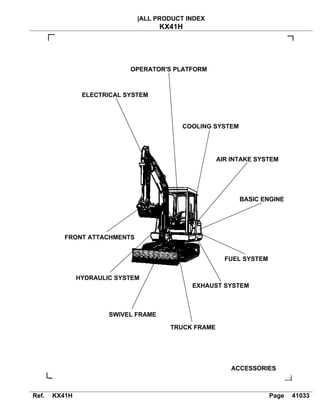

Kubota KX41-3 Parts Diagram for Efficient Maintenance

When it comes to maintaining heavy machinery, a clear comprehension of its various elements is crucial for optimal performance and longevity. This section aims to provide an insightful look into the intricate relationships between different components, enhancing your ability to troubleshoot and repair effectively.

Visual aids play an essential role in understanding these relationships, offering a detailed representation that simplifies complex information. By exploring a comprehensive layout of the machine’s structure, operators and technicians alike can quickly identify essential parts and their functions.

Ultimately, gaining familiarity with these components not only streamlines maintenance processes but also empowers users to make informed decisions regarding repairs and upgrades. With a well-rounded understanding, you can ensure that your equipment operates at its best.

Kubota KX41-3 Overview

This compact excavator stands out in the world of construction machinery, offering a blend of power and precision. Designed for versatility, it efficiently handles a variety of tasks, making it a popular choice among professionals.

Key Features: The machine boasts a robust engine that delivers exceptional performance while maintaining fuel efficiency. Its compact size allows for easy maneuverability in tight spaces, ensuring that operators can tackle even the most challenging projects with ease.

Applications: Ideal for landscaping, utility work, and small construction jobs, this excavator excels in environments where larger equipment may struggle. Its innovative design and reliable components contribute to a seamless operational experience, enhancing productivity on every site.

Key Features of KX41-3 Model

The compact excavator in focus stands out for its remarkable efficiency and versatility, catering to a wide range of applications. Its design incorporates cutting-edge technology, ensuring optimal performance while maintaining user-friendly operation.

Powerful Engine: Equipped with a robust power unit, this machine delivers exceptional torque and speed, making it ideal for heavy-duty tasks.

Compact Size: The minimal footprint allows for easy maneuverability in tight spaces, enhancing productivity on job sites where space is limited.

Advanced Hydraulic System: The innovative hydraulic mechanism ensures precise control and responsive operation, facilitating various attachments and functions.

Operator Comfort: Designed with ergonomics in mind, the spacious cabin includes intuitive controls and excellent visibility, promoting a comfortable working environment.

Durability: Built with high-quality materials, this model offers exceptional durability, ensuring longevity even under challenging conditions.

Fuel Efficiency: The engine’s design maximizes fuel economy, reducing operating costs while minimizing environmental impact.

Importance of Parts Diagrams

Understanding the intricate details of machinery requires a clear visual representation. Such illustrations serve as crucial tools for maintenance, ensuring that every component is correctly identified and managed. They enhance the efficiency of repairs and replacements, leading to minimized downtime and improved performance.

Enhanced Clarity

Visual aids provide clarity that text alone often cannot achieve. By offering a comprehensive view of each element, they allow operators to pinpoint issues swiftly and accurately, streamlining troubleshooting processes.

Facilitated Training

Newcomers to the field benefit greatly from these resources. Educational visuals promote better understanding and retention, making it easier for trainees to grasp complex systems and learn proper handling techniques.

