Kubota L45 Parts Diagram Overview

In the world of heavy equipment, a clear visual representation of various components is essential for maintenance and repair. Each piece of machinery consists of intricate parts that work together to ensure optimal performance. By familiarizing oneself with the layout of these elements, operators can enhance their efficiency and troubleshoot issues more effectively.

Accurate depictions of machinery elements not only aid technicians in identifying specific components but also facilitate the ordering of necessary replacements. A comprehensive view can demystify the complexities of assembly and disassembly, making it easier for professionals to approach repairs with confidence.

Furthermore, a well-structured visual guide serves as a valuable reference for anyone looking to deepen their understanding of mechanical systems. Whether you’re a seasoned expert or a novice, grasping the relationships between different parts can significantly improve your skills in handling machinery and prolong its lifespan.

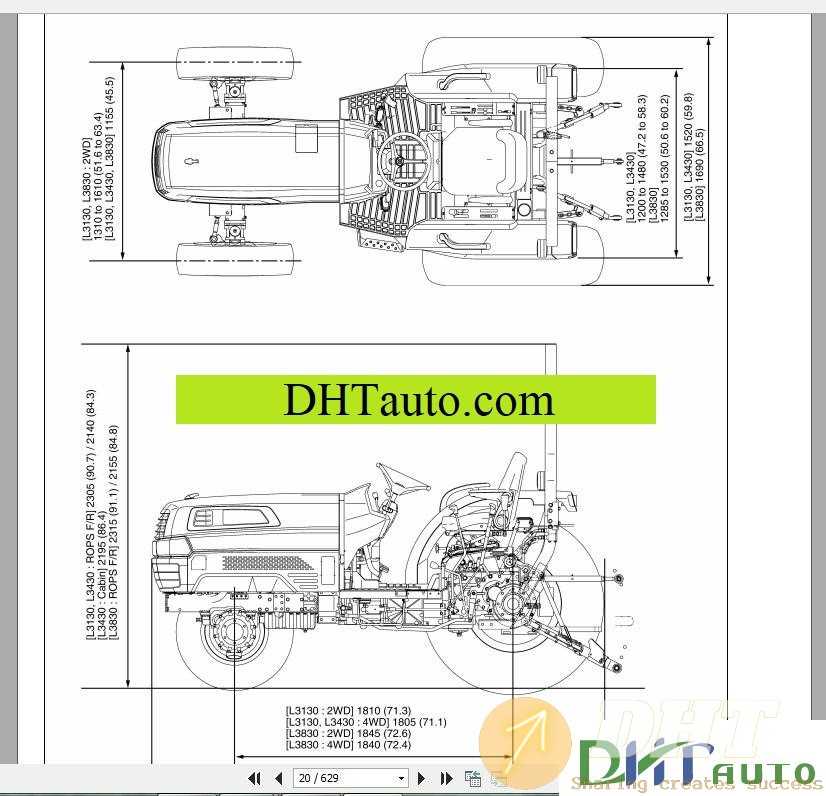

Understanding the Kubota L45 Layout

Grasping the configuration of machinery components is essential for efficient operation and maintenance. A well-organized layout facilitates easy identification and accessibility of various elements, ensuring that users can perform tasks effectively. Familiarity with the arrangement not only streamlines workflows but also enhances safety measures during operation.

This particular model features a variety of sections, each serving a distinct purpose. From the engine compartment to the hydraulic system, understanding these divisions is crucial for both troubleshooting and routine maintenance.

| Section | Description |

|---|---|

| Engine Compartment | Houses the power unit and essential components for operation. |

| Hydraulic System | Facilitates the movement and operation of attachments and implements. |

| Operator Station | Controls and displays for managing functions and monitoring performance. |

| Chassis | Base structure that supports all other components and ensures stability. |

| Fuel Tank | Storage for fuel required to power the machinery. |

Understanding this configuration not only aids in operational efficiency but also minimizes downtime through effective maintenance strategies. Regular inspections and familiarity with the layout can lead to improved performance and longevity of the equipment.

Essential Components of Kubota L45

Understanding the fundamental elements of this compact machine is crucial for effective operation and maintenance. Each component plays a vital role in ensuring optimal performance and reliability, making it important for users to familiarize themselves with their functions and interconnections.

