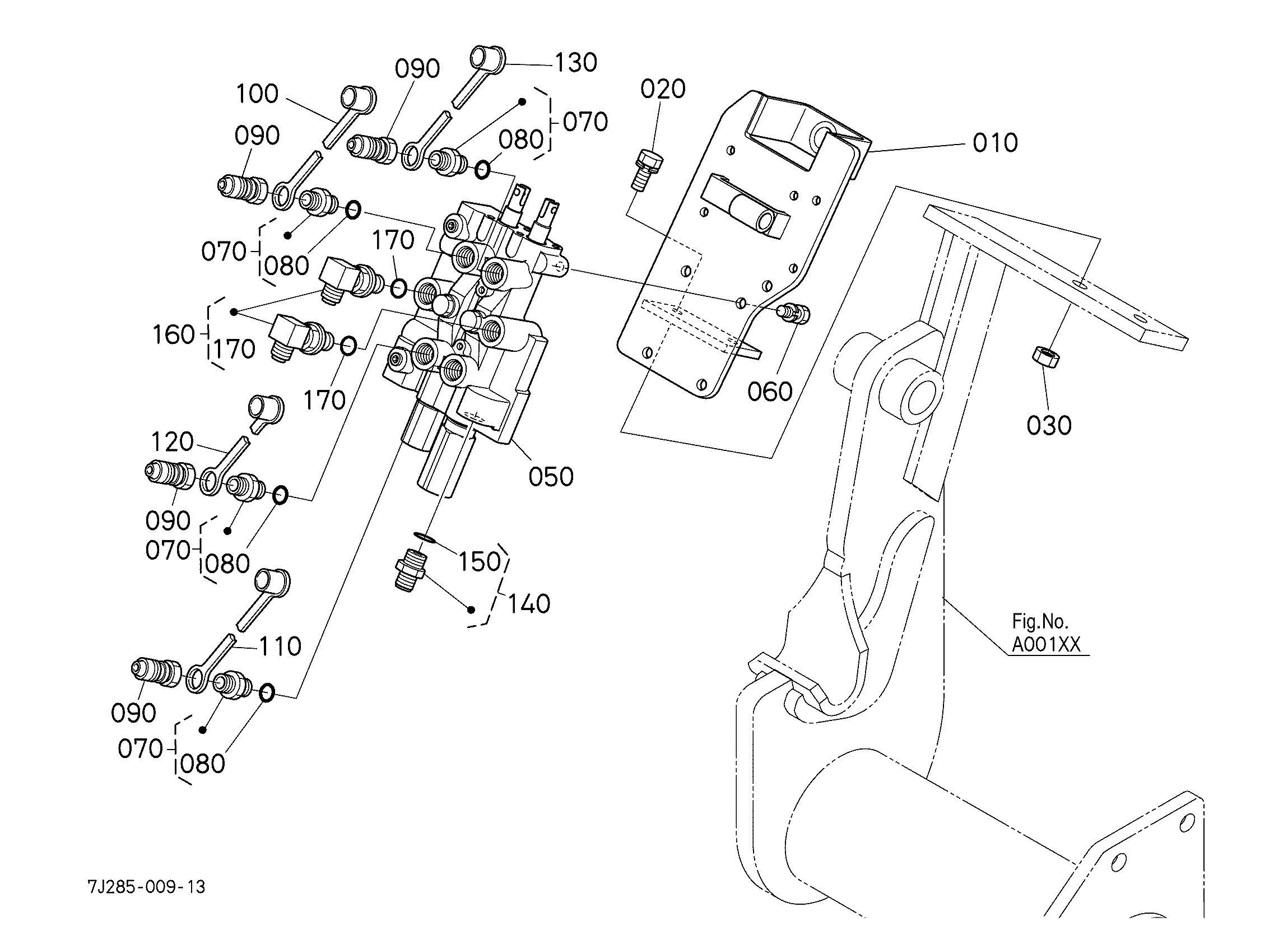

Kubota LA525 Parts Diagram for Easy Reference

The intricate world of machinery requires a comprehensive understanding of its various elements and their interconnections. Each component plays a crucial role in the overall functionality, contributing to the efficiency and performance of the entire system. Exploring these elements can significantly enhance maintenance practices and repair strategies.

