Kubota B3350 Parts Diagram for Easy Reference

In the realm of heavy equipment maintenance, having a clear overview of the components and their functions is essential for optimal performance. This section aims to provide an in-depth exploration of various elements that contribute to the effective operation of your vehicle. By breaking down the assembly and identifying each part’s role, users can ensure longevity and reliability.

Visual aids serve as invaluable tools in grasping the intricate relationships between components. Through detailed representations, one can easily locate and recognize individual sections, enhancing troubleshooting and repair processes. The importance of a well-organized reference cannot be overstated; it ultimately empowers operators to tackle maintenance tasks with confidence.

As we delve into this topic, it becomes evident that understanding the anatomy of your equipment not only streamlines repairs but also fosters a deeper appreciation for its engineering. By equipping yourself with this knowledge, you are taking the first step towards maximizing efficiency and reducing downtime.

Overview of the Compact Tractor

This section provides a comprehensive look at a powerful and versatile machine designed for various agricultural and landscaping tasks. Its robust engineering ensures reliability and efficiency, making it an excellent choice for both professional and hobbyist users.

Key Features

Equipped with a strong engine and user-friendly controls, this compact vehicle excels in maneuverability and performance. Its attachments allow for a wide range of applications, from mowing to digging, enhancing productivity on any project.

Applications

Ideal for small farms, residential properties, and commercial landscaping, this machine adapts effortlessly to different tasks. Whether plowing fields or maintaining gardens, its functionality makes it a valuable asset for any user.