Identifying Common Replacement Parts

Understanding the components of a compact excavator is essential for maintaining its performance and longevity. Regular wear and tear can necessitate the replacement of certain elements to ensure optimal operation. Familiarizing yourself with frequently needed components can streamline maintenance and reduce downtime.

| Component | Description | Signs of Wear |

|---|---|---|

| Bucket | The attachment used for digging and moving materials. | Cracks, excessive wear on edges, or deformities. |

| Hydraulic Filter | Filters contaminants from the hydraulic fluid. | Reduced performance, strange noises, or slow operation. |

| Tracks | Provide traction and stability for movement. | Visible cracks, missing links, or excessive wear patterns. |

| Swing Motor | Enables the rotating motion of the upper structure. | Inconsistent movement or unusual sounds during operation. |

| Engine Oil Filter | Removes impurities from the engine oil. | Engine noise, overheating, or reduced efficiency. |

By keeping an eye on these critical components and their indicators of deterioration, operators can ensure their machinery runs smoothly and efficiently. Regular inspections and timely replacements can prevent larger issues and costly repairs in the long run.

Understanding Hydraulic System Components

Hydraulic systems play a crucial role in modern machinery, utilizing fluid power to facilitate movement and force generation. By comprehending the various elements involved, operators can ensure optimal performance and maintenance of their equipment.

Key Elements of Hydraulic Systems

At the heart of these systems are pumps, which create fluid flow necessary for operation. Coupled with valves, these components regulate pressure and direction, allowing for precise control of machinery functions.

Importance of Maintenance

Regular inspections and servicing of hydraulic components can prevent breakdowns and enhance longevity. Neglecting these parts may lead to inefficiencies, increasing operational costs and downtime. Understanding the intricacies of each component is essential for effective management.

Engine Parts and Their Functions

The functionality of any mechanical system relies heavily on its individual components. In the realm of internal combustion units, understanding how each element contributes to the overall operation is crucial for effective maintenance and troubleshooting. This section explores the key components, their roles, and how they work together to ensure optimal performance.

Key Components

Pistons play a vital role in converting fuel energy into mechanical power. They move within the cylinder, creating compression necessary for ignition. Meanwhile, crankshafts transform the linear motion of the pistons into rotational motion, which is essential for driving various systems.

Supporting Elements

Another important part is the valve train, which controls the intake of air and the expulsion of exhaust gases, ensuring efficient combustion cycles. Additionally, the oil pump circulates lubricant throughout the engine, reducing friction and preventing overheating, ultimately prolonging the lifespan of the unit.

Electrical System Layout Explained

The electrical framework of machinery plays a crucial role in ensuring efficient operation and reliability. Understanding the arrangement of components within this system helps in diagnosing issues and performing maintenance effectively. This section aims to clarify the configuration and interconnections of the electrical elements involved.

Key Components

Several vital elements comprise the electrical setup. Each part contributes to the overall functionality, making it essential to know their roles and locations.

| Component | Description |

|---|---|

| Batteries | Store electrical energy for starting and powering systems. |

| Wiring Harness | Connects all electrical components, ensuring proper communication. |

| Fuse Box | Protects circuits by interrupting excessive current flow. |

| Relays | Act as switches that control larger currents with smaller ones. |

Understanding Connections

Grasping the relationships among these components is essential for troubleshooting. Each connection influences how power flows, and identifying any faulty links can lead to the ultimate resolution of electrical issues.

Transmission Components and Maintenance

Understanding the elements that make up the transmission system is crucial for ensuring optimal performance and longevity of the machinery. These components work in harmony to facilitate smooth power transfer, making it essential to be aware of their roles and maintenance requirements.

The main elements include gears, clutches, and shafts, each contributing to the effective operation of the machine. Regular inspection of these parts can help identify wear and tear, preventing costly repairs down the line. Lubrication is vital, as it reduces friction and heat, thereby enhancing the lifespan of the transmission system.

Additionally, operators should pay attention to fluid levels and quality, as these factors significantly impact performance. Contaminated or insufficient fluid can lead to serious issues, including overheating and failure of key components. Routine maintenance schedules should be established to monitor and replace fluids as necessary.

By staying proactive with maintenance and understanding the function of each component, operators can ensure reliable performance and extend the service life of their equipment.