Delving into the visual representations of these crucial elements allows for better comprehension of how they fit together. By examining schematics, one can identify specific pieces, their placement, and the relationships between them. This knowledge is essential for anyone involved in the upkeep or repair of equipment, ensuring that interventions are precise and informed.

Moreover, familiarity with these detailed representations empowers operators and technicians alike. With a clear understanding of each component’s role, professionals can troubleshoot issues more effectively, leading to improved productivity and reduced downtime. This exploration of machinery elements not only fosters skill development but also promotes a culture of safety and efficiency in the workplace.

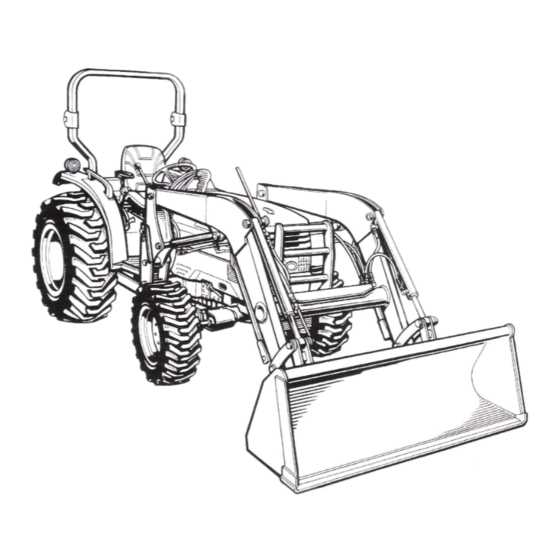

Kubota LA525 Overview

This section provides a comprehensive look at a compact machine designed for efficiency and versatility in various tasks. With a focus on user-friendliness and robust performance, this equipment serves as a reliable solution for both agricultural and landscaping needs.

Key features include:

- Exceptional maneuverability in tight spaces

- Powerful hydraulic system for enhanced lifting capacity

- Durable construction ensuring longevity and reliability

The design emphasizes ease of use, allowing operators to handle various attachments effortlessly. Maintenance is straightforward, contributing to minimal downtime and optimal productivity.

Applications for this versatile machine encompass:

- Soil preparation and tilling

- Loading and transporting materials

- Landscaping and grading tasks

Overall, this compact loader stands out as an essential asset for those seeking to enhance efficiency in their operations while ensuring dependable performance across different tasks.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components play a crucial role in ensuring that individuals can accurately identify and replace essential elements without confusion.

These visual aids simplify the process of assembly and disassembly, allowing technicians to navigate complex systems with ease. When one can easily locate each element, the risk of errors decreases significantly.

Moreover, detailed illustrations enhance communication between users and service professionals. They provide a common language that bridges the gap, ensuring everyone is on the same page when discussing repairs or upgrades.

Ultimately, leveraging such resources leads to improved efficiency, reduced downtime, and increased longevity of equipment. Knowledge of these resources is invaluable in the maintenance landscape.

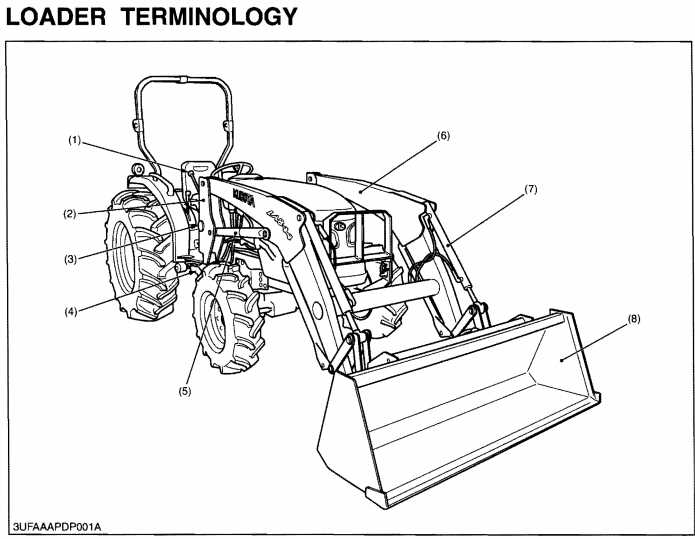

Key Components of LA525

Understanding the essential elements of this equipment is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring functionality and efficiency, contributing to the overall effectiveness of the machine.