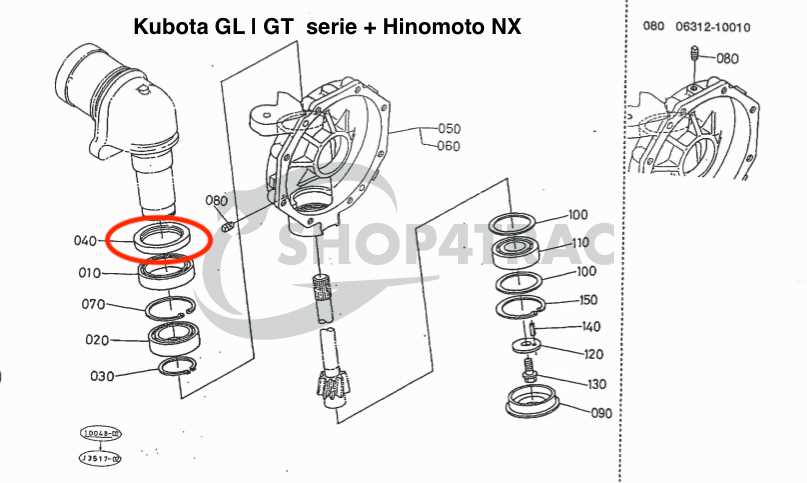

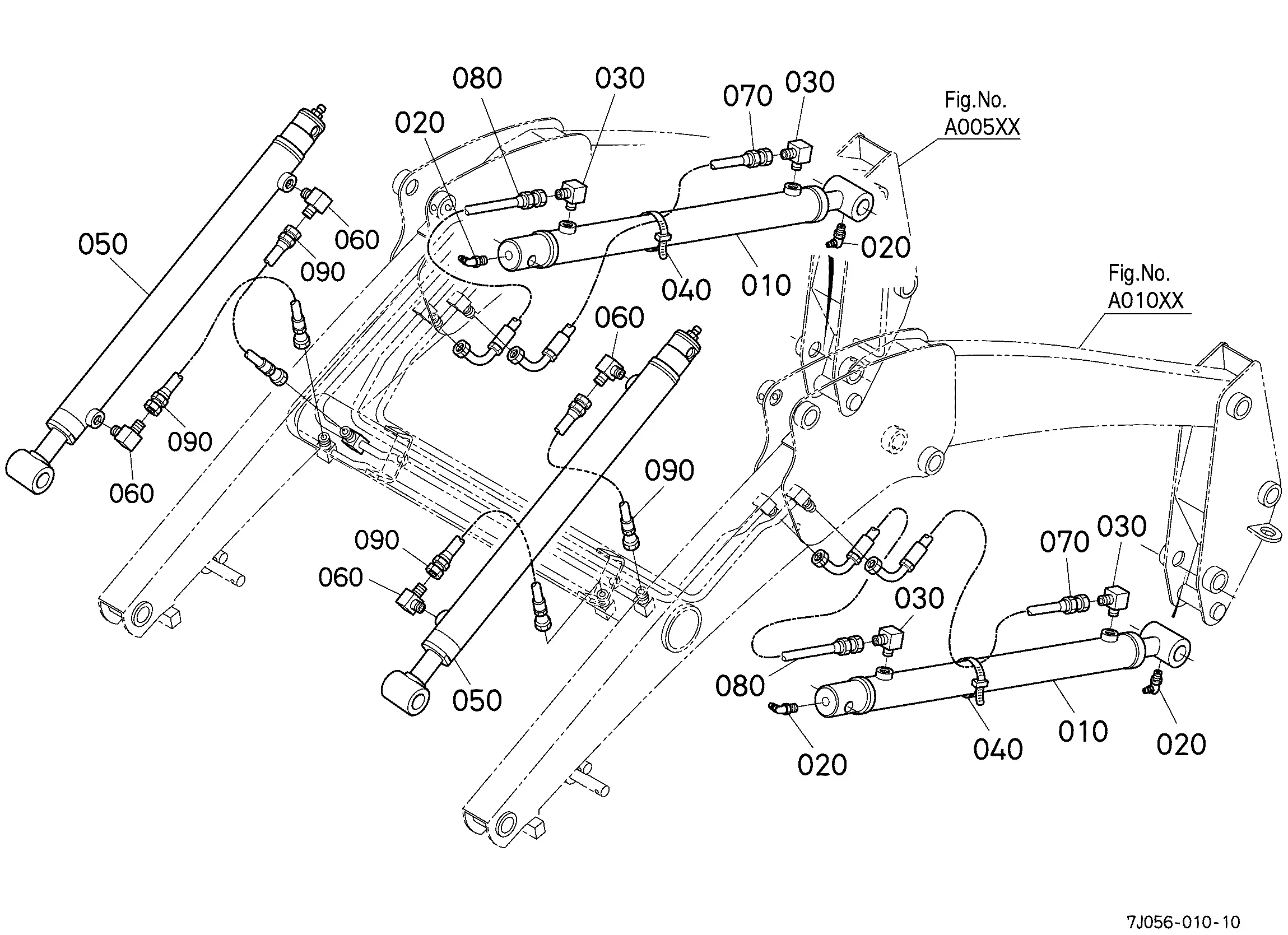

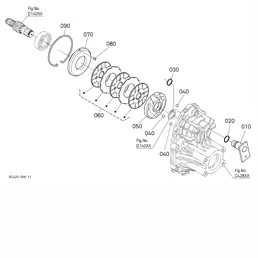

Understanding Parts Diagrams

Comprehending schematics is crucial for effective maintenance and repair of machinery. These visual representations serve as invaluable guides, showcasing components and their relationships within a system.

Key benefits of studying these illustrations include:

- Enhanced clarity in identifying individual elements.

- Streamlined troubleshooting processes.

- Improved communication among technicians and users.

When examining a schematic, consider the following:

- Familiarize yourself with the symbols used to represent various components.

- Understand the layout and how different parts interact.

- Pay attention to annotations that provide additional context.

By delving into these resources, users can gain the ultimate insight necessary for maintaining their equipment efficiently.

Importance of Accurate Diagrams

Precise representations of mechanical components are crucial for efficient maintenance and repair processes. These visual aids serve as essential tools that enhance understanding and facilitate the identification of various elements within a system. By providing clarity, they help technicians navigate complex assemblies and ensure that every part is addressed appropriately.

Accurate illustrations not only improve the efficiency of repairs but also minimize the risk of errors during assembly. Technicians rely on these detailed schematics to determine the correct placement and orientation of each component, ultimately leading to more reliable performance. When discrepancies arise, it can lead to costly mistakes and prolonged downtime, highlighting the necessity for high-quality visual guides.

Moreover, comprehensive representations aid in training new personnel, allowing them to familiarize themselves with the intricacies of the machinery. This foundational knowledge enhances overall productivity and safety within the workplace, as individuals are better equipped to recognize potential issues before they escalate. In this way, the importance of accurate visual aids extends beyond immediate repairs, contributing to the long-term efficiency of operations.

Key Components of B3350

Understanding the essential elements of a compact utility tractor can enhance both its performance and maintenance. Each critical part plays a significant role in the overall functionality, ensuring that the machine operates efficiently in various tasks.

Core Functional Elements

- Engine: Powers the machine, providing the necessary torque and horsepower.

- Transmission: Facilitates smooth gear shifts for better control and speed management.

- Hydraulic System: Enables the operation of attachments and implements with ease.

Support Structures

- Chassis: The framework that supports all components and maintains structural integrity.

- Wheels and Tires: Essential for mobility, ensuring stability and traction on various terrains.

- Control Panel: Provides the user interface for monitoring and managing the tractor’s functions.

How to Read Diagrams

Understanding visual representations is crucial for effective interpretation and application. These illustrations often serve as a guide, allowing individuals to visualize components and their relationships within a system. Mastering the skill of reading these visuals can enhance problem-solving and maintenance capabilities.

Start with the Legend: Many visuals include a legend or key that explains symbols and notations. Familiarizing yourself with this section is essential, as it provides context for interpreting the information accurately.

Identify the Main Components: Focus on the primary elements depicted in the illustration. Recognizing these key parts allows for better comprehension of their functions and how they interact within the overall structure.

Follow the Connections: Pay attention to the lines and arrows that connect different components. These indicators often represent relationships or pathways, guiding you through the operational flow and helping to clarify how various elements are linked.

