Kubota KX121 2 Parts Diagram Overview

In the realm of heavy equipment, a thorough comprehension of the individual elements that constitute a machine is essential for effective maintenance and repair. Each segment plays a pivotal role in ensuring optimal functionality and longevity of the equipment.

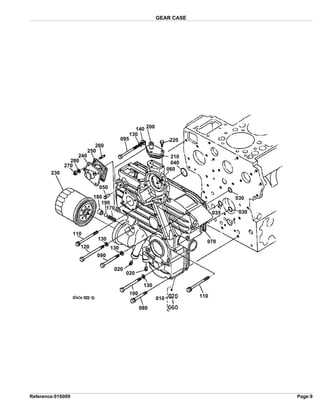

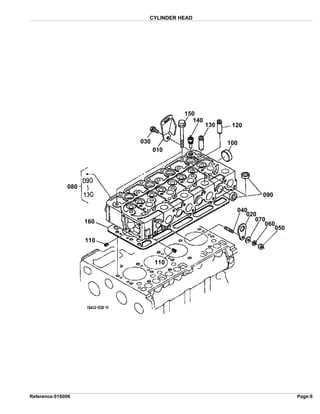

Visual aids serve as invaluable tools for technicians and operators, providing clarity and insight into the intricate workings of the machinery. By examining these illustrations, one can easily identify where each piece fits within the larger system.

Furthermore, analyzing the layout of components not only facilitates troubleshooting but also enhances overall operational efficiency. Understanding these connections ultimately empowers users to perform more informed service and repairs.

Kubota KX121-2 Overview

This section provides a comprehensive look at a compact excavator known for its reliability and versatility in various applications. Designed for efficiency and maneuverability, it excels in tight spaces while delivering impressive power and performance.

With a robust build and advanced features, this machine meets the needs of both professionals and hobbyists. Its user-friendly controls and well-thought-out design enhance productivity, making it a popular choice in the construction and landscaping industries.

| Feature | Description |

|---|---|

| Engine Power | Reliable engine providing optimal performance. |

| Operating Weight | Designed for stability and balance during operation. |

| Hydraulic System | Efficient system for improved digging and lifting. |

| Cab Comfort | Ergonomic design for operator ease and visibility. |

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations provide a clear overview of how different elements fit together, aiding both professionals and enthusiasts in identifying issues quickly. Such illustrations serve as crucial references during troubleshooting, ensuring that each piece is accounted for in the assembly process.

Facilitating Maintenance

One of the key advantages of these visual aids is their role in simplifying maintenance tasks. By clearly depicting each component’s location and relationship to others, users can easily spot worn or damaged items. This clarity not only speeds up the repair process but also minimizes the risk of overlooking critical aspects that could lead to further complications.

Enhancing Efficiency

Efficiency is paramount in any operational environment. Visual guides streamline the workflow by providing immediate access to information about necessary replacements or adjustments. When mechanics can visualize the entire system, they can work more swiftly and accurately, leading to reduced downtime and improved productivity. Overall, the utilization of these illustrations is integral to maintaining optimal functionality in machinery.

Key Components of KX121-2

The efficiency of a compact excavator hinges on its essential elements, which work in harmony to deliver optimal performance. Understanding these critical components enhances maintenance and operational effectiveness.

Engine: The powerhouse of the machine, providing the necessary energy for all functions. Its performance directly impacts productivity.

Hydraulic System: This system is vital for powering various attachments and implements, ensuring smooth operation and flexibility.

Undercarriage: The foundation of the vehicle, offering stability and mobility across diverse terrains. A robust undercarriage supports heavy loads while navigating challenging environments.

Cab: The operator’s space, designed for comfort and visibility. A well-designed cab enhances control and safety during operation.

Attachments: Various implements that can be connected to the main unit, allowing for a range of tasks from digging to lifting. The versatility of attachments is crucial for adapting to different job requirements.

In summary, these fundamental components collectively contribute to the machine’s overall functionality and adaptability, making it a valuable asset on any job site.

Understanding Hydraulic Systems

Hydraulic systems play a vital role in many machines, utilizing fluid mechanics to generate force and movement. By understanding their components and functions, one can appreciate their efficiency and application across various industries.

- Basic Components:

- Pumps

- Actuators

- Valves

- Reservoirs

- Hydraulic fluid

- How They Work:

- Fluid is pressurized by a pump.

- Pressure is transmitted through hoses and tubes.

- Actuators convert fluid pressure into mechanical work.

Understanding these systems not only enhances operational efficiency but also aids in troubleshooting and maintenance, ensuring optimal performance and longevity.