Powertrain and Engine Features

The powertrain is at the heart of any machinery, providing the necessary energy to drive various attachments and perform tasks efficiently. The engine is designed for durability and efficiency, featuring advanced technology to optimize fuel consumption and reduce emissions. Key aspects include the cooling system, which maintains optimal temperatures, and the transmission, which allows smooth transitions between different speeds and directions.

The hydraulic system is essential for executing various functions, from lifting loads to powering implements. This system relies on hydraulic fluid to transfer power, making it crucial for tasks that require significant force. Additionally, a range of attachments can be connected, enhancing versatility and enabling the machine to tackle diverse applications, from landscaping to construction.

Benefits of Using Genuine Parts

Utilizing authentic components in machinery ensures optimal performance and longevity. These original elements are specifically designed to meet the precise requirements of the equipment, resulting in enhanced efficiency and reliability.

One significant advantage of authentic components is the assurance of quality. They undergo rigorous testing and adhere to stringent manufacturing standards, which minimizes the risk of failure. This reliability translates into lower maintenance costs and reduced downtime, ultimately saving both time and resources.

Moreover, genuine components often come with a warranty, providing added peace of mind. In contrast, counterfeit or generic alternatives may lack proper support, leading to potential complications and increased expenses in the long run.

Additionally, using original components can preserve the value of the machinery. Equipment that has been maintained with authentic parts typically retains its performance and appeal, which is crucial for resale or trade-in situations.

In summary, opting for genuine components ensures superior quality, reliability, and overall value, making it a smart investment for any equipment owner.

Common Issues with Kubota L45 Parts

Understanding the frequent challenges associated with machinery components is crucial for maintenance and operational efficiency. Various issues can arise from wear and tear, environmental conditions, and improper usage. Identifying these common problems early can help in implementing effective solutions, ensuring the longevity of the equipment.

Wear and Tear

Over time, components experience natural degradation due to consistent use. Hydraulic seals and gaskets are particularly susceptible, leading to leaks that can compromise performance. Regular inspections can help detect these signs early and prevent further damage.

Environmental Factors

Exposure to harsh weather conditions can also impact machinery parts. Corrosion and rust can develop on metal surfaces, especially if the equipment is not stored properly. Employing protective measures, such as covers and rust inhibitors, can mitigate these risks significantly.