| Component | Description |

|---|---|

| Engine | Powers the entire system, providing the necessary energy for operation. |

| Hydraulic System | Facilitates movement and control, allowing for various attachments to function smoothly. |

| Transmission | Transmits power from the engine to the wheels, ensuring effective mobility. |

| Chassis | Provides structural support and stability, essential for durability and balance. |

| Control Panel | Enables operators to manage functions and monitor performance effectively. |

How to Read Diagrams

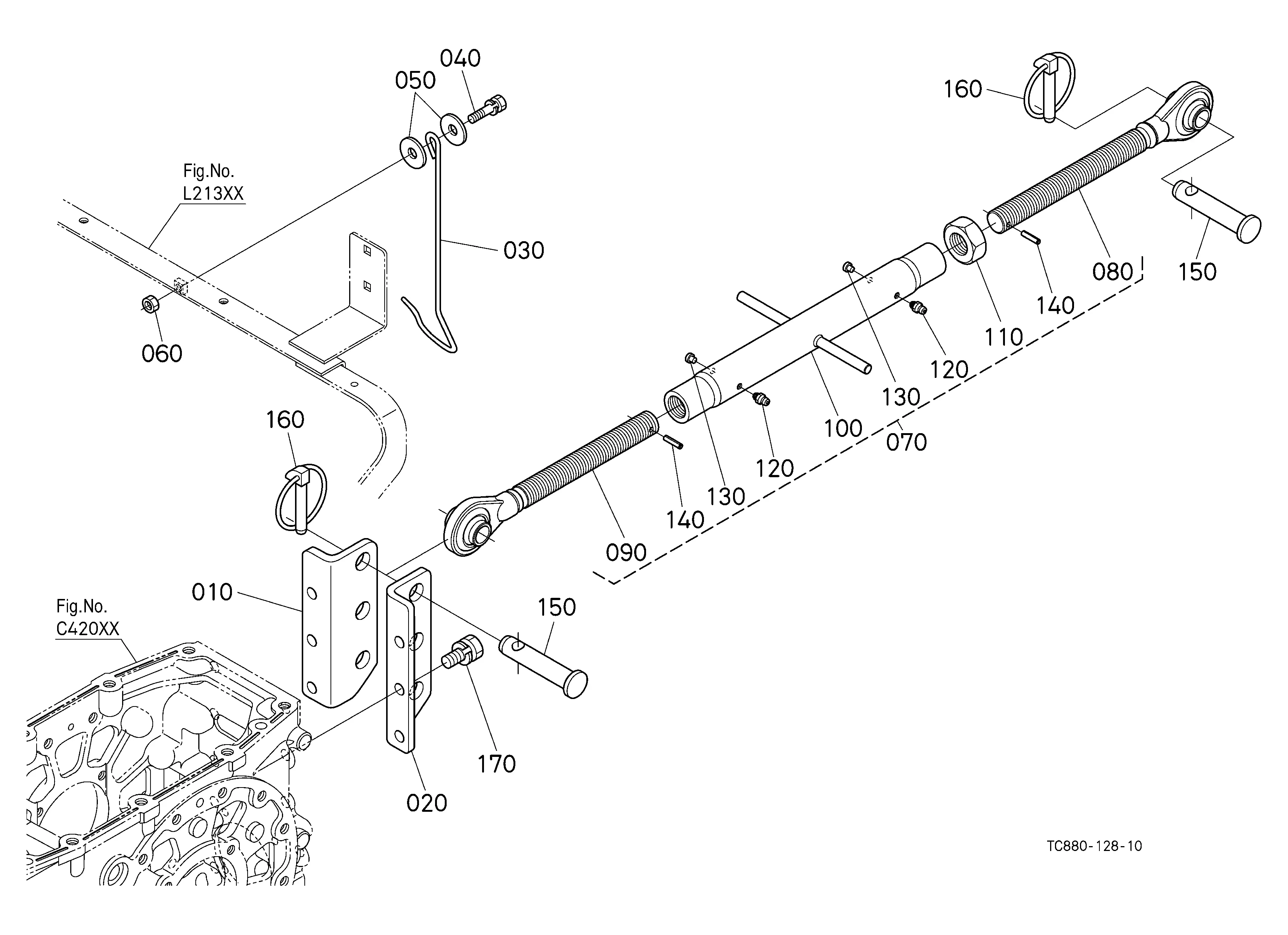

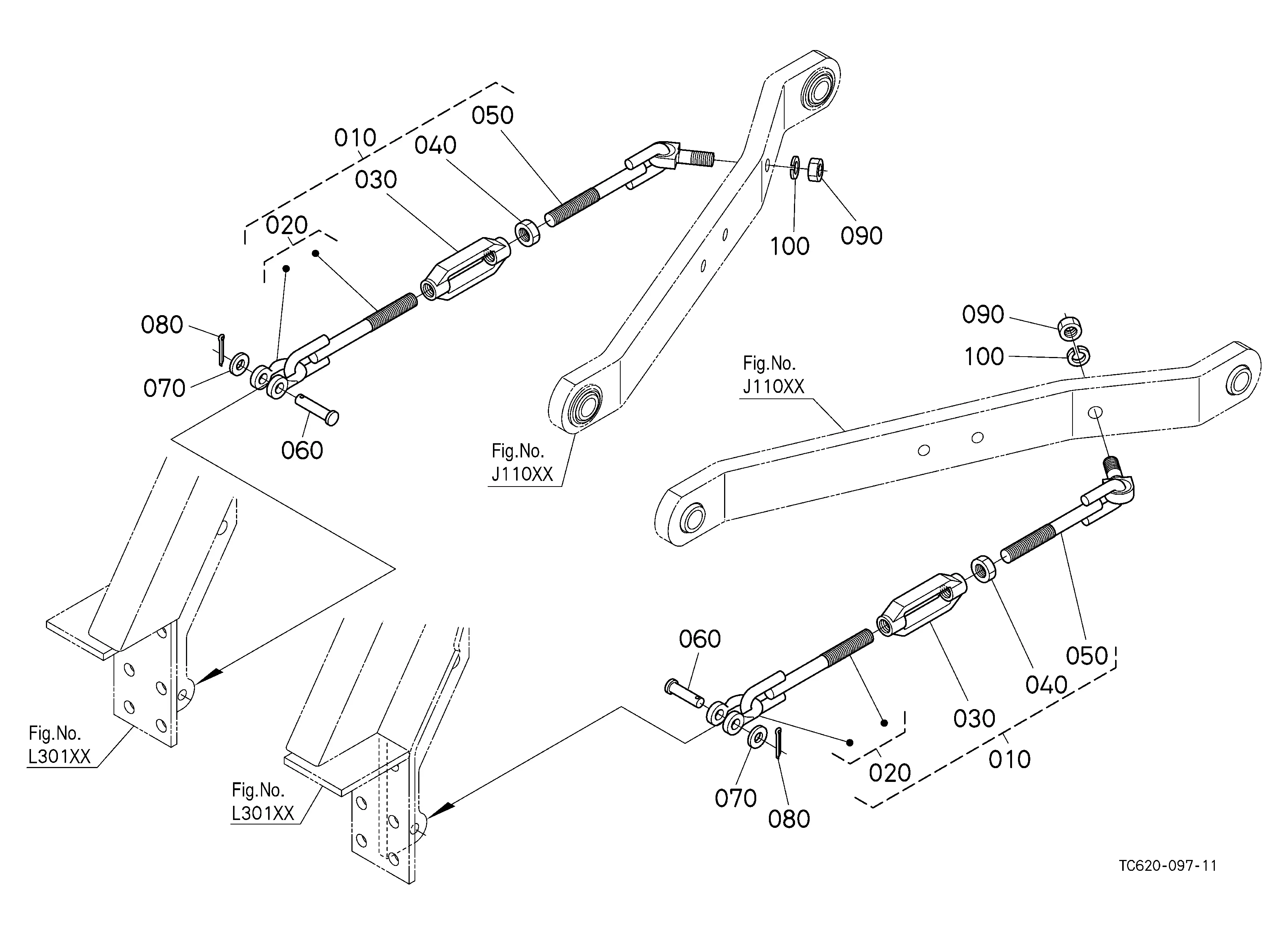

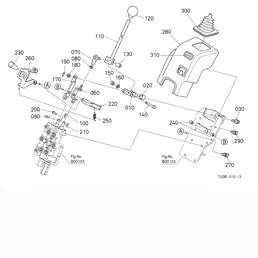

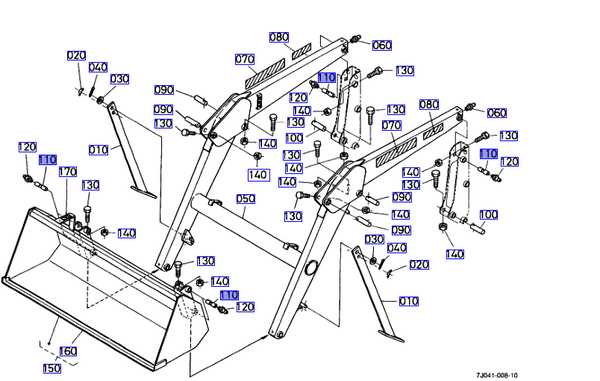

Understanding visual representations of mechanical systems is essential for effective maintenance and repair. These illustrations provide a roadmap to various components, enabling users to identify parts and their relationships with each other.

Identifying Components

Begin by familiarizing yourself with the symbols and notations used in the illustration. Each element typically corresponds to a specific part or function, often indicated by labels or numbers. Pay attention to legends or keys that clarify these symbols.

Understanding Connections

Next, observe how different elements are connected. Lines often represent relationships, such as fluid flow or electrical wiring. By tracing these connections, you can grasp the overall functionality of the system and locate areas that may require attention.