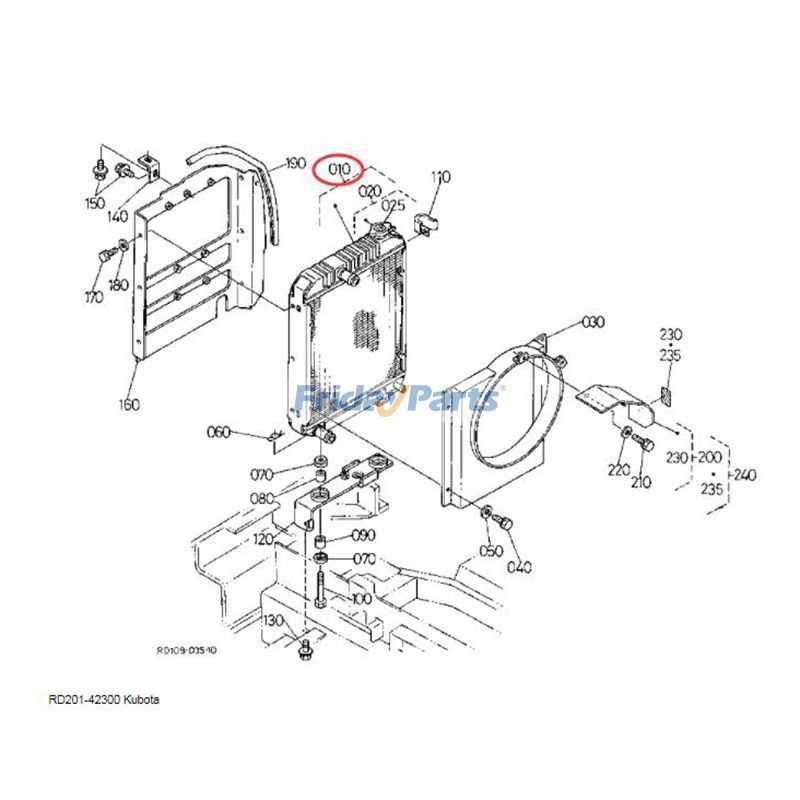

Common Issues and Repairs

When working with compact excavators, operators may encounter various challenges that require attention. Understanding these frequent problems and their solutions can help maintain efficiency and prolong the lifespan of the equipment. Here, we discuss some typical issues that may arise, along with suggested repairs.

| Issue | Description | Suggested Repair |

|---|---|---|

| Hydraulic Leaks | Fluid loss can occur due to damaged hoses or seals. | Inspect and replace worn components; ensure proper fittings. |

| Engine Overheating | Excessive heat may result from coolant issues or debris clogging. | Check coolant levels and clean the radiator; replace damaged parts. |

| Electrical Failures | Malfunctions can arise from faulty wiring or connections. | Examine wiring harnesses; repair or replace corroded connections. |

| Track Misalignment | Tracks may become misaligned due to wear or debris. | Adjust the track tension; clear any obstructions in the path. |

| Poor Performance | Loss of power can stem from fuel or air filter issues. | Replace clogged filters and ensure fuel supply is uninterrupted. |

Parts Replacement Procedures

Effective maintenance requires understanding the methods for exchanging essential components within machinery. Following structured procedures not only ensures longevity but also enhances performance. This section outlines key steps for successful replacements.

- Gather Necessary Tools and Components

- Review the Equipment Manual for Specific Instructions

- Ensure Safety Measures Are in Place

- Begin the Removal Process with Caution

- Install the New Component, Ensuring Proper Alignment

- Conduct a Final Check and Test the Equipment

By adhering to these guidelines, operators can achieve optimal functionality and reliability.

Where to Find Diagrams

Locating detailed schematics for machinery can significantly enhance maintenance and repair tasks. Understanding the layout and components is crucial for effective troubleshooting and service. Here are some reliable sources for obtaining these essential visuals.

Online Resources

- Manufacturer’s Official Website: Check the resources or support section for downloadable content.

- Online Forums: Participate in communities where users share technical documents and diagrams.

- Specialized Websites: Look for platforms dedicated to machinery manuals and resources.

Physical Resources

- Local Dealerships: Visit or contact authorized dealers for printed materials.

- Repair Shops: Experienced technicians often have access to hard copies of schematics.

- Library Archives: Some public libraries maintain collections of technical manuals and guides.

Benefits of Using Original Parts

Utilizing components that are specifically designed for machinery ensures optimal performance and longevity. When maintaining heavy equipment, selecting authentic items significantly contributes to the overall reliability and efficiency of the machine. This choice not only enhances functionality but also promotes safety and durability.