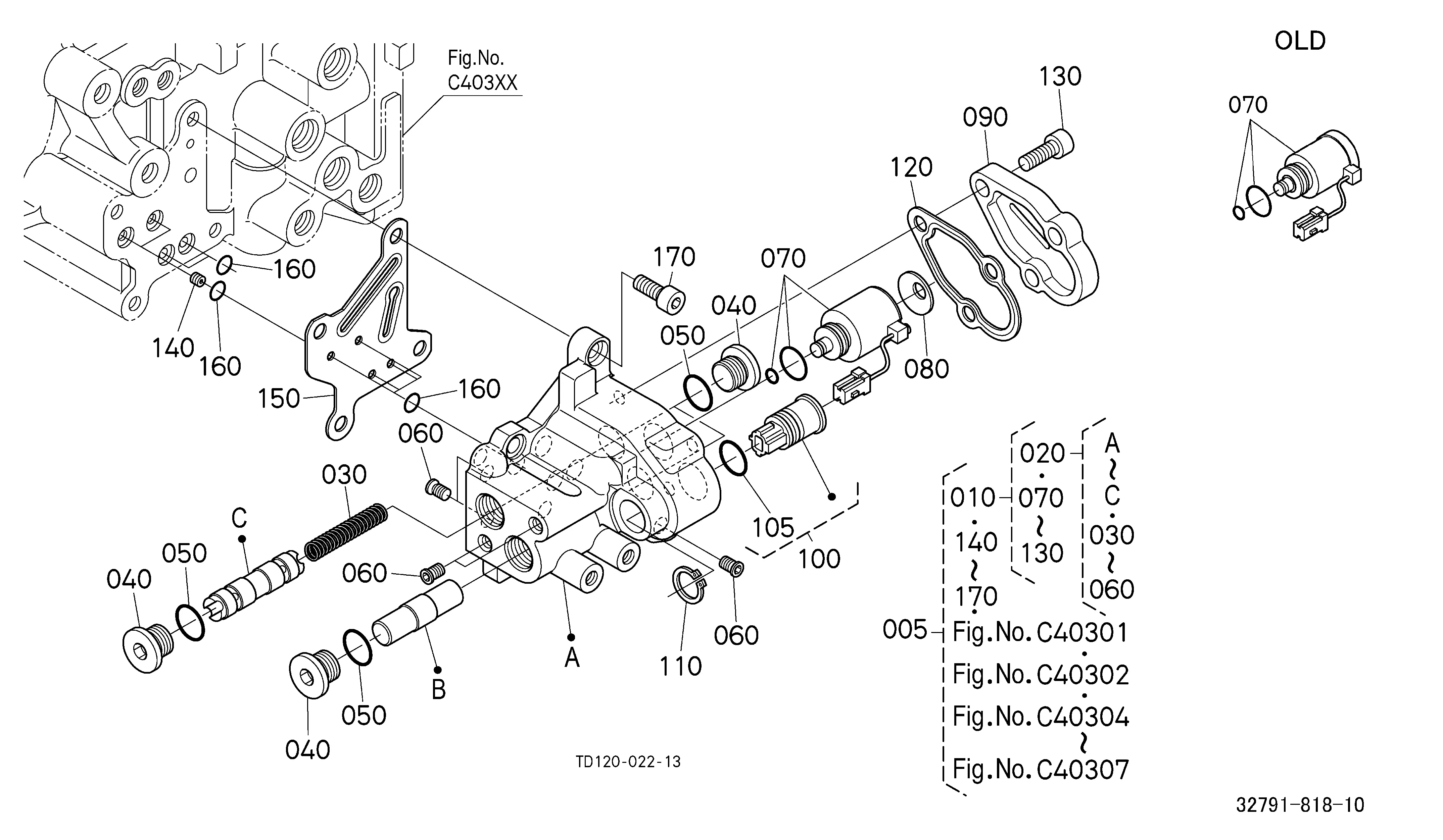

How to Read the Parts Diagram

Understanding a schematic layout is crucial for anyone involved in maintenance or repair tasks. It serves as a visual guide that simplifies the identification of various components and their relationships within a machine. By mastering how to interpret this visual representation, you can enhance your efficiency and ensure accurate repairs.

Familiarizing Yourself with Symbols

Each illustration contains specific symbols that denote different elements. Familiarity with these icons is essential, as they can vary between different models. Take the time to study the legend or key provided; this will help you quickly associate symbols with their corresponding parts.

Understanding the Layout

The arrangement of components is typically organized in a logical manner. Components are often grouped based on functionality or location within the machine. Pay attention to the flow indicated in the schematic, as this can provide insights into how parts interact during operation. Additionally, noting the reference numbers associated with each element will aid in cross-referencing with parts catalogs or manuals.

Identifying Parts by Model Number

Understanding the significance of model numbers is crucial for effective maintenance and repair of machinery. Each identifier corresponds to a specific assembly, ensuring that users can accurately locate and source components necessary for optimal performance. This systematic approach streamlines the repair process and minimizes downtime.

When examining a particular model, it is essential to reference the designated number. This identifier can usually be found on the machine itself or in the accompanying documentation. By utilizing this information, individuals can navigate through catalogs or online resources to find exact replacements or upgrades.

Additionally, familiarity with model variations enhances the ability to differentiate between components that may appear similar but serve distinct functions. Understanding these nuances not only aids in selecting the correct items but also promotes a deeper knowledge of the equipment as a whole.

In conclusion, leveraging model numbers as a tool for identification simplifies the process of locating the right components, ultimately contributing to better functionality and longevity of the machinery.