Common Parts for Replacement

In machinery maintenance, certain components frequently require attention due to wear and tear. Understanding which elements typically need replacement can enhance performance and extend the life of the equipment. Regular inspection and timely substitutions can prevent larger issues down the line.

Key Components to Monitor

Several critical elements often exhibit signs of fatigue and should be checked routinely. These include items that directly influence functionality and safety. Below is a list of commonly replaced components.

| Component | Purpose | Frequency of Replacement |

|---|---|---|

| Filters | Maintain clean fluid circulation | Every 100 hours |

| Belt | Ensure proper drive transmission | Every 500 hours |

| Blades | Facilitate effective cutting | As needed |

| Seals | Prevent fluid leaks | Every 200 hours |

Maintenance Tips

Regular checks and proper lubrication can significantly enhance the durability of these vital components. Staying proactive about replacements will ensure the equipment operates at its ultimate efficiency.

Where to Find Diagrams

Locating visual references for machinery components can be essential for effective maintenance and repair. Several reliable sources offer detailed illustrations that can assist users in identifying parts and understanding their arrangements. These resources can range from official manufacturer websites to dedicated forums and online marketplaces.

Official Manufacturer Websites: Many companies provide access to technical resources directly on their sites. By navigating to the support or resources section, users can often find comprehensive guides and schematics specific to their equipment.

Online Forums and Communities: Engaging with fellow enthusiasts and professionals in specialized forums can yield valuable insights. Members frequently share links, files, and personal experiences, which can be incredibly helpful in tracking down visual aids.

Repair Manuals: Purchasing or downloading repair manuals is another excellent approach. These documents typically include extensive illustrations along with step-by-step instructions, offering a thorough understanding of the equipment’s structure.

Online Marketplaces: Various e-commerce platforms also list manuals and parts breakdowns. Users can often find both new and used resources that provide visual representations crucial for repairs.

Utilizing these avenues not only enhances your understanding of machinery but also facilitates smoother maintenance processes.

Benefits of Genuine Parts

Using authentic components ensures optimal performance and longevity for machinery. These high-quality replacements are designed specifically for compatibility and reliability, making them a smart investment for any operator. Authentic items not only enhance functionality but also provide peace of mind, knowing that you’re maintaining the integrity of your equipment.