Quality Assurance

Original components undergo rigorous testing and quality control processes. This guarantees that they meet the highest industry standards, resulting in superior performance. High-quality materials and precise engineering reduce the risk of failure, providing peace of mind to operators and owners alike.

Cost Efficiency

While imitation options may seem more affordable, they often lead to additional expenses over time. Authentic components typically require fewer replacements and repairs, which ultimately saves money. Investing in genuine parts minimizes downtime and enhances productivity, making it a wise financial decision.

| Factor | Original Components | Aftermarket Options |

|---|---|---|

| Quality | High and consistent | Variable |

| Durability | Long-lasting | Shorter lifespan |

| Cost | Higher initial investment | Lower initial cost |

| Performance | Optimized for equipment | May not fit properly |

Maintenance Tips for Longevity

Ensuring the extended lifespan of machinery involves a combination of regular care and preventive measures. By adhering to specific practices, operators can enhance performance and minimize costly repairs over time.

Regular Inspection

Consistent examination of equipment is vital. Look for signs of wear, leaks, or any unusual noises that may indicate potential issues.

Proper Lubrication

Keeping components well-lubricated reduces friction and prevents premature wear. Follow the manufacturer’s recommendations for lubricants and intervals.

| Maintenance Task | Frequency |

|---|---|

| Fluid Checks | Weekly |

| Filter Replacements | Monthly |

| Full Inspection | Quarterly |

| Greasing Points | Bi-weekly |

Aftermarket vs. OEM Parts

The choice between alternative and original components often poses a significant dilemma for equipment owners. Each category offers unique advantages and potential drawbacks, influencing maintenance strategies and overall performance. Understanding the nuances can ultimately guide informed decisions that align with specific needs and budgets.

Advantages of Alternative Components

Alternative components frequently come with lower price points, making them appealing for cost-conscious consumers. They often provide a wider variety of options, allowing users to select products that may enhance functionality or performance. However, quality can vary, so careful consideration is essential.

Benefits of Original Components

Original components, designed specifically for particular machinery, usually ensure compatibility and reliability. They often come with warranties and assurances regarding performance standards. Investing in these parts can lead to long-term savings through reduced risks of failure and the need for replacements.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in diagnosing issues within machinery. They allow operators to quickly identify components and understand their relationships, facilitating more efficient problem-solving. By examining these illustrations, users can pinpoint areas of concern and devise effective solutions.

Benefits of Visual Aids

- Enhanced understanding of complex systems

- Quick identification of faulty elements

- Streamlined maintenance processes

Steps for Effective Troubleshooting

- Refer to the visual guide relevant to your machinery.

- Identify the component in question.

- Analyze the connections and functions associated with that part.

- Note any discrepancies and consult the troubleshooting section for further guidance.

Upgrades and Modifications Available

Enhancing the performance and versatility of compact machinery can significantly improve efficiency and productivity. Various upgrades and modifications can be implemented to tailor equipment to specific tasks or operational needs.

- Attachment Options: Consider adding specialized tools such as hydraulic thumbs, augers, or buckets to increase functionality.

- Power Enhancements: Upgrading the engine or fuel system can provide more power and improve fuel efficiency.

- Track Width Modifications: Adjusting the track width can enhance stability and maneuverability on uneven terrain.

- Cab Accessories: Installing ergonomic seats, additional lighting, or climate control systems can improve operator comfort.

- Control System Upgrades: Implementing advanced control technologies can enhance precision and ease of operation.

When considering modifications, it’s essential to assess the specific requirements of your projects and the compatibility of each upgrade with your machinery. Customizing your equipment not only extends its capabilities but can also lead to increased longevity and value.

Customer Reviews and Feedback

Understanding user experiences and insights is crucial for evaluating the quality and reliability of any machinery. Feedback from those who have utilized the equipment provides valuable information about its performance, durability, and overall satisfaction. Here, we gather various perspectives from customers to paint a clearer picture of what to expect.

Many users appreciate the efficiency and ease of operation, highlighting several key aspects:

- Performance under various working conditions

- Fuel efficiency and operational costs

- Comfort and ergonomics during long hours of use

However, some feedback points to areas for improvement:

- Maintenance requirements and accessibility of components

- Availability of support and replacement options

- Initial learning curve for new operators

Overall, the testimonials reflect a blend of satisfaction and constructive criticism, guiding potential buyers in their decision-making process. Engaging with this community of users can provide further insights and help enhance future experiences.