Maintenance Tips for Kubota L45

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check and change the engine oil | Every 50 hours of operation | Use the recommended oil type for best results. |

| Inspect air filter | Every 100 hours of operation | Clean or replace as needed to ensure optimal airflow. |

| Examine hydraulic fluid levels | Weekly | Keep within the recommended range for efficient operation. |

| Check tire pressure | Weekly | Maintain proper pressure to avoid uneven wear and improve handling. |

| Inspect belts and hoses | Monthly | Look for signs of wear or damage and replace as necessary. |

| Grease fittings | Every 10 hours of operation | Use appropriate grease to ensure smooth operation of moving parts. |

Where to Find Replacement Parts

Locating the necessary components for machinery maintenance is crucial for optimal performance. Whether you’re conducting repairs or upgrades, understanding where to source high-quality items can save both time and money. There are various avenues available for acquiring these essentials, each offering unique advantages.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers provide genuine components, ensuring compatibility and reliability. They often have knowledgeable staff to assist with inquiries. |

| Online Marketplaces | Websites such as eBay and Amazon feature a wide range of options, including new and used items. This is an excellent way to compare prices and find deals. |

| Local Repair Shops | Many local mechanics maintain a stock of frequently needed components and can often order specific items for you. |

| Manufacturer’s Website | Visiting the official website can lead to direct purchasing options and information on the latest available products. |

| Salvage Yards | These facilities can offer used components at reduced prices. It’s a cost-effective option for those willing to search through inventory. |

Comparing Aftermarket vs. OEM Parts

When maintaining or repairing machinery, choosing the right components is crucial for performance and longevity. Two primary options exist: components produced by the original manufacturer and those created by third-party suppliers. Each category has distinct advantages and considerations that can impact both functionality and cost-effectiveness.

Original Manufacturer Components are designed specifically for the equipment in question, ensuring compatibility and adherence to the highest quality standards. These items typically come with warranties and are rigorously tested to meet the exact specifications set by the manufacturer. However, they often come at a premium price, which can be a significant factor for many users.

Third-Party Components, on the other hand, are produced by independent manufacturers and may offer a more economical solution. These alternatives can provide similar performance at a reduced cost, making them appealing for budget-conscious operators. However, the quality can vary widely, and some may not meet the stringent standards of the original manufacturer, potentially leading to premature wear or failures.

Ultimately, the choice between these two options will depend on individual priorities, including budget, performance expectations, and the specific application of the machinery. Careful consideration of both categories can lead to informed decisions that best suit operational needs.

Repairing Common Failures in L45

Maintenance and troubleshooting are essential for ensuring the longevity of any machinery. Common issues can arise from wear and tear, improper usage, or lack of regular upkeep. This section will guide you through identifying and addressing frequent problems to keep your equipment running smoothly.

Hydraulic System Leaks: One prevalent issue is hydraulic fluid leakage. This can lead to decreased performance and potential damage. Inspect hoses and connections for signs of wear, and replace any damaged components promptly. Ensure that the system is properly filled with the correct fluid to prevent further complications.

Engine Overheating: Overheating can significantly affect operation. Regularly check coolant levels and ensure the radiator is free of debris. If the engine continues to run hot, investigate the thermostat and water pump for faults. Maintaining optimal temperatures is crucial for overall functionality.

Electrical Failures: Electrical issues can manifest as starting problems or malfunctioning lights. Begin by inspecting the battery for corrosion and ensuring connections are tight. Test fuses and relays, replacing any that are faulty. A well-functioning electrical system is vital for reliable operation.

Transmission Problems: Shifting difficulties often indicate transmission concerns. Check fluid levels and condition, as dirty or low fluid can hinder performance. If issues persist, more in-depth inspections may be necessary, potentially involving internal components that require expert attention.

By addressing these common failures promptly, you can significantly enhance the performance and lifespan of your machinery, ensuring it remains an effective asset for your tasks.