Quality Assurance

Authentic components undergo rigorous testing and adhere to strict manufacturing standards. This commitment to quality means fewer failures and reduced maintenance costs over time, ultimately leading to improved efficiency.

Enhanced Performance

Utilizing genuine components guarantees that your machinery operates at its best. These parts are engineered to work seamlessly together, providing superior performance and extending the lifespan of the entire system.

Identifying Wear and Tear

Recognizing signs of deterioration is crucial for maintaining the longevity and performance of machinery. Over time, components may exhibit various forms of damage due to regular usage and environmental factors. Understanding these indicators can help prevent further issues and ensure optimal functionality.

Visual inspections play a key role in this process. Look for cracks, discoloration, or any irregularities on surfaces that might indicate excessive wear. Additionally, listen for unusual sounds during operation; they can signify internal problems that require immediate attention.

Monitoring performance changes is equally important. A drop in efficiency or unexpected vibrations can signal underlying wear. Regularly documenting these observations will provide valuable insights into the machine’s condition, helping to inform maintenance decisions.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in the functionality of various machinery by utilizing fluid mechanics to transmit power efficiently. These systems rely on the principles of fluid dynamics to enable the transfer of energy, allowing for smooth and controlled movement of components. By harnessing the power of liquids, they facilitate operations that require significant force with minimal effort.

At the core of hydraulic technology are several key components, including pumps, valves, and cylinders. Each part works in unison to convert mechanical energy into hydraulic energy and vice versa, making these systems versatile and reliable for numerous applications. Understanding the interactions between these elements is essential for optimizing performance and ensuring longevity.

Maintenance and troubleshooting are vital for the proper functioning of hydraulic systems. Regular inspections and timely repairs can prevent failures and prolong the lifespan of the machinery. Familiarity with common issues, such as leaks or pressure drops, enables operators to address problems proactively, thereby enhancing overall efficiency.

In summary, mastering the fundamentals of hydraulic systems equips users with the knowledge to effectively operate and maintain equipment. This understanding not only boosts productivity but also ensures safety and reliability in various industrial applications.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of machinery requires regular upkeep and attention to detail. Adopting best practices can significantly extend the lifespan of equipment, reducing the likelihood of unexpected failures and costly repairs. This section outlines essential strategies for maintaining your machinery effectively.

Regular Inspections

Conduct routine inspections to identify wear and tear before it becomes a significant issue. Check all components for signs of damage, leaks, or unusual noises. Keeping a log of these inspections can help track performance and highlight any areas needing attention.

Fluid Management

Maintaining proper fluid levels is crucial for optimal operation. Regularly check and change oils, coolants, and hydraulic fluids according to the manufacturer’s recommendations. Clean filters and ensure all seals are intact to prevent contamination and ensure smooth functioning.

How to Order Replacement Parts

Acquiring necessary components for your machinery can seem daunting, but following a clear process can simplify the task. Understanding where to find reliable suppliers and how to identify the correct items is crucial for maintaining optimal performance.

Identify the Required Components

Start by determining the specific items you need. Consult your equipment’s manual or service guide to ensure you have accurate descriptions and part numbers. This step is essential to avoid errors during the ordering process.

Find a Trusted Supplier

Once you’ve identified the required components, search for reputable vendors. Check for authorized dealers or online retailers with positive reviews. Comparing prices and availability will help you make informed decisions.

Resources for DIY Repairs

For those who enjoy hands-on maintenance, having access to reliable materials is crucial. Whether you’re troubleshooting issues or performing routine upkeep, comprehensive resources can make the process smoother and more efficient.

Online Manuals: Many manufacturers provide digital guides that outline maintenance procedures and specifications. These documents often include valuable insights into common issues and troubleshooting tips.

Forums and Community Groups: Engaging with online communities can be beneficial. Enthusiasts often share personal experiences, advice, and solutions to common problems.

Video Tutorials: Platforms like YouTube host countless videos demonstrating repair techniques. Visual guidance can enhance understanding and confidence in performing repairs.

Specialty Tools: Having the right tools is essential for any repair job. Invest in quality equipment to ensure tasks are completed efficiently and safely.

By utilizing these resources, anyone can enhance their repair skills and tackle projects with confidence.