Check for Annotations: Look for any additional notes or labels that provide further information. Annotations can offer insights into specifications, measurements, or special instructions that are crucial for proper understanding.

Practice Makes Perfect: Regularly engaging with these illustrations will build familiarity and confidence. Over time, you will develop the ability to quickly grasp the essential details, making your interpretation more efficient and accurate.

Common Issues with Parts

Mechanical components often encounter various challenges that can impact their functionality and longevity. Understanding these common issues can aid in effective maintenance and troubleshooting.

- Wear and Tear: Over time, components can degrade due to regular usage.

- Corrosion: Exposure to moisture can lead to rust and deterioration.

- Misalignment: Improper installation may cause parts to be out of sync.

Identifying these problems early can prevent further damage and ensure optimal performance.

- Inspect regularly for any signs of wear.

- Keep components clean and dry to avoid corrosion.

- Ensure proper installation to maintain alignment.

Addressing these issues promptly can prolong the life of mechanical systems.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your machinery. By implementing a consistent maintenance routine, you can enhance performance and extend the life of your equipment. This section outlines key practices that contribute to the longevity of your machine.

Regular Inspections

Conduct frequent examinations of all critical components to identify wear and tear. Look for signs of leaks, cracks, or any unusual noises that may indicate underlying issues.

Fluid Management

Maintaining optimal fluid levels is crucial for the smooth operation of your machinery. Regularly check and change engine oil, hydraulic fluid, and coolant to prevent damage.

| Maintenance Task | Frequency |

|---|---|

| Fluid Check | Every 50 hours |

| Filter Replacement | Every 100 hours |

| Overall Inspection | Every season |

Finding Replacement Parts

When it comes to maintaining your machinery, sourcing the right components is essential for optimal performance. Understanding where to find these crucial items can significantly enhance your repair efforts and prolong the life of your equipment.

- Authorized Dealers: These suppliers offer genuine components that meet original specifications.

- Online Retailers: Numerous websites specialize in aftermarket and original parts, often providing detailed descriptions and diagrams.

- Local Repair Shops: Many independent mechanics can order specific items for you and offer installation services.

- Salvage Yards: A great option for budget-conscious individuals, these locations may have used components in good condition.

Exploring these avenues can help you find exactly what you need for effective maintenance and repairs.

Benefits of OEM vs Aftermarket

Choosing between original equipment manufacturer (OEM) and third-party components can significantly impact performance and longevity. Understanding the distinctions between these options is crucial for making informed decisions that align with maintenance goals and budget constraints.

Quality and Reliability

OEM products are designed to meet specific standards, ensuring compatibility and durability. They often provide superior performance compared to aftermarket alternatives, which may vary in quality. Investing in OEM can lead to fewer issues and longer service life.

Cost Considerations

While aftermarket items may present a lower upfront cost, they can result in additional expenses due to potential failures or subpar performance. Evaluating the long-term costs versus the initial savings is essential for making the ultimate choice that benefits both efficiency and finances.

Tools Needed for Repairs

Having the right tools is essential for performing effective maintenance and repairs. This section outlines the necessary equipment that will facilitate a smooth and efficient workflow, ensuring that tasks can be completed safely and accurately.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are crucial for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are needed for various fastening tasks.

- Pliers: Needle-nose and standard pliers will help grip, twist, and cut materials as needed.

- Jack stands: Essential for safely lifting and supporting equipment during repairs.

- Torque wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

In addition to these basic tools, having a selection of specialty items can be beneficial:

- Multimeter: Useful for diagnosing electrical issues.

- Oil filter wrench: Designed specifically for easy removal of oil filters.

- Cutting tools: Include utility knives and snips for cutting through various materials.

- Cleaning supplies: Brushes and cloths are necessary for maintaining cleanliness during repairs.

- Safety gear: Goggles, gloves, and ear protection are critical for personal safety.

Equipping yourself with these tools will not only streamline the repair process but also enhance your ability to tackle any challenges that arise. Proper preparation leads to better outcomes and a safer working environment.

Community Resources and Forums

Engaging with fellow enthusiasts can significantly enhance your understanding and troubleshooting skills. Online communities and discussion boards offer invaluable insights, allowing users to share experiences, advice, and solutions related to machinery maintenance and repair. These platforms foster collaboration and provide access to a wealth of knowledge from various perspectives.

Popular Online Communities

- Dedicated Machinery Forums: These forums focus on equipment discussions, featuring sections for troubleshooting and modifications.

- Social Media Groups: Many users connect through Facebook or Reddit groups, where they exchange tips and post questions.

- Local Clubs: Community organizations often host events and provide resources for members looking to enhance their skills.

Benefits of Participating

- Access to Expert Advice: Experienced users frequently share their insights, helping newcomers navigate challenges.

- Resource Sharing: Members often post links to manuals, guides, and other useful documents.

- Networking Opportunities: Building connections with others can lead to collaborations and recommendations for services.