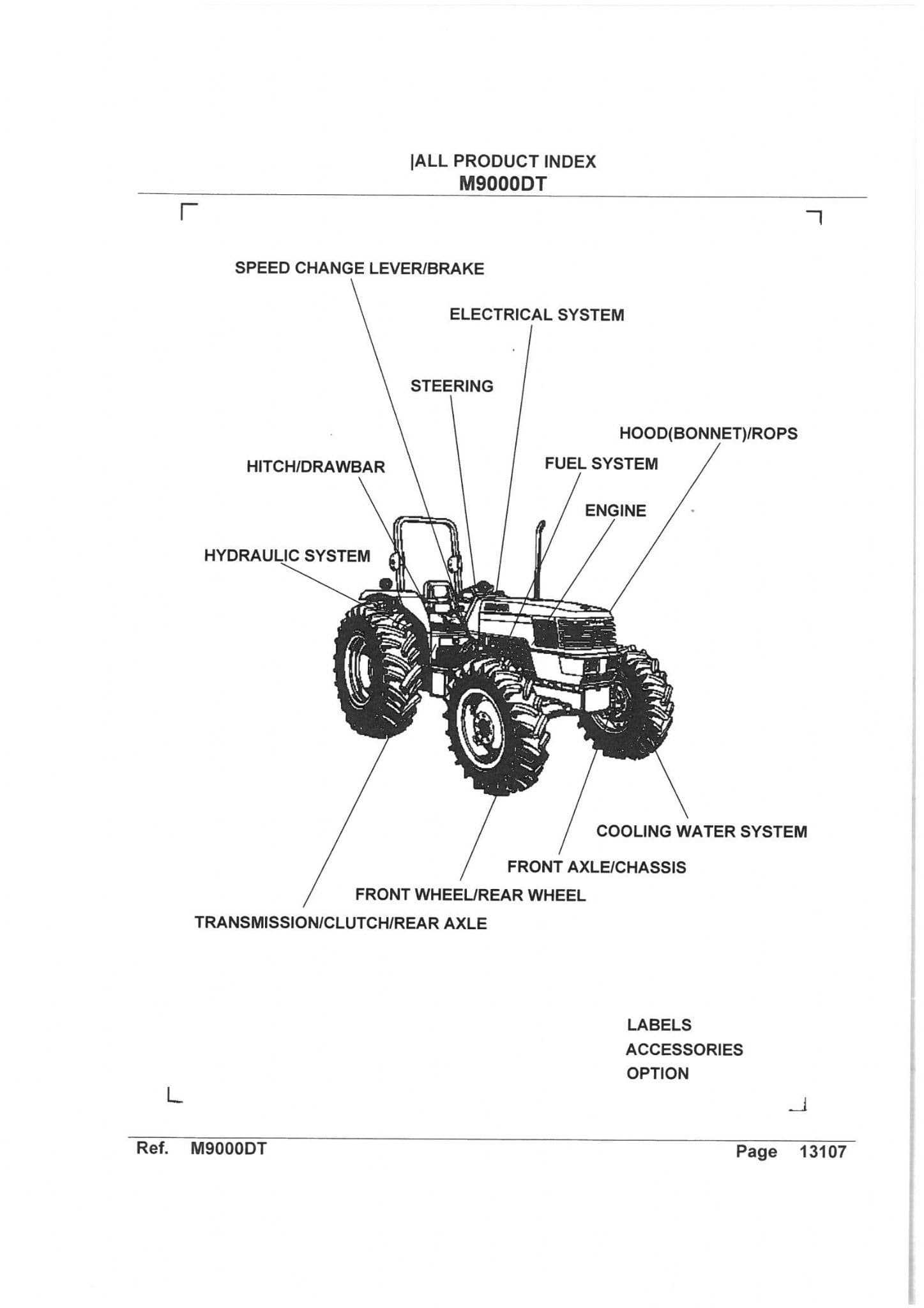

Kubota L5740 Parts Diagram Overview

In the world of farming equipment, comprehending the intricate details of machinery is essential for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and longevity, making it imperative for operators and technicians alike to familiarize themselves with these elements.

