correct components for your specific model.

- Guaranteed authenticity, ensuring you receive high-quality products.

Utilizing Online Resources

In addition to visiting physical stores, there are numerous online platforms that specialize in OEM items. Here are some tips for successful online searches:

- Use the specific model number or reference to narrow down the search results.

- Read customer reviews to assess the reliability of the seller.

- Check for warranty options that come with the components, as this adds a layer of security to your purchase.

Tools for Analyzing Parts Diagrams

Understanding the intricacies of assembly illustrations requires a variety of resources and instruments. These tools can enhance one’s ability to dissect complex representations and facilitate effective maintenance and repair processes.

Digital Software is crucial for interpreting visual representations. Programs designed for automotive mechanics often include interactive features that allow users to zoom in, rotate, and manipulate images for better clarity. These applications may also incorporate search functionalities, enabling users to locate specific components swiftly.

Printed Manuals provide a tangible reference that can be easily annotated. Many enthusiasts prefer physical copies as they allow for straightforward access during hands-on work. These documents typically offer detailed instructions and contextual information, enhancing the overall understanding of the assembly process.

Online Forums and Communities serve as invaluable platforms for sharing insights and experiences. Engaging with fellow enthusiasts can provide different perspectives on interpreting illustrations, uncovering tips, and addressing common challenges encountered during maintenance.

Video Tutorials have gained popularity for their visual approach to instruction. These resources can demonstrate specific procedures step-by-step, providing a practical guide that complements the illustrations. Observing real-life applications can enhance comprehension and confidence in tackling similar tasks.

Utilizing a combination of these resources not only enriches the learning experience but also empowers individuals to approach maintenance tasks with greater efficiency and confidence.

Maintenance Tips from Parts Diagrams

Understanding how different components interact within a machine is crucial for effective upkeep. Utilizing visual representations of these elements can enhance the maintenance process by providing clarity and insight into potential issues. This section offers valuable suggestions based on these illustrations to ensure optimal performance and longevity.

Here are some essential tips to consider:

- Regular Inspections: Schedule frequent checks to identify wear and tear on key components. Early detection can prevent more significant issues down the line.

- Refer to Visual Guides: Use visual aids to familiarize yourself with the layout and function of various elements. This knowledge can simplify troubleshooting and repairs.

- Replacement Schedules: Keep track of parts that have recommended replacement intervals. Adhering to these guidelines can help maintain efficiency and safety.

- Clean Components: Regularly clean essential elements to prevent dirt and debris buildup. This practice can improve performance and extend the lifespan of your equipment.

- Use Quality Parts: When replacing elements, opt for high-quality alternatives. Quality components can enhance durability and reliability.

Implementing these strategies can lead to a more reliable operation and decrease the likelihood of unexpected breakdowns.

Parts Diagrams vs. Service Manuals

When it comes to maintaining and repairing any machinery, two key resources often come into play. Understanding the differences between these resources can save time and ensure that maintenance is performed effectively. Each type of document serves a distinct purpose, and knowing when to use which can streamline the repair process.

Understanding the Purpose

Both resources provide crucial information, but they cater to different aspects of maintenance. One focuses on visual breakdowns, while the other dives into detailed step-by-step instructions. By recognizing their unique roles, you can optimize how you approach repairs and upkeep.

Key Differences

- One type of guide offers a visual representation of all components and how they fit together, which aids in identifying parts quickly.

- The other offers detailed instructions on how to perform specific tasks such as replacements or adjustments.

- While one is excellent for locating specific components, the other is indispensable for understanding procedures and ensuring everything is correctly reassembled.

Identifying Aftermarket vs. OEM Parts

When it comes to maintaining and upgrading your vehicle, understanding the differences between original equipment manufacturer (OEM) components and aftermarket alternatives is crucial. Each type offers distinct advantages and potential drawbacks that can impact performance, reliability, and overall satisfaction.

OEM components are produced by the same manufacturer that designed the original vehicle parts. These items typically meet specific quality standards and are often favored for their compatibility and reliability. On the other hand, aftermarket options are produced by third-party manufacturers and can vary widely in terms of quality, price, and performance. While they may provide a cost-effective solution, the consistency and longevity of these alternatives can be unpredictable.

To make an informed choice, it is essential to evaluate factors such as warranty coverage, installation ease, and the intended use of the vehicle. Researching manufacturer reputations and reading customer reviews can also provide valuable insights into the reliability and effectiveness of both types. Ultimately, the decision should align with your specific needs, budget, and preferences for performance.

Diagram Resources for Kawasaki Owners

For enthusiasts and owners of specific motorcycle models, having access to reliable visual resources is crucial for understanding the structure and components of their vehicles. These resources facilitate the maintenance and repair processes, ensuring that every element is correctly identified and addressed. Below is a collection of valuable references that can assist in navigating through various assembly and configuration aspects.

| Resource Type | Description | Link |

|---|---|---|

| Official Manuals | Comprehensive guides that cover all aspects of assembly and maintenance. | Visit here |

| Online Forums | Communities where owners share insights, tips, and personal experiences related to their vehicles. | Visit here |

| Repair Guides | Step-by-step instructions for specific repairs and adjustments. | Visit here |

| Video Tutorials | Visual demonstrations that show repair techniques and assembly tips. | Visit here |

Frequently Asked Questions about Diagrams

This section addresses common inquiries regarding visual representations of components and their functions. Understanding these illustrations can greatly enhance the comprehension of mechanical systems and their maintenance. Here, we provide insights into the typical questions posed by users to facilitate a better understanding of these valuable resources.

What is the purpose of these visual aids?

Visual aids serve as essential tools for identifying various elements within a mechanical assembly. They provide clarity and simplify the process of locating specific components, making it easier for users to reference parts during repairs or upgrades.

How can I effectively use these illustrations?

To maximize the benefit of these illustrations, it is advisable to familiarize oneself with the layout and labeling conventions used. Cross-referencing with the accompanying documentation can also provide deeper insights into the functionality and interaction of different elements.

| Question | Answer |

|---|---|

| Are these visual aids universal? | Not all illustrations are standardized, so it is important to consult the specific resources related to your model. |

| Can I find these resources online? | Yes, many manufacturers provide digital versions of these resources on their official websites or support platforms. |

| Do I need special tools to interpret them? | Generally, no special tools are needed; basic familiarity with the components depicted is sufficient for effective interpretation. |