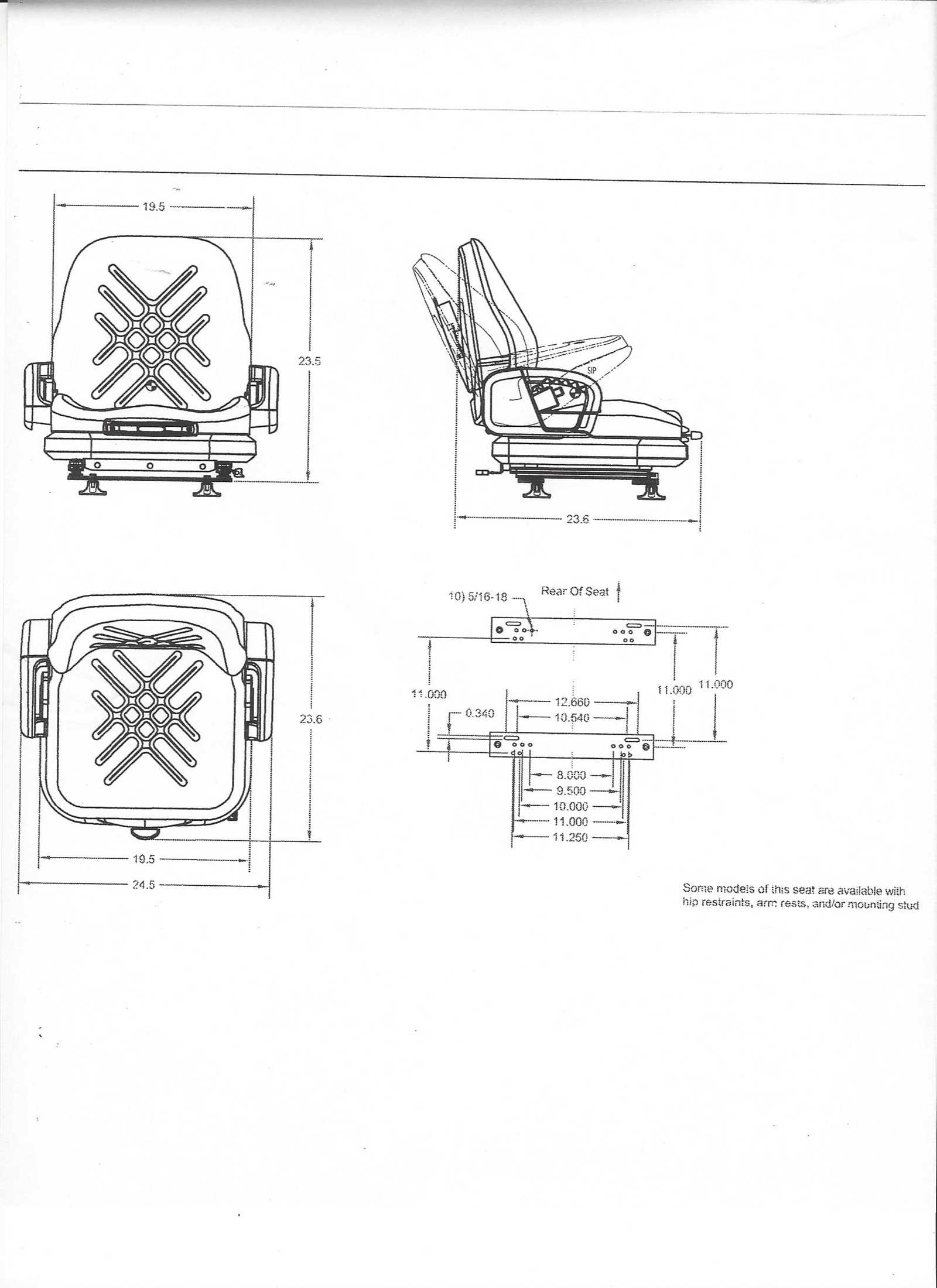

Best Practices for Parts Installation

Ensuring the proper installation of components is crucial for maintaining the efficiency and longevity of machinery. Adhering to established guidelines can significantly reduce the risk of errors and enhance overall performance. This section outlines essential practices that should be followed during the installation process to achieve optimal results.

| Practice | Description |

|---|---|

| Read the Manual | Always consult the manufacturer’s instructions for specific guidelines related to installation and compatibility. |

| Gather Tools | Ensure all necessary tools are on hand before starting to avoid interruptions during the process. |

| Inspect Components | Examine each item for any signs of damage or wear before installation to prevent future issues. |

| Follow Sequence | Adhere to the recommended order of installation to ensure proper fitting and function of all elements. |

| Use Proper Torque | Apply the correct torque settings as specified to avoid over-tightening or under-tightening components. |

| Check Alignment | Ensure that all parts are aligned correctly to prevent mechanical failure and ensure smooth operation. |

| Test Functionality | After installation, conduct a thorough test to confirm that everything is working as intended before regular use. |