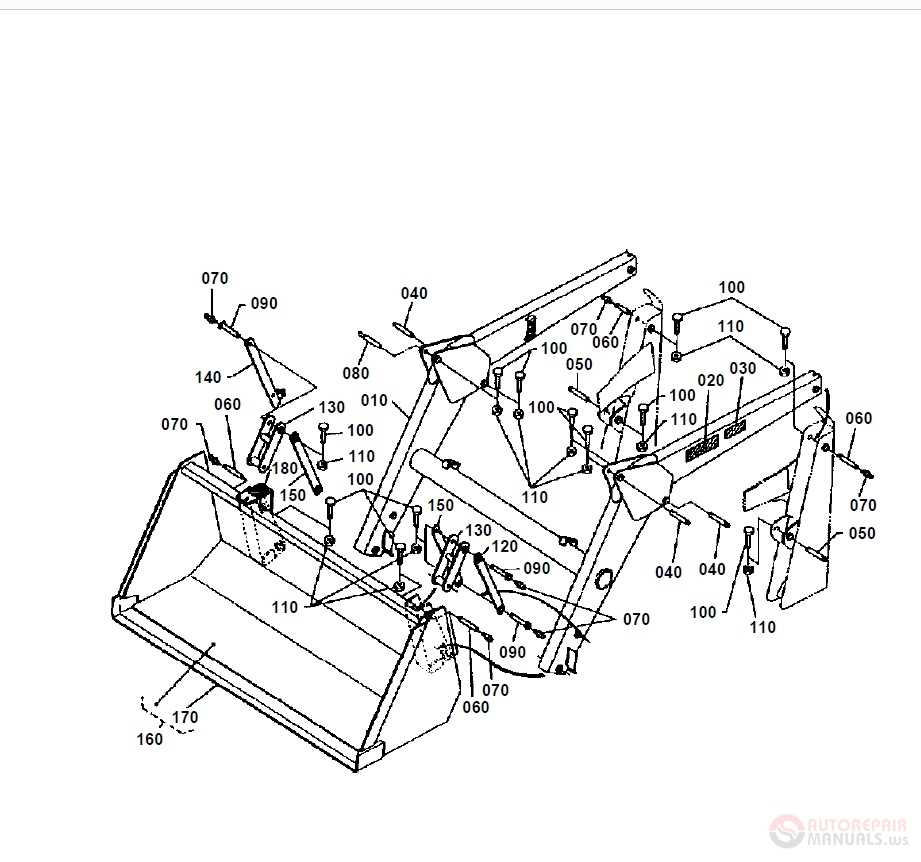

Visual aids that depict the arrangement and function of various parts can significantly enhance one’s understanding. By breaking down the complexities into manageable sections, users can easily identify individual elements and their contributions to the overall functionality of the equipment.

This exploration into the mechanical layout provides an ultimate resource for those looking to enhance their knowledge. Whether you are a seasoned professional or a novice, delving into these illustrations can empower you to make informed decisions regarding repairs and upgrades.

Kubota L5740 Overview

This section provides a comprehensive look at a powerful agricultural machine designed for versatility and efficiency. With its robust build and advanced features, it is ideal for various farming tasks and landscape management.

- Engine Performance: Equipped with a high-performance engine, ensuring reliable operation under demanding conditions.

- Hydraulic System: Features a sophisticated hydraulic setup, allowing for smooth operation of attachments and implements.

- Operator Comfort: Designed with user-friendly controls and ergonomic seating for enhanced comfort during long hours of work.

- Durability: Built with high-quality materials, providing longevity and resistance to wear and tear.

This machine stands out for its ability to tackle diverse applications, making it a valuable asset in any agricultural or landscaping endeavor.

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations of various elements serve as invaluable resources, providing clarity and facilitating the identification of each piece’s role within the larger system. This knowledge helps ensure optimal performance and longevity of the equipment.

Enhancing Maintenance Efficiency

Utilizing visual aids allows technicians to quickly locate and assess individual components, streamlining the maintenance process. By having a clear reference, they can diagnose issues more accurately and expedite repairs. This efficiency ultimately reduces downtime, saving both time and money for operators.

Improving Communication

When discussing repairs or modifications, having a visual reference fosters better communication among team members. It eliminates ambiguity and enables everyone involved to understand exactly which components are being referred to. This collaborative clarity is crucial in ensuring that all repairs are executed correctly and efficiently.

Key Components of Kubota L5740

This section explores the essential elements that contribute to the functionality and performance of a robust agricultural machine. Understanding these crucial components is vital for effective maintenance and optimal operation.

Engine: The heart of the machinery, providing the necessary power for various tasks. Its design ensures efficiency and reliability, crucial for heavy-duty operations.

Transmission: This system plays a pivotal role in controlling speed and torque. A well-engineered transmission enhances maneuverability and adaptability in diverse working conditions.

Hydraulics: A key system enabling the execution of various implements, the hydraulic setup allows for smooth operation and precise control, making it indispensable in agricultural tasks.

Chassis: The structural framework supports all other components, ensuring stability and durability under challenging conditions. A robust chassis is essential for longevity and performance.

Control Systems: User interfaces and electronic systems that enhance operator control and monitoring. These systems improve efficiency and safety during operation.

Wheels and Tires: Designed for optimal traction and stability, the right wheels ensure that the machine can navigate different terrains effectively, maximizing its versatility.

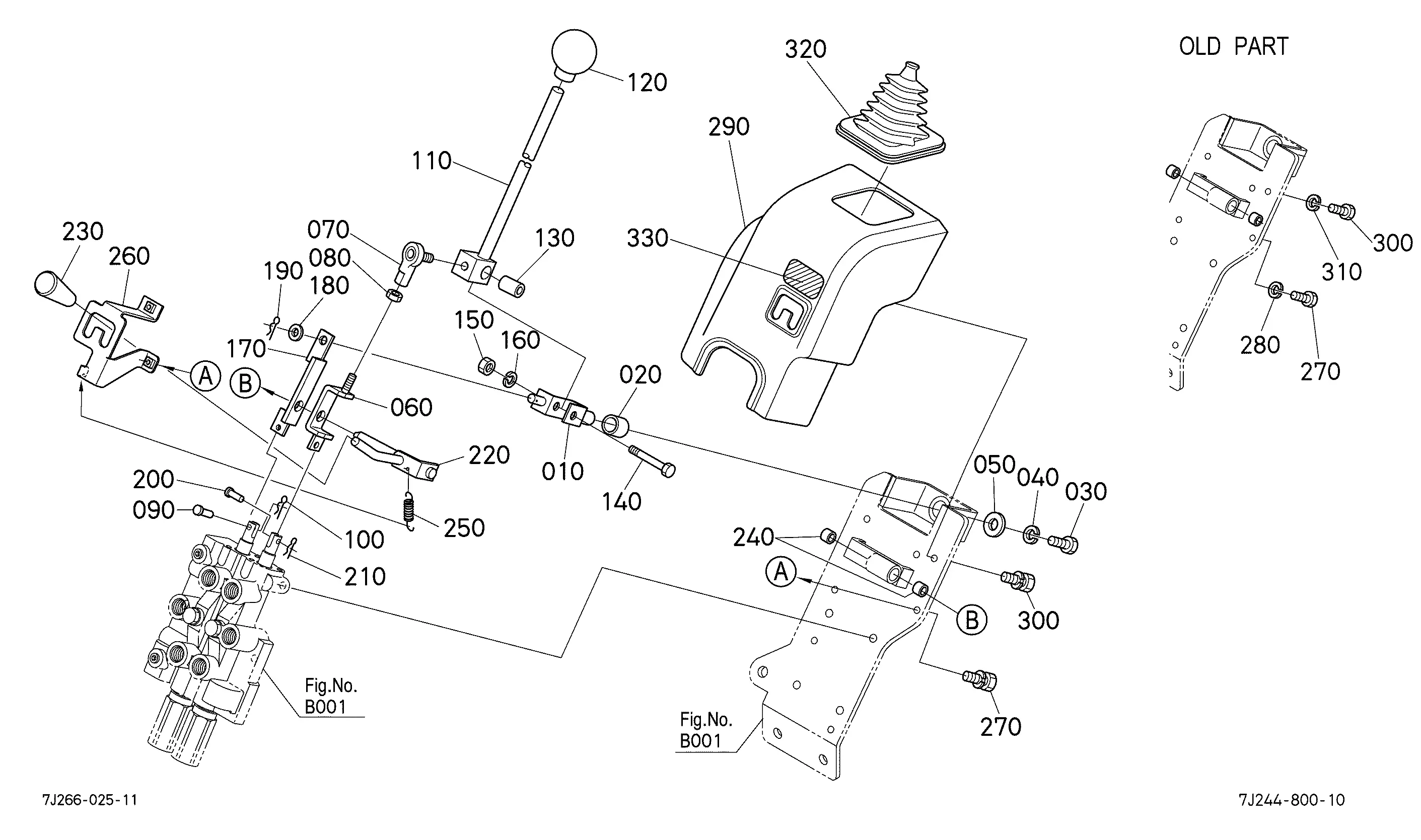

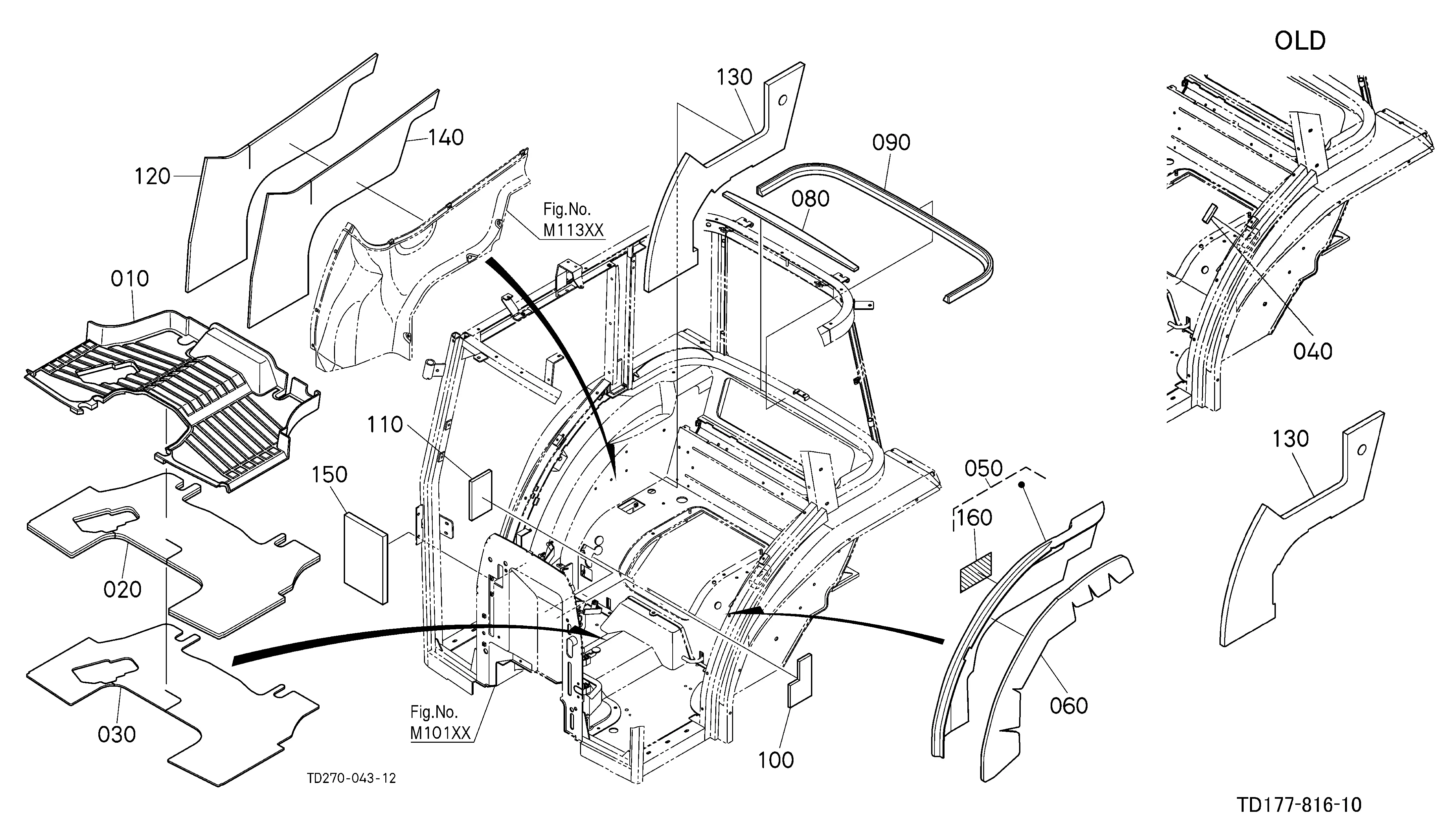

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repairs. These illustrations provide valuable information about the structure and relationship between various elements of a machine. By familiarizing yourself with these visuals, you can streamline your troubleshooting and replacement processes.

Here are key steps to effectively interpret these illustrations:

- Identify the Components: Start by recognizing each part shown in the illustration. Each element is usually labeled with a specific identifier.

- Understand the Relationships: Pay attention to how components connect and interact with each other. Look for lines or arrows that indicate assembly order or attachment points.

- Reference the Legend: Many illustrations include a legend or key that explains symbols or color codes. This information is crucial for accurate interpretation.

- Consult the Manual: Often, manuals provide additional context or details that can enhance your understanding of the visual representation.

- Take Notes: As you study the illustration, jot down any relevant information or questions that arise for future reference.

By following these steps, you can gain a comprehensive understanding of the components and their functions, leading to more effective repairs and maintenance. Practice will enhance your ability to quickly and accurately interpret these visual aids.

Finding Replacement Parts Online

In today’s digital age, locating components for machinery has become more accessible than ever. A wealth of resources and online marketplaces provide users with the ability to source necessary items quickly and efficiently. This guide aims to streamline the process, ensuring you find the right elements for your equipment without hassle.

Key Steps to Consider

When searching for suitable components, follow these essential steps:

| Step | Description |

|---|---|

| 1 | Identify the exact specifications needed for your machinery. |

| 2 | Visit reputable online retailers or manufacturer websites. |

| 3 | Compare prices and read customer reviews to ensure quality. |

| 4 | Check for warranties or return policies to protect your purchase. |

Benefits of Online Shopping

Purchasing components online offers numerous advantages, including a broader selection and often lower prices. Additionally, the convenience of home delivery saves time, allowing you to focus on other important tasks related to your machinery maintenance.

Common Issues and Solutions

When operating agricultural machinery, it’s not uncommon to encounter various challenges that can affect performance and efficiency. Understanding these issues and their remedies can greatly enhance the longevity of the equipment and ensure smooth operations. Below are some frequently observed problems along with practical solutions to address them effectively.

Engine Overheating

One of the most prevalent issues faced by operators is engine overheating. This can be caused by low coolant levels, a malfunctioning thermostat, or a clogged radiator. To remedy this, regularly check coolant levels and top them up as needed. Ensure that the radiator is clean and free of debris, and replace the thermostat if it is not functioning correctly. Routine maintenance can help prevent this issue from arising.

Hydraulic System Failures

Hydraulic system failures can lead to a significant loss of functionality, impacting tasks that rely on hydraulic power. Common causes include low fluid levels, leaks, or contaminated fluid. To solve this, check the hydraulic fluid levels regularly and top them off if necessary. Inspect hoses and connections for leaks and replace any damaged components. Additionally, ensure that the fluid is clean and free of contaminants to maintain optimal performance.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires a commitment to regular upkeep and attention to detail. Implementing a solid maintenance routine can significantly extend the lifespan of your equipment, minimizing unexpected breakdowns and costly repairs.

Here are some essential maintenance tips to consider:

- Regular Inspections: Conduct frequent checks on critical components to identify wear and tear early.

- Fluid Changes: Replace oil, coolant, and hydraulic fluids as per the manufacturer’s recommendations to keep systems running smoothly.

- Filter Replacement: Change air and fuel filters regularly to ensure optimal airflow and fuel efficiency.

- Battery Care: Inspect and clean battery terminals, ensuring connections are tight and free from corrosion.

- Tire Maintenance: Check tire pressure and tread regularly, rotating tires to ensure even wear.

- Cleaning: Keep the equipment clean to prevent dirt and debris from causing damage or inefficiency.

By following these guidelines, you can help maximize the functionality and lifespan of your equipment, ensuring it remains reliable for years to come.

Understanding Engine Specifications

Engine specifications provide crucial insights into the performance and capabilities of machinery. These details help users assess the power output, efficiency, and overall functionality of the unit. By examining these characteristics, one can make informed decisions regarding maintenance and upgrades.

Key attributes such as displacement, horsepower, and torque define the engine’s potential and suitability for various tasks. Displacement indicates the size of the engine, while horsepower reflects the power available for operation. Torque is essential for understanding the force that drives the vehicle or equipment, especially under load.

Additionally, fuel type and consumption rates play significant roles in determining operational costs and environmental impact. Understanding these factors allows for optimized performance and better resource management, ultimately enhancing productivity and longevity of the equipment.

Hydraulic System Components Explained

The hydraulic system in machinery plays a crucial role in facilitating efficient power transmission through fluid movement. Understanding the various elements that make up this system is essential for maintenance and optimal performance. Each component works in harmony to convert mechanical energy into hydraulic energy, enabling effective operation.

At the heart of the hydraulic system lies the pump, responsible for generating fluid flow. This pump draws hydraulic fluid from a reservoir and pushes it through the system, creating the necessary pressure for operation. The fluid then travels through hoses and pipes to various components, allowing for the transfer of force to execute tasks.

Another critical element is the actuator, which converts hydraulic energy back into mechanical energy. Actuators can be cylinders or motors, and they are responsible for moving parts of the machine, such as lifting or pushing loads. The efficiency of these actuators greatly impacts the overall functionality of the hydraulic system.

Control valves also play a vital role, regulating the flow and pressure of the hydraulic fluid. These valves ensure that the right amount of fluid reaches the actuators at the right time, providing precision in operation. By adjusting the flow path, operators can control the speed and direction of movement effectively.

Additionally, filters are essential for maintaining the integrity of the hydraulic fluid. They remove contaminants that could damage the components and reduce system efficiency. Regular monitoring and maintenance of these filters are crucial for the longevity of the hydraulic system.

In summary, the hydraulic system comprises several key components, including pumps, actuators, control valves, and filters. Each part plays an integral role in ensuring the machinery operates smoothly and efficiently, making it essential to understand their functions for effective maintenance and operation.

Transmission Parts and Functions

The transmission system is a vital component of any vehicle, responsible for transferring power from the engine to the wheels. This intricate assembly enables the machine to operate efficiently across various terrains and conditions. Understanding its components and their roles can significantly enhance maintenance and performance.

Key Components

At the heart of the transmission lies the gearbox, which adjusts the torque and speed. It works in conjunction with the clutch, allowing for smooth engagement and disengagement of the engine’s power. Additionally, various sensors monitor performance, ensuring optimal functioning and providing essential feedback for adjustments.

Functions and Operations

The primary role of the transmission system is to facilitate gear changes, which is crucial for managing speed and power. The design ensures that the vehicle can operate efficiently, whether moving at low speeds or cruising at higher rates. Furthermore, the incorporation of hydraulic systems enhances the shifting process, making it more responsive and reducing wear on mechanical components.

Importance of Genuine Kubota Parts

Utilizing authentic components for machinery is crucial for optimal performance and longevity. These high-quality items ensure compatibility and reliability, significantly impacting overall functionality.

- Enhanced durability: Genuine items are designed to withstand rigorous conditions, reducing the risk of breakdowns.

- Improved efficiency: Authentic components work seamlessly with existing systems, maximizing productivity.

- Warranty protection: Using original parts often safeguards warranties, providing peace of mind to the owner.

- Resale value: Equipment with genuine components typically retains higher market value.

Ultimately, investing in original elements is a wise decision that pays off in performance and reliability.

DIY Repair vs. Professional Help

When it comes to maintaining and fixing machinery, individuals often face the choice between tackling repairs themselves or seeking the expertise of a professional. Each approach has its own set of advantages and challenges, making it crucial for owners to weigh their options carefully before proceeding.

Do-It-Yourself repairs can be a rewarding experience, allowing owners to save money and gain a deeper understanding of their equipment. With the right resources and a bit of determination, many issues can be resolved without the need for external assistance. This method fosters a sense of accomplishment and can be particularly beneficial for those who enjoy hands-on work.

On the other hand, professional assistance provides access to trained technicians who possess specialized knowledge and tools. This option can be particularly advantageous for complex repairs that require a high level of expertise or when time constraints are a factor. By relying on professionals, owners can ensure that repairs are performed correctly and efficiently, potentially avoiding future complications.

Ultimately, the decision between DIY and hiring a professional will depend on individual skill levels, available time, and the complexity of the task at hand. Evaluating these factors can help ensure that the chosen approach leads to effective and lasting solutions.

Resources for Parts Lookup

Finding the right components for machinery can be a challenging task. Utilizing various resources can streamline this process and ensure accuracy in identifying necessary items.

- Official Manuals: These documents provide detailed information, including specifications and installation guidance.

- Online Retailers: Websites that specialize in equipment can offer extensive catalogs with searchable features.

- Forums and Community Groups: Engaging with other users can yield helpful insights and recommendations for sourcing specific items.

- Manufacturer Websites: Often, official sites have sections dedicated to supporting customers with parts identification tools.

By exploring these avenues, one can effectively navigate the complexities of obtaining the right items for maintenance or repair.