Safety Features and Their Importance

Ensuring the highest level of protection during operation is crucial in heavy machinery. Safety mechanisms are designed not only to prevent accidents but also to enhance overall efficiency. Understanding these features can significantly contribute to a safer working environment.

Key Safety Mechanisms

- Emergency Stop Functions

- Operator Presence Controls

- Stability Systems

- Warning Alarms

The Importance of Safety Features

Implementing robust safety elements is vital for minimizing risks and promoting operator confidence. Regular maintenance and familiarization with these features can lead to a significant reduction in workplace incidents.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. By mastering this skill, users can identify individual elements, their functions, and how they interconnect, ultimately streamlining the repair process.

Familiarizing Yourself with Symbols

Each symbol in the representation corresponds to a specific component. Recognizing these symbols is the first step in interpreting the layout:

- Shapes typically indicate different types of elements, such as mechanical or electrical parts.

- Lines represent connections, showing how components interact.

- Labels provide crucial information regarding specifications and functions.

Following the Flow

Understanding the order of operations can greatly aid in troubleshooting:

- Start from the power source and trace the path to the end component.

- Note any junctions or connections, which may require special attention.

- Review the layout to understand the sequence of assembly or disassembly.

Resources for Finding Replacement Parts

When it comes to sourcing components for machinery, various avenues can provide essential information and accessibility. Understanding where to look can significantly ease the process of locating the necessary elements for maintenance or repair.

Here are some reliable options to consider:

| Resource Type | Description |

|---|---|

| Online Retailers | Websites dedicated to heavy equipment often have extensive catalogs, making it easy to search for specific items. |

| Manufacturer Websites | Official sites typically offer a wealth of resources, including product specifications and guidance on sourcing components. |

| Forums and Community Groups | Engaging with other users can provide insights and recommendations for trusted suppliers. |

| Local Dealers | Visiting nearby distributors can allow for direct assistance and often faster access to needed materials. |

Utilizing these resources will ultimately enhance your ability to find the right items efficiently.

Tips for Maintaining KX41-3

Regular upkeep of your compact excavator is essential for ensuring optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents costly repairs down the line. Below are some practical suggestions to keep your machine in top condition.

Routine Checks

Establish a routine for inspecting key components. Focus on the engine, hydraulic system, and undercarriage. Keeping an eye on fluid levels, belts, and hoses can help you catch potential issues early.

| Component | Inspection Frequency | Notes |

|---|---|---|

| Engine Oil | Every 50 hours | Change oil and filter regularly. |

| Hydraulic Fluid | Every 100 hours | Check for contamination and leaks. |

| Air Filter | Every 200 hours | Clean or replace as needed. |

Seasonal Maintenance

Adjust your maintenance practices according to seasonal changes. In colder months, ensure the engine is winter-ready, and check the battery for performance. In warmer weather, inspect cooling systems to prevent overheating.

Frequently Asked Questions about Parts

This section aims to address common inquiries regarding components and their specifications. Understanding these elements is crucial for maintenance and effective operation. Below, you will find answers to frequently raised questions that can help clarify any uncertainties.

What should I consider when replacing a component?

When looking to substitute a part, it’s essential to verify compatibility with your machine’s model. Additionally, consider the quality of the replacement to ensure optimal performance and longevity.

How can I identify the correct component for my equipment?

To identify the right component, consult the manufacturer’s manual or reference materials. These documents typically provide detailed information about compatible items and their specifications.

Are there alternative options available for specific components?

Yes, there are often aftermarket alternatives available. However, it’s advisable to research the reliability and warranty offered by these options to avoid potential issues.

What are the signs that a component needs replacement?

Common indicators include unusual noises, decreased efficiency, or visible wear and tear. Regular inspections can help detect these signs early and prevent further complications.

Where can I purchase reliable components?

Reputable dealers, authorized distributors, and specialized online platforms are good sources for quality replacements. Always check reviews and ratings before making